Die clamping and stripping device for epoxy resin casting workpiece

An epoxy resin assembly and detachment technology, which is applied in the field of assembly and release devices for epoxy resin cast parts, can solve problems such as clamping difficulties and achieve the effect of avoiding clamping difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

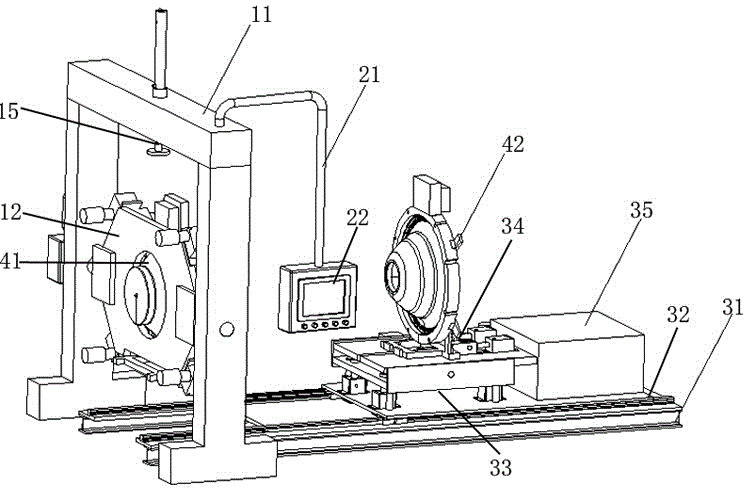

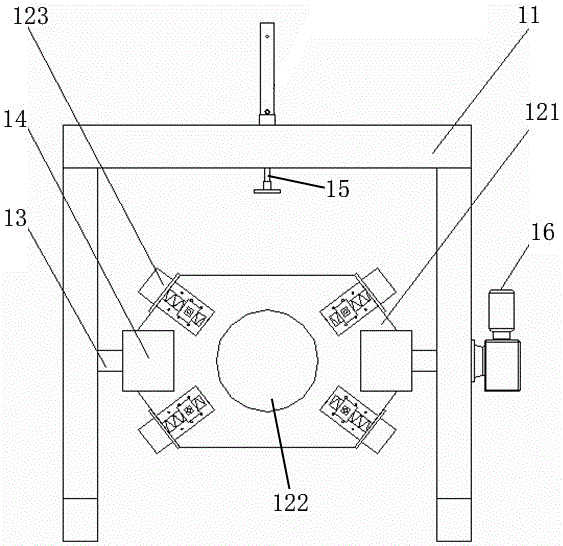

[0019] In the present invention, epoxy resin pouring part is used the embodiment of dress demoulding device: as Figure 1 to Figure 4 As shown, the mounting and demoulding device is a casting mold for large-scale epoxy resin pot-type insulators for UHV, which realizes the automatic operation of the mold mounting and demoulding process, and improves the manufacturing process level of epoxy resin pouring, mounting and demoulding operations. The demoulding device is mainly composed of a demoulding mechanism and a mold opening mechanism arranged before and after.

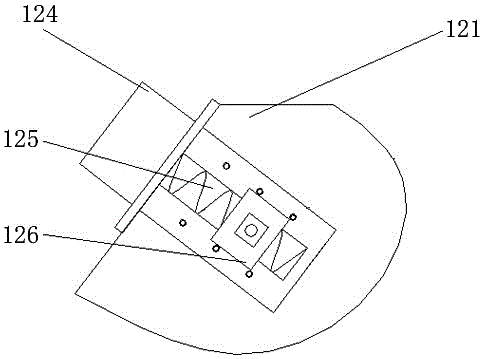

[0020] The demoulding mechanism comprises a die support and a die clamp 12 which is rotatably assembled around an axis extending left and right. The die support includes a door-type demoulding support 11. The two columns of the demoulding support 11 are arranged opposite to each other. Die ejector pin 15, the upper end of demoulding ejector pin 15 is fixedly connected with the demoulding oil cylinder that is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com