Adjustable fixture used for wet etching anisotropic velocity test of hemispheric test piece

A wet etching and anisotropic technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of lack of efficient and practical special fixtures for spherical crystal materials, lack of positioning and protection of the bottom surface of the sphere, and poor versatility. , to avoid unreliable clamping, reduce experimental costs, and avoid falling off and displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

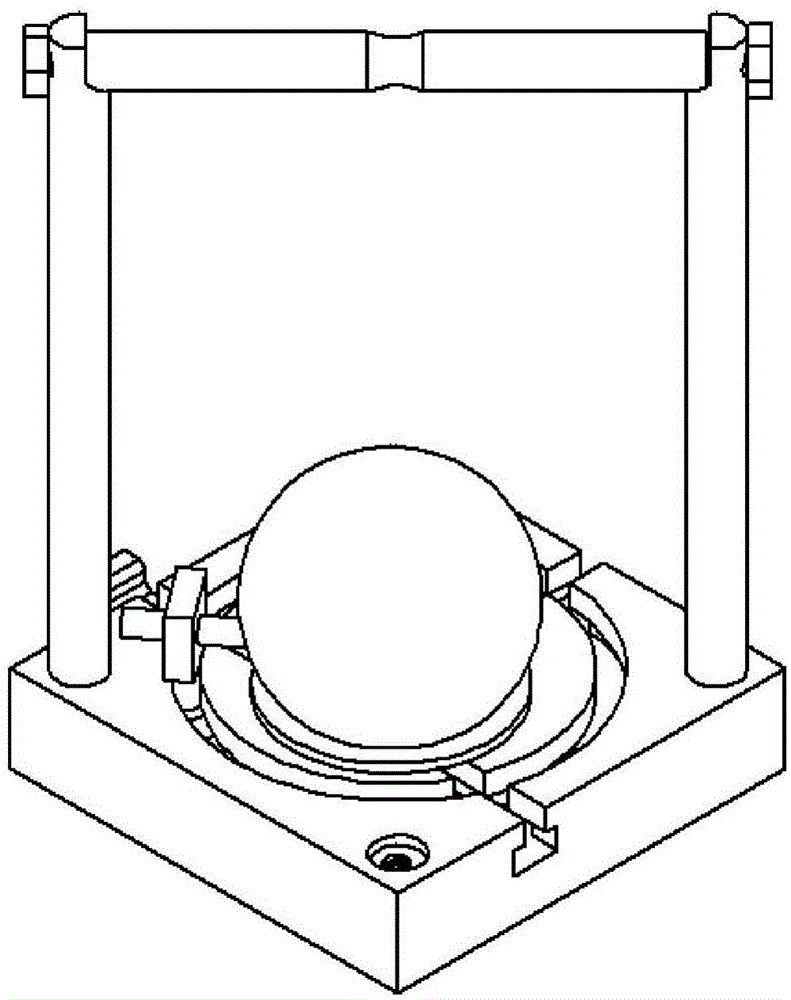

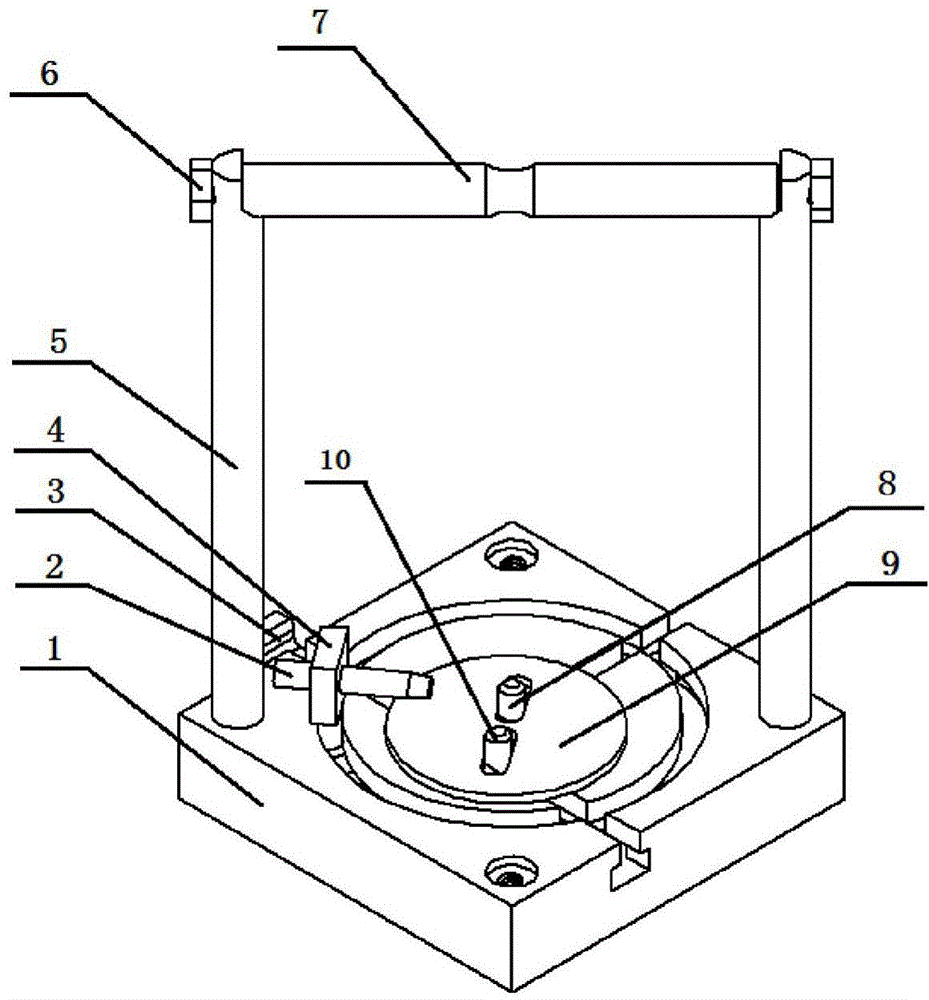

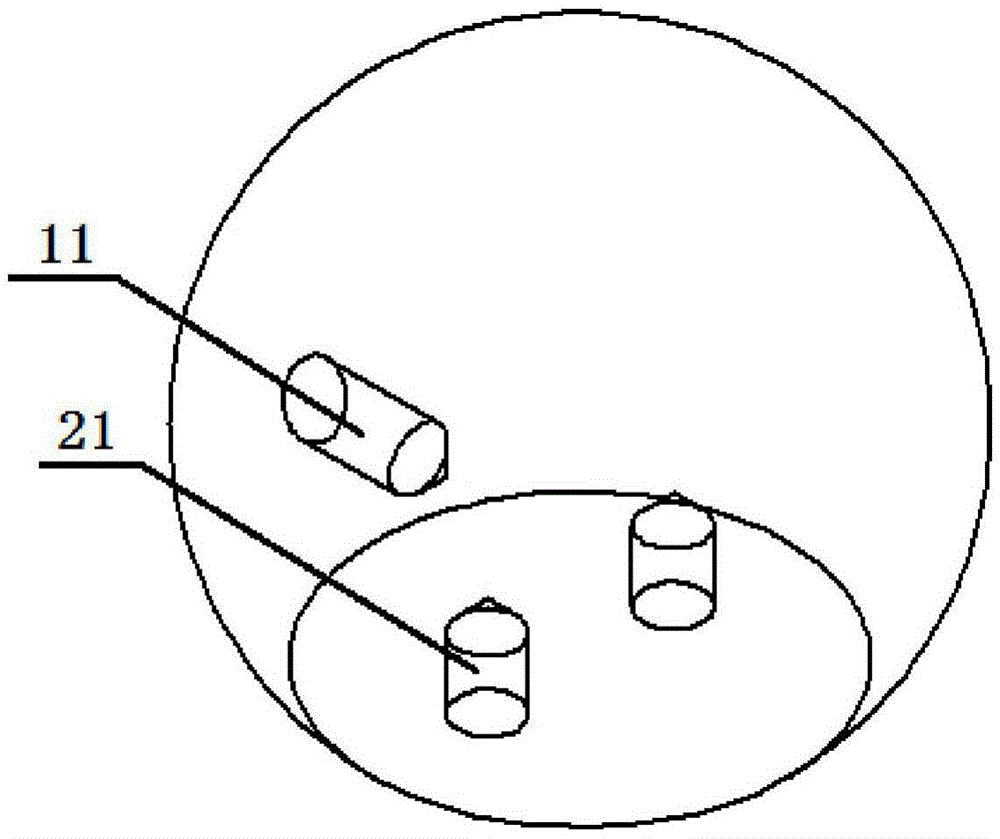

[0024] The adjustable fixture used for the wet etching anisotropy rate test of the hemispherical specimen of the present invention includes: a positioning and clamping module, a spherical bottom protection module and an extraction module, wherein all parts are made of corrosion-resistant and high-temperature-resistant , Made of Teflon plastic with certain elasticity. In the positioning and clamping module, the base 1 is provided with a full-through straight T-slot 13, a half-through straight T-slot 14 and a circular T-slot 15, and the circular T-slot 15 takes the centroid of the base surface as the center of the circle. , and make the sliding nail base 4 relatively slide inside it, the half-through linear T-slot 14 is located on the center line of the base and extends to the center of the base, the full-through straight T-slot 13 is perpendicular to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com