Transfer device for packaging of automobile components

A technology of auto parts and transfer devices, which is applied in the direction of support parts, trolley accessories, transportation and packaging, etc., and can solve the problems of picking and placing, inability to layer, inconvenient parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

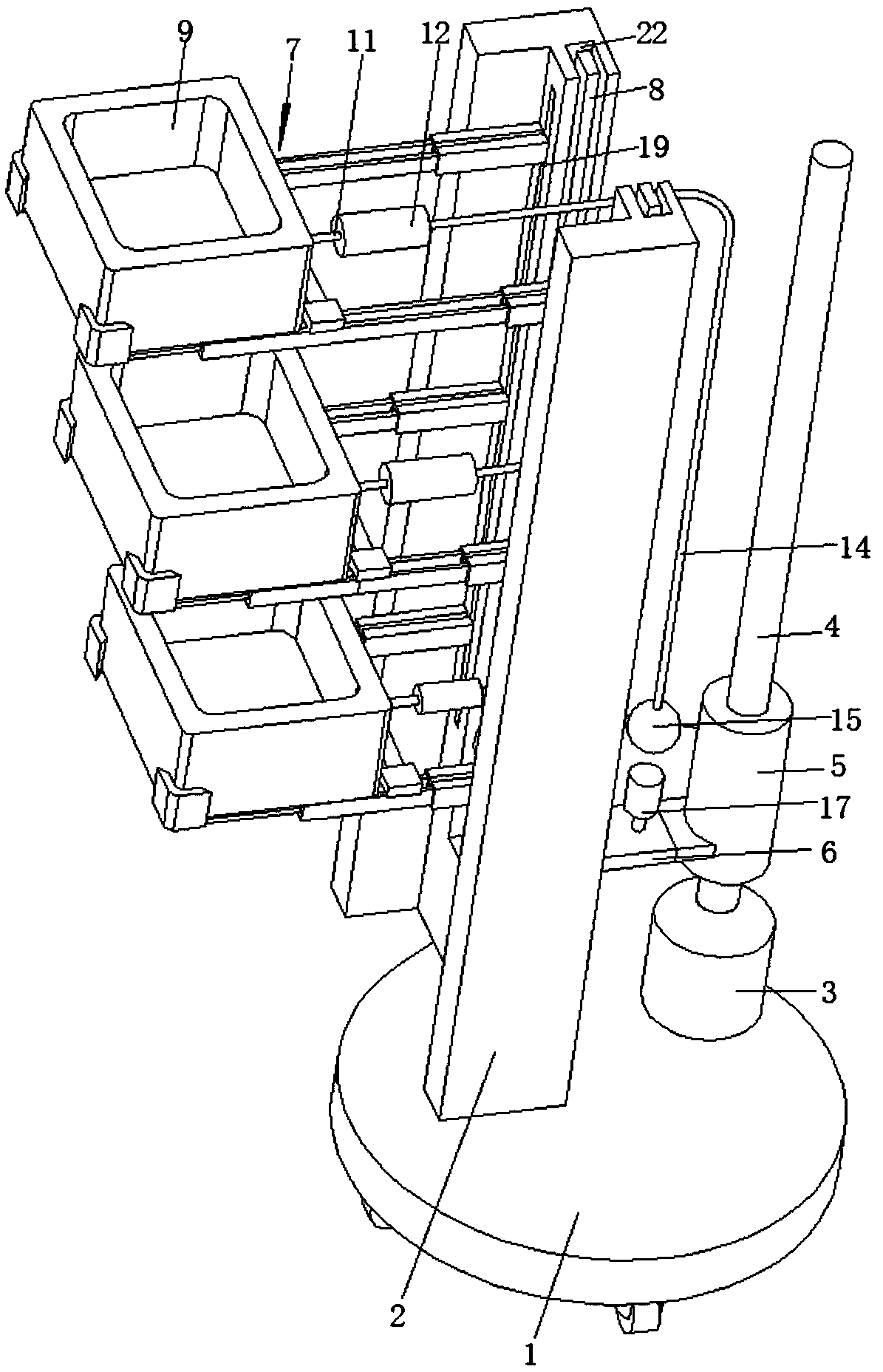

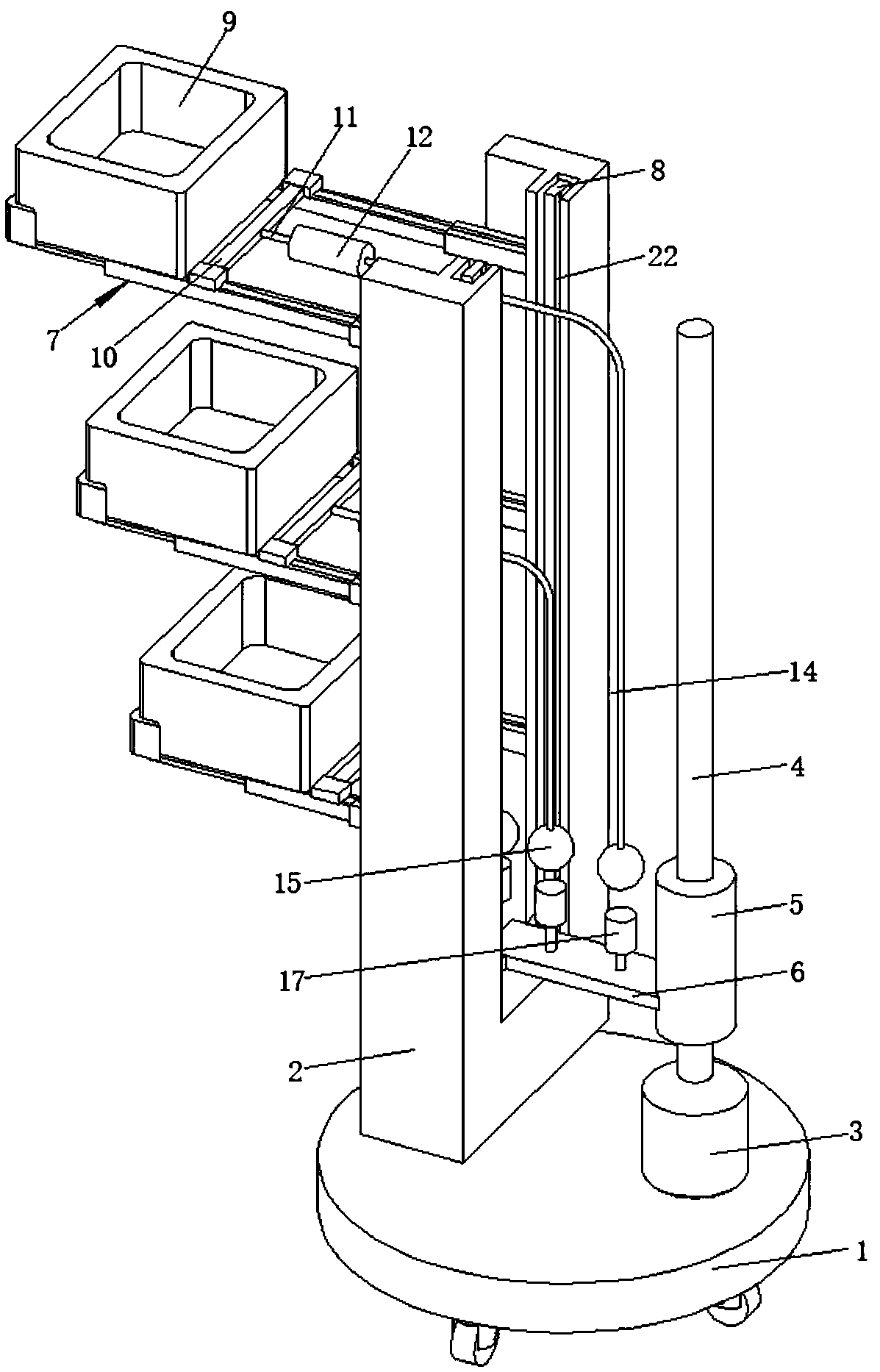

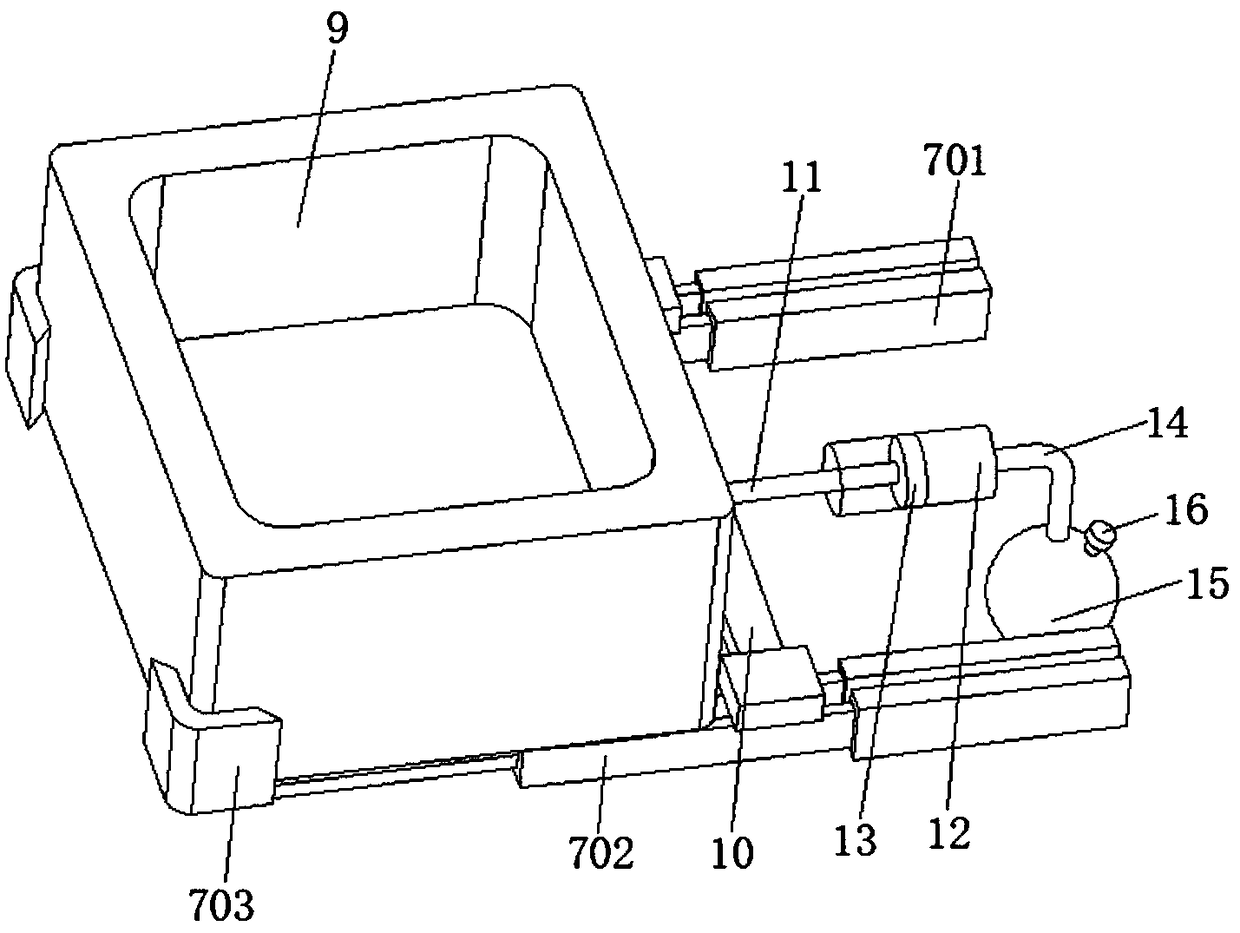

[0038] refer to figure 1 , figure 2 , image 3 , Figure 4 , Image 6 , Figure 7 , Figure 9, a kind of transfer device for auto parts packaging, comprising a base 1, a pole 2, the pole 2 is fixedly connected to the top of the base 1, the base 1 is provided with a drive motor 3, and the output end of the drive motor 3 is connected to The lead screw 4 is connected with the lead screw nut 5, and the lead screw nut 5 is connected with the support plate 6 through the mounting plate; the support rod 2 is slidably connected with a plurality of hierarchically arranged supports 7, and the plurality of supports 7 are placed on the One end inside the pole 2 is connected with a slide plate 8, the end of the support plate 6 away from the screw nut 5 is fixedly connected with the slide plate 8, the end of the support 7 away from the pole 2 is provided with a transfer box 9, and the top of the support 7 is slidingly connected with a stop bar 10, and the stop rod 10 is fixedly connec...

Embodiment 2

[0041] refer to Figure 8 , a kind of transshipment device for auto parts packaging, which is basically the same as Embodiment 1, furthermore, the inside of the fixed rod 701 is provided with a slide rail groove 18, and the telescopic rod 702 is slidably connected in the slide rail groove 18, and the slide rail groove The presence of 18 facilitates the sliding of the telescopic rod 702 on the fixed rod 701 , thereby realizing the expansion and contraction of the transfer box 9 on the fixed rod 701 to obtain the movement of the transfer box 9 .

Embodiment 3

[0043] refer to figure 1 , Image 6 , a transfer device for auto parts packaging, which is basically the same as that of Embodiment 1, furthermore, the support rod 2 is provided with sliding holes 19 distributed along the vertical direction, and the fixed rod 701 is slidably connected in the sliding holes 19, The existence of the sliding hole 19 is convenient for the fixed rod 701 to slide up and down on the side wall of the pole 2, thereby driving the transfer box 9 on the telescopic rod 702 to move up and down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com