Production method based on intelligent vision feeder

A production method and technology of intelligent vision, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low production efficiency, inability to realize automatic control, limit the use range of plates, etc., to improve production efficiency and shape requirements. Low, high utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

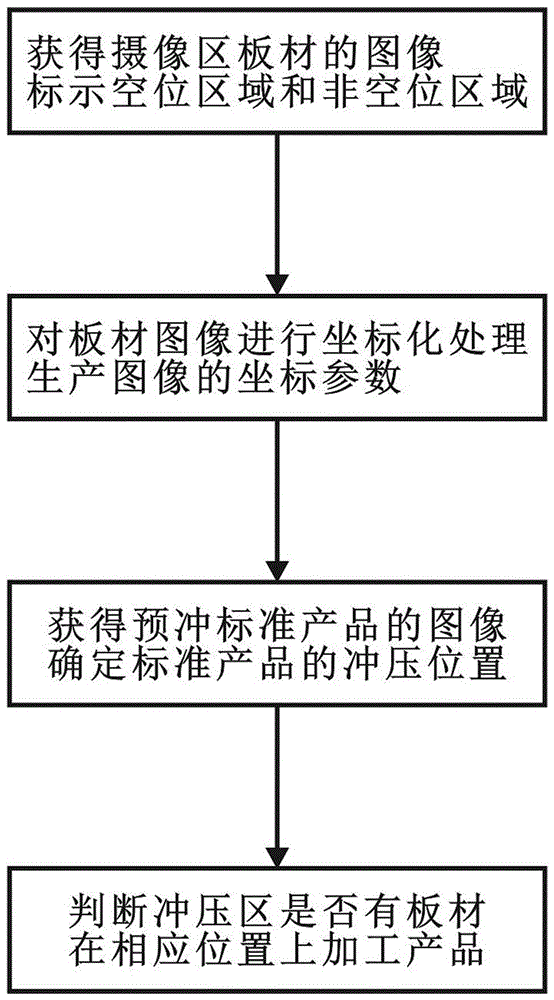

[0029] The present invention is directed at the production method of the visual feeder, which can automatically and intelligently utilize irregular or waste plate production models in conjunction with the intelligent visual feeder. This method should also belong to the protection scope of this application.

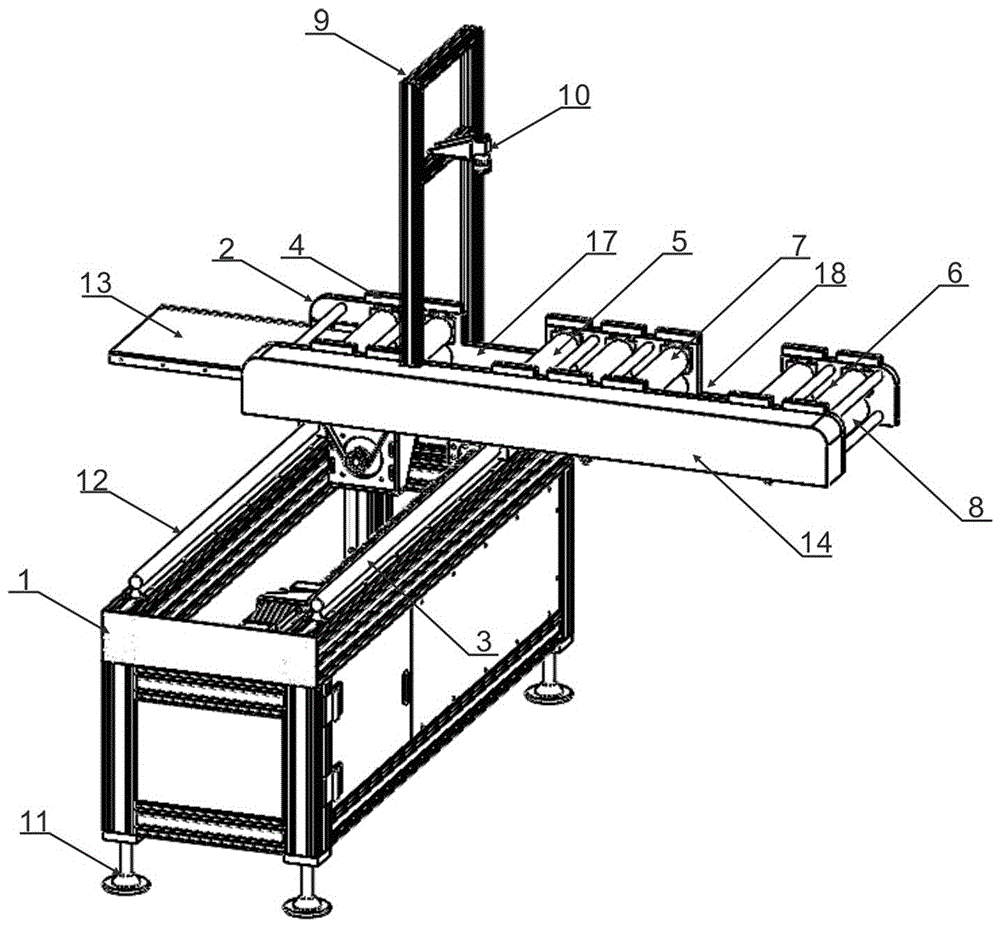

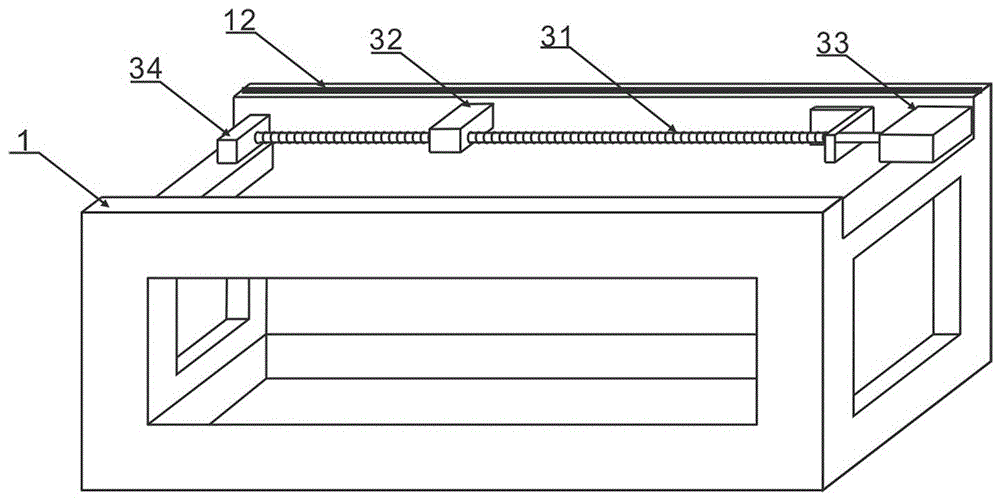

[0030] An intelligent visual feeder of the present application includes a machine base 1 and a sliding seat 2 arranged on the machine base 1 . The machine base 1 can be fixed to form a hollow rectangular frame seat by strip-shaped aluminum rods. Support feet 11 are installed on the bottom of the machine base 1, which is convenient for transportation and plays a supporting and buffering role.

[0031] The base 1 is provided with a lead screw slide assembly 3, the lead screw slide assembly 3 includes a lead screw base 32 arranged on the slide base 2 and a motor 33 mounted on the other end of the base 1 to drive the lead screw to rotate, the lead screw 31 is assembled on The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com