High-wear-resistance super-amphiphobic nanometer coating layer, and preparation method thereof

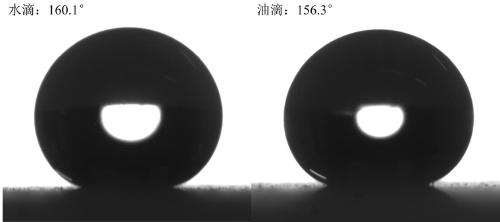

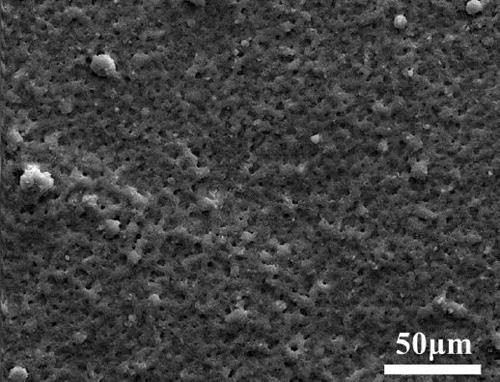

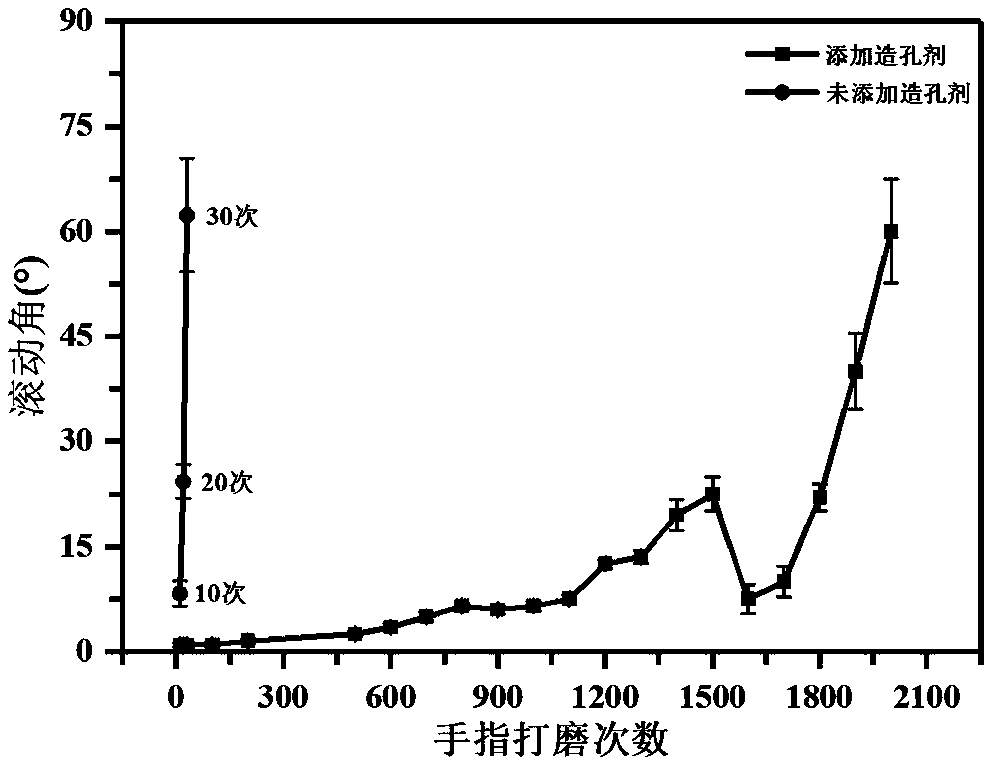

A nano-coating, super-amphiphobic technology, used in coatings, polyurea/polyurethane coatings, devices for coating liquids on surfaces, etc., can solve problems such as limited improvement, weak bonding, and poor coating adhesion. , to achieve the effect of low requirements on substrate material and shape, avoiding incomplete processing and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of preparation method of high wear-resisting super amphiphobic nano-coating, resin is fluorocarbon resin and polyurethane resin in the present embodiment, and mass ratio is 1:1, and curing agent is hexamethylene diisocyanate isocyanate, volatilizes The neutral organic solution is butyl acetate, and the liquid pore-forming agent is Freon, and the method comprises the following steps:

[0035] (1) Add 6 parts by mass of resin and 4 parts by mass of curing agent to 13 parts by mass of volatile organic solution, and mechanically stir for 10 minutes to obtain a clear mixed solution;

[0036] (2) Add 12 parts by mass of a liquid pore-forming agent to the clarified mixed solution after the treatment in step (1), and mechanically stir for 10 minutes to obtain a uniformly dispersed adhesive resin coating;

[0037] (3) Disperse 8 parts by mass of nano-silica sol, 6 parts by mass of ammonia water, 12 parts by mass of deionized water, 0.5 parts by mass of tetraethyl orthosil...

Embodiment 2

[0041] A kind of preparation method of high wear-resisting super amphiphobic nano-coating, in the present embodiment, resin is fluorocarbon resin and acrylic resin, and mass ratio is 1:1, and curing agent is pherone dimonocyanate, volatile organic The solution is butyl acetate, and the powdery pore-forming agent is azodicarbonamide, and the method comprises the following steps:

[0042] (1) Add 3 parts by mass of resin and 2 parts by mass of curing agent to 25 parts by mass of volatile organic solution, and stir mechanically for 5 minutes to obtain a clear mixed solution;

[0043] (2) Add 1 part by mass of powdery pore-forming agent to the clarified mixed solution after the treatment in step (1), and mechanically stir for 5 minutes to obtain a uniformly dispersed adhesive resin coating;

[0044] (3) Disperse 1 mass part of nano-silica sol, 2 mass parts of ammonia water, 6 mass parts of deionized water, 0.1 mass part of tetraethyl orthosilicate, and 0.1 mass part of hydrophobic...

Embodiment 3

[0048] A kind of preparation method of high wear-resisting super amphiphobic nano-coating, in the present embodiment resin is fluorocarbon resin, polyurethane resin and acrylic resin, and mass ratio is 1:1:1, and curing agent is benzoyl peroxide, volatilizes The neutral organic solution is butyl acetate, and the liquid pore-forming agent is Freon, and the method comprises the following steps:

[0049] (1) Add 12 parts by mass of resin and 8 parts by mass of curing agent to 10 parts by mass of volatile organic solution, and mechanically stir for 10 minutes to obtain a clear mixed solution;

[0050] (2) Add 15 parts by mass of a liquid pore-forming agent to the clarified mixed solution after the treatment in step (1), and mechanically stir for 10 minutes to obtain a uniformly dispersed adhesive resin coating;

[0051] (3) Disperse 15 parts by mass of nano-silica sol, 10 parts by mass of ammonia water, 16 parts by mass of deionized water, 1 part by mass of tetraethyl orthosilicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com