Coiling device applied to textile machinery

A technology of coiling device and textile machinery, which is applied in the direction of winding strips, transportation and packaging, and thin material processing, etc. It can solve problems such as troublesome installation and disassembly, loose and uneven fabrics, and loose winding of fabrics, etc., to reduce wear and tear , tight winding, prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

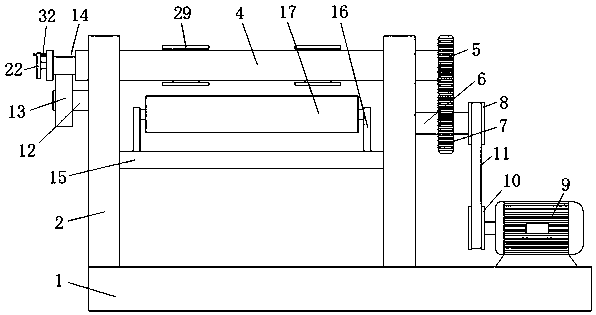

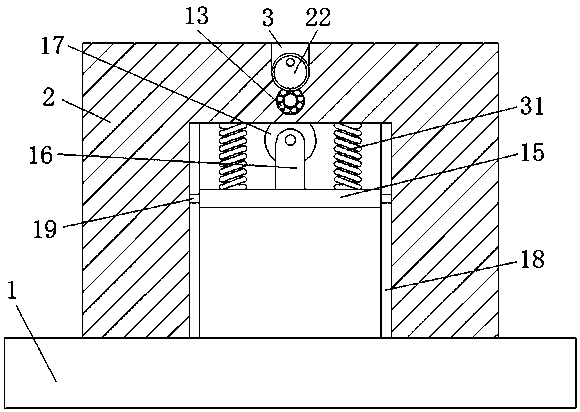

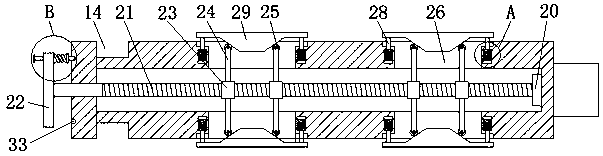

[0028] see Figure 1-5, this embodiment provides a winding device for textile machinery, including a base 1, the upper surface of the base 1 is vertically and symmetrically fixedly connected with a support plate 2, and the support plate 2 has an inverted U-shaped structure, and the top ends of the two support plates 2 The middle part is provided with a placement slot 3, and the interior of the placement slot 3 is provided with a winding roller 4, and one end of the winding roller 4 is fixedly connected with the first gear 5, and one side of the support plate 2 corresponds to the rotation below the first gear 5 A fixed rod 6 is connected, and a second gear 7 is fixedly connected to the fixed rod 6. The second gear 7 meshes with the first gear 5. The side of the fixed rod 6 corresponding to the second gear 7 is fixedly connected with the first belt pulley 8. A motor 9 is fixedly connected to one side of one of the support plates 2 on the upper surface of the base 1, and a second...

Embodiment 2

[0031] see Figure 1-5 , a further improvement has been made on the basis of Example 1: several clamping holes 33 are arranged along the circumference of the screw rod 21, and the angles between two adjacent clamping holes 33 are the same, by setting the clamping holes with equal angles 33. It is convenient to fix the sliding rod 3201. The thread direction of the two sliding seats 23 in each group is opposite. Through the sliding seat 23 with the opposite thread direction, the sliding of the sliding seat 23 is convenient, and the sliding of the fixed block 29 is convenient. Paper bobbins are fixed.

[0032] Wherein, the model of the motor 9 is TCH / V-1500.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com