Tooth harrow sewage cleaning machine with back flushing function

A technology of backwashing and cleaning machine, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of enhancing solid-liquid separation efficiency

Inactive Publication Date: 2012-04-25

YANGZHOU TIANLONG ENVIRONMENTAL PROTECTION EQUIP

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the pretreatment stage of municipal sewage, the large and heavy dirt in the sewage is preliminarily filtered by the toothed rake cleaner. raking, which affects the cleaning efficiency of the preliminary filtration, and sometimes the dirt will be brought into the filtered liquid, resulting in incomplete slag removal

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

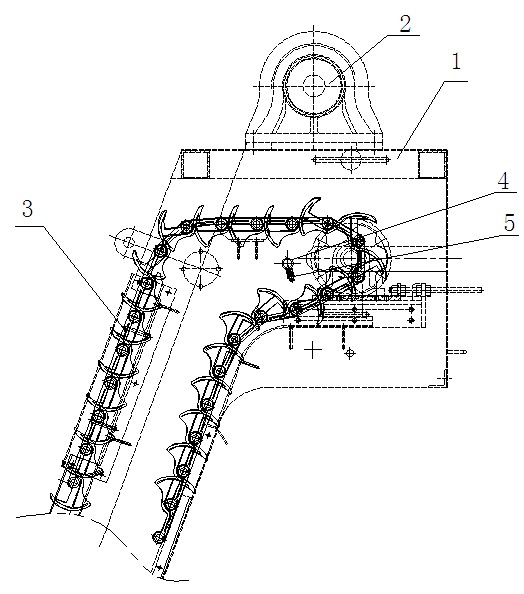

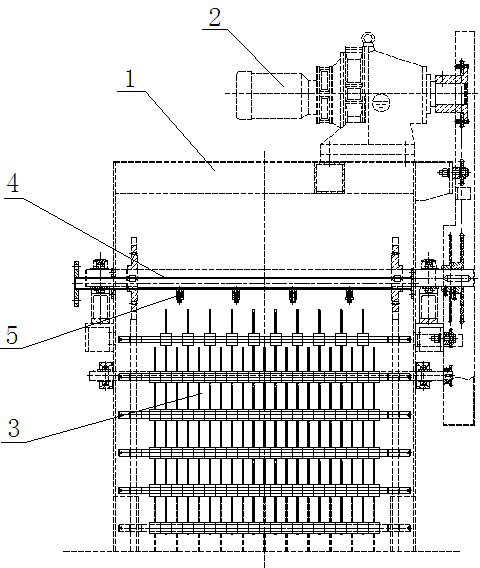

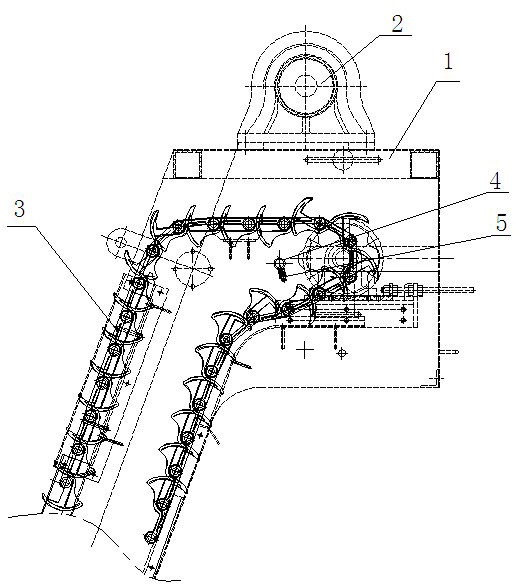

[0008] like figure 1 , 2 As shown, a transmission motor 2 and a guide wheel are fixedly arranged on the frame 1 of the present invention, and a rake type grille chain 3 is transmission-connected between the transmission motor 2 and the guide wheel.

[0009] A water inlet pipe 4 is arranged on the frame 1, and a plurality of nozzles 5 with water outlets facing the rake type grille chain 3 are evenly distributed on the water inlet pipe 4.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a tooth harrow sewage cleaning machine with a back flushing function, which relates to the technical field of sewage purification treatment. A transmission motor and a guide wheel are fixedly arranged on a machine frame, and a tooth harrow type grating chain is in transmission connection between the transmission motor and the guide wheel. The tooth harrow sewage cleaning machine is characterized in that a water inlet pipe is arranged on the machine frame, and spray nozzles with water outlets facing the tooth harrow type grating chain are uniformly distributed on the water inlet pipe. Pressing-back water can be introduced into a water inlet of the water inlet pipe, and the powerful flushing force can be formed through the spray nozzles, so each tooth harrow on the tooth harrow type grating chain in the spray nozzle flushing region can be powerfully flushed, and dregs salved by the sewage cleaning machine can be effectively flushed. The tooth harrow sewage cleaning machine has the advantages that the solid-liquid separation efficiency can be enhanced, and the groundwork is laid for the subsequent work procedure circulation.

Description

technical field [0001] The invention relates to the technical field of sewage purification treatment. Background technique [0002] In the pretreatment stage of municipal sewage, the large and heavy dirt in the sewage is preliminarily filtered by the tooth rake cleaner. Rakes affect the cleaning efficiency of the preliminary filtration, and sometimes the dirt is brought into the filtered liquid, resulting in incomplete slag removal. Contents of the invention [0003] The object of the present invention is to design a tooth rake cleaning machine with backwashing function which can improve the cleaning efficiency of the tooth rake cleaning machine. [0004] The invention includes a frame, on which a transmission motor and a guide wheel are fixedly arranged, and a rake type grille chain is connected between the transmission motor and the guide wheel. Evenly distribute the water outlets towards the nozzles of the rake-type grille chain. [0005] The present invention can co...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F1/00

Inventor 江昌富韩国亮陈莲花

Owner YANGZHOU TIANLONG ENVIRONMENTAL PROTECTION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com