Sliding compression continuous solid-liquid separator

A technology of a solid-liquid separator and a pressure regulating mechanism, which is applied in the direction of a press, filtration separation, separation method, etc., and can solve problems such as limited stroke of a hydraulic cylinder, difficulty in pressing, and unfavorable increase in output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

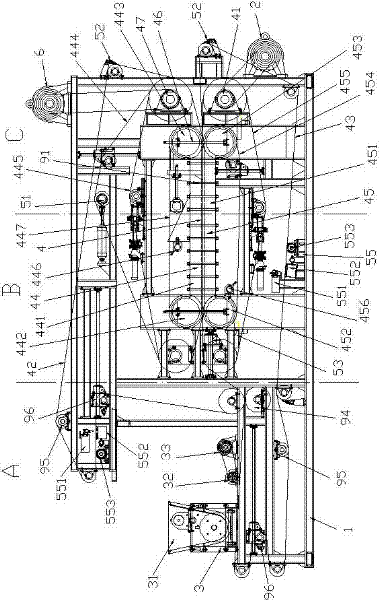

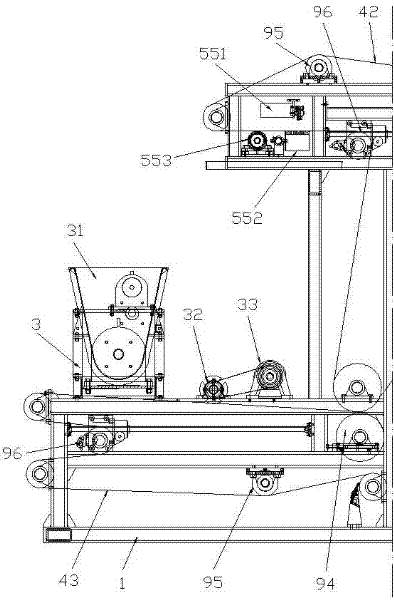

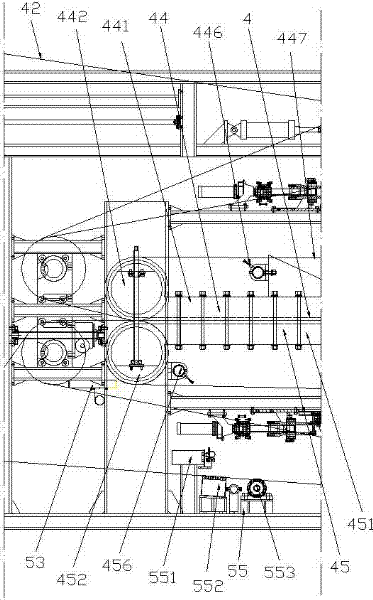

[0054] See Figure 1 to Figure 5 , Figure 25 to Figure 27 , The sliding pressurized continuous solid-liquid separator in this embodiment includes a frame 1, a driving device with a transmission belt, a feeding device 3, an upper filter belt 42, a lower filter belt 43, a pressing zone 4 and auxiliary devices, among which, The auxiliary device includes a tension roller 51, a scraper device 52, a water receiving device 53, a correction device and a filter belt cleaning device 55, and the filter belt cleaning device 55 further includes a flushing pipe 551, a vacuum box 552 and a rolling brush 553. The feeding device 3 includes a distributor 31, a screed roller 32, and a screed roller motor 33; the driving device with a transmission belt includes an upper driving device 6 with an upper transmission belt 445 and a lower driving device 2 with a lower transmission belt 455, and An upper driving roller 47 is provided in the upper driving device 6, and a lower driving roller 41 is provid...

Embodiment 2

[0072] See Figure 5 to Figure 9 , Figure 25 to Figure 27 , The sliding pressurized continuous solid-liquid separator in this embodiment includes a frame 1, a driving device with a transmission belt, a feeding device 3, an upper filter belt 42, a lower filter belt 43, a pressing zone 4 and auxiliary devices, among which, The auxiliary device includes a tension roller 51, a scraper device 52, a water receiving device 53, a correction device and a filter belt cleaning device 55, and the filter belt cleaning device 55 further includes a flushing pipe 551, a vacuum box 552 and a rolling brush 553. The feeding device 3 includes a distributor 31, a screed roller 32, and a screed roller motor 33; the driving device with a transmission belt is a lower driving device 2 with a lower transmission belt 455, and the lower driving device 2 is provided with a lower driving roller 41 With the transmission motor, the lower filter belt 43 is wrapped around the lower driving roller 42, and the lo...

Embodiment 3

[0081] See Figure 10 to Figure 16 , Figure 25 to Figure 27 , The sliding pressurized continuous solid-liquid separator in this embodiment includes a frame 1, a driving device with a transmission belt, a feeding device 3, an upper filter belt 42, a lower filter belt 43, a pressing zone 4 and auxiliary devices, among which, The auxiliary device includes a tension roller 51, a scraper device 52, a water receiving device 53, a correction device and a filter belt cleaning device 55, and the filter belt cleaning device 55 further includes a flushing pipe 551, a vacuum box 552 and a rolling brush 553. The feeding device 3 includes a distributor 31, a screed roller 32, and a screed roller motor 33; the driving device with a transmission belt is a lower driving device 2 with a lower transmission belt 455, and the lower driving device 2 is provided with a lower driving roller 41 With the transmission motor, the lower filter belt 43 is wrapped around the lower driving roller 42, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com