Vacuumizing, liquid filling and sealing device and method for plate multi-channel heat pipe

A flat heat pipe and sealing device technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of high cost and low efficiency, and achieve the effects of precise liquid injection, low energy consumption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

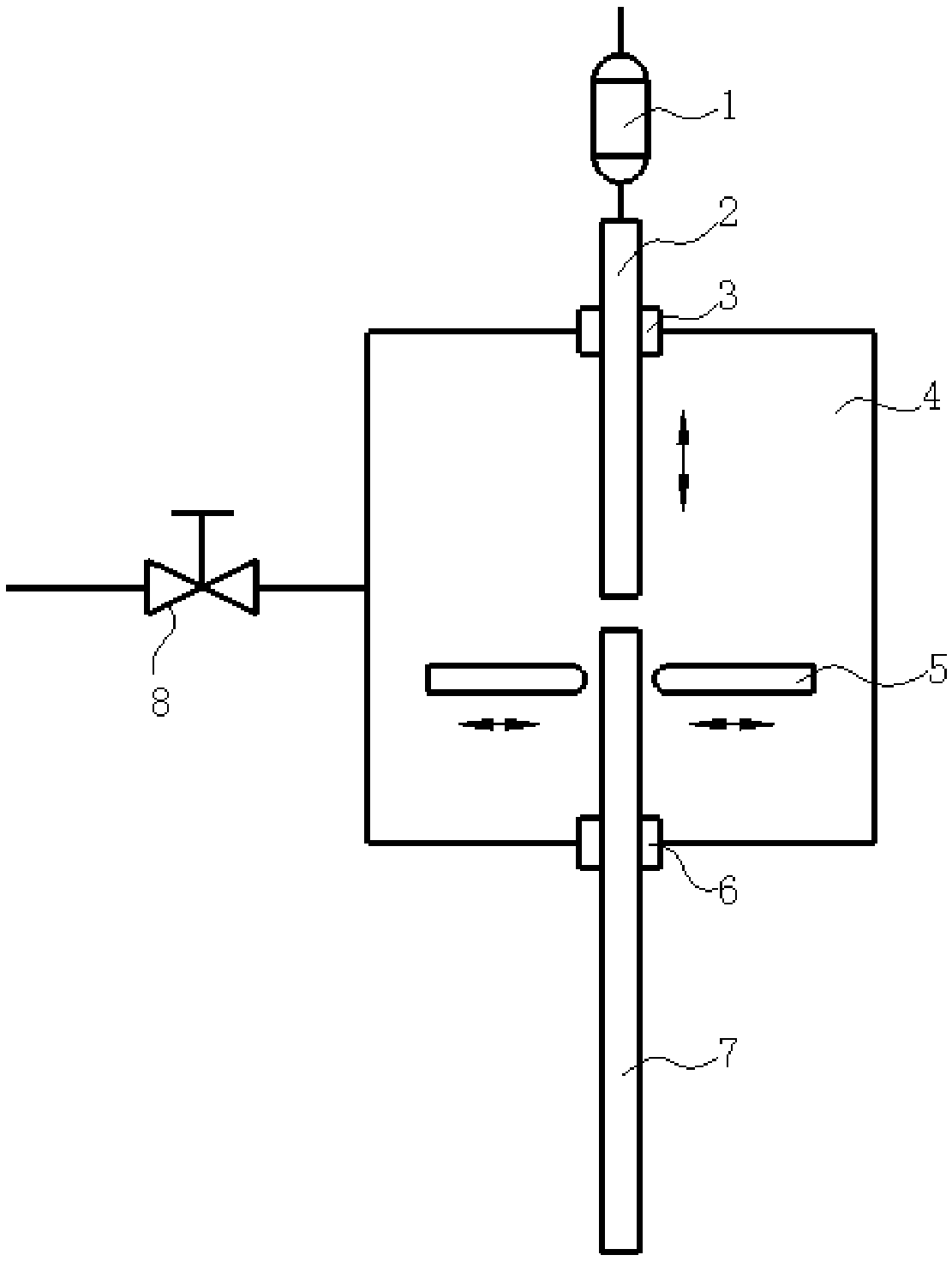

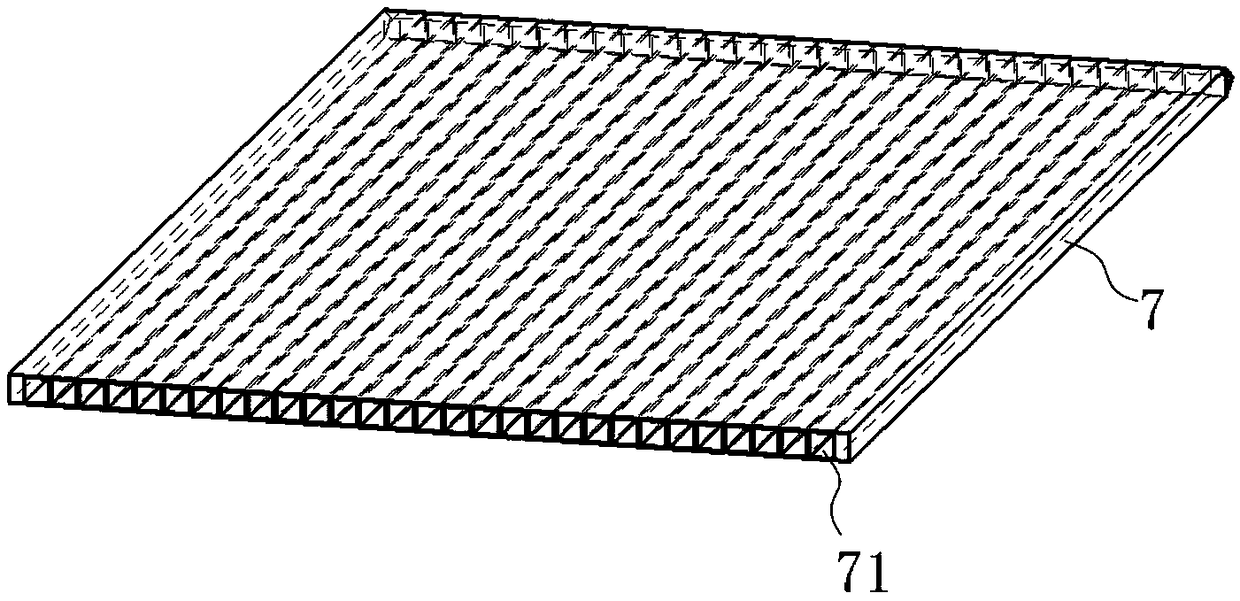

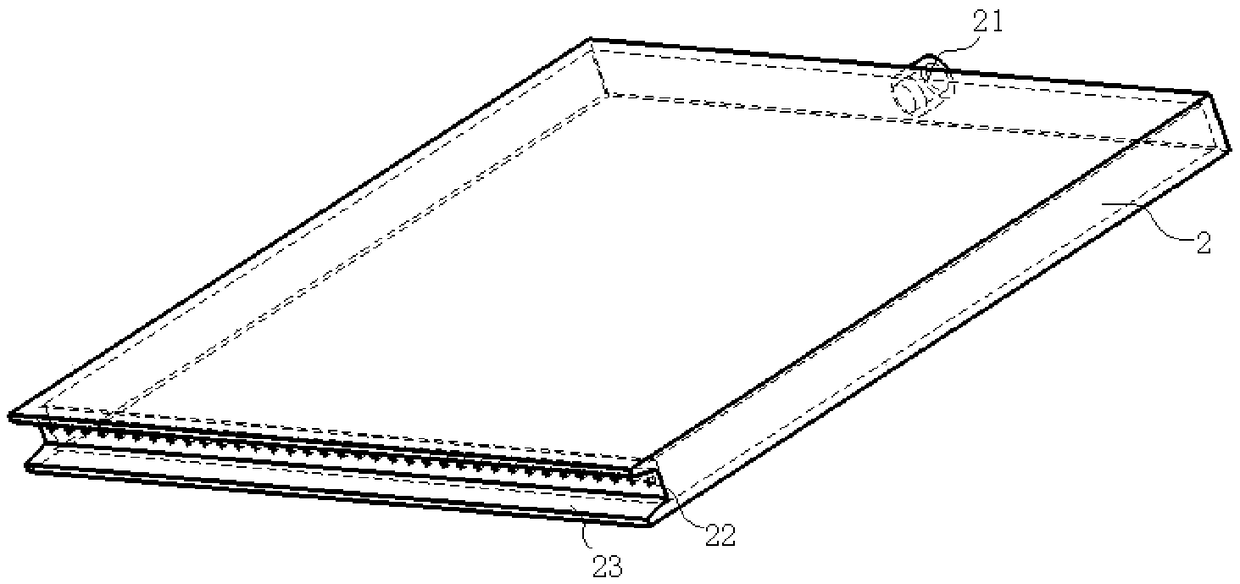

[0035] like figure 1 As shown, a vacuum injection liquid sealing device for a flat multi-channel heat pipe includes a vacuum cavity 4 connected to a vacuum valve 8, a quantitative liquid injection pump 1, a liquid injection plate 2, and a sealing mold 5. In this embodiment, as figure 2 As shown, a plurality of channels 71 are arranged inside the flat heat pipe 7 , each channel 71 is not connected to each other, one end is sealed by welding, and the other end is opened for vacuuming and liquid injection. like image 3 As shown, the liquid injection plate 2 is provided with a cavity, one end of which is provided with a liquid inlet 21 connected to the quantitative liquid injection pump 1, and the other end is provided with a number of passages 71 with the same number and positions as the flat heat pipe 7. Corresponding to the liquid injection hole 22, the liquid inlet 21 is connected to the quantitative liquid injection pump 1 through a pipeline, and one end provided with the ...

Embodiment 2

[0039] A method for vacuumizing liquid injection and sealing by using the device as described, comprising the steps of:

[0040] 1) Insert the flat heat pipe 7 vertically into the vacuum chamber 4 from the lower end through the sealed socket and control the distance between the upper end of the flat heat pipe 7 and each liquid injection hole 22 to be 0.5-5mm, so that each liquid injection hole 22 One-to-one correspondence with each channel 71 of the flat heat pipe 7;

[0041] 2) The vacuum valve 8 is opened to communicate with the vacuum pump and the vacuum chamber 4, and the vacuum valve 8 is closed after becoming a vacuum state in the vacuum chamber 4 to disconnect the vacuum pump and the vacuum chamber 4;

[0042] 3) Start the quantitative injection pump 1 to inject a quantitative working medium, the working medium is acetone or ammonia water, the working medium passes through the liquid inlet 21, and then passes through a plurality of liquid injection holes 22 to evenly di...

Embodiment 3

[0047] A method for vacuumizing liquid injection and sealing by using the device as described, comprising the steps of:

[0048] 1) Insert the flat heat pipe 7 vertically from the lower end into the vacuum chamber 4 through the sealed socket;

[0049] 2) The vacuum valve 8 is opened to communicate with the vacuum pump and the vacuum chamber 4, and the vacuum valve 8 is closed after becoming a vacuum state in the vacuum chamber 4 to disconnect the vacuum pump and the vacuum chamber 4;

[0050] 3) The liquid injection plate 2 is moved down close to the flat heat pipe 7, so that each liquid injection hole 22 corresponds to each channel 71 of the flat heat pipe 7;

[0051] 4) Start the quantitative injection pump 1 to inject a quantitative working medium, the working medium is acetone or ammonia water, the working medium passes through the liquid inlet 21, and then passes through a plurality of liquid injection holes 22 to evenly distribute the working medium into each channel 71 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com