Concrete mixing plant control method, computer device and computer readable storage medium

A control method and concrete technology, applied in calculation, design optimization/simulation, resources, etc., can solve problems such as unclearness, discontinuous pouring, waste of concrete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

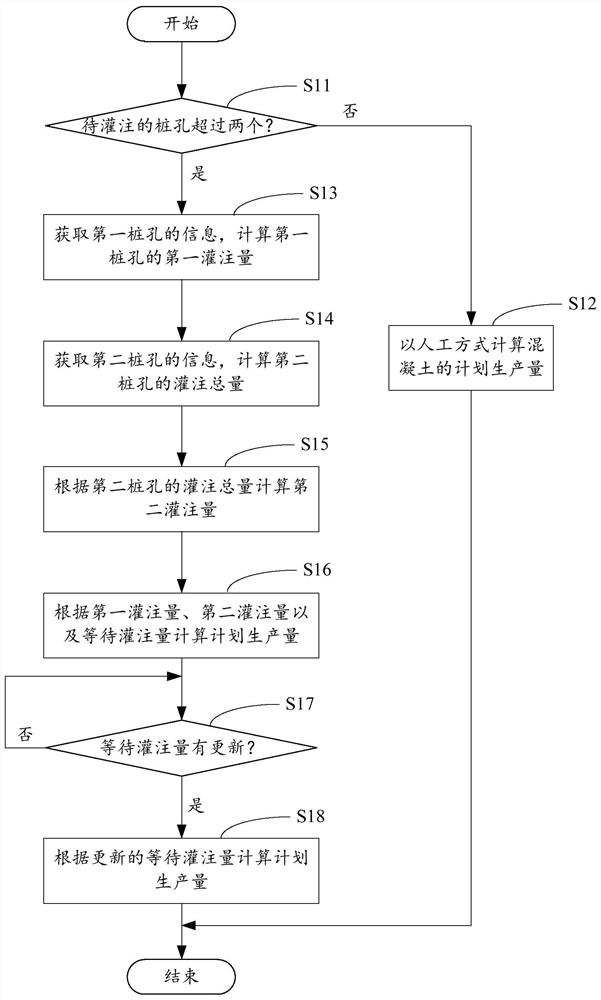

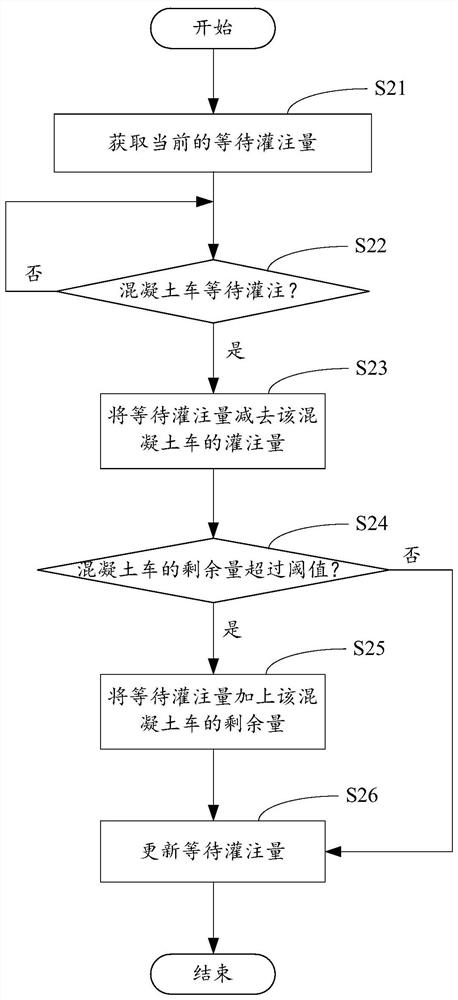

[0030] The control method of the concrete mixing station of the present invention is applied to the mixing station for concrete production. The mixing station is set at a position with a certain distance from the construction site of the pile hole, and the concrete produced by the mixing station needs to be transported to the construction site of the pile hole by a concrete truck . Specifically, the present invention is applied to a control server of a mixing plant. The server has a processor and a memory, and a computer-readable storage medium is stored on the memory. When the processor executes the computer-readable storage medium, the above-mentioned concrete mixing plant control method can be realized. .

[0031] Example of control method for concrete mixing plant:

[0032] This embodiment is applied in a concrete mixing plant to control the production of concrete in the mixing plant. Specifically, the planned production volume of the concrete mixing plant can be calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com