Patents

Literature

544results about How to "Fit firmly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

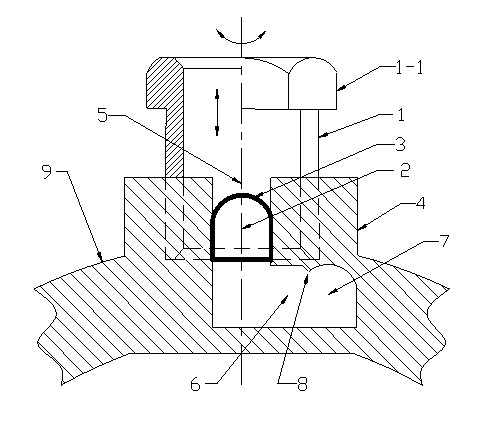

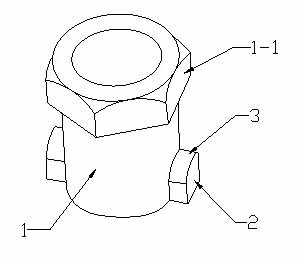

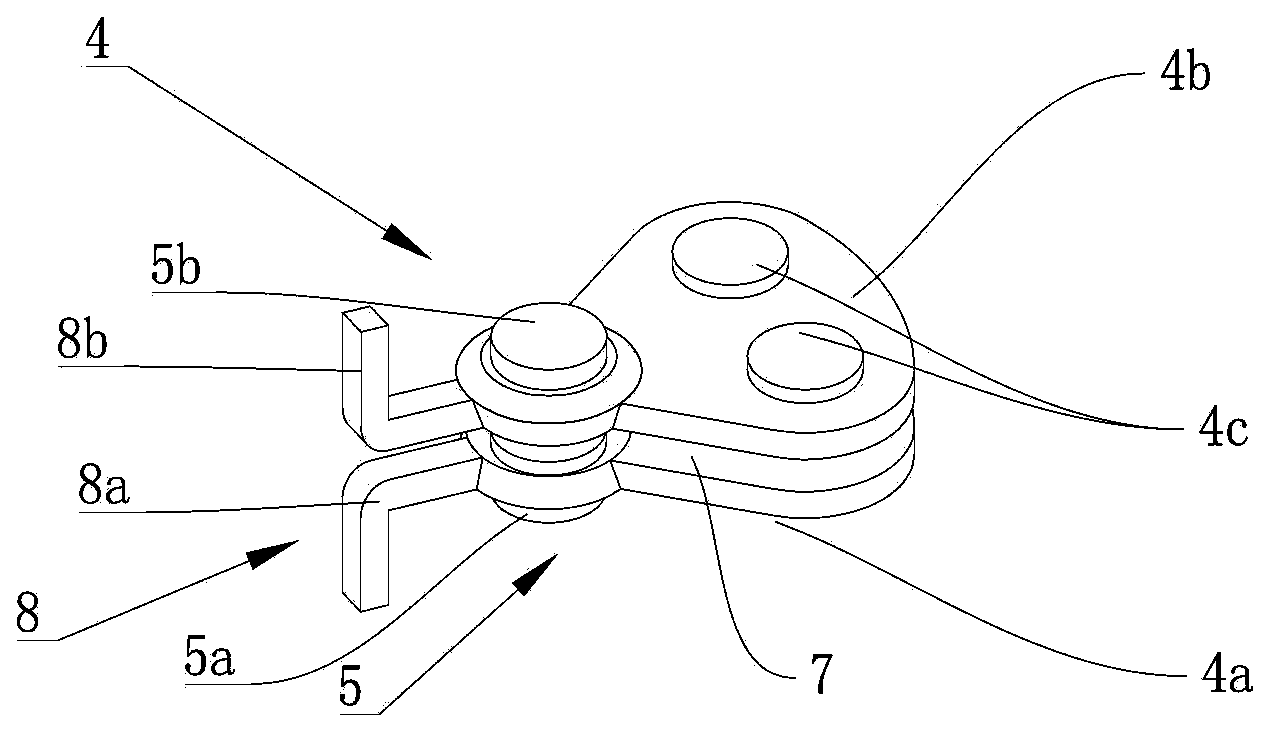

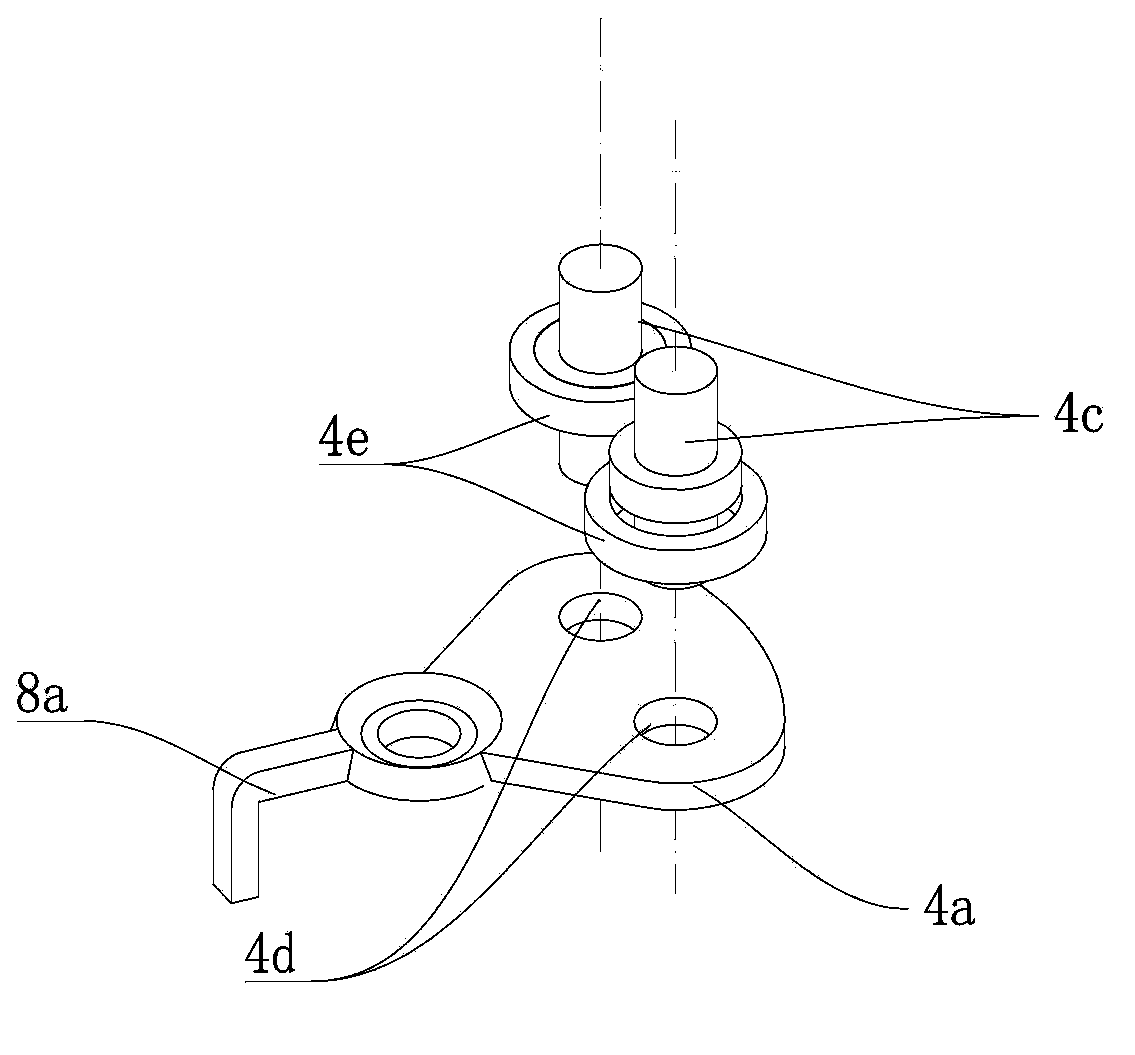

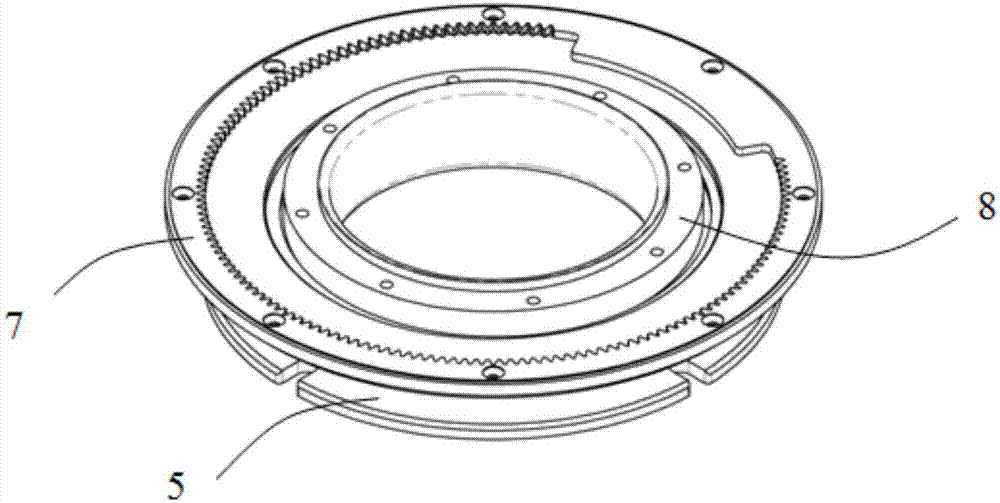

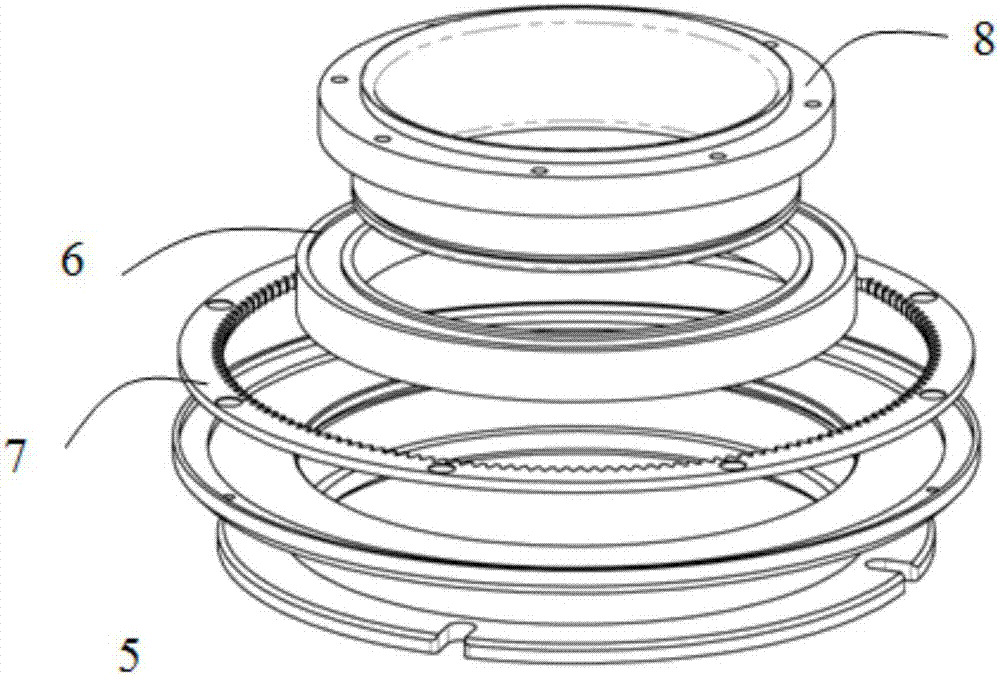

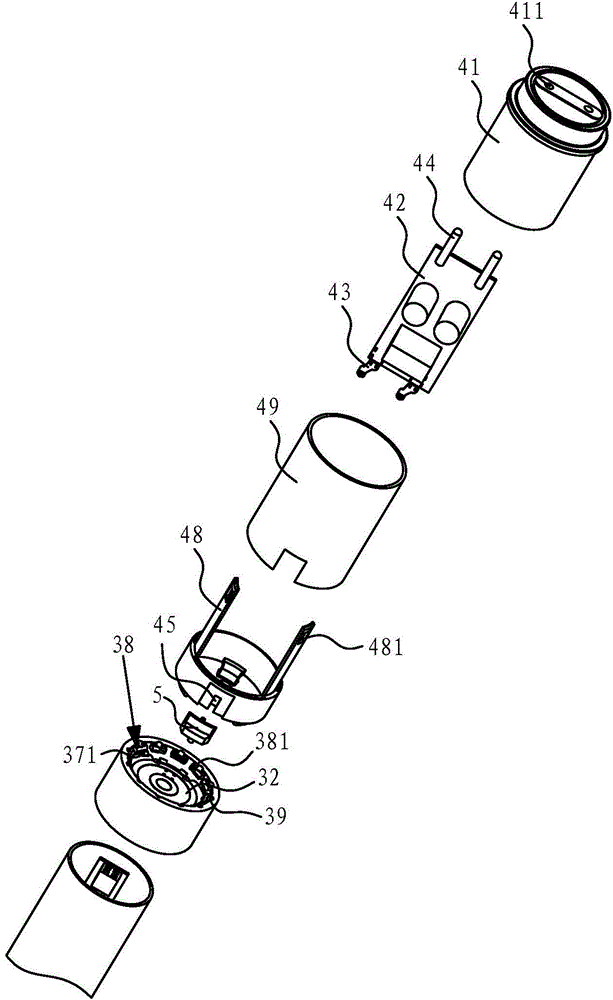

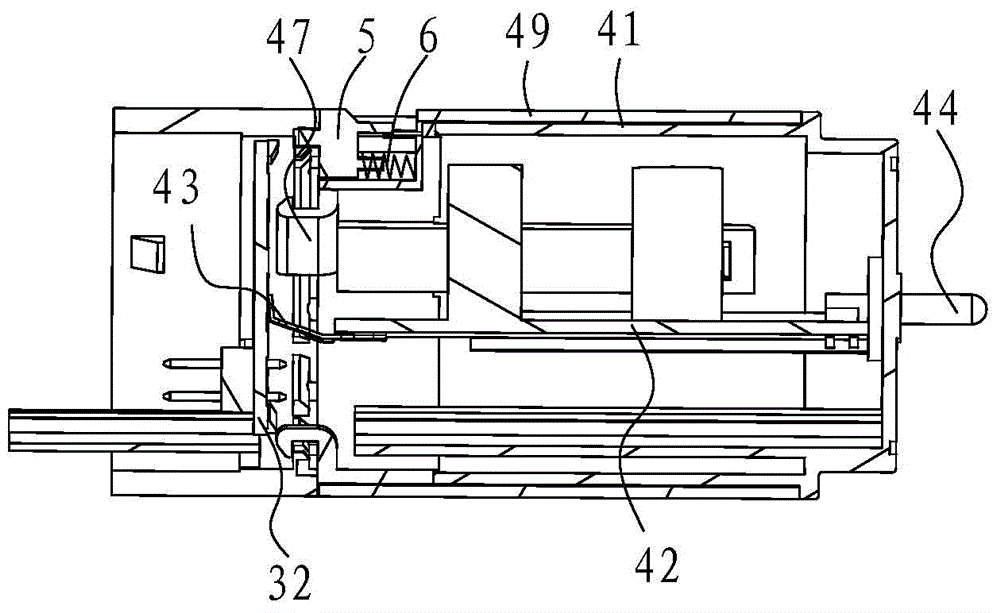

Clutch mechanism for single drive system of washing machine

InactiveCN102628208ACompact structureReduce volumeOther washing machinesTextiles and paperDrive shaftEngineering

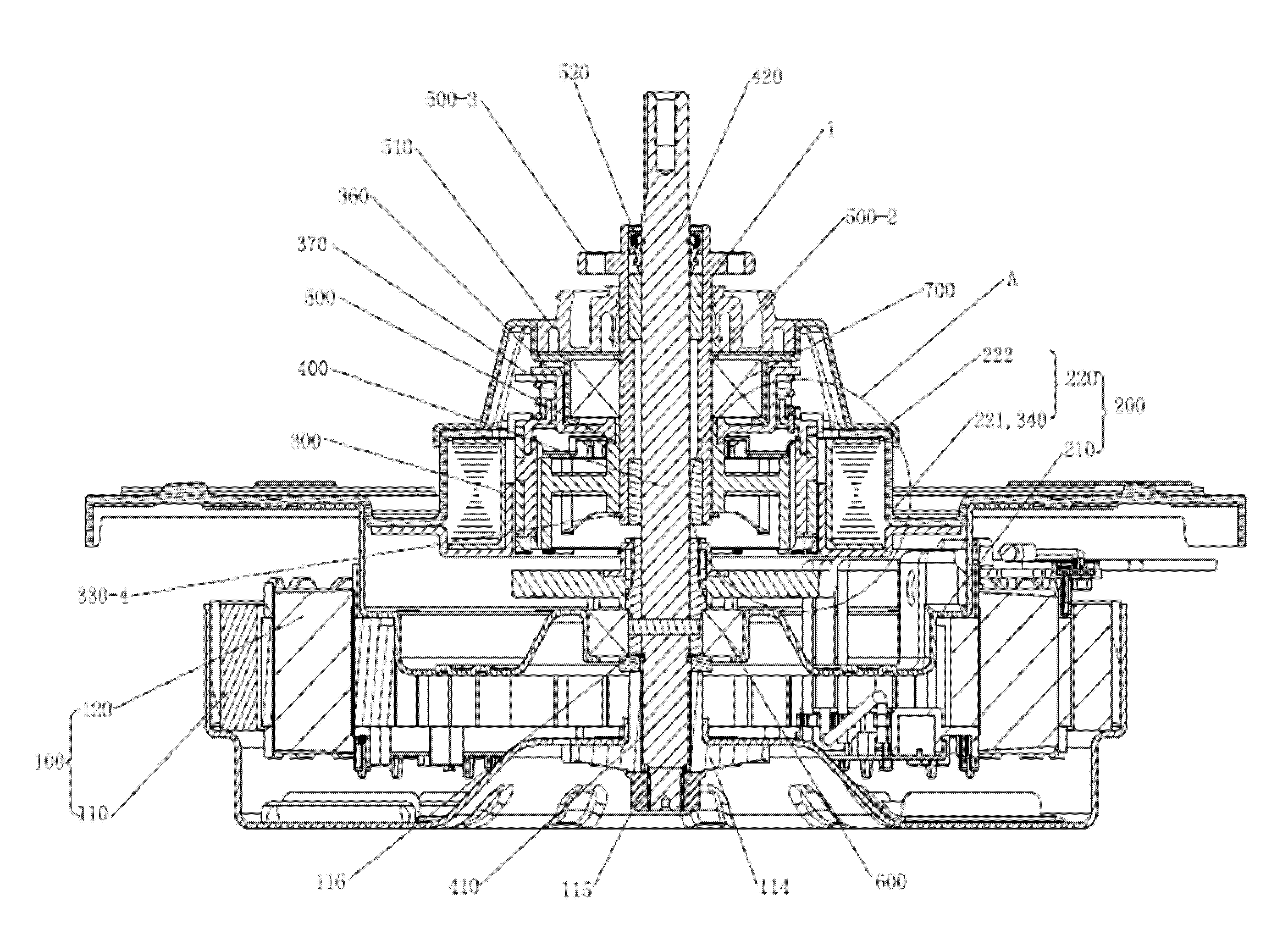

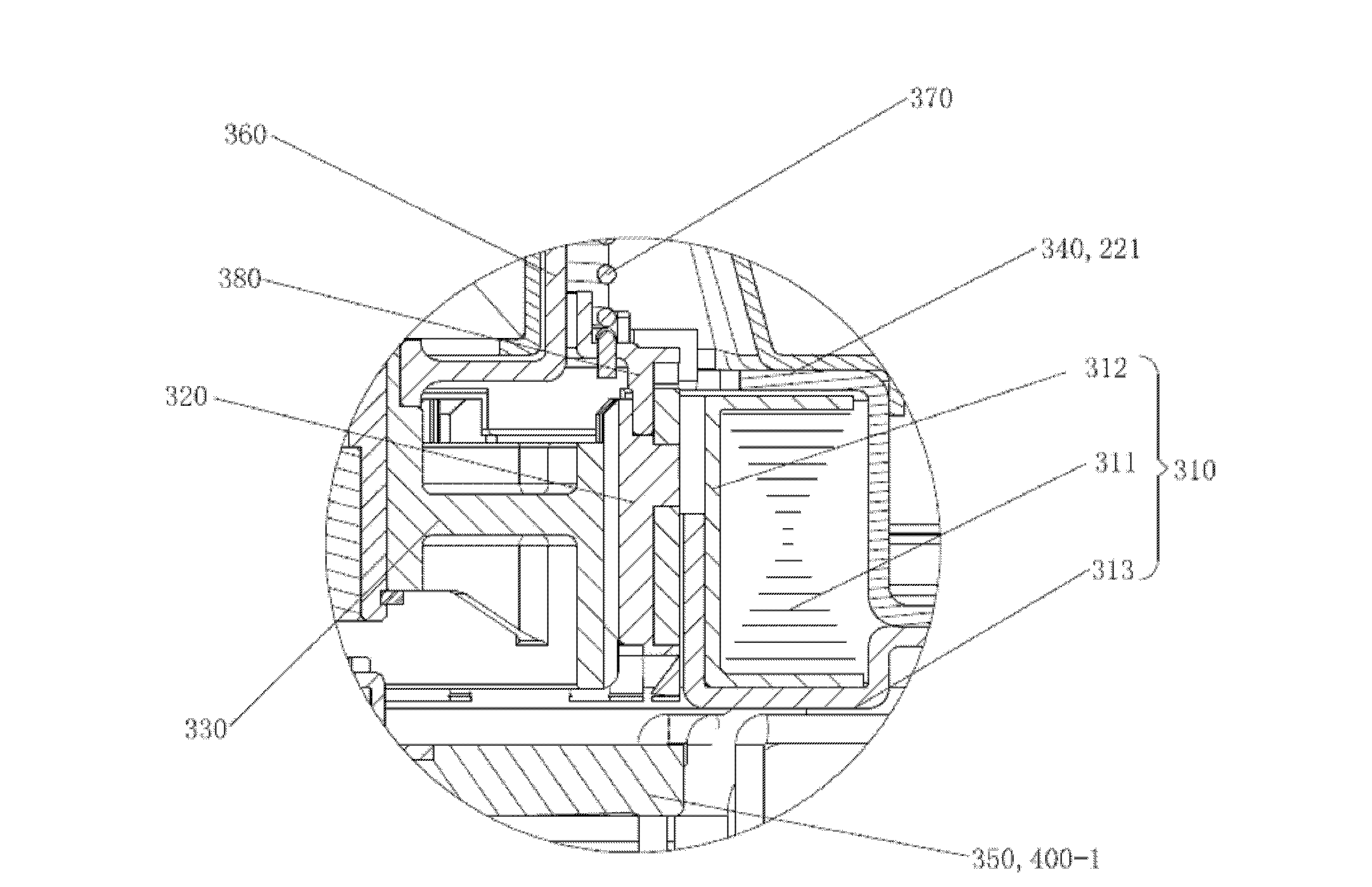

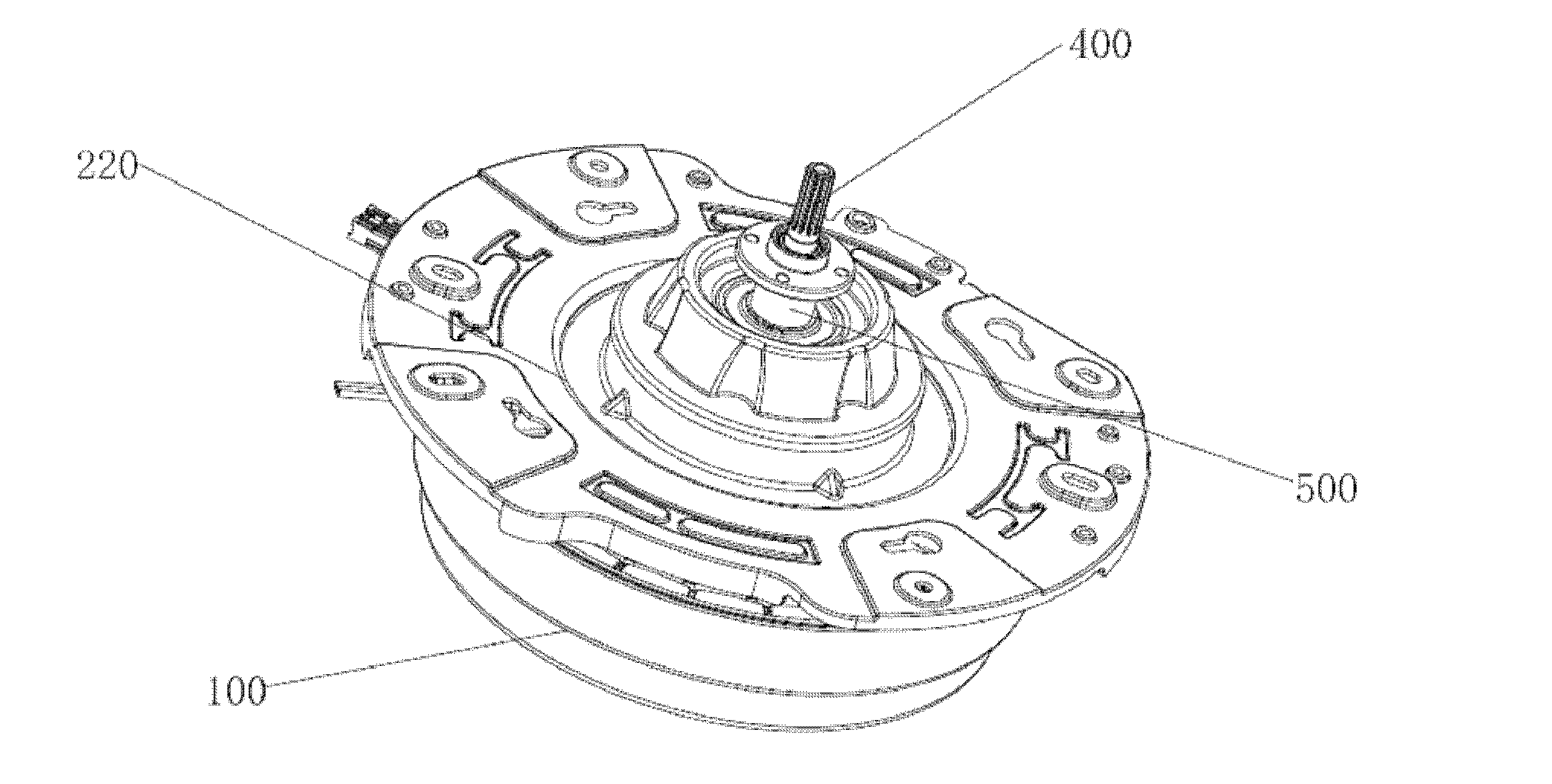

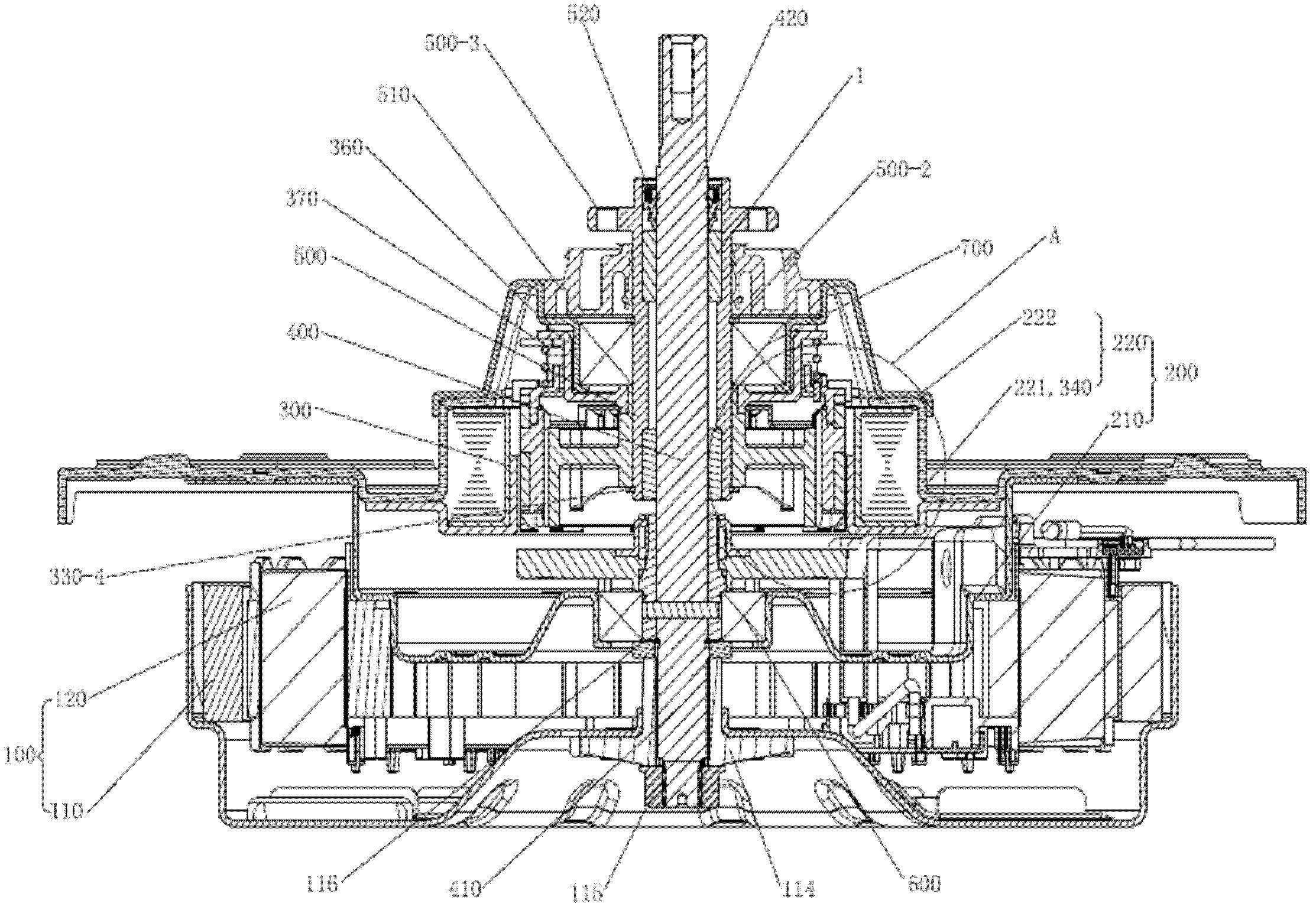

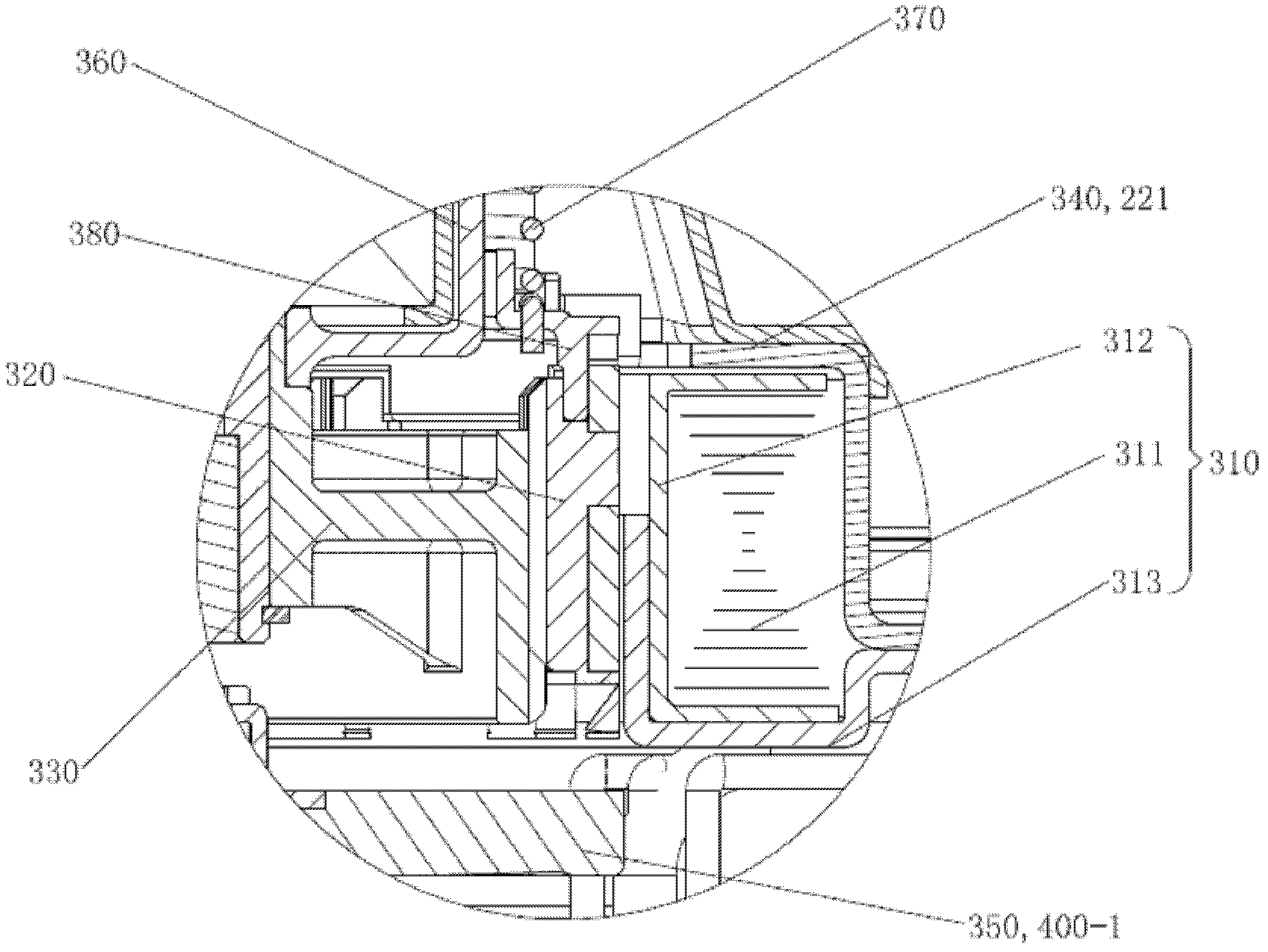

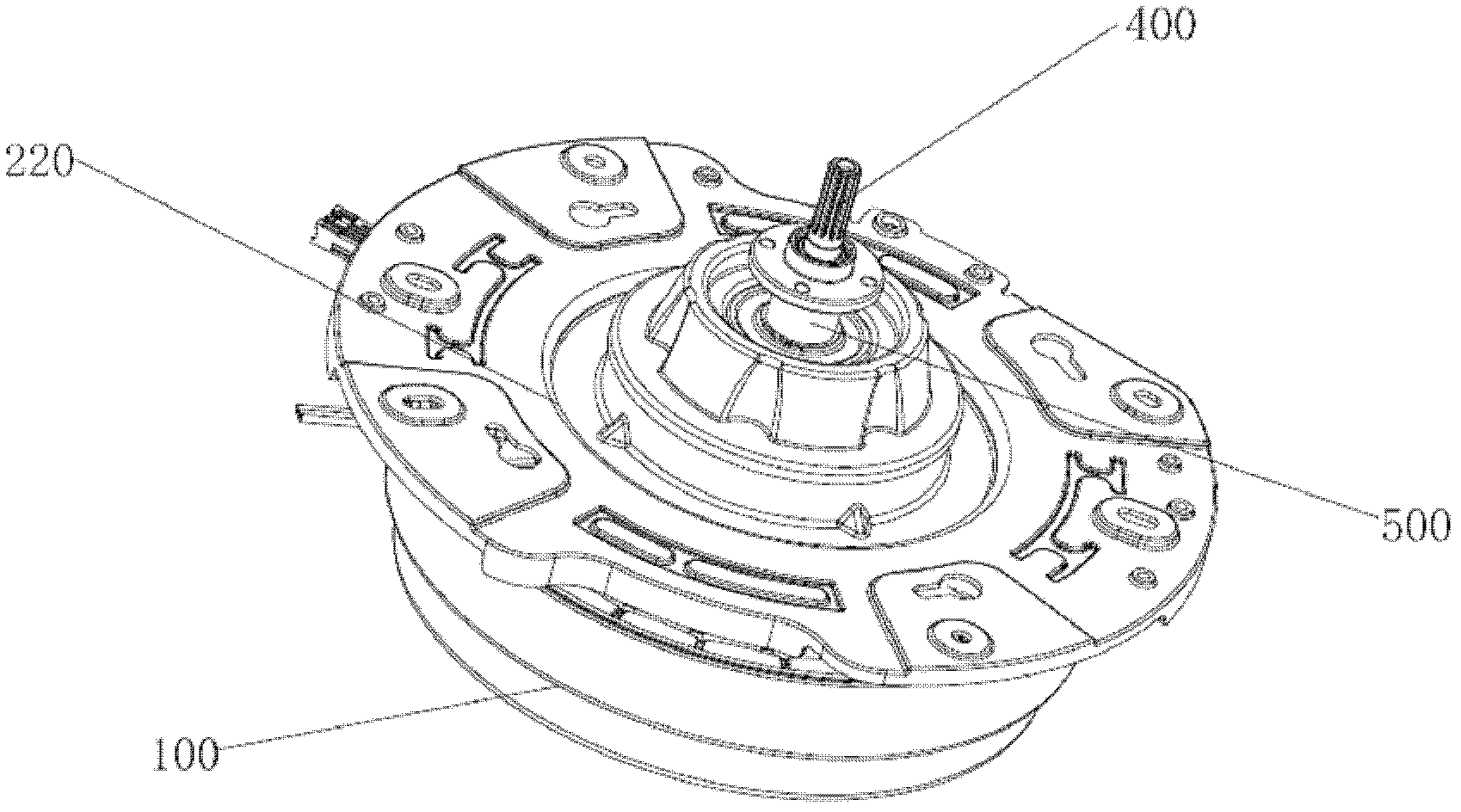

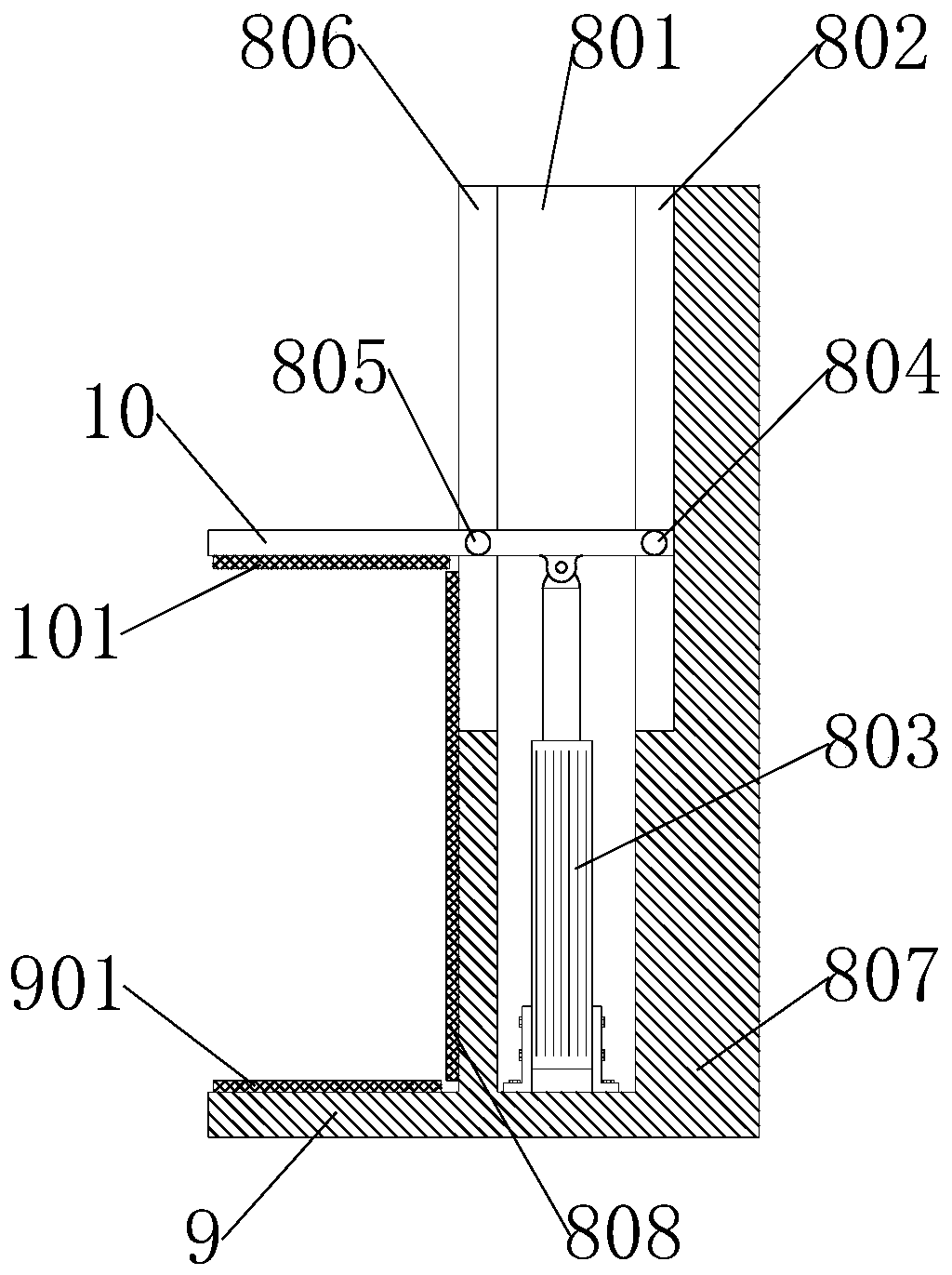

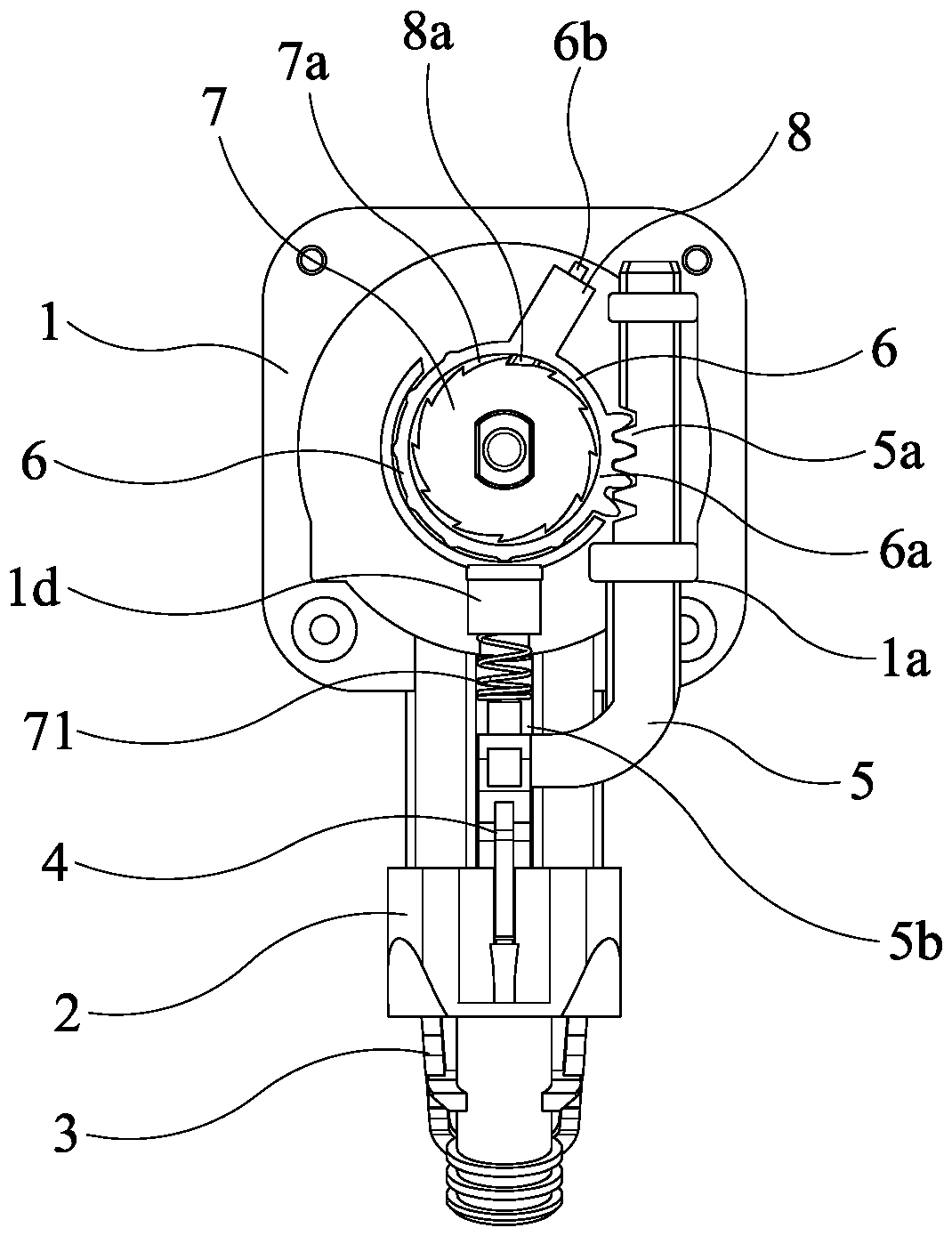

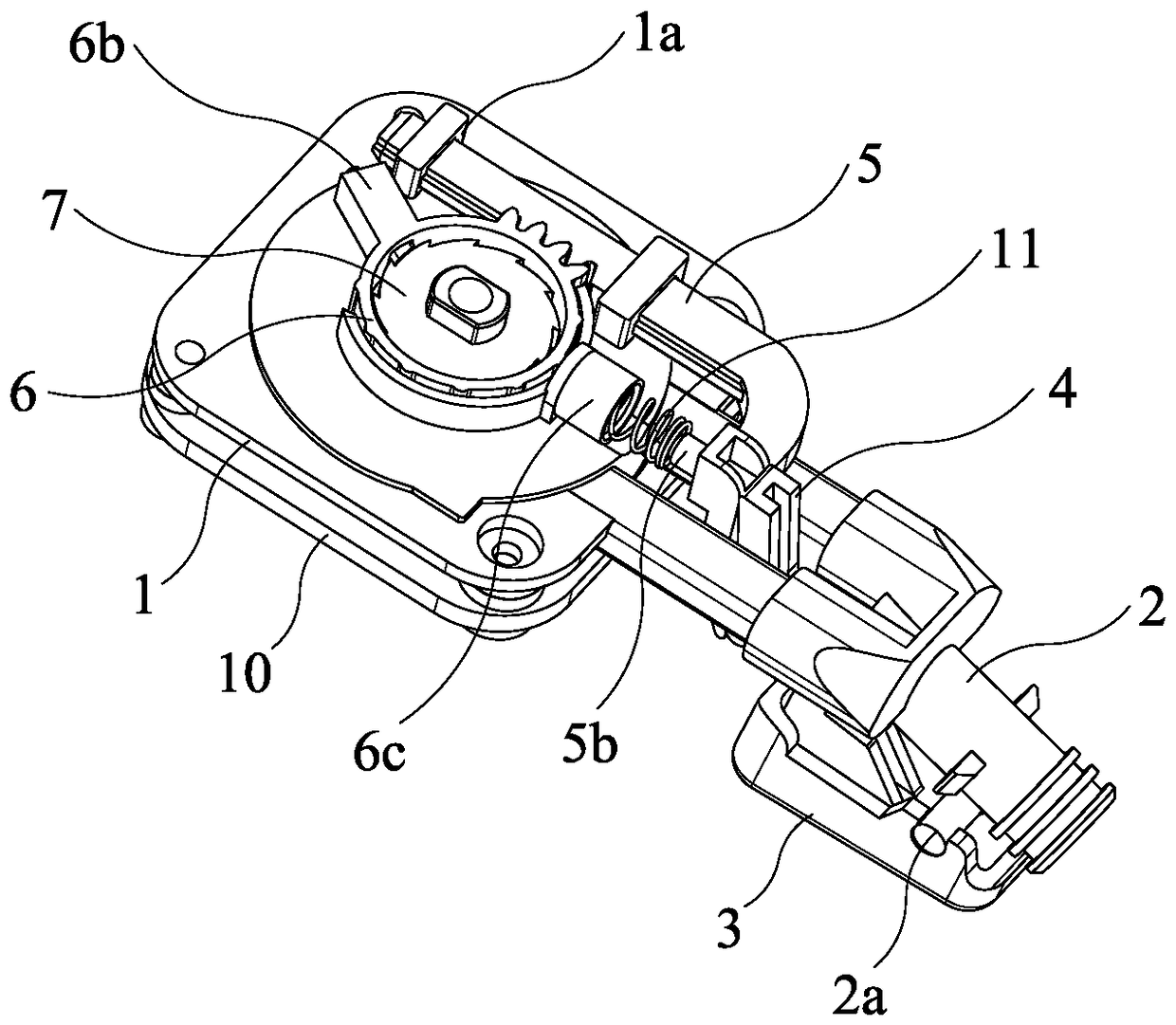

The invention relates to a clutch mechanism for a single drive system of a washing machine. A lower shell body and an upper shell body are fixedly connected to form an inside space in which the clutch mechanism is located. The clutch mechanism comprises an electromagnetic coil mechanism, a clutch gear ring, a meshing part, an upper matching part and a lower matching part. A mounting plate serves as the upper matching part. A drive shaft located above a stator retainer is fixedly connected with a clutch tooth disc. The clutch tooth disc serves as the lower matching part to achieve vertical movement of the clutch gear ring along the meshing part and select one to match with the mounting plate and the clutch tooth disc. The clutch mechanism is good in clutch performance, low in manufacture cost, small in noise, convenient to mount and suitable for popularization and application in production.

Owner:CHANGZHOU XINYA ELECTROMOTOR

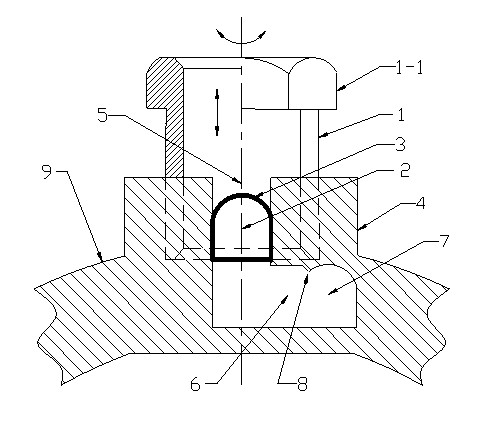

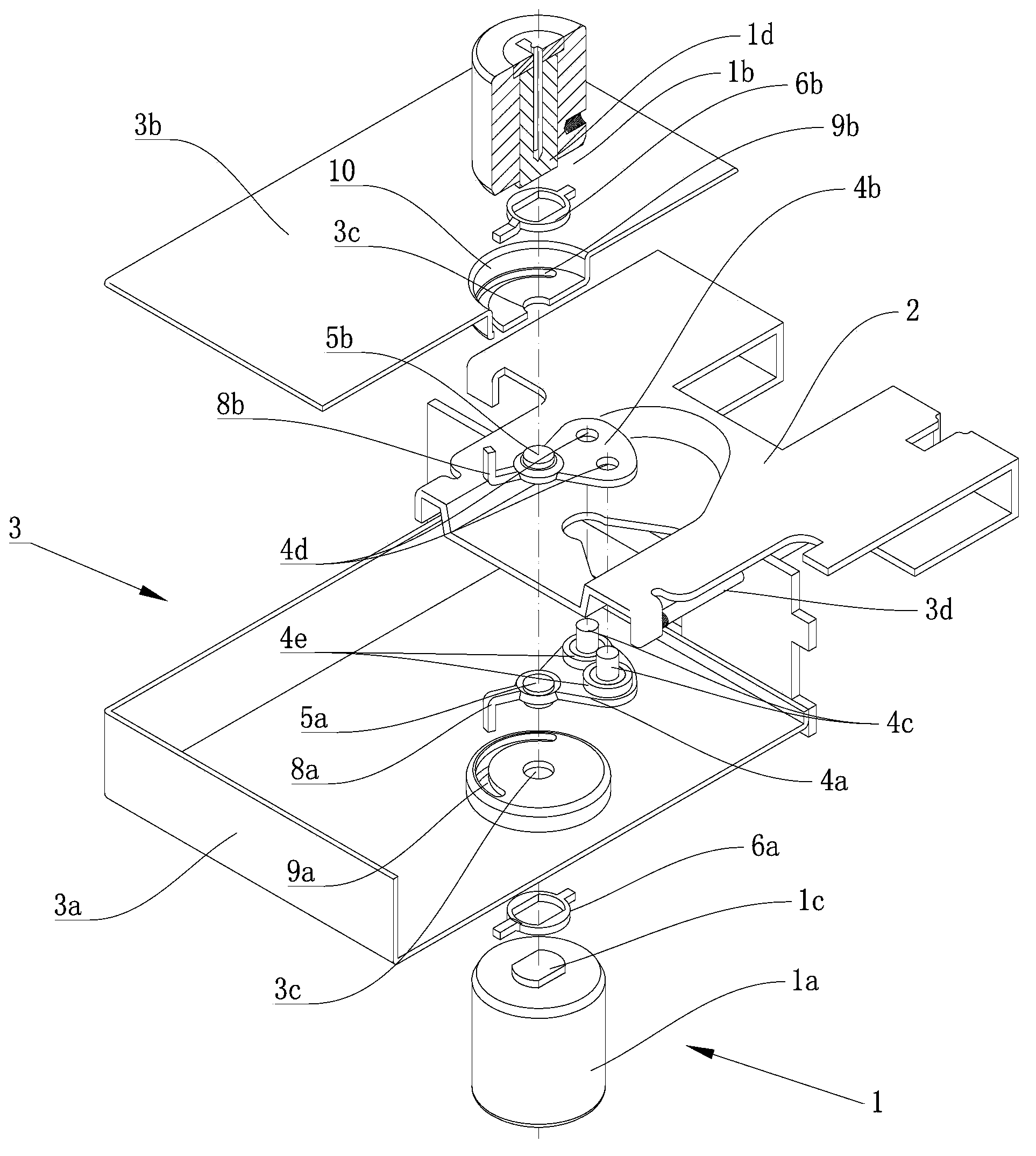

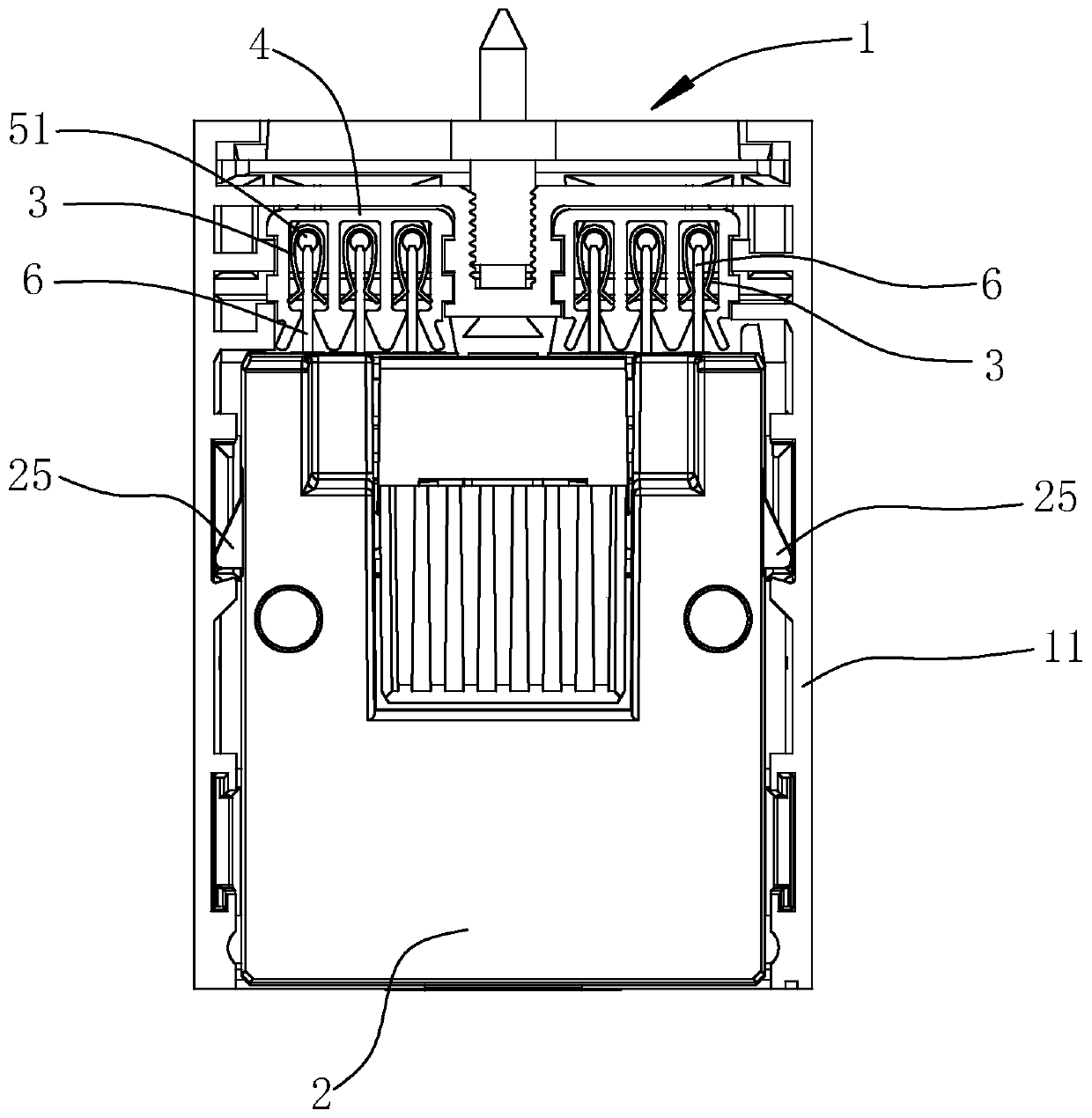

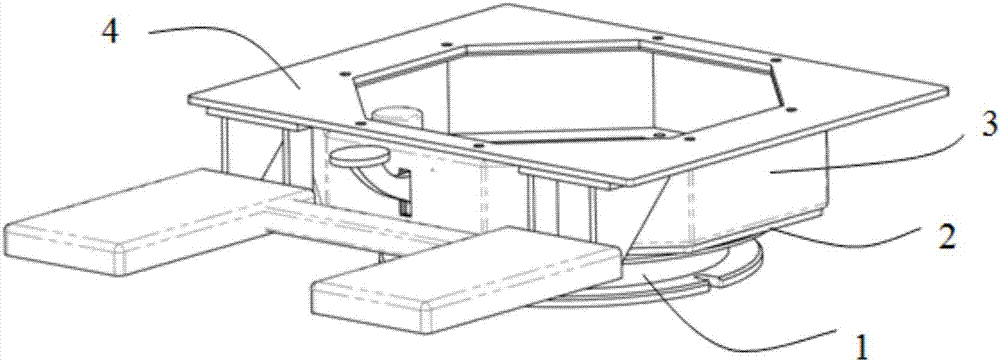

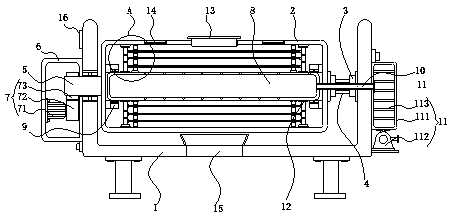

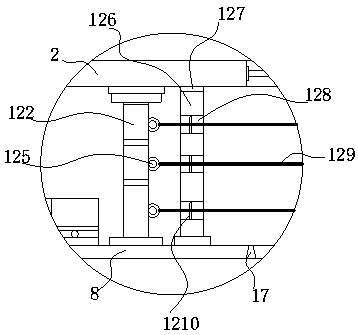

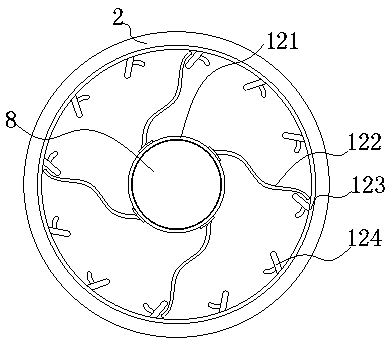

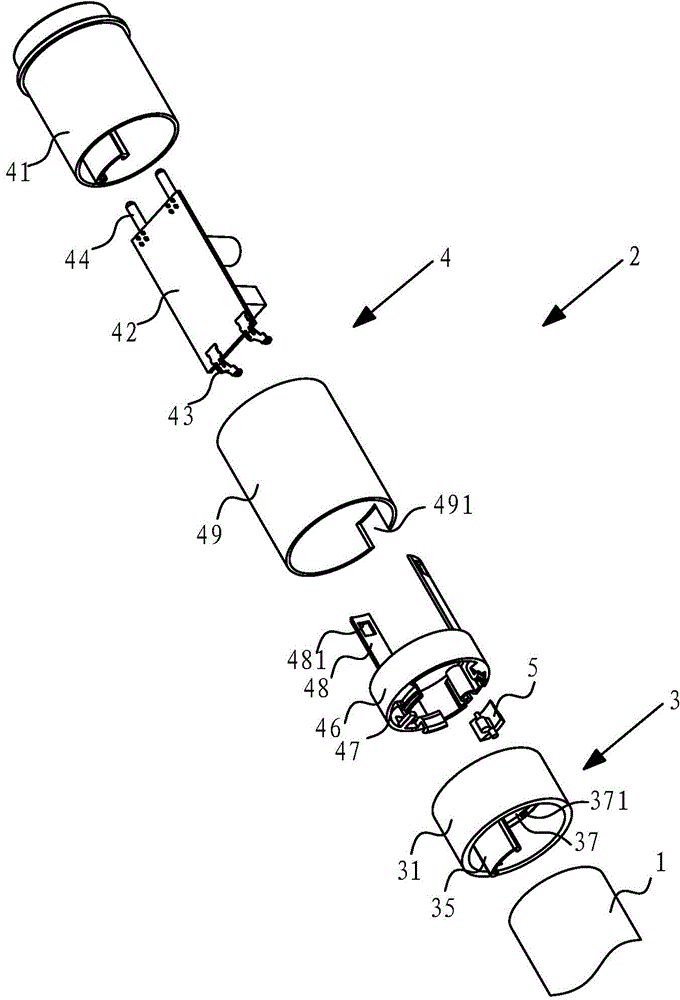

Single-driving system of washing machine

InactiveCN102619069ACompact structureReduce volumeOther washing machinesTextiles and paperInterior spaceDrive shaft

The invention relates to a single-driving system of a washing machine, which comprises a motor, a shell, a clutch mechanism, a driving shaft and a driving shaft sleeve. The driving shaft is rotatably arranged in the driving shaft sleeve, the motor is an outer rotor motor, the shell comprises a lower shell and an upper shell which are fixedly connected, the lower shell is used as a stator retainer of an inner stator, the stator retainer is fixedly connected with the inner stator, the clutch mechanism is located in an inner space, the lower shell and the upper shell are fixedly connected to form the inner space, the clutch mechanism comprises an electromagnetic coil mechanism, a clutch gear ring, a meshing component, an upper matching component and a lower matching component, a mounting plate is used as the upper matching component, the driving shaft located above the stator retainer is fixedly connected with a clutch gear disc, the clutch gear disc is used as the lower matching component, and the clutch gear ring vertically moves along the meshing component and selectively matches with the mounting plate and the clutch gear disc. The single-driving system of the washing machine is fine in clutch performance, low in manufacturing cost and noise, convenient in installation and quite suitable for popularization and application in production.

Owner:CHANGZHOU XINYA ELECTROMOTOR

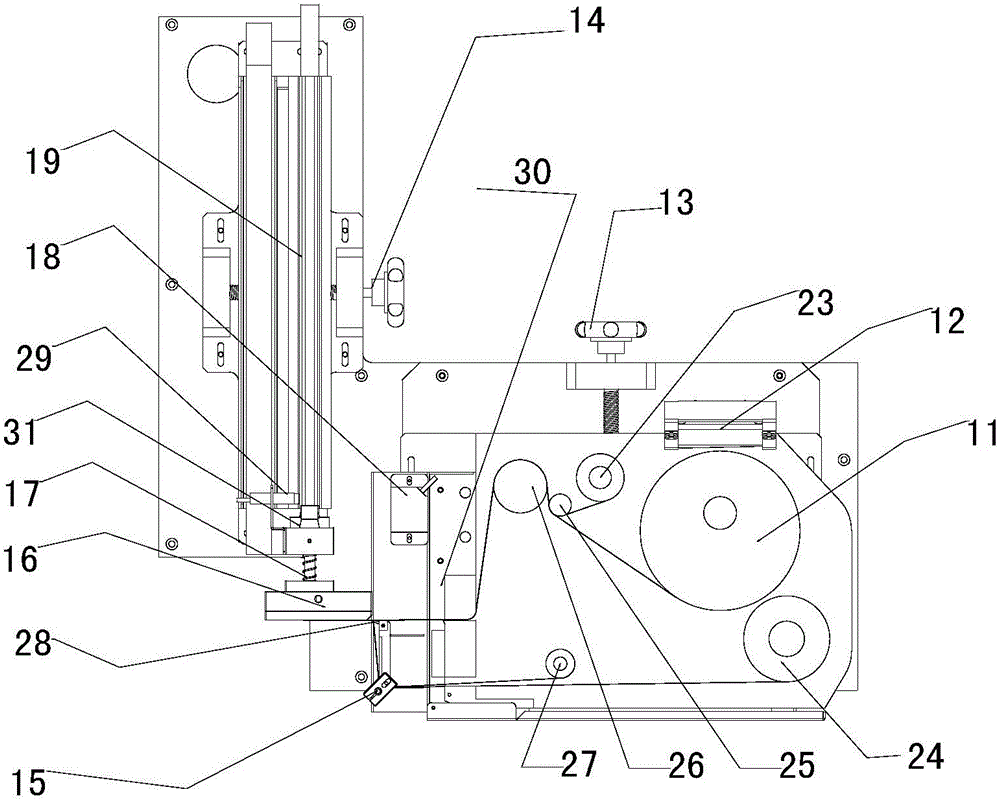

Product identification printing, pasting and detecting system and printing, labeling and detecting method adopting product identification printing, pasting and detecting system

InactiveCN105819052AFit firmlyReduce bad labelingTypewritersLabelling machinesObject detectionManufacturing line

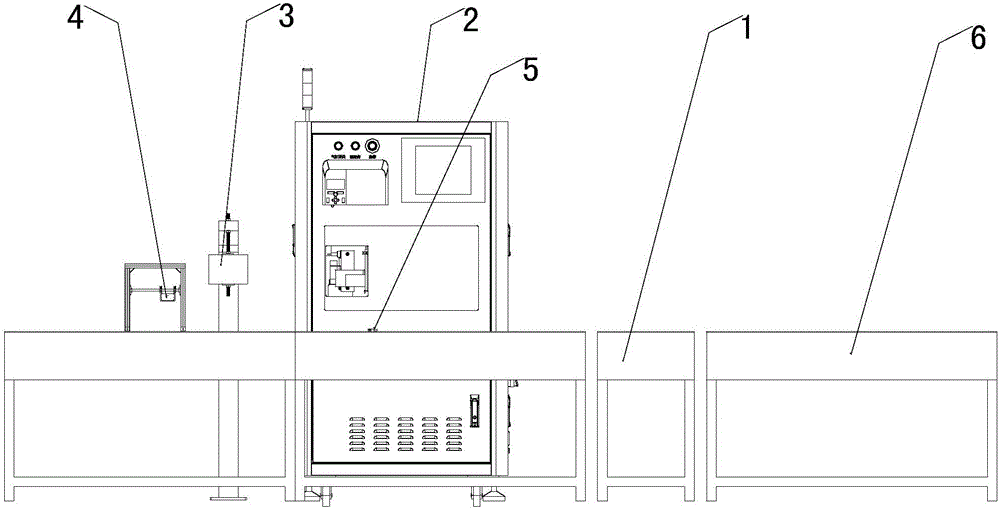

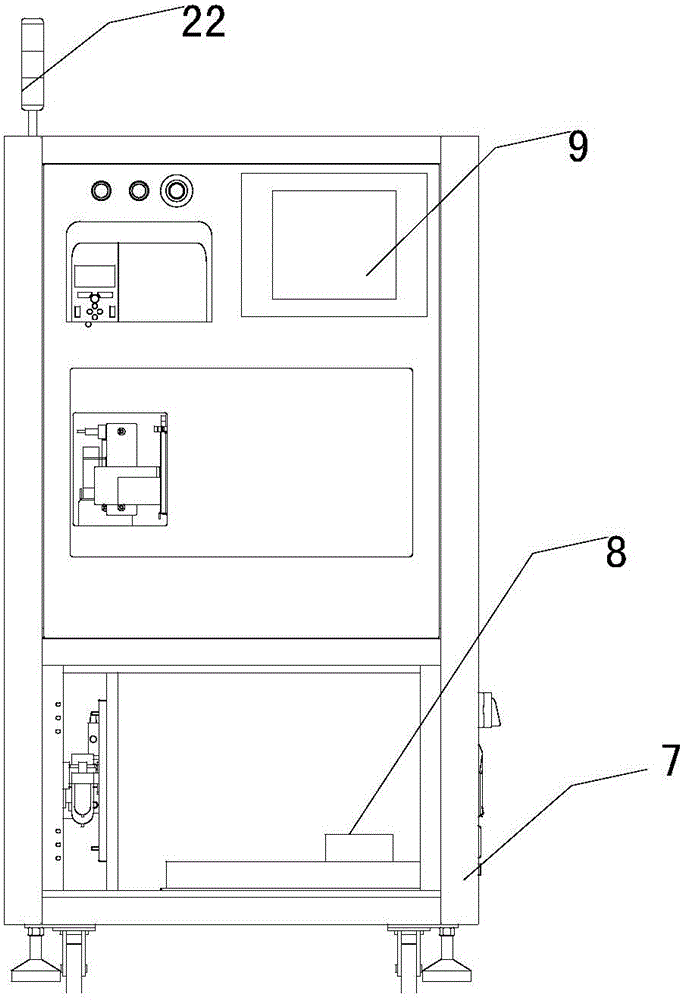

The invention discloses a product identification printing and sticking detection system and a printing and labeling detection method thereof. The system includes a conveying line, a weighing machine, a measuring sensor, a printing and labeling machine, and a label leakage detection sensor. The printing and labeling machine is equipped with an industrial control PC, a label printer, a PLC controller, an infrared detector, and a labeling device; The weighing machine is connected with the industrial control PC, and the industrial control PC, label printer, infrared detector, measuring sensor, labeling device, and missing label detection sensor are electrically connected with the PLC controller; the missing label detection sensor is a color code sensor. In the printing and labeling detection method of the present invention, the relevant equipment of the above-mentioned product identification printing and pasting detection system executes actions sequentially to complete the printing and labeling detection. The invention can reduce the generation of bad labeling, improve production efficiency, and reduce the labor intensity of workers on the production line.

Owner:HANGZHOU PUJIANG TECH CO LTD

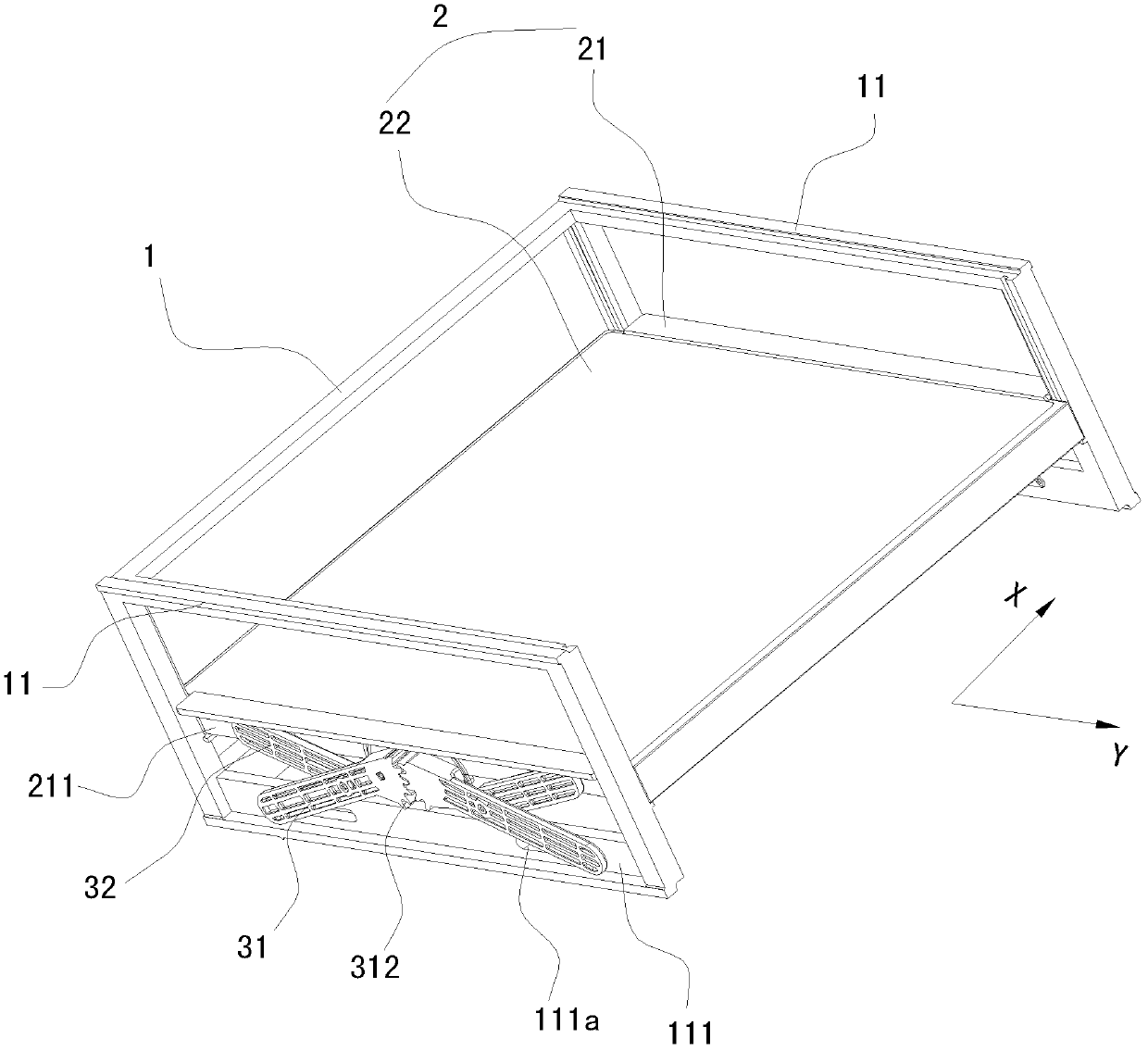

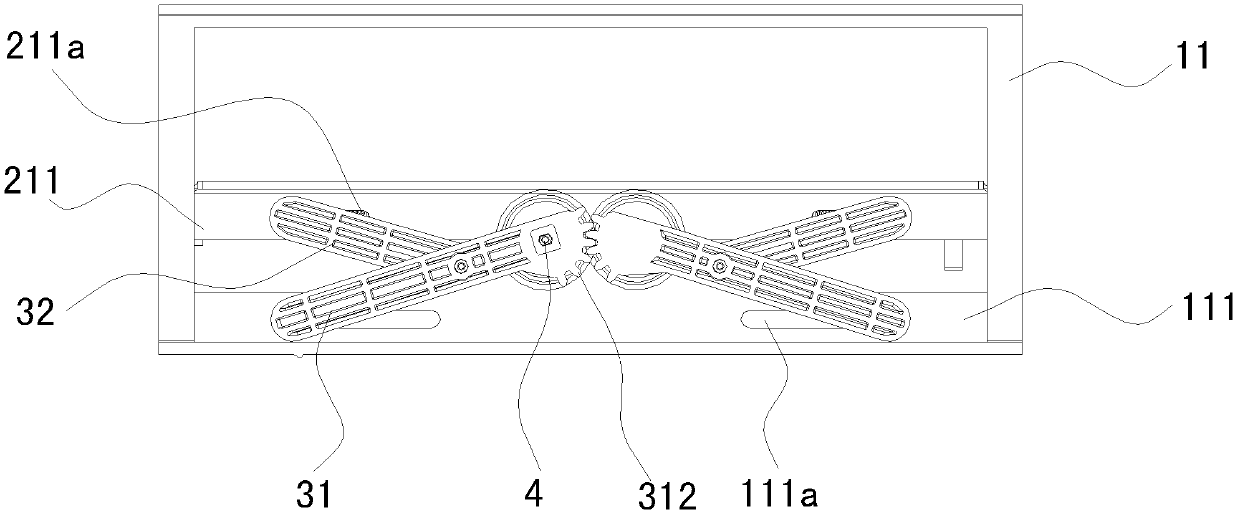

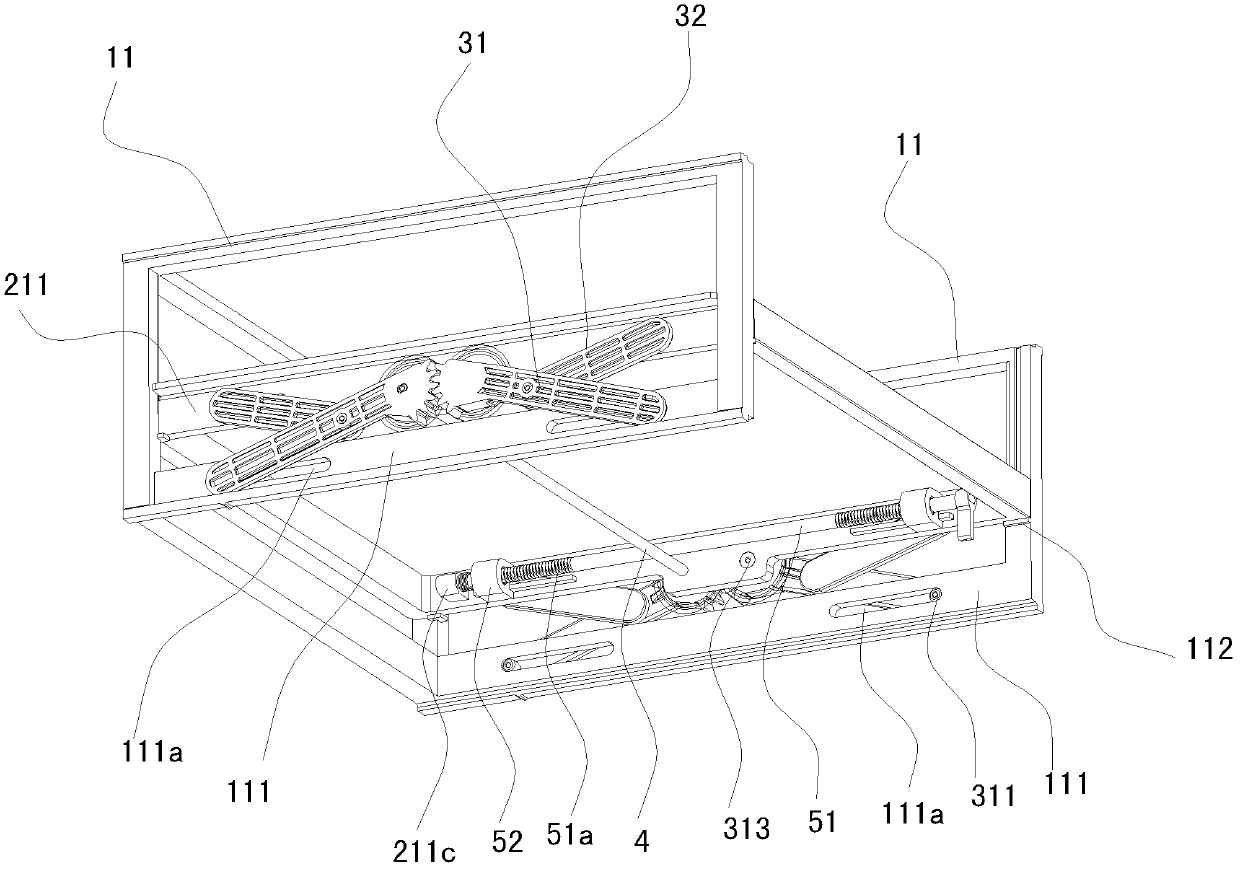

Refrigerator shelf component and refrigerator

ActiveCN103375962AGood self-locking efficiencyFit firmlyLighting and heating apparatusDomestic refrigeratorsSelf lockingRefrigerated temperature

Owner:GREE ELECTRIC APPLIANCES INC

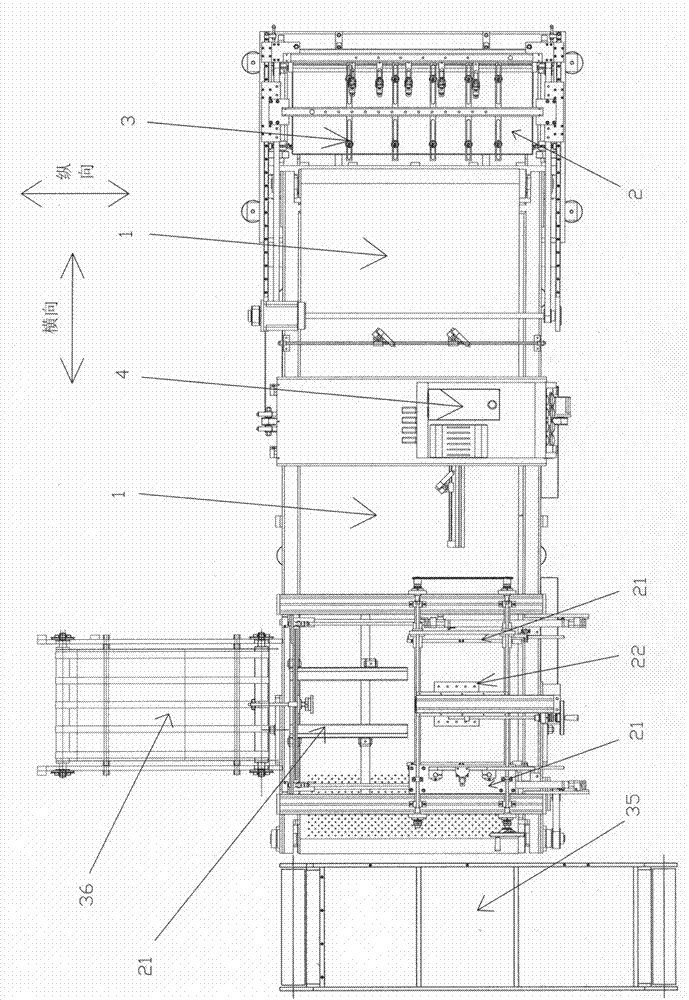

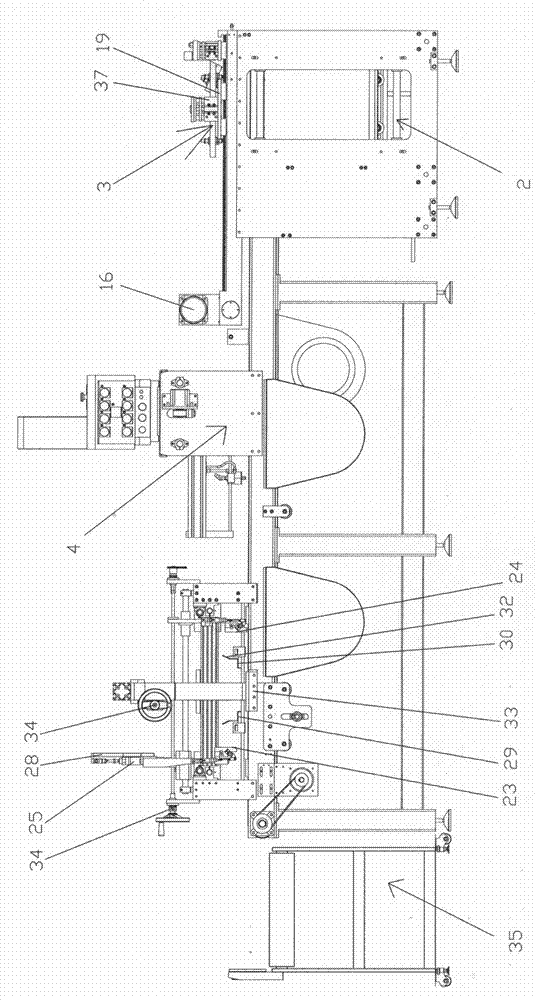

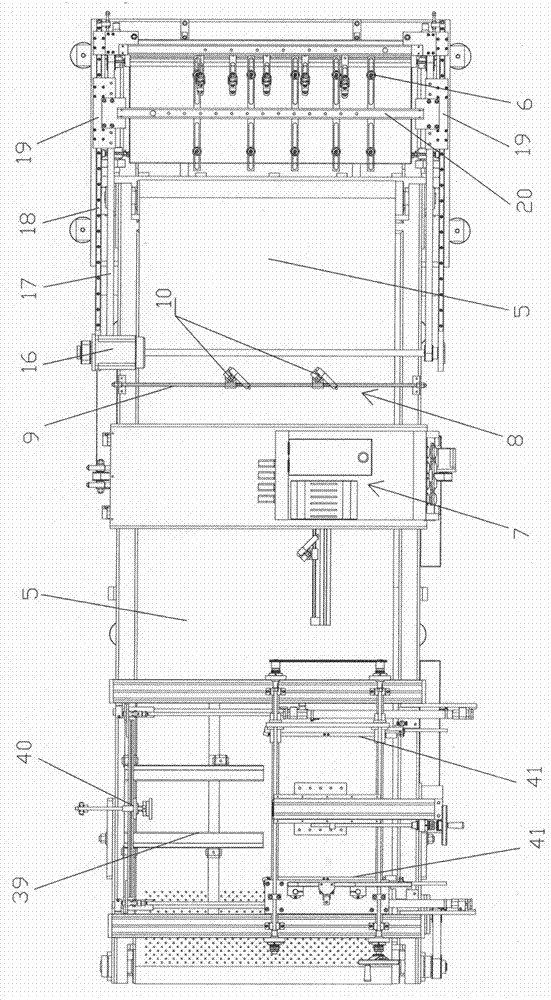

Full-automatic glue spraying and box making production line

ActiveCN103203894AFit firmlyImprove box making precisionPaper-makingBox making operationsManipulatorEngineering

A full-automatic glue spraying and box making production line comprises a framework. A conveying mechanism, a plate feeding mechanism, a transferring manipulator, a glue spraying mechanism, a box conveying positioning mechanism and a box placing mechanism are arranged on the framework, the conveying mechanism comprises a conveying belt which is arranged on the framework and is driven by a power source, the transferring manipulator is arranged between the plate feeding mechanism and the conveying mechanism, the glue spraying mechanism is arranged above a conveying path of the conveying belt, the box conveying positioning mechanism conveys a box to a fitting station on the conveying belt, and the box placing mechanism is arranged above the fitting station. The full-automatic glue spraying and box making production line has the advantages that the full-automatic glue spraying and box making production line is accurate in positioning, the mechanization degree and the production efficiency are improved, the labor cost is reduced, and the box can be automatically fit with a bottom plate firmly.

Owner:ZHEJIANG XINWEI MACHINERY

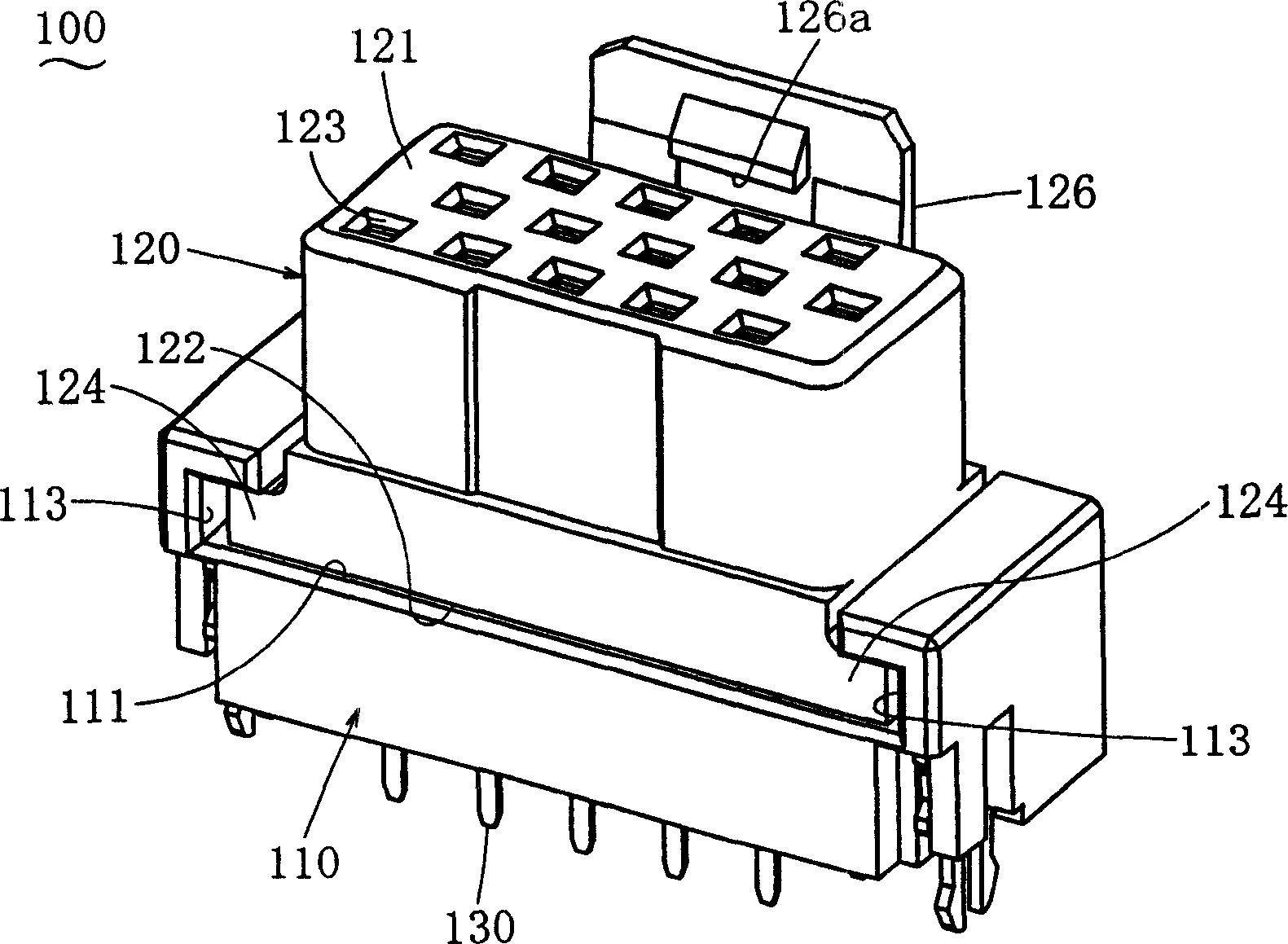

Floating connector

InactiveCN1581593AFit firmlySecuring/insulating coupling contact membersCouplings bases/casesUltimate tensile strengthMechanical engineering

Owner:JST MFG CO LTD

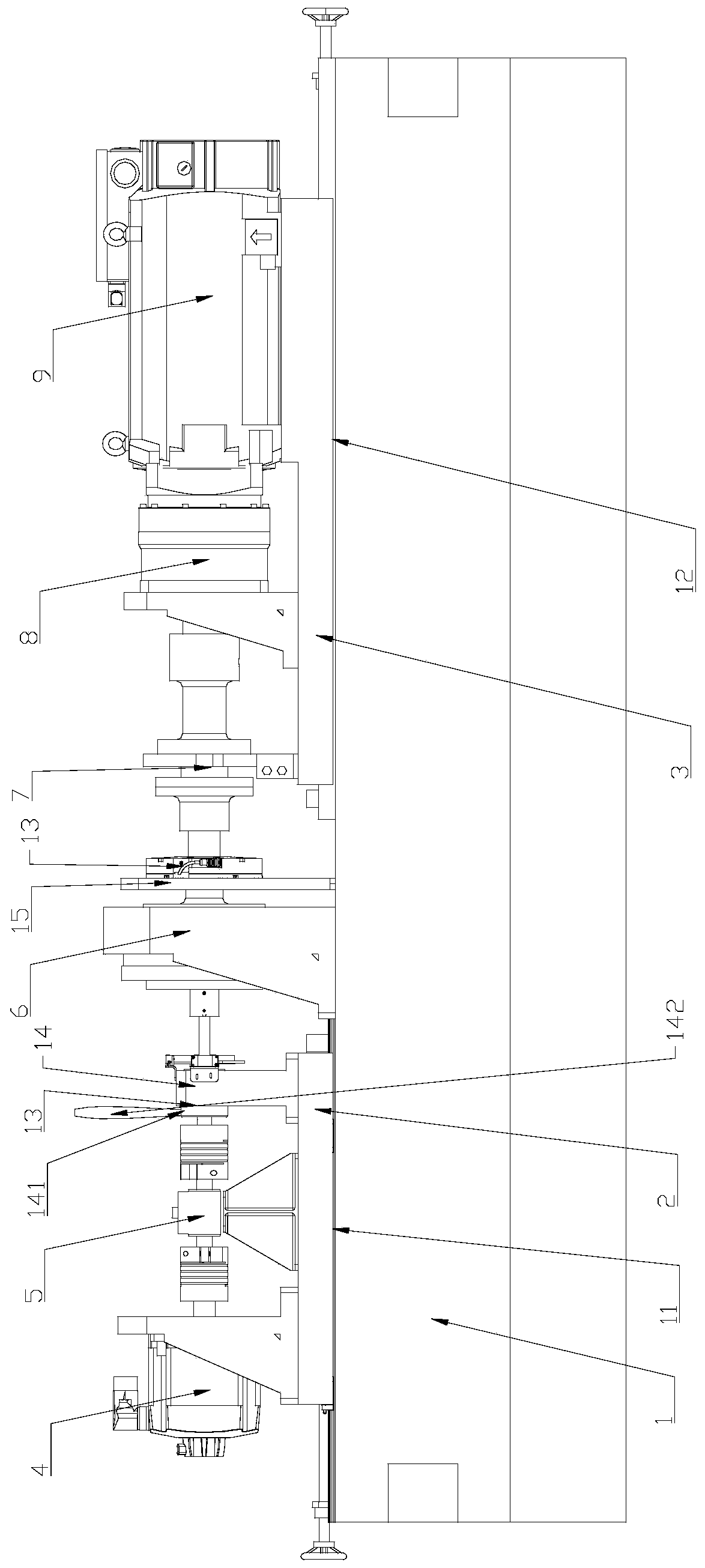

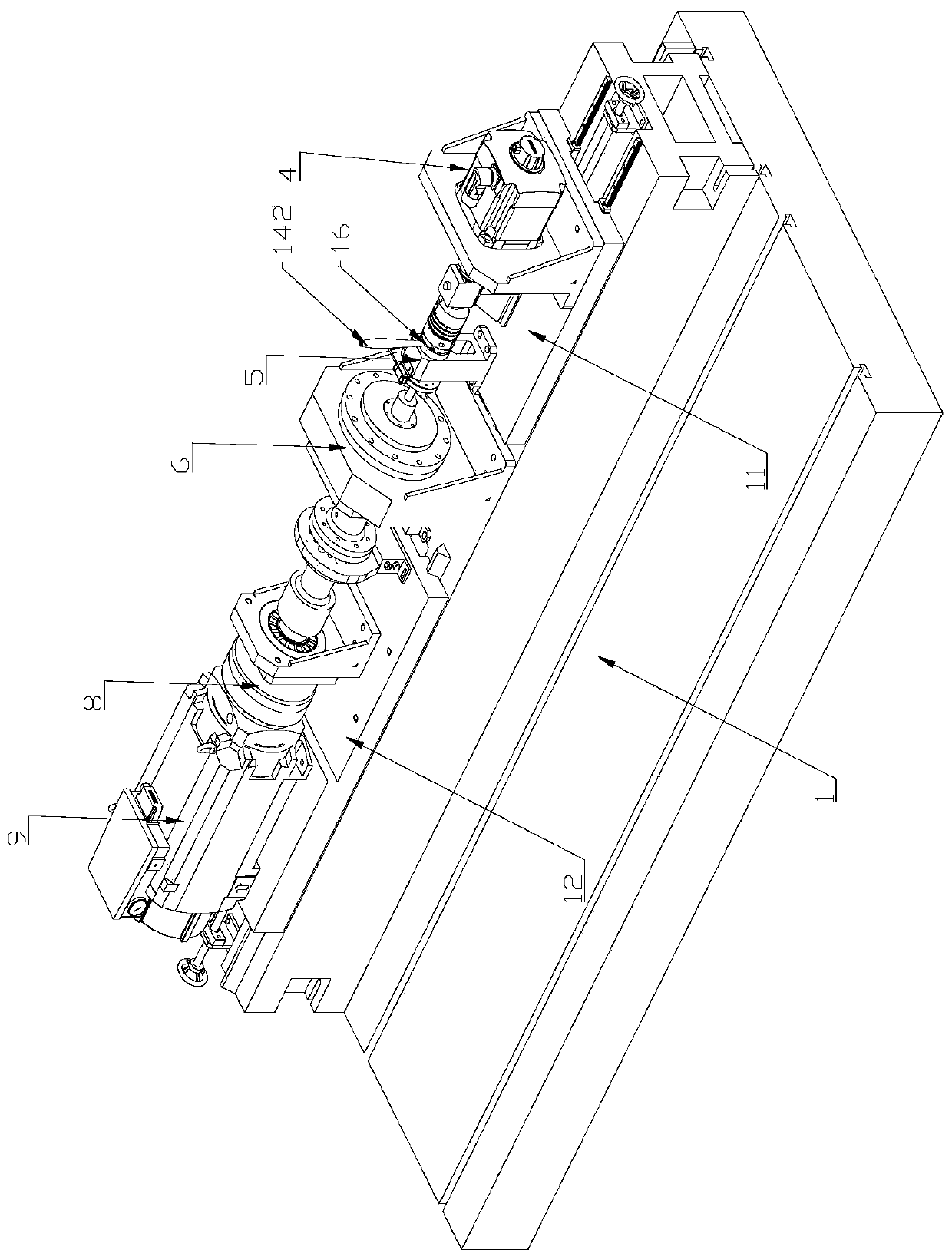

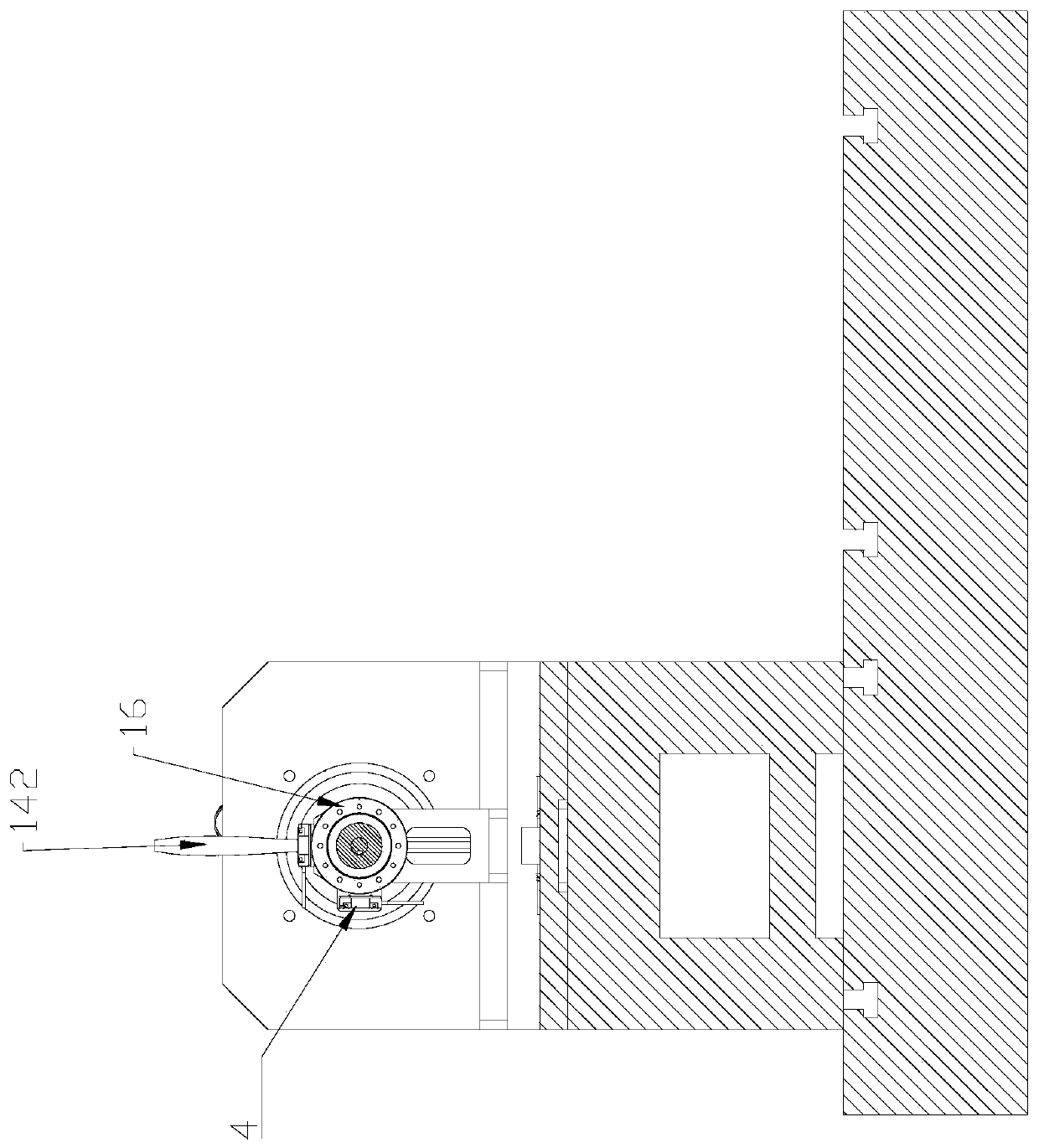

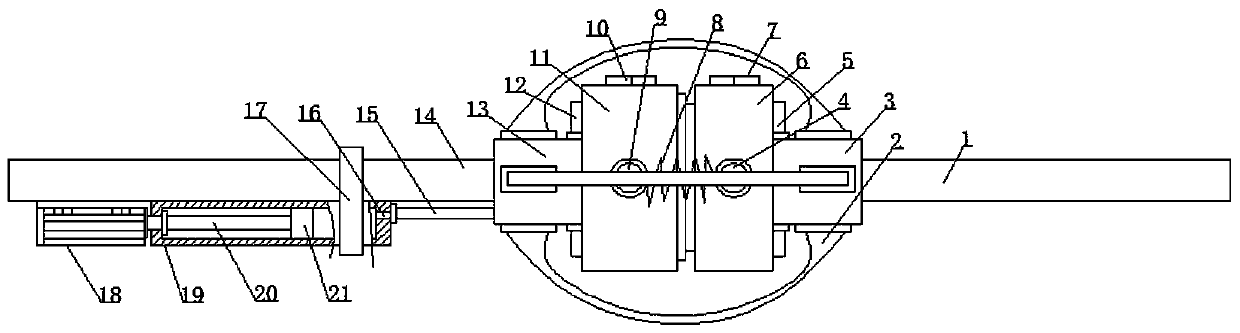

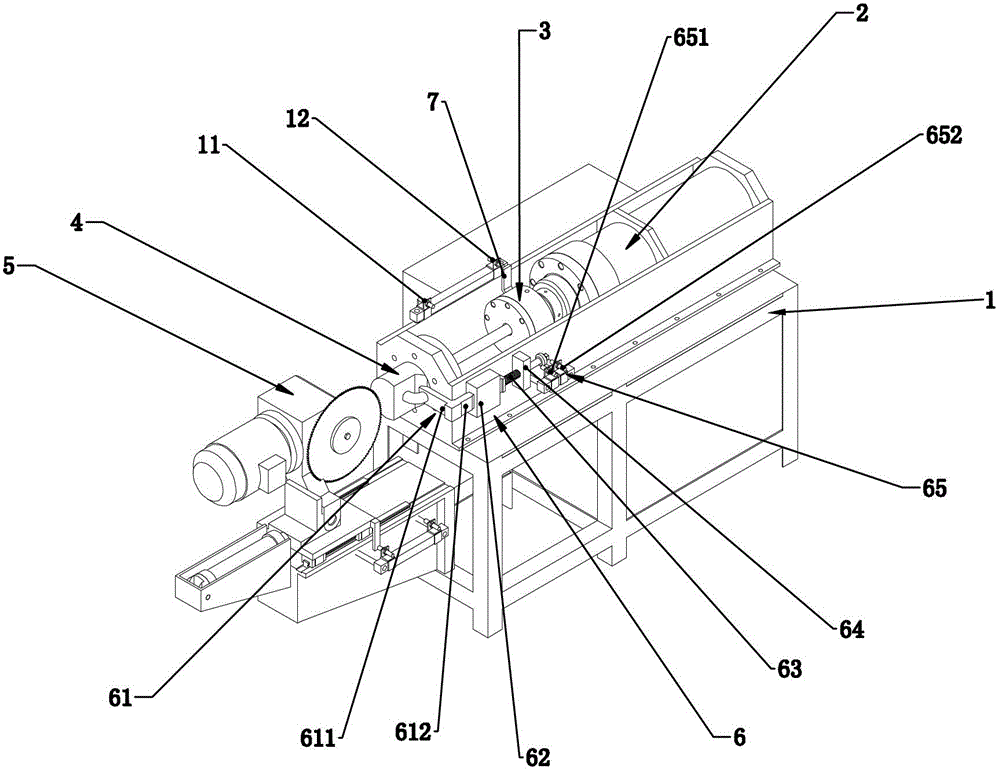

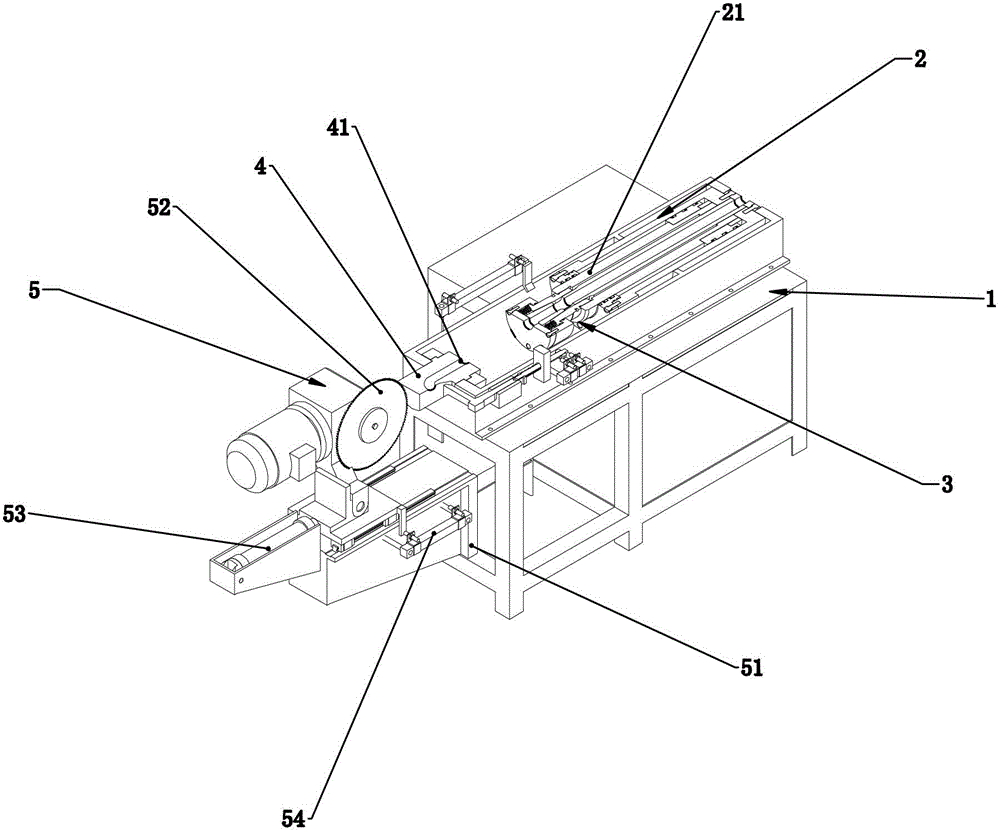

High-precision RV speed reducer comprehensive testing device

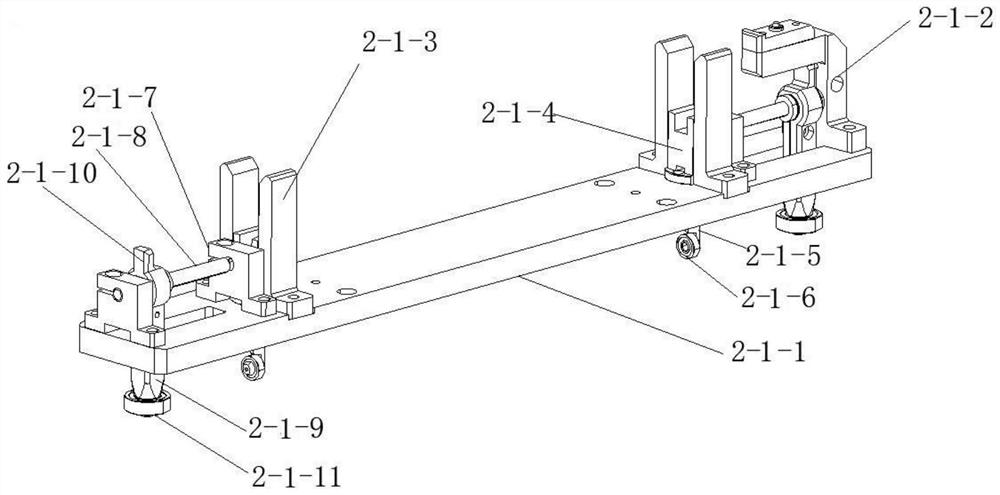

PendingCN110487545AEasy assembly and disassemblyEasy to assembleMachine part testingCombined testTorque sensor

The invention relates to a high-precision RV speed reducer comprehensive testing device, which comprises a base, a first sliding platform, a second sliding platform, a first motor, a first torque sensor, a second motor, a second torque sensor, a first angle sensor, an input shaft bracket and an output shaft bracket. Compared with the prior art, the high-precision RV speed reducer comprehensive testing device designs the sliding platform assembly capable of being rapidly disassembled and assembled, so that the assembling and disassembling process of an to-be-tested RV speed reducer is more convenient and faster; the output shaft bracket and the input shaft bracket can be used for adapting to the requirements of sensors with different specifications; the limiting parts of the sliding platforms improve the test precision; the double-measuring-range torque sensors can adapt to measurement of speed reducers of different series models, and can also realize test of transmission precision under light load; an input shaft of the to-be-tested RV speed reducer is installed in two bearing inner rings sharing the same horizontal axis, thereby facilitating the adjustment of a bearing clearance;and the double-reading-head circular grating angle sensors meet the requirement that the transmission precision is tested in a high-speed state.

Owner:上海羿弓精密科技有限公司

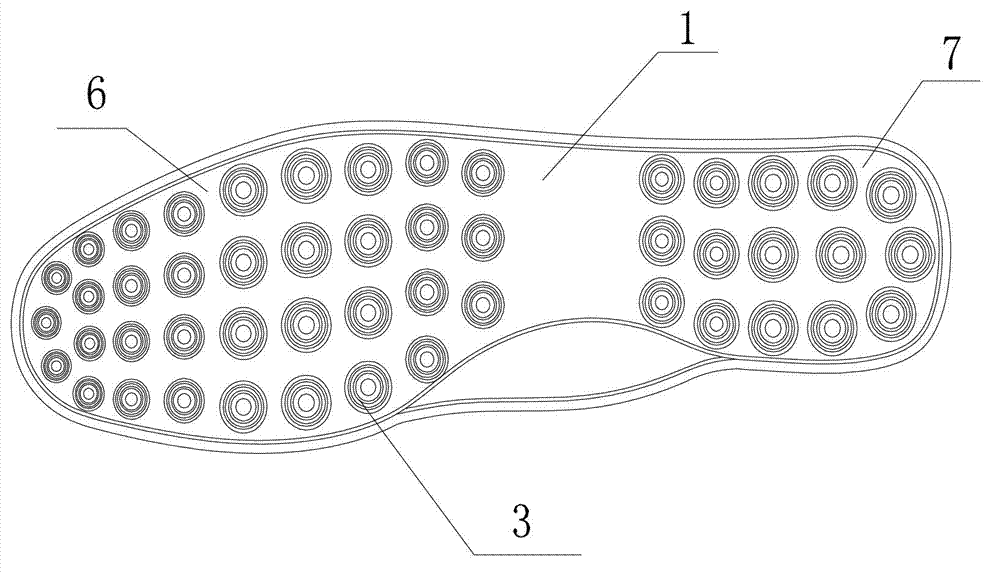

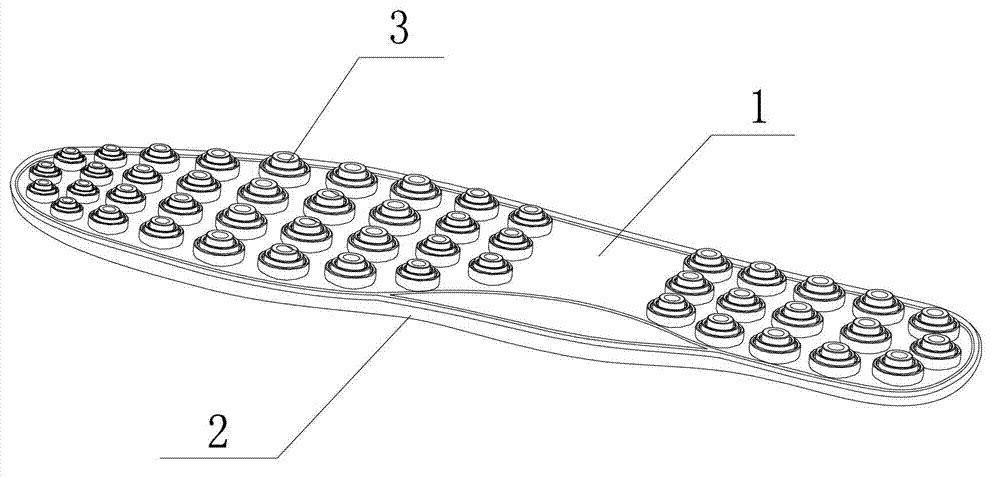

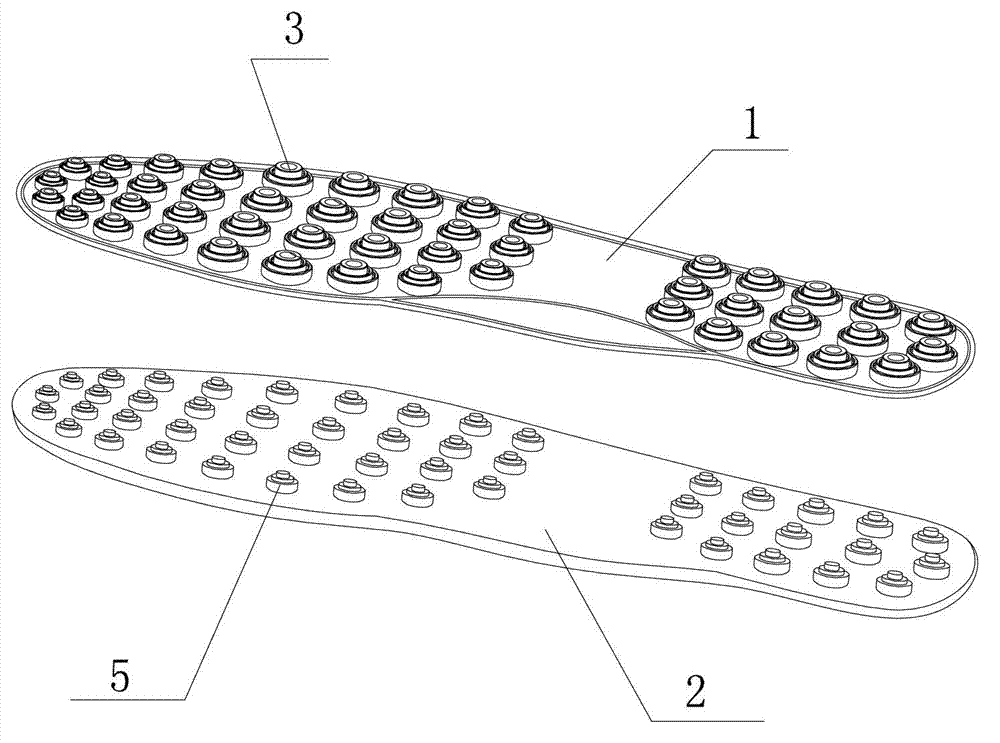

Shock-absorbing sole

The invention relates to a shock-absorbing sole which comprises a sole body. The sole body is used for contacting with the ground, a plurality of shock-absorbing elements which are protruded towards the ground are arranged on the sole body and are hollow, and an opening is arranged at one end, which is far away from the ground, of each shock-absorbing element. The shock-absorbing sole overcomes the shortcoming that an existing shoe is poor in shock-absorbing effect, and the shock-absorbing effect of the shock-absorbing sole is remarkably improved.

Owner:MAOTAI FUJIAN SOLES CO LTD

Full-automatic mylar adhering equipment

ActiveCN102951317AFitting position is accurateFit firmlyPackaging automatic controlFixed frameEngineering

Owner:昆山金群力精密组件有限公司

Pueraria powder processing device

Owner:CHONGQING TIANXINGZHAI PUERARIA THOMSONII FOOD CO LTD

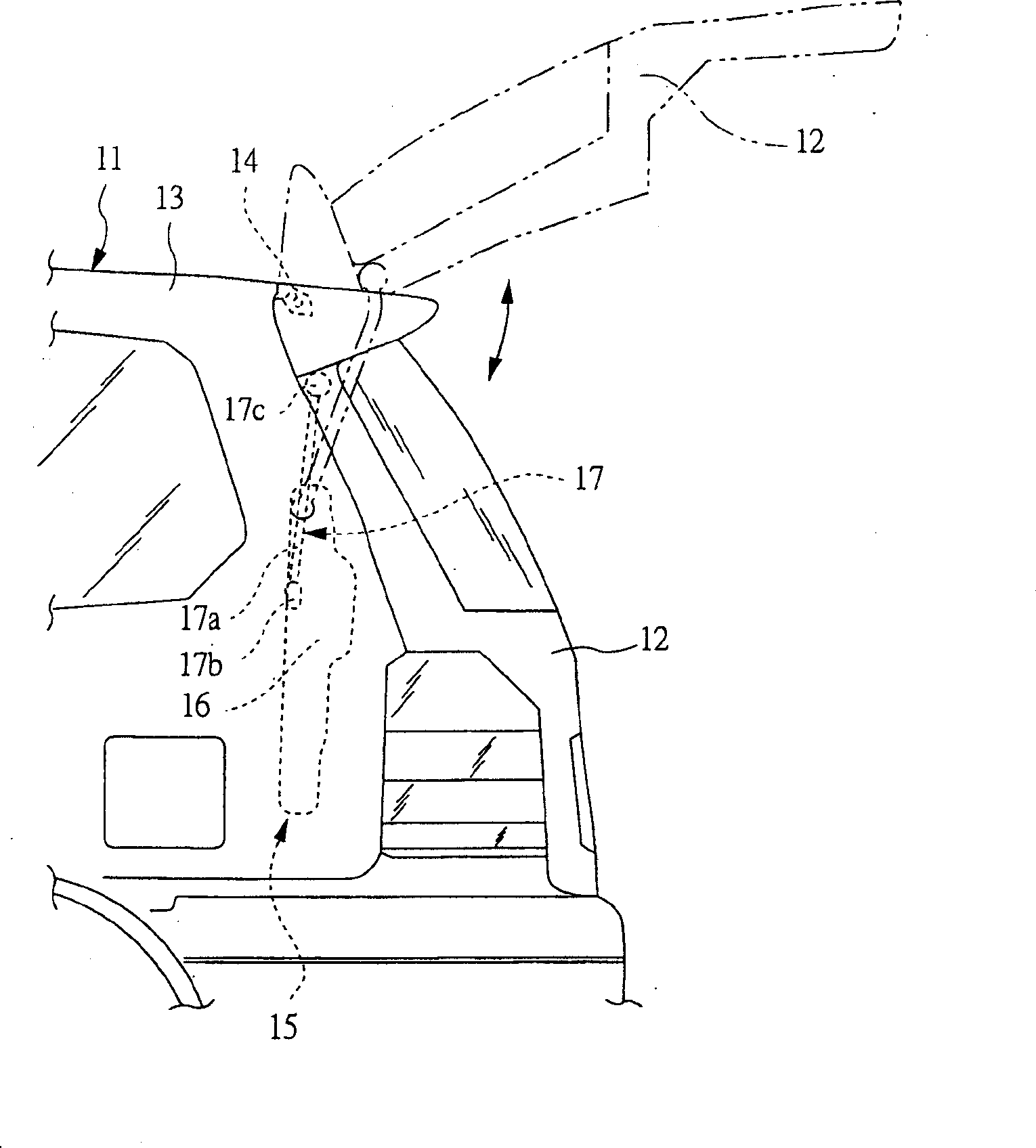

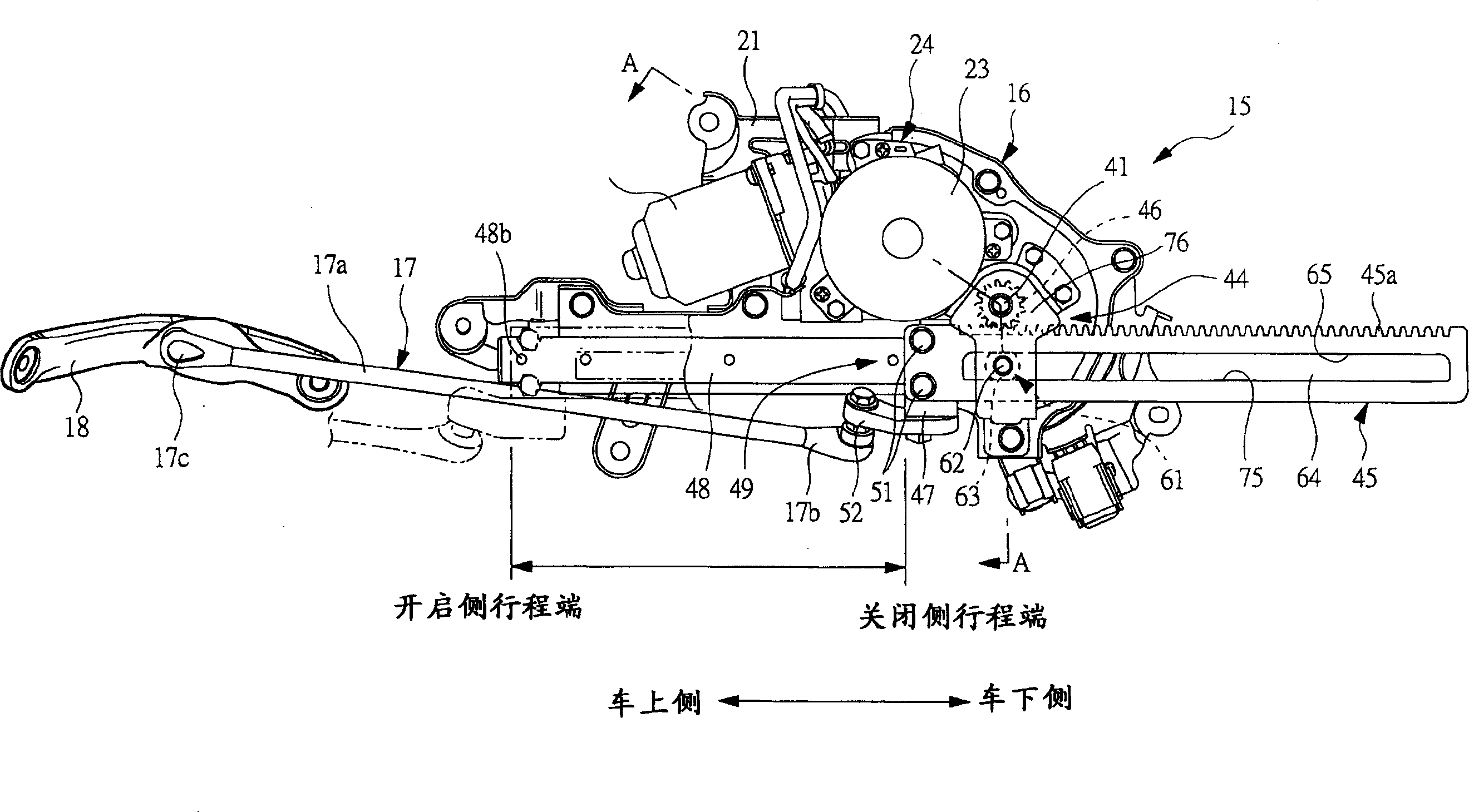

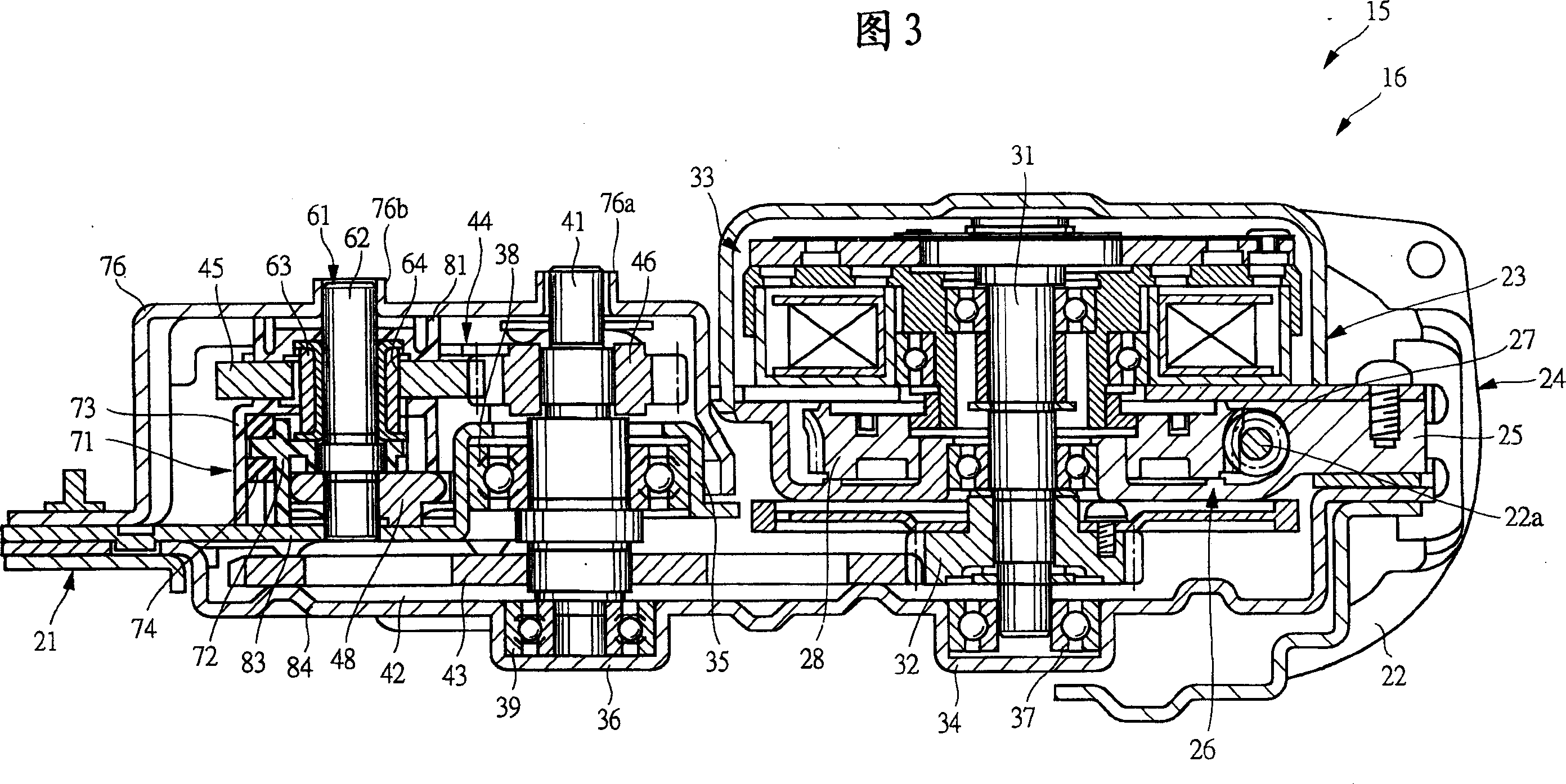

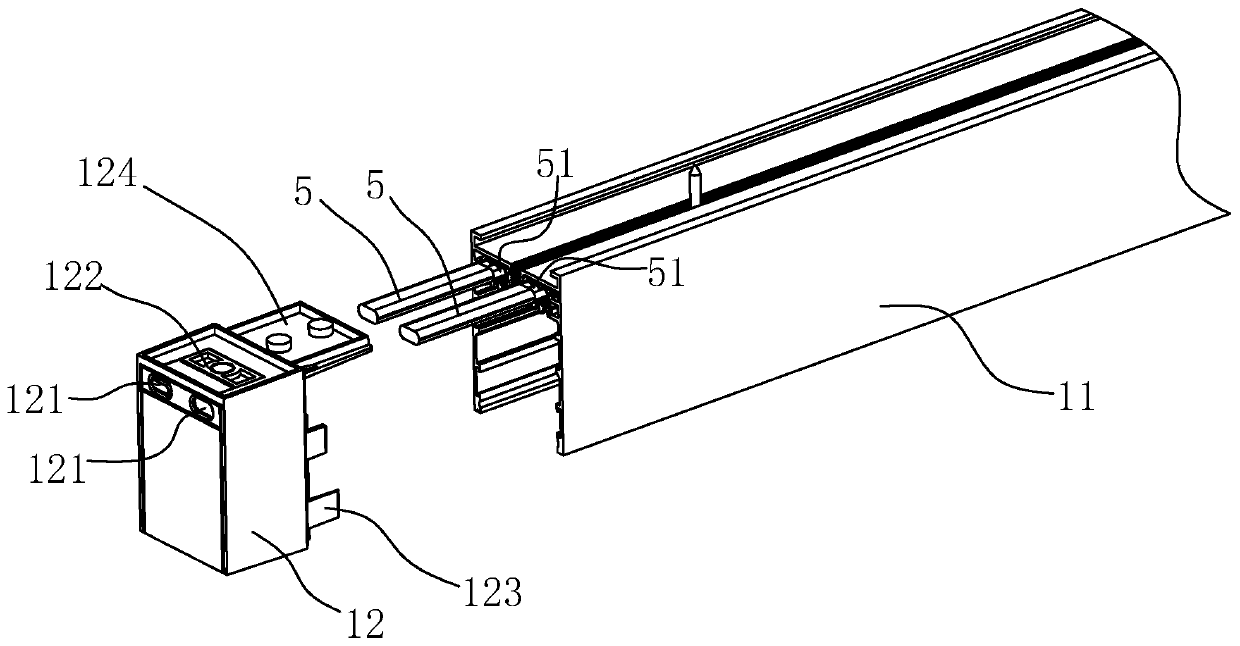

Automatically opening/closing apparatus for vehicle

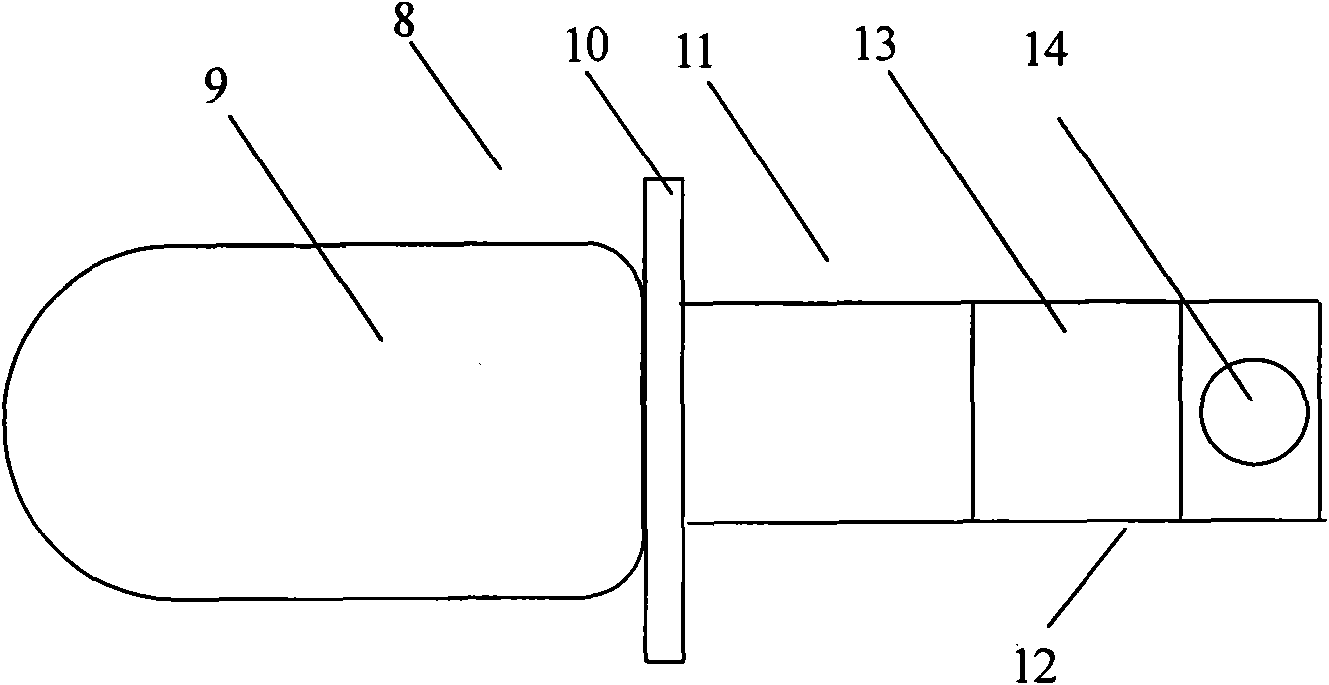

InactiveCN1619086AShorten the lengthSmall sizeMechanical apparatusMan-operated mechanismGear wheelTransfer mechanism

A rack and pinion type that can be reduced in size is used for automatic opening / closing equipment of vehicles. The rotation of the motor is transmitted to the rear door through a driving force transmission mechanism including a gear and a rack, and an automatic opening / closing device for a vehicle can be automatically opened / closed. The rack is linearly and reciprocally supported by a sliding mechanism including a slider and a guide rail. If the slide block is formed such that it is obviously shorter than the overall length of the rack, the correspondingly formed guide track should also be short. Furthermore, the toothed rack has a groove portion in which the toothed rack is seated in contact with the clamping surface. The clearance between the rack and the pinion is then maintained by the clamping surfaces, thus ensuring the ensuing meshing of the pinion.

Owner:HONDA MOTOR CO LTD +1

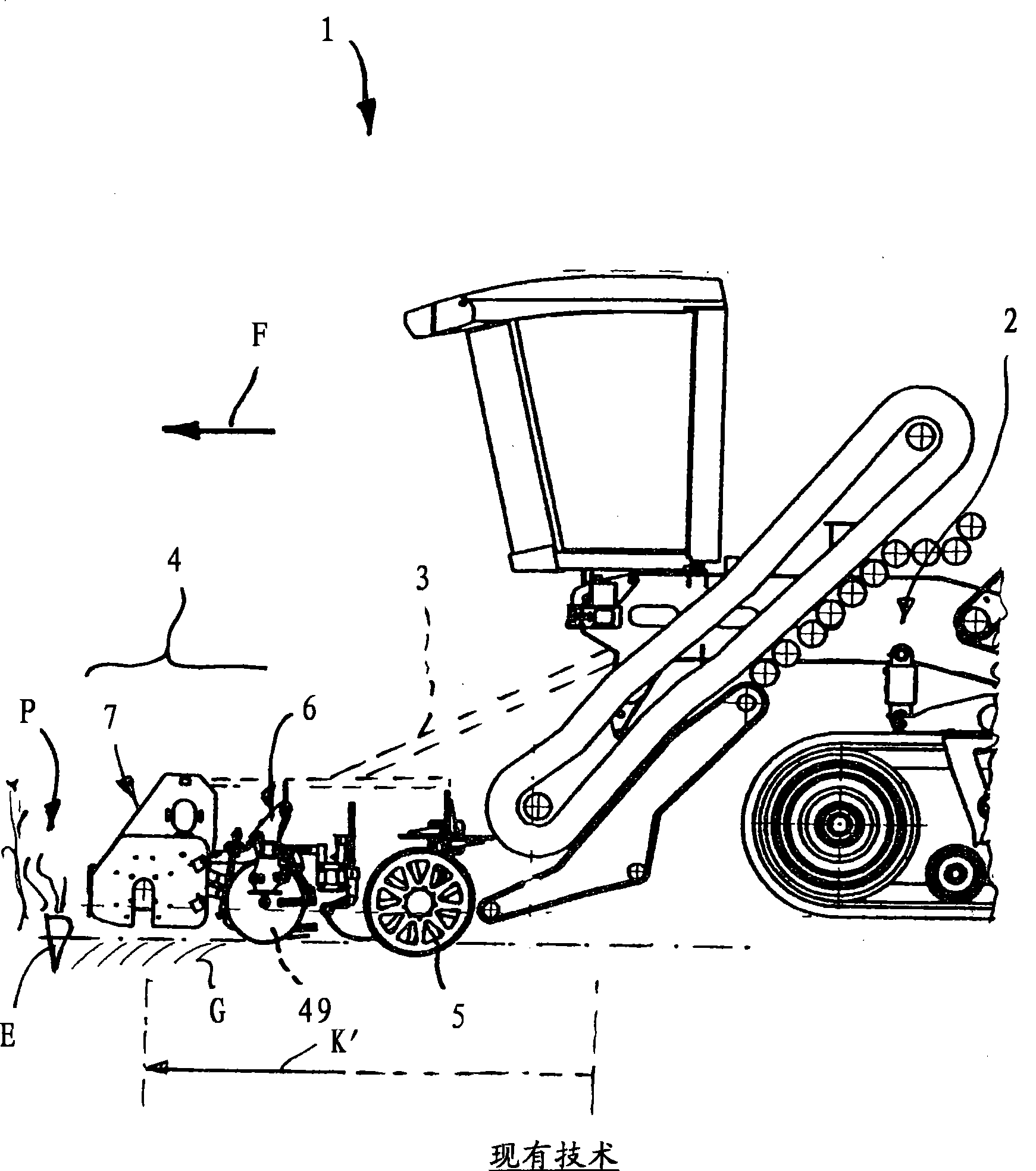

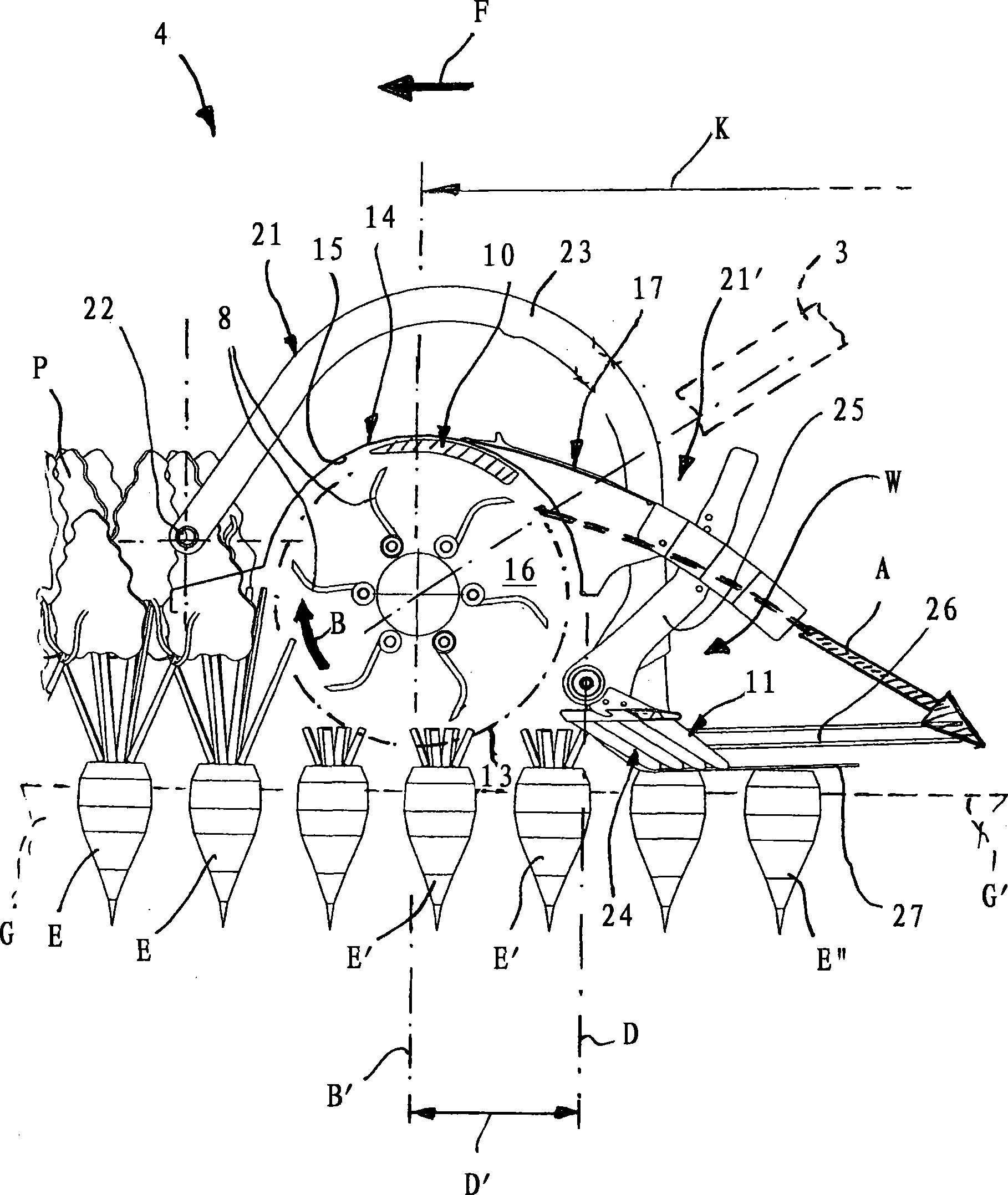

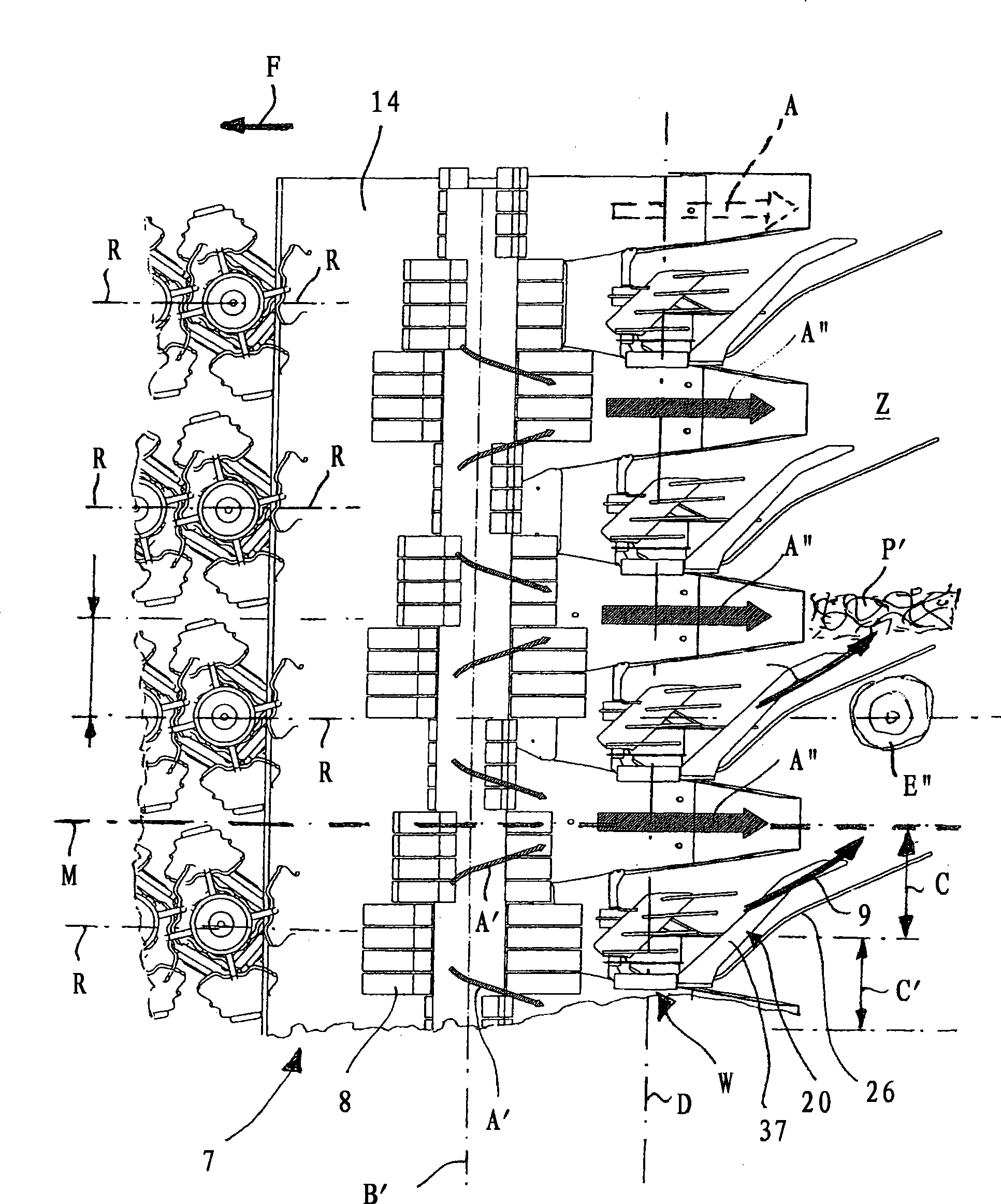

Turnip harvesting machine

InactiveCN101411263AImprove productivityAvoid additional pollutionLiftersTopping machinesPlant PartCUTEr

The invention relates to a beet harvester applied to sugar beet or crops of the like, comprising leaf cutter set between a plurality of lines of corps for removing beet leaves, green plants and the plant parts of the like, wherein a second tool in form of at least one top cuter of the assembly of the likes is set behind the cutting element of the lead cutter along the traveling direction. The present invention assigns that the plant part obtained by the lead cutter construct a transportation flow almost moving to the back of at least one placed at the rear part.

Owner:GRIMME LANDMASCHFAB

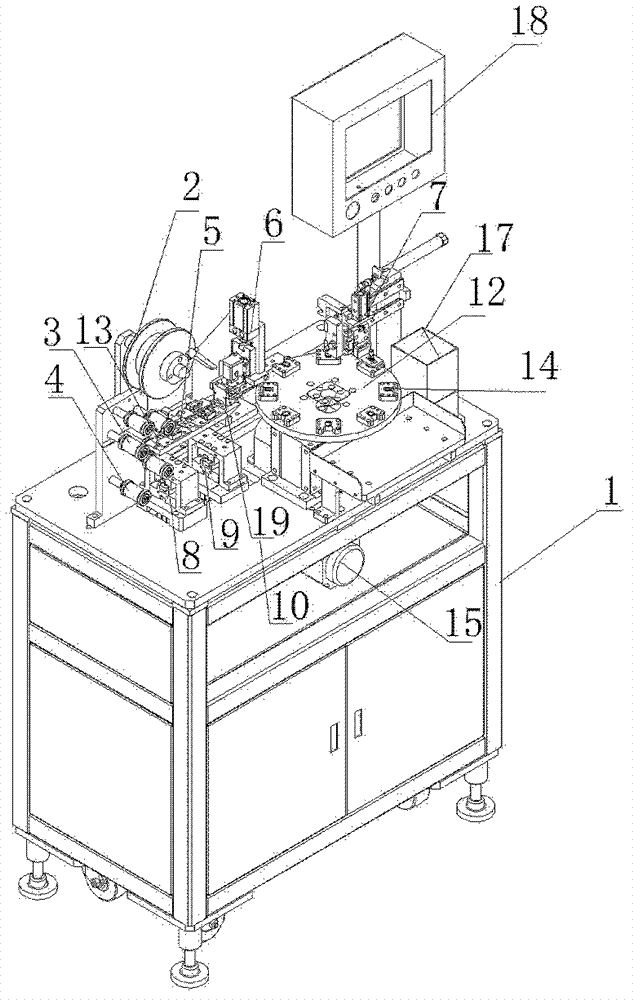

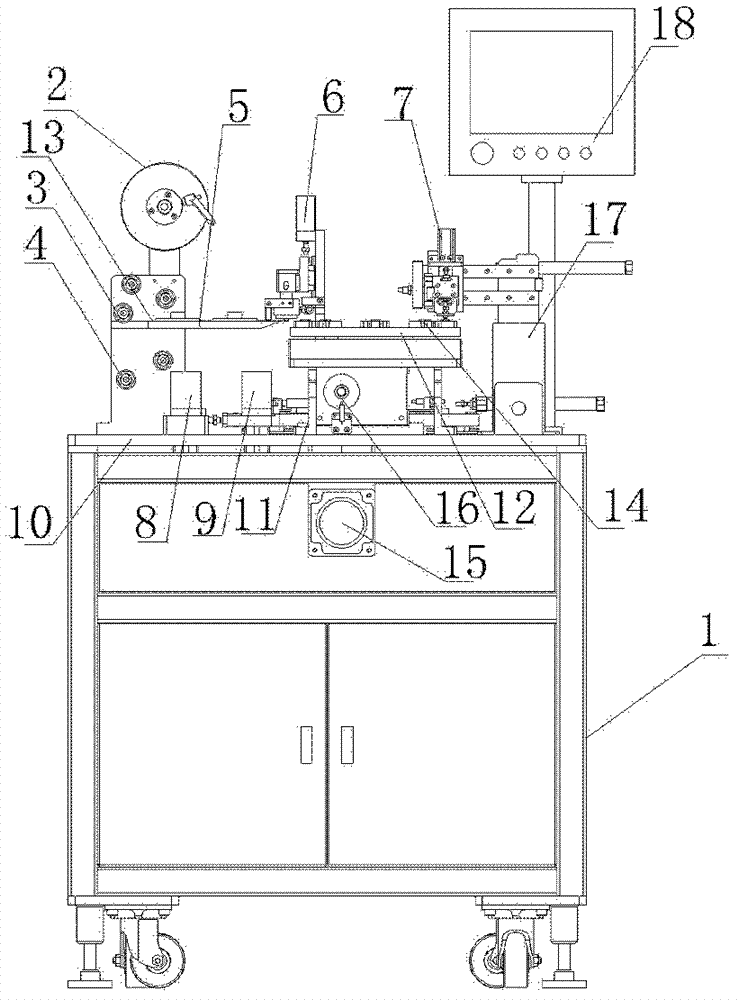

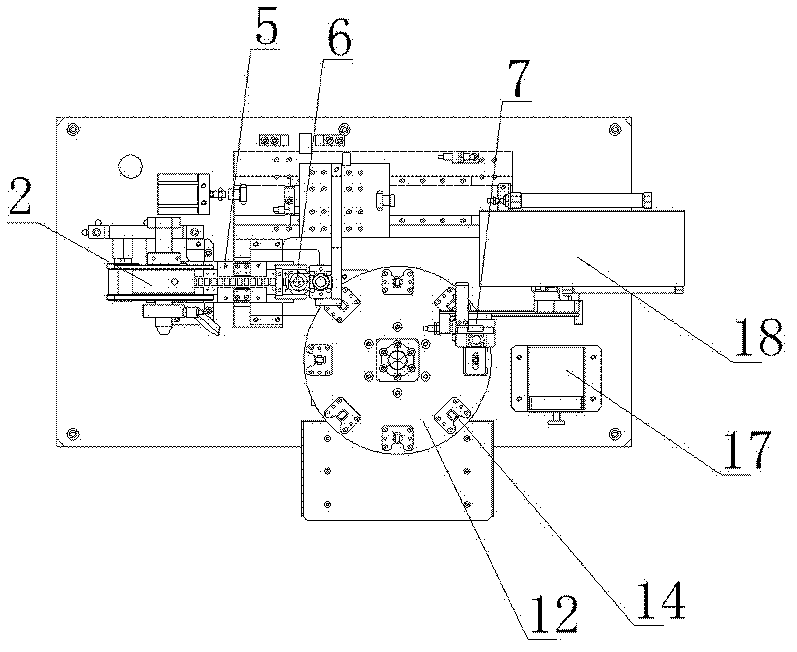

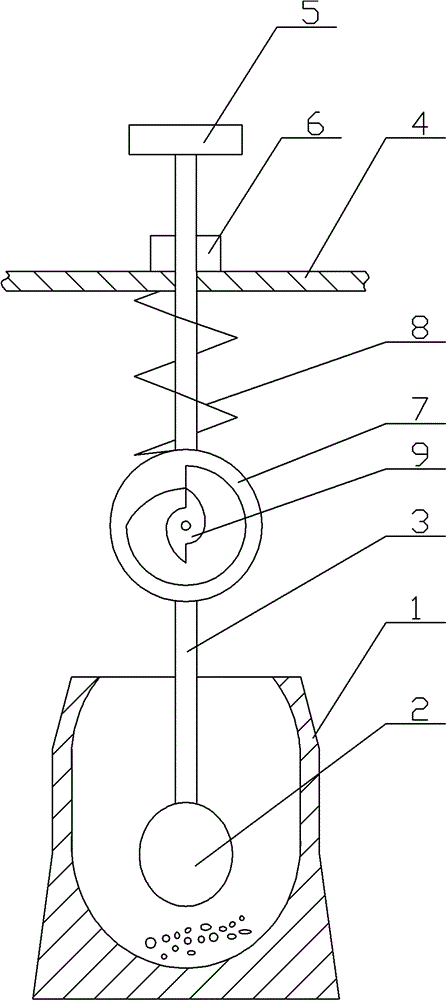

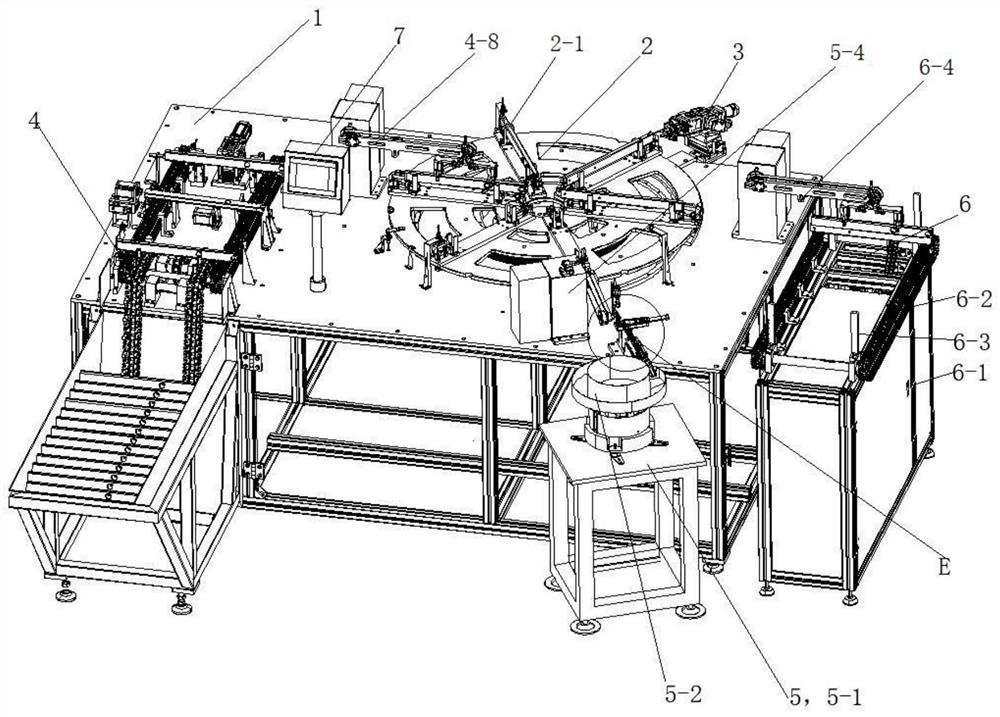

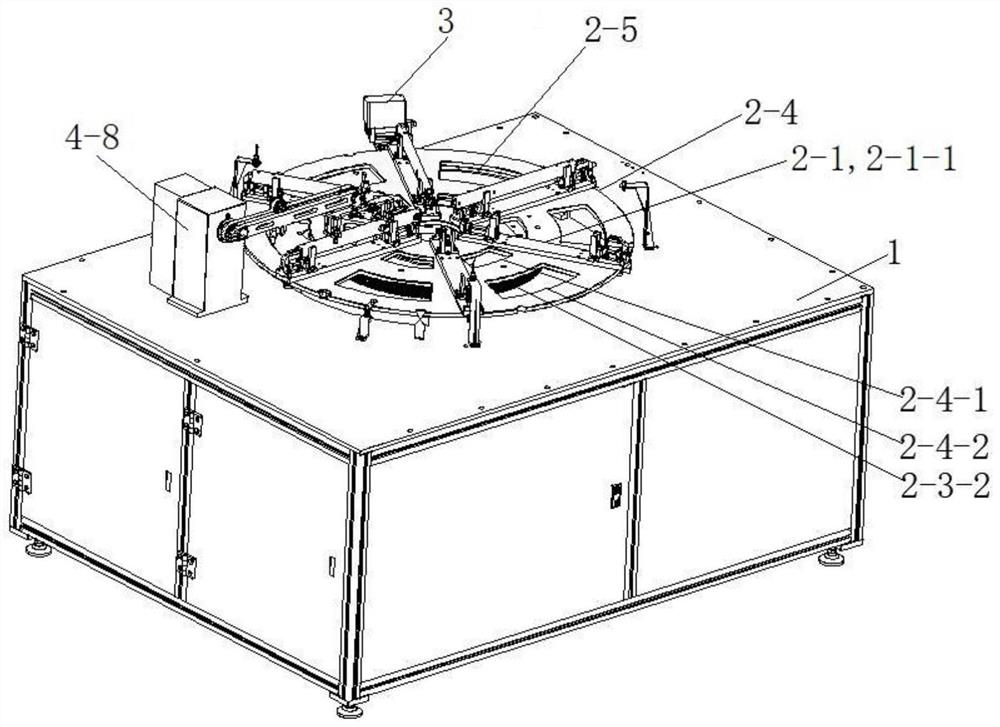

Automatic welding machine for square pipes and gaskets

PendingCN111958141AReduce human inputImprove welding accuracy andWelding/cutting auxillary devicesAuxillary welding devicesSmall footprintManufacturing engineering

The invention discloses an automatic welding machine for square pipes and gaskets. The welding machine comprises an operating table, a rotary worktable fixedly installed on the operating table, and anautomatic gasket feeding device, an automatic square pipe feeding device, a welding device and an automatic discharging device which are arranged around the rotary worktable sequentially. A welding assembly mechanism is arranged on the rotary worktable; the rotary worktable drives the welding assembly mechanism to circulate and operate among the automatic gasket feeding device, the automatic square pipe feeding device, the welding device and the automatic discharging device; and the welding assembly mechanism receives gaskets at the automatic gasket feeding device and square pipes at the automatic square pipe feeding device, and assembly of the gaskets and the square pipes is completed before movement to the welding device. According to the automatic welding machine, automatic feeding, automatic assembly and welding of the square pipes and the gaskets can be achieved, welded parts are conveyed to a discharging area, manual operation is not needed in the whole process, manpower input is reduced, the welding accuracy and the production safety are improved, the floor area is small, and the production cost is greatly reduced.

Owner:常州三拓焊接设备有限公司

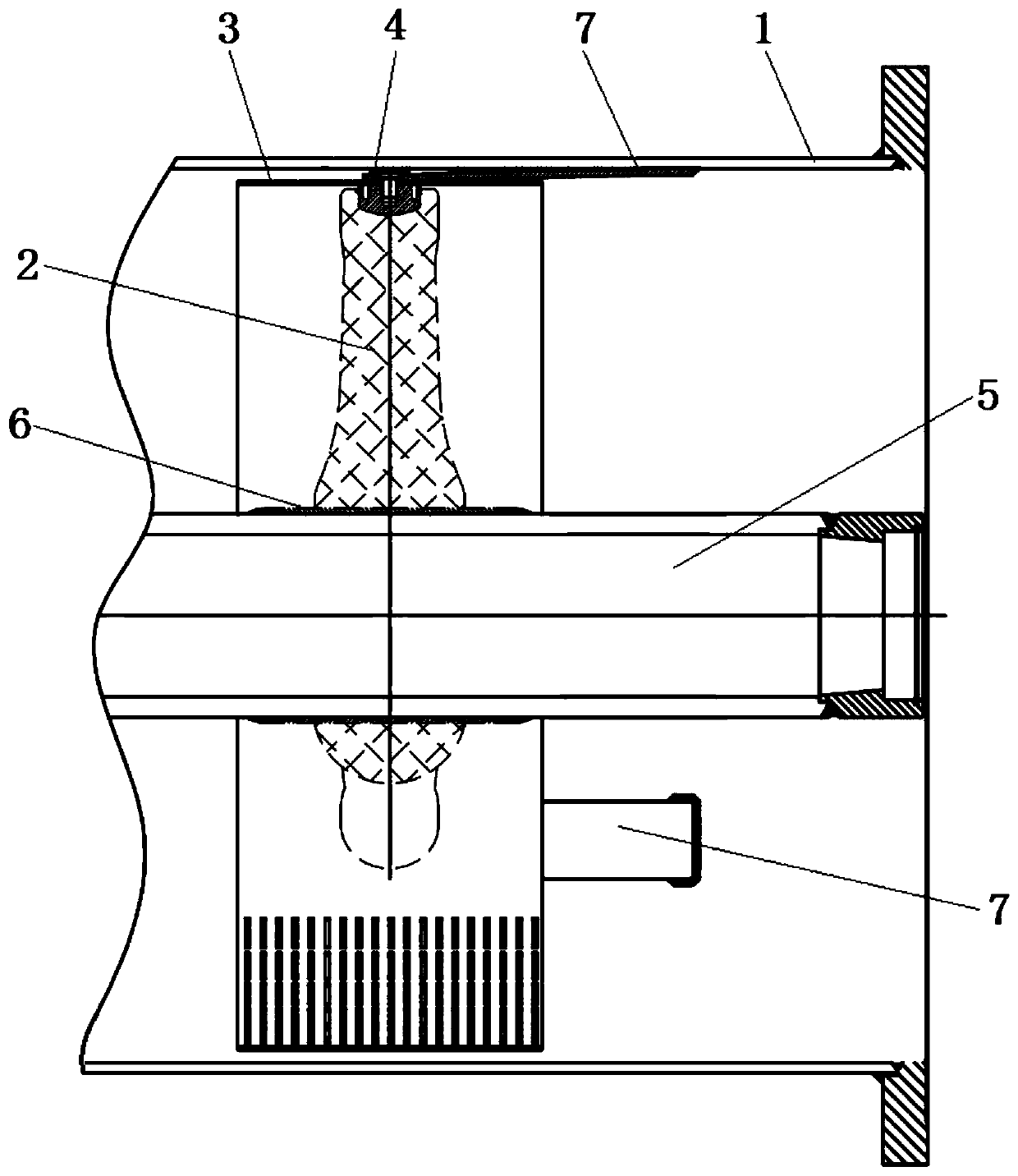

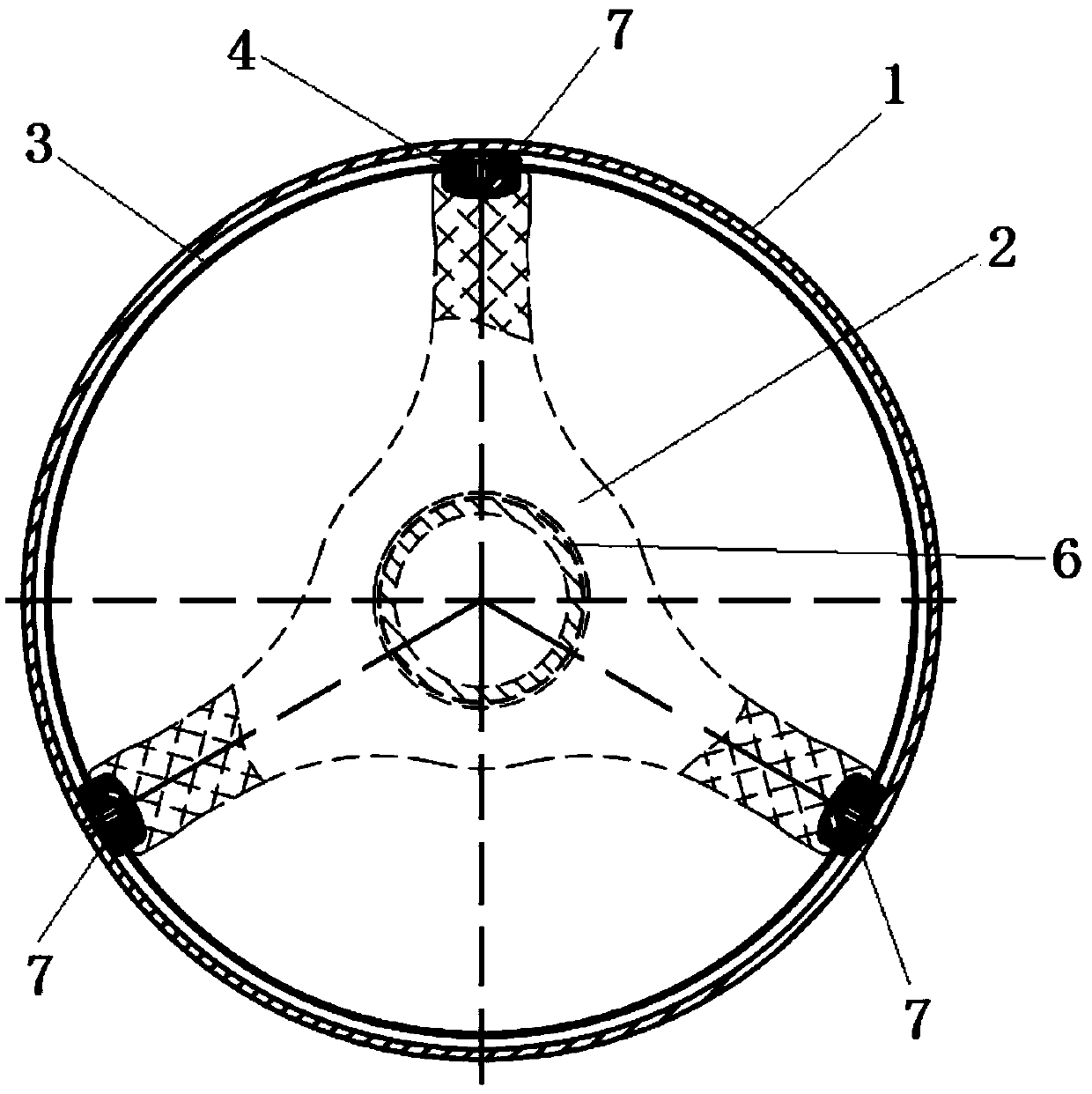

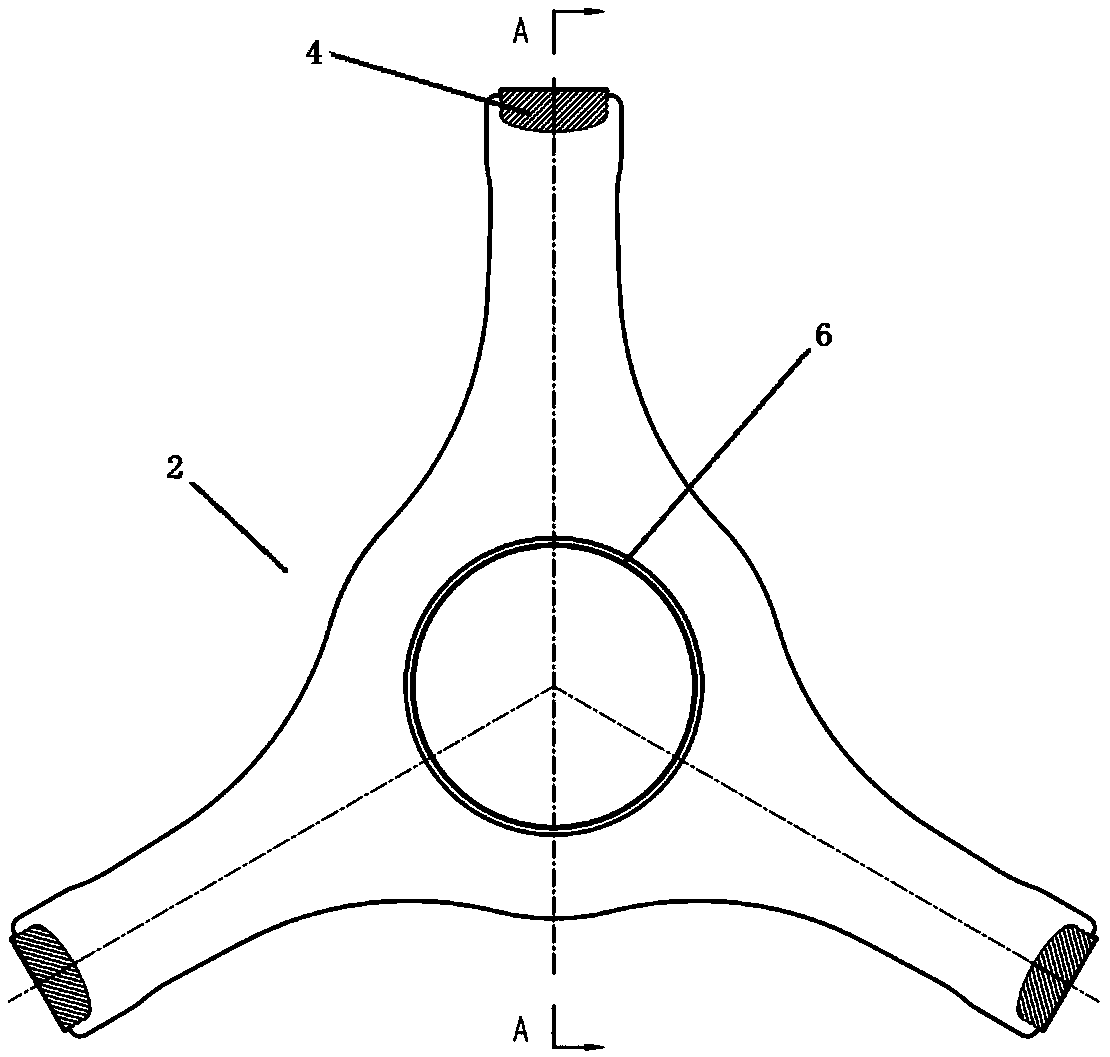

Three-post insulator of GIL

The invention relates to the technical field of high-voltage power transmission, and particularly provides a three-post insulator of a GIL, wherein the three-post insulator comprises a post main bodyand an insert poured at the end part of the post main body, and the end surface, far away from the post main body, of the insert is provided with a stress groove for making the insert radially contract to adapt to the contraction deformation of the post main body. According to the invention, by arranging a stress groove in an insert, when the insert is located in the post insulator, the insert cantransmit the residual stress generated by the post insulator to the insert outwards through the stress groove, so that the stress structure of the insert is improved, and the defects of deformation,micro-cracking and the like of the insert are avoided so as to ensure the assembly relationship between the insert and the post insulator and ensure the insulation capability of the post insulator.

Owner:PINGGAO GRP +2

Multi-level guiding dental implantation guiding device and using method thereof

The invention relates to a multi-level guiding dental implant guiding device and a using method thereof. The device comprises a dental implantation guiding template provided with a positioning abutment, wherein a drill positioning duct is formed on the positioning abutment. The device is characterized in that: a positioning guidance sleeve is arranged on the drill positioning duct; a positioning bump which is matched with the drill positioning channel and prevents the positioning guidance sleeve from separating upwards is arranged on the peripheral wall of the lower part of the positioning guidance sleeve; a tunnel for guiding the positioning bump to move downwards is formed on the drill positioning duct; and a cambered transverse slot facilitating rotary clamping of the positioning bump is formed on the inner wall of the drill positioning duct. The device overcomes the defects of incapacity of realizing multi-level drill guidance, unstable matching, low guiding accuracy and the like, and ensures accuracy, high efficiency and safety of surgery.

Owner:FUZHOU UNIV

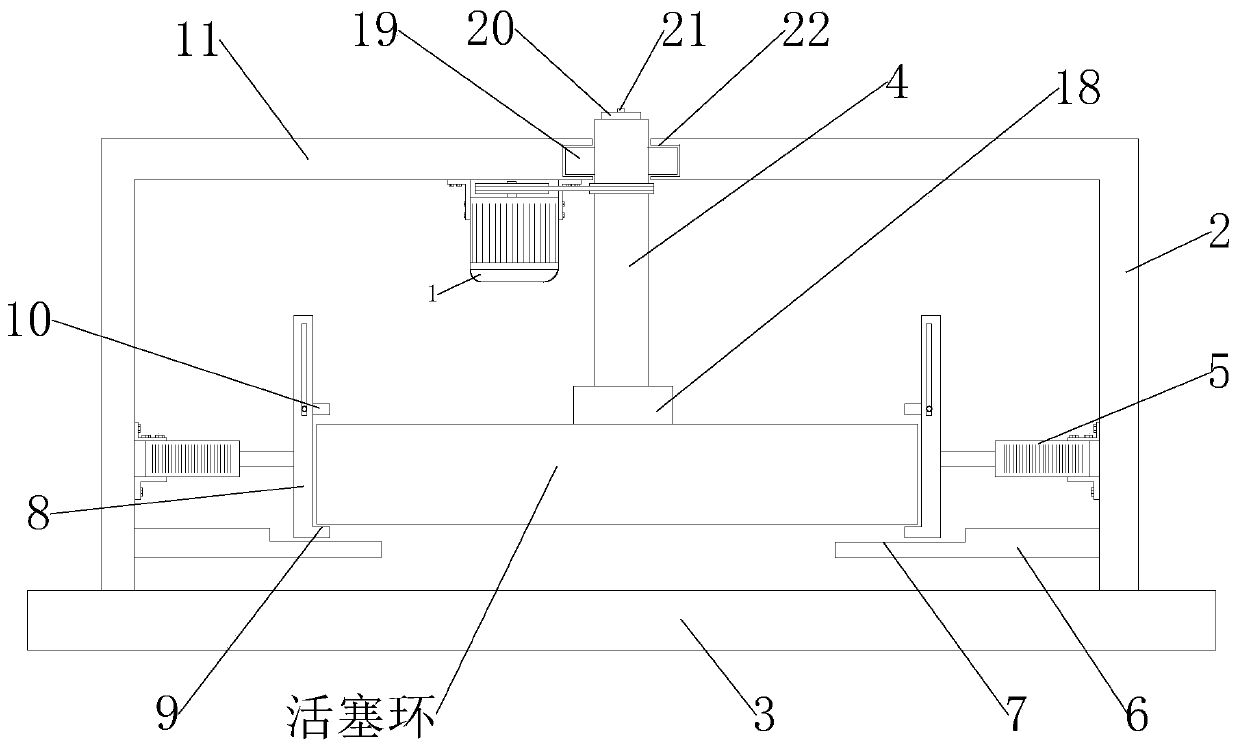

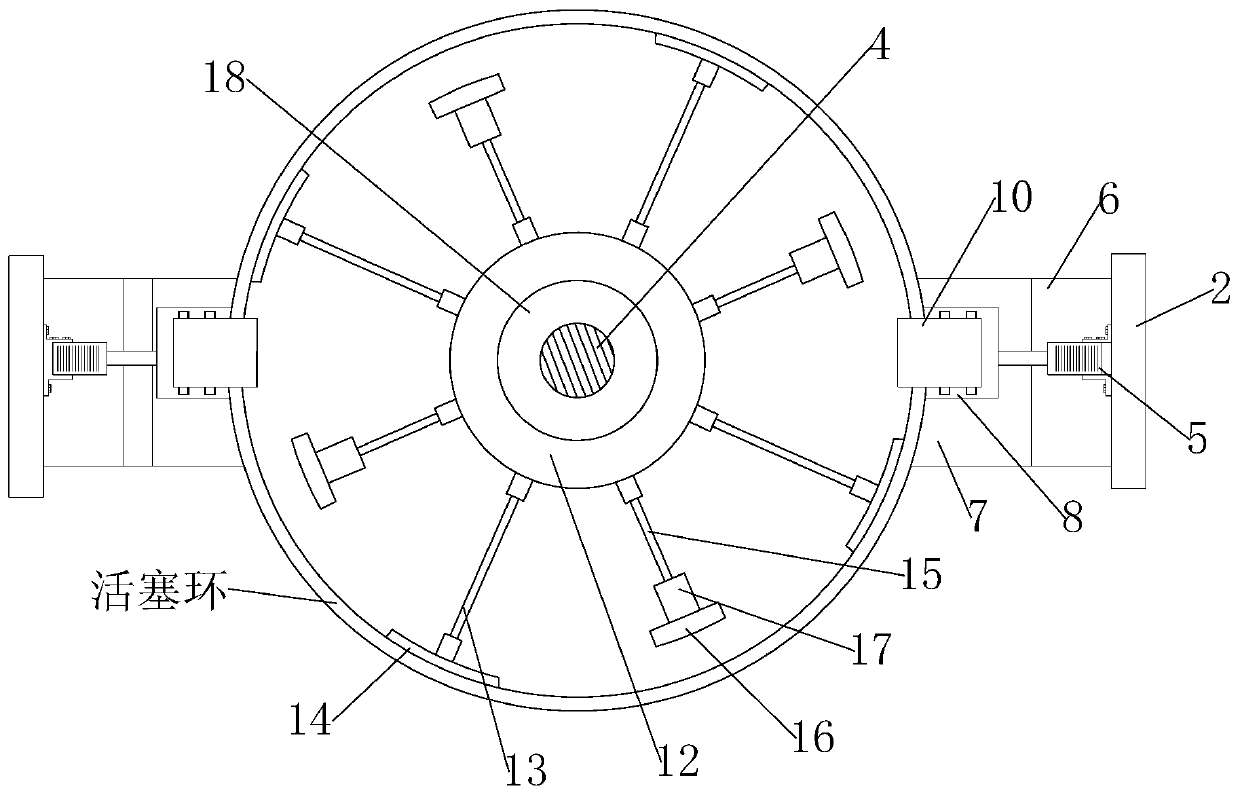

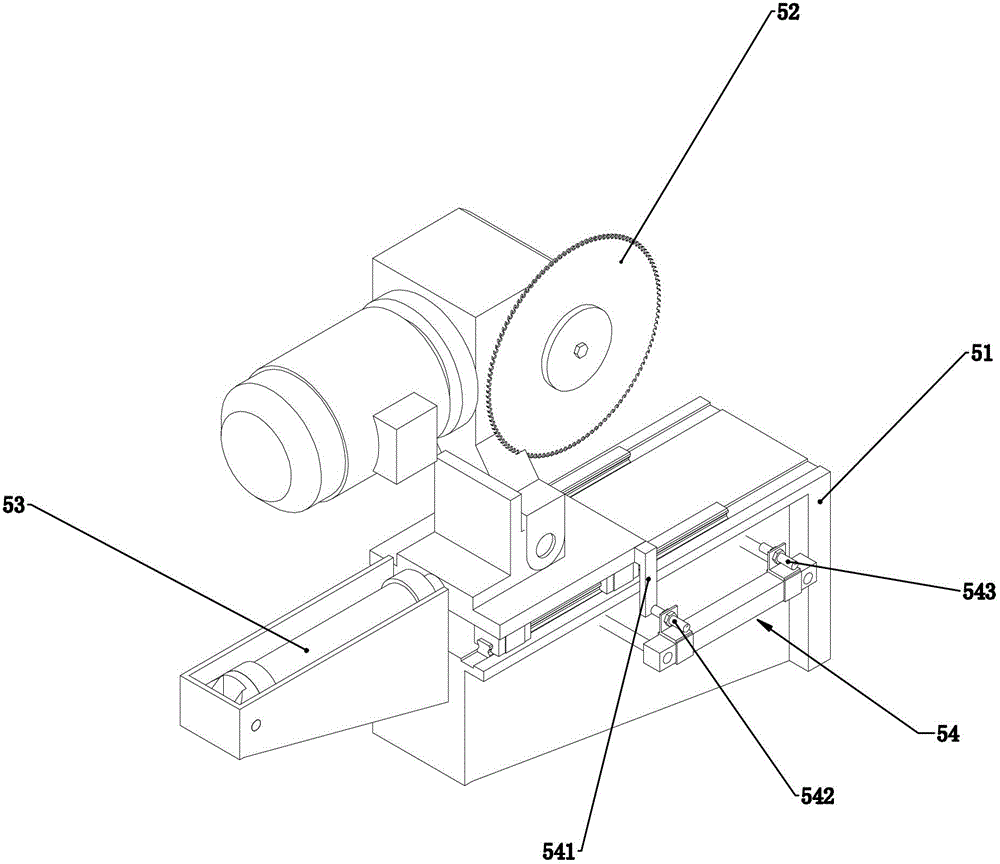

Vacuum pump piston ring finish machining process

PendingCN111185813AImprove grinding efficiencyFit firmlyGrinding drivesGrinding work supportsEngineeringMachining process

The invention discloses a vacuum pump piston ring finish machining process, and relates to the technical field of machining. The vacuum pump piston ring finish machining process is completed through cooperation of a vacuum pump piston ring finish machining device, the vacuum pump piston ring finish machining device comprises a base horizontally fixed to the ground, supporting legs erected at the top end of the base are symmetrically arranged on the two sides of the top end of the base, a horizontally-fixed top supporting plate is arranged at the top ends of the supporting legs on the two sides, the two ends of the top supporting plate are fixedly connected with the top ends of the supporting legs on the two sides, a downwards-through shaft hole is formed in the middle of the top end of thetop supporting plate, and an annular clamping groove is formed in the inner wall of the shaft hole of the top supporting plate. According to the vacuum pump piston ring finish machining process, through cooperation of outer clamping and inner clamping, the outer wall of a vacuum pump piston ring and the inner wall of the vacuum pump piston ring are ground in the one-time clamping process of the vacuum pump piston ring, and the grinding practicability of the device is improved.

Owner:储德姣

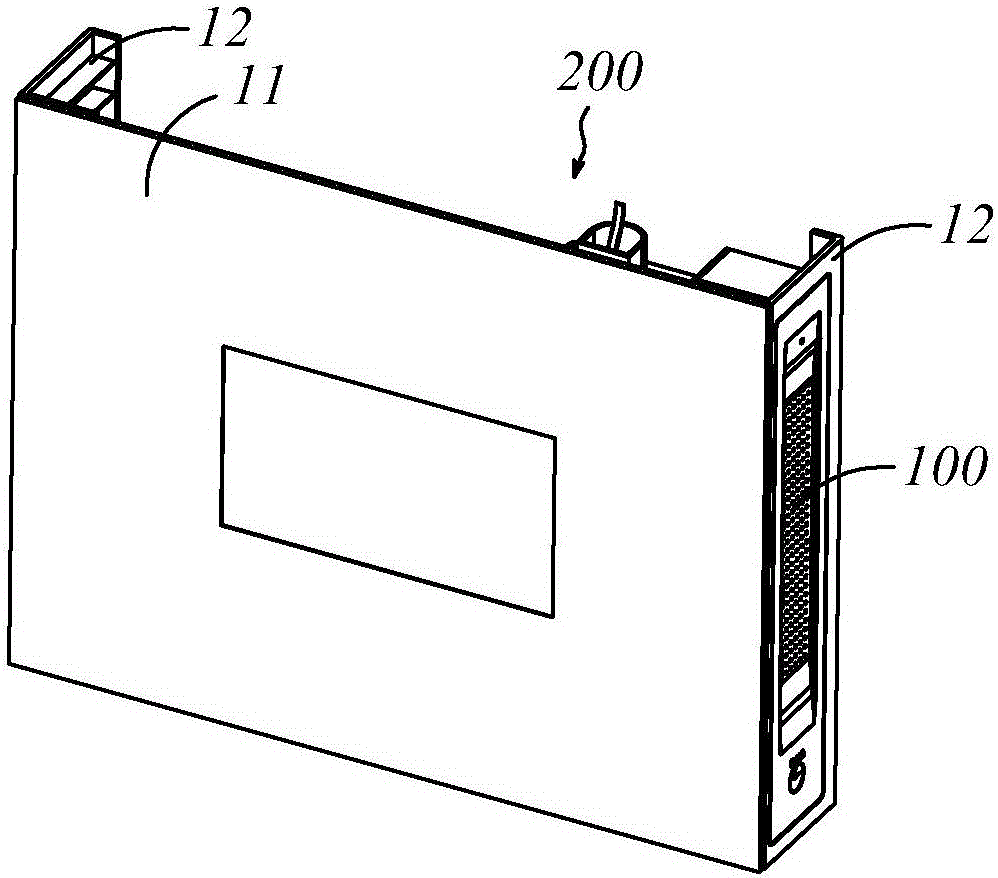

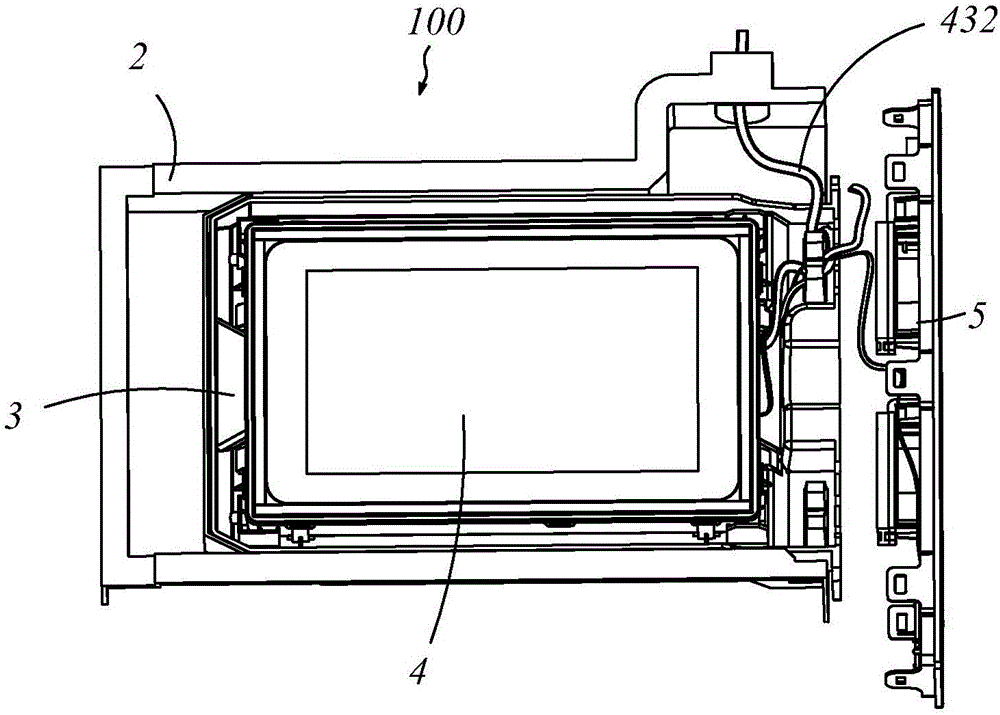

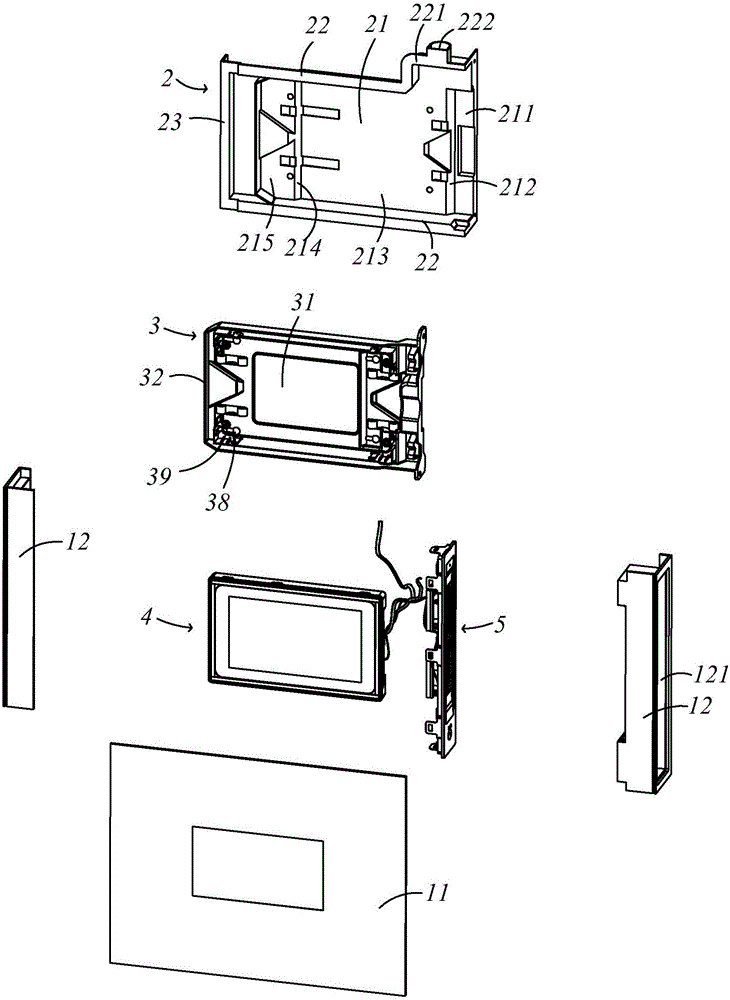

Display screen assembly and refrigeration household appliance

ActiveCN106097891AWith stableEnsure air circulationIdentification meansElectrical apparatus casings/cabinets/drawersEngineeringMouth shape

The invention provides a display screen assembly which comprises an embedded box, an installation support, a display screen module and a cover plate assembly. The display screen is located inside the display screen module. The installation support comprises a supporting wall, and a peripheral wall convexly stretching from the peripheral edge of the supporting wall to the same side of the supporting wall. The side, facing the peripheral wall, of the supporting wall is provided with a positioning piece for positioning the display screen module, a plurality of clamping buckles for clamping the display screen module and mouth-shaped frame ribs for supporting the display screen module. The display screen module is provided with a clamping groove matched with the clamping buckles. When the display screen module is assembled to the installation support, the display screen module is supported on the mouth-shaped frame ribs. The mouth-shaped frame ribs are arranged on the installation support, matching of the display screen module and the installation support is more stable, and a certain gap exists between the display screen module and the installation support, so that air circulation is ensured, and heat is prevented from being gathered.

Owner:HAIER SMART HOME CO LTD

Control mechanism of dual-opening lock

ActiveCN104100146AMovement does not blockThere will be no co-rotationBuilding locksMechanical engineeringEngineering

The invention discloses a control mechanism of a dual-opening lock. The control mechanism comprises a lock assembly, a lock-in and lock-out mechanism, a swinging piece and two switching pieces, wherein the lock-in and lock-out mechanism comprises an installing shaft, the installing shaft is located between lock cores of an indoor lock and an outdoor lock, the position of the installing shaft is fixed relative to lock core shafts, and the installing shaft is independent of the lock core shafts; the swinging piece is rotationally arranged on the installing shaft and is provided with sliding pins which are used for pushing a bolt plate to move along the lock-in and lock-out direction; the two switching pieces are used for respectively driving the swinging piece to rotate around the installing shaft under the driving of the corresponding lock core shafts; one switching piece does not rotate synchronously when the swinging piece is driven to rotate by the other switching piece; a gap which is used for a bolt plate to move along the lock-in and lock-out direction is reserved between the lock core of the indoor lock and the lock core of the outdoor lock.

Owner:WONLY SECURITY & PROTECTION TECH CO LTD

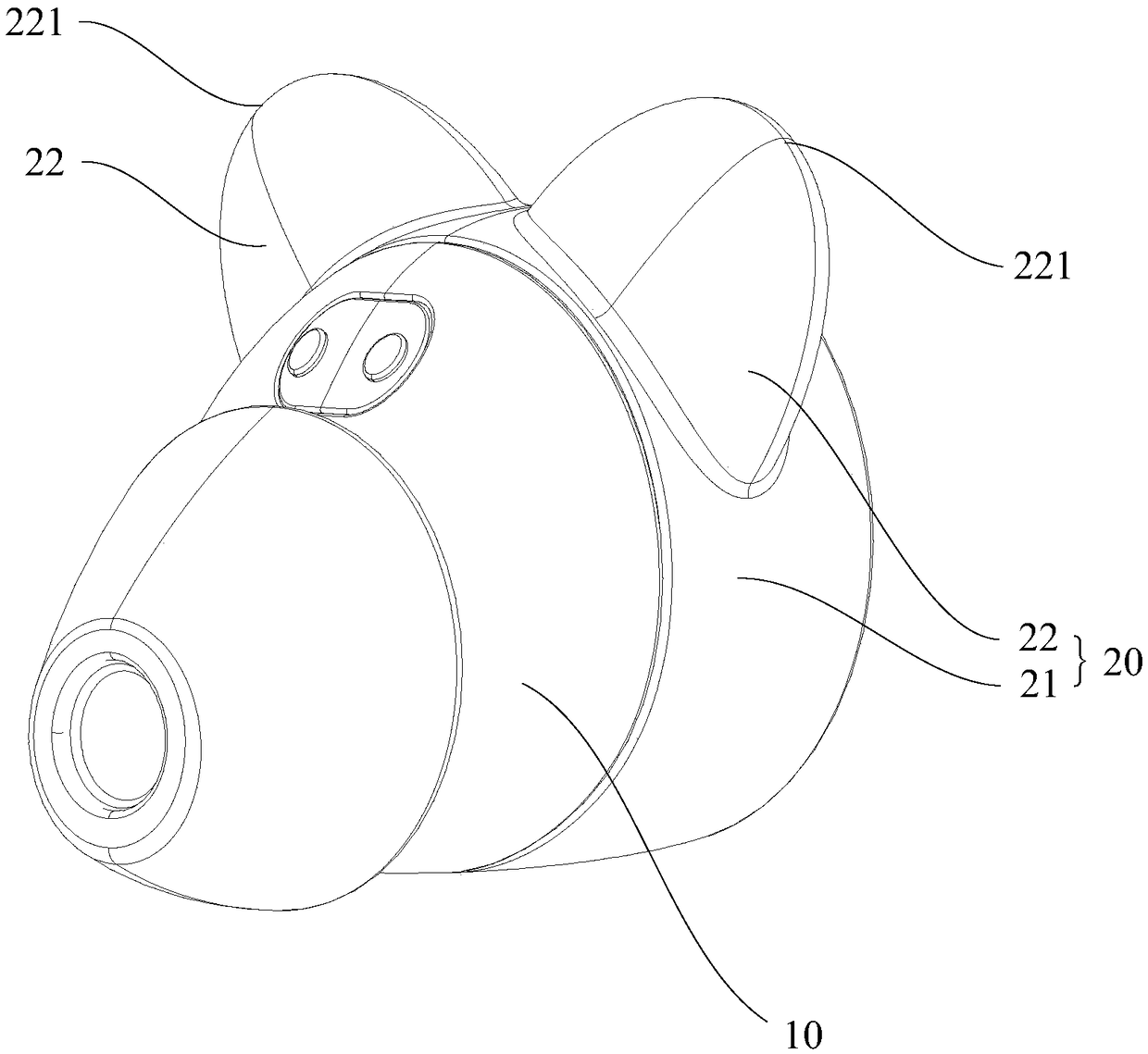

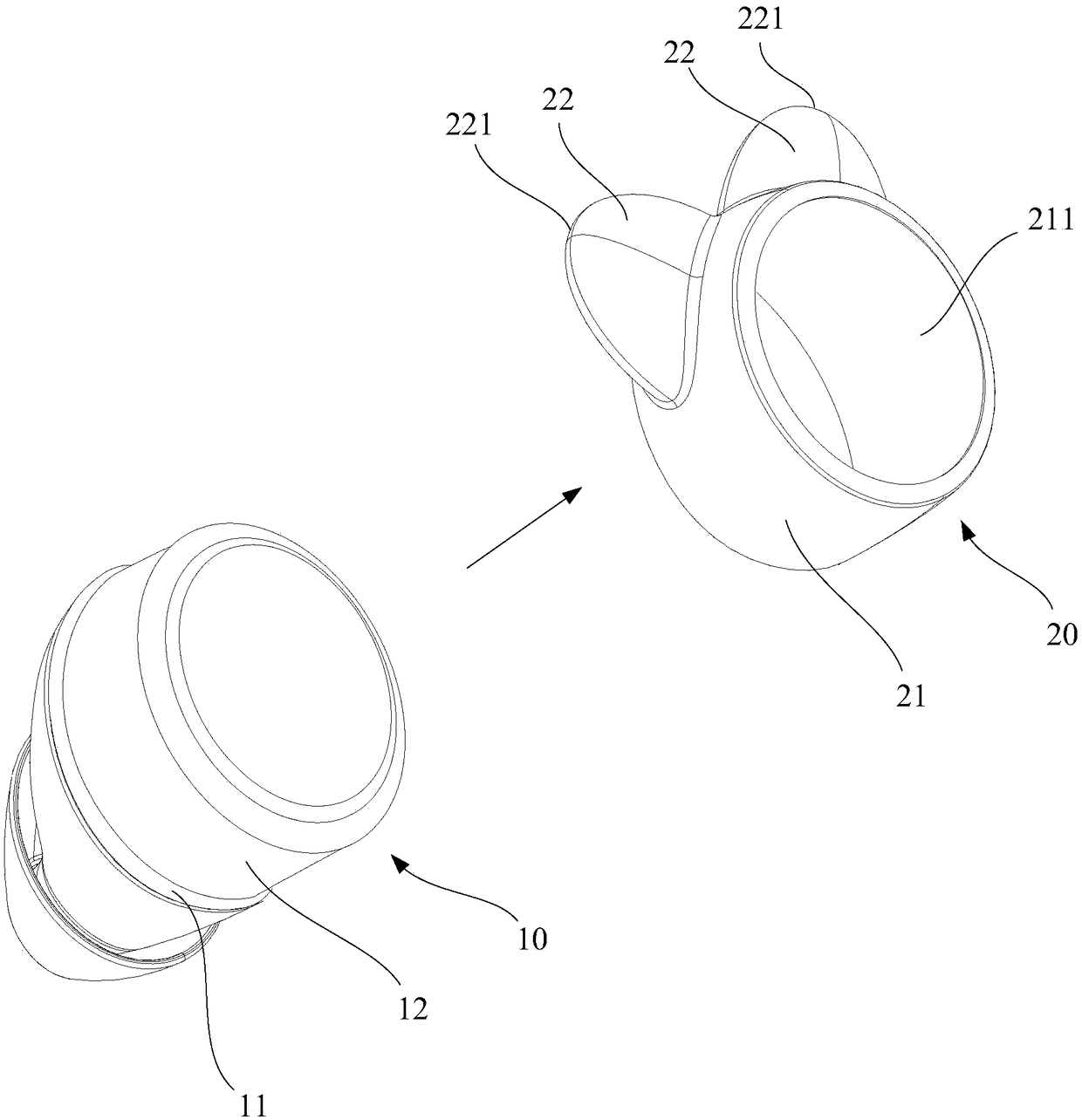

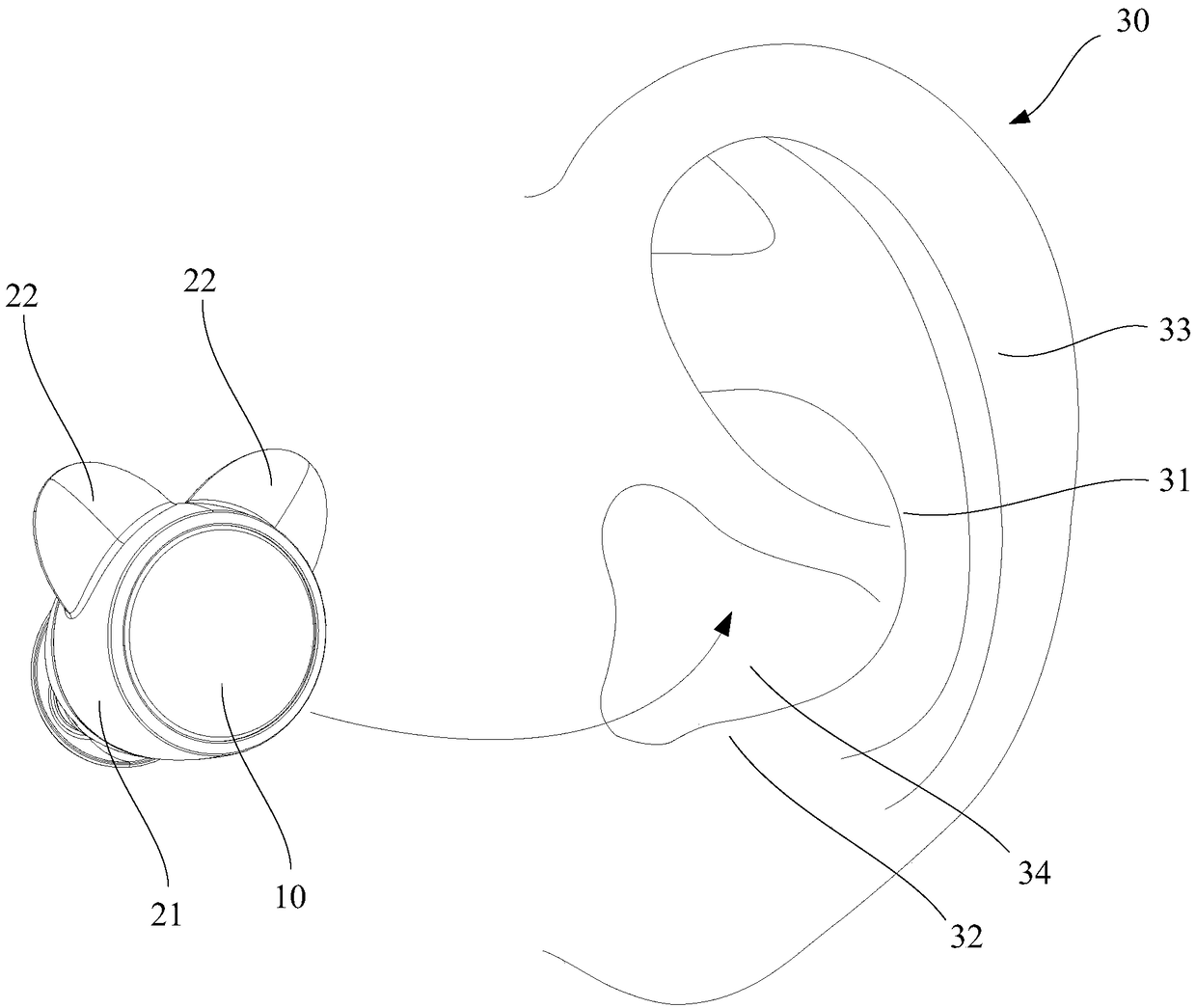

Earphone sleeve and earphone component

Owner:深圳市鸿太科技有限公司

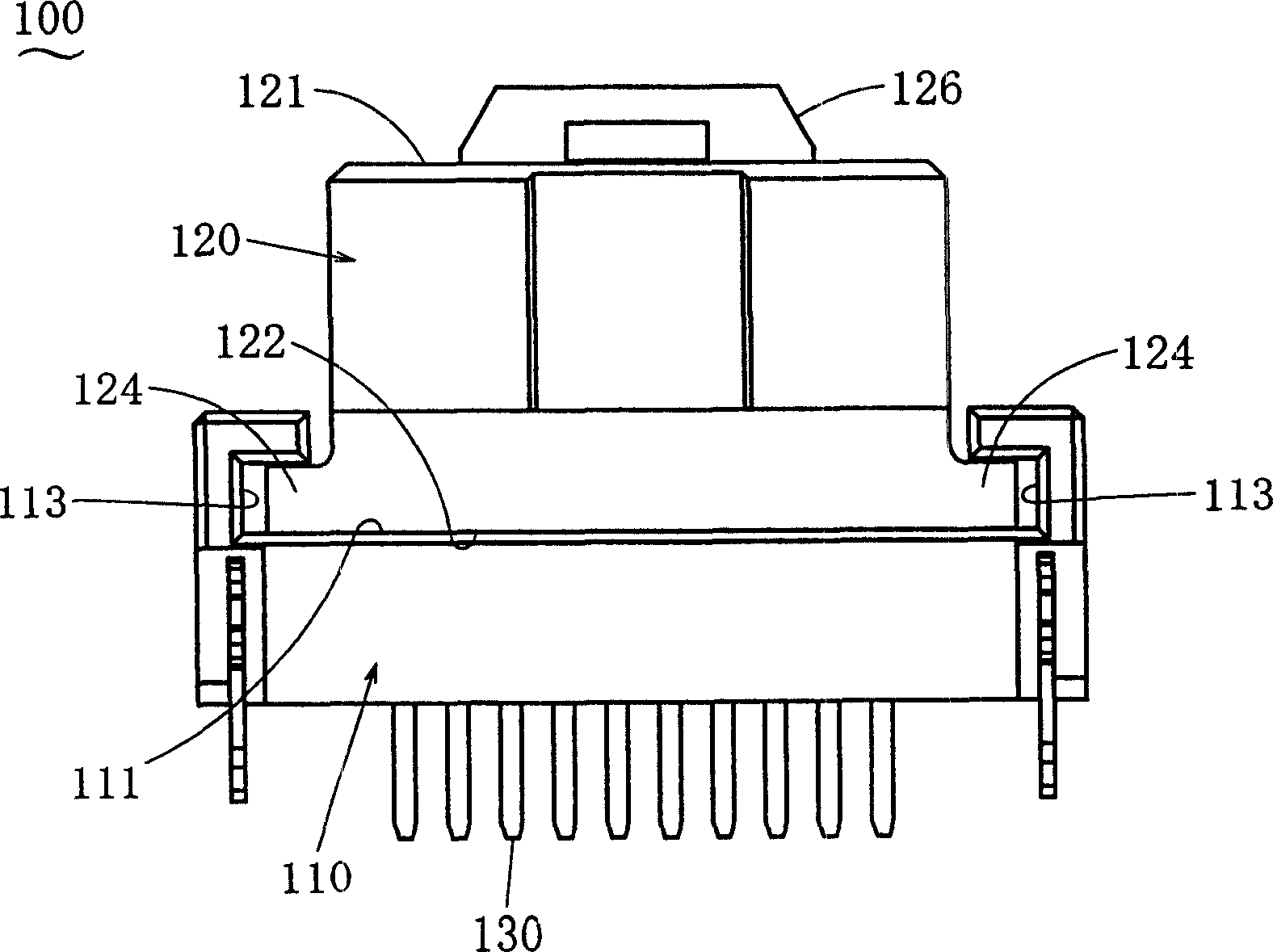

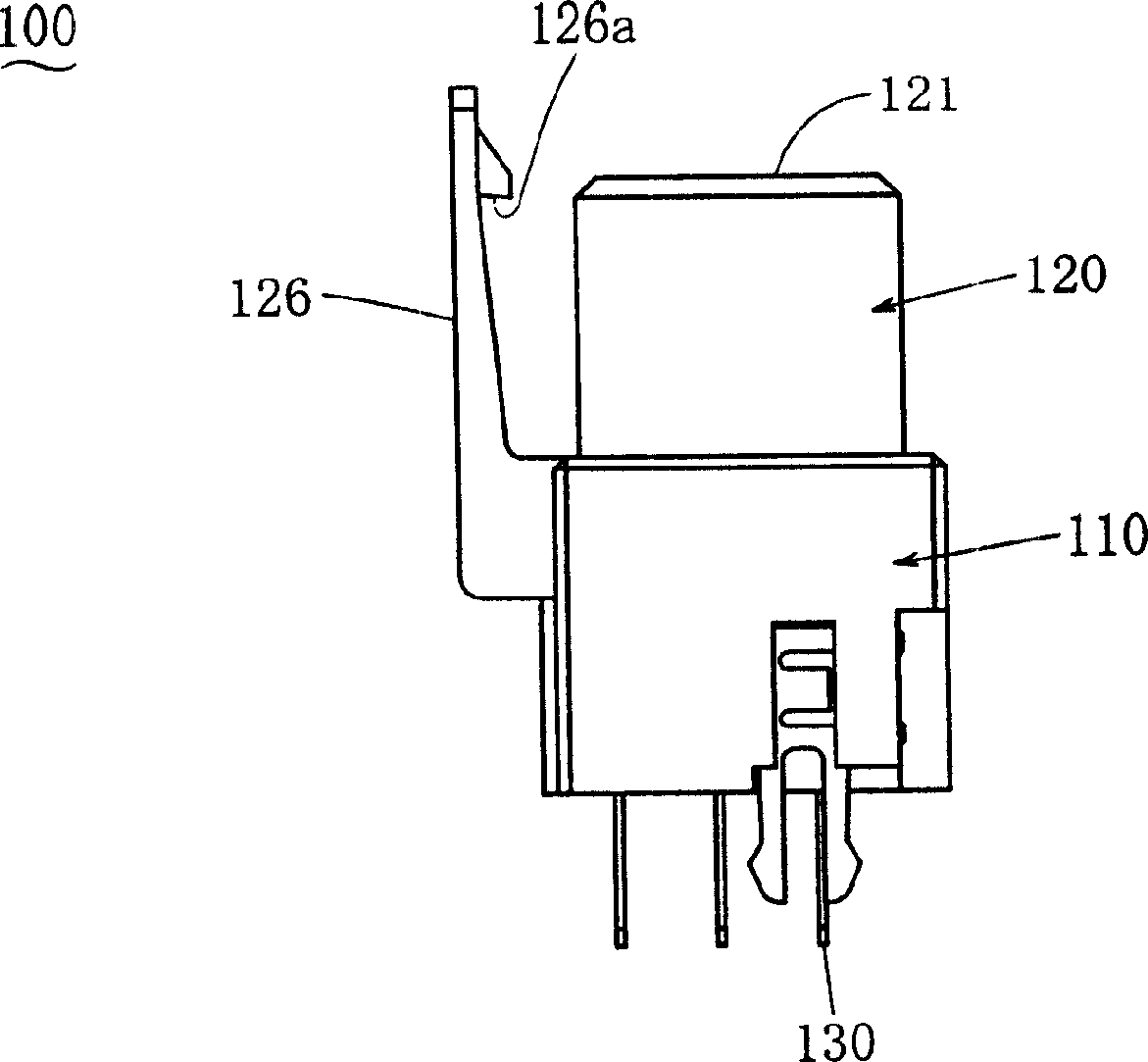

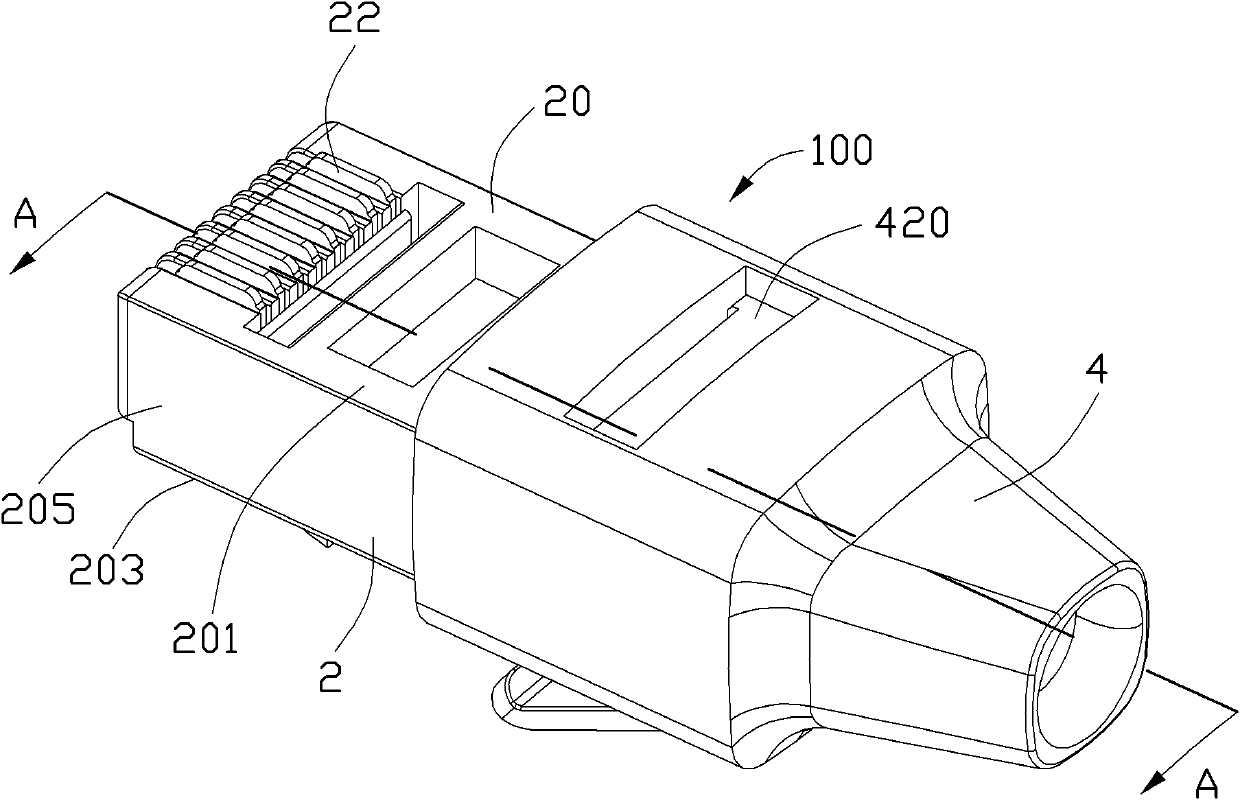

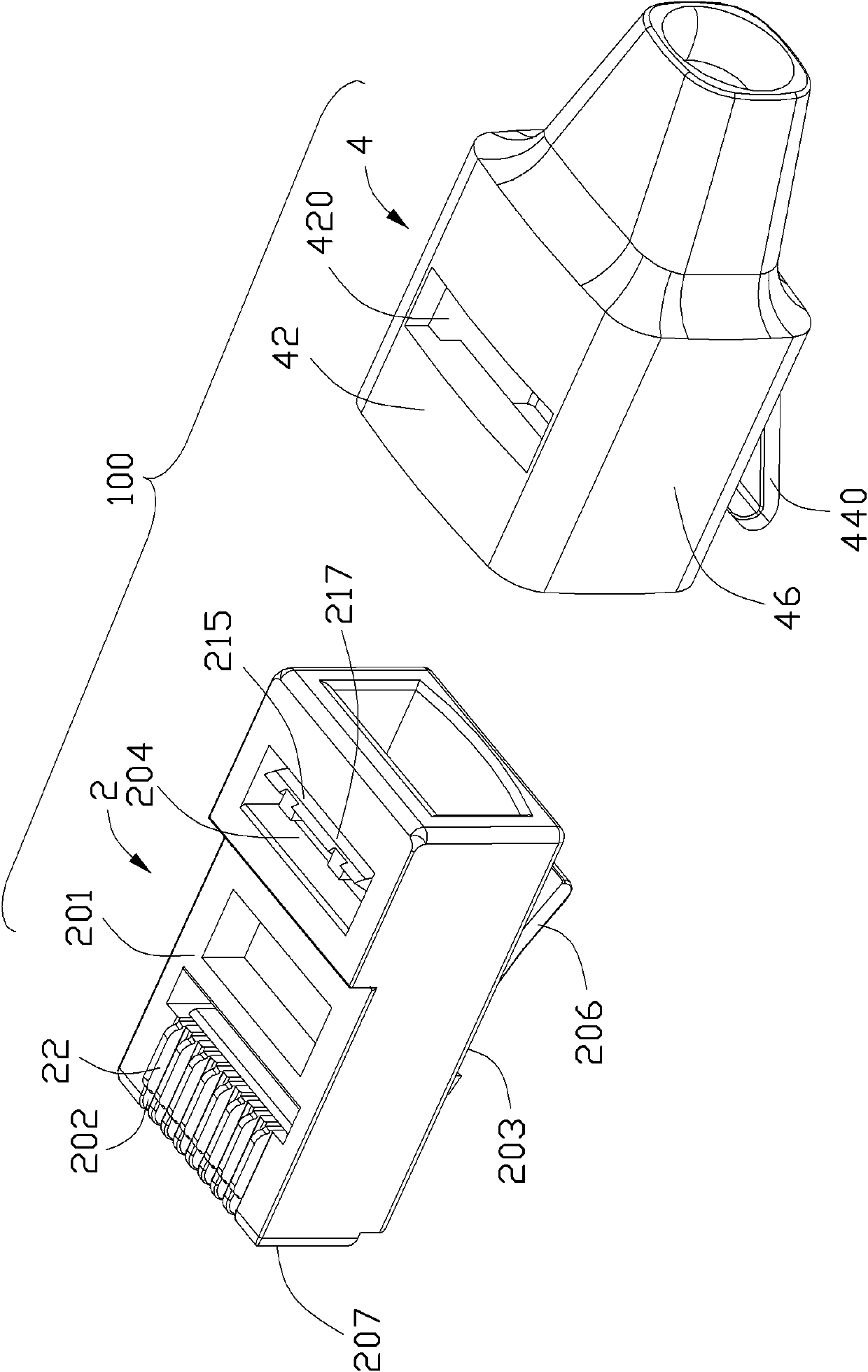

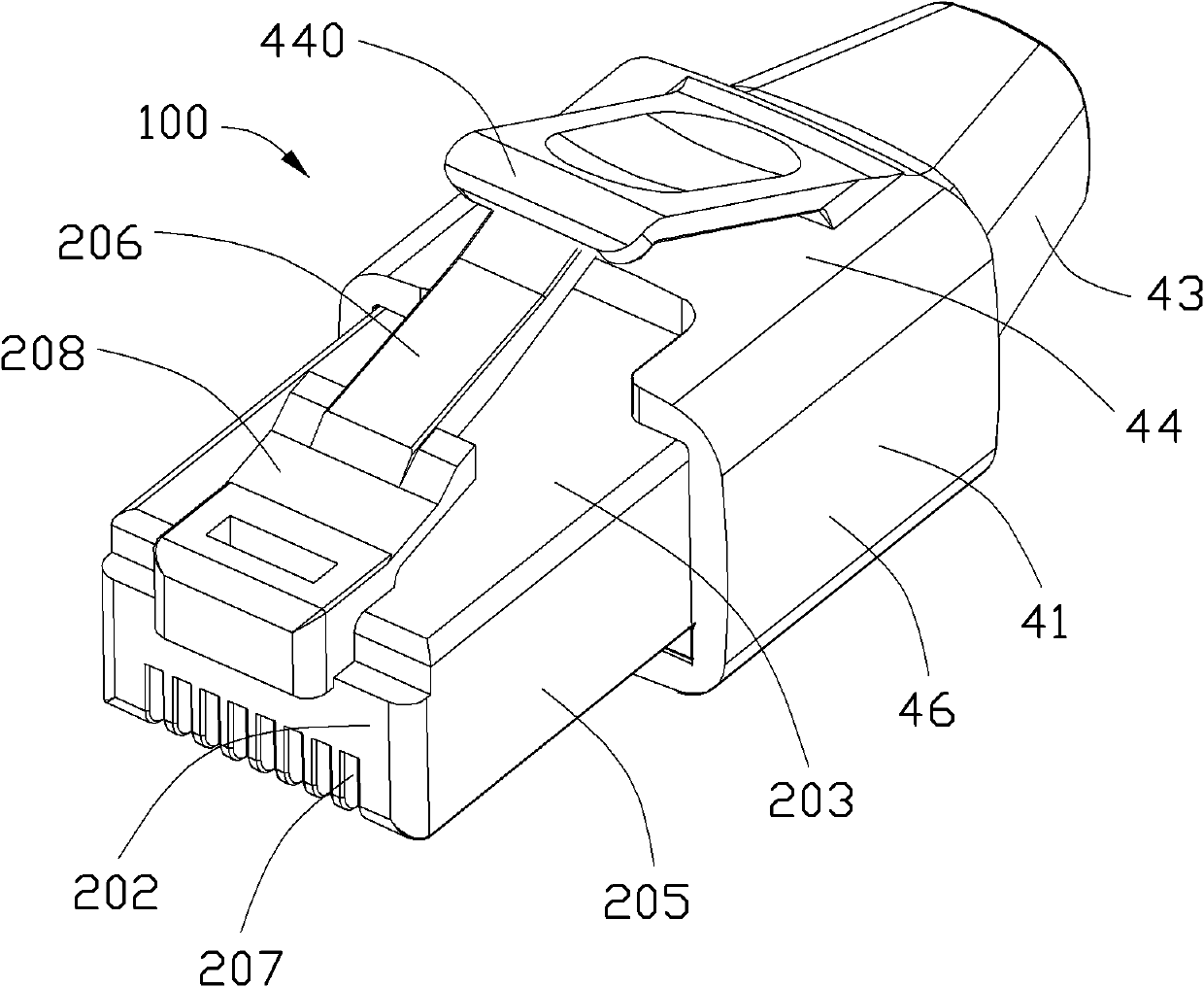

Electric connector component

InactiveCN102201631ANot easy to fall offFit firmlyRelieving strain on wire connectionTwo-part coupling devicesElectricityEngineering

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

Improved automobile heavy-load connector capable of improving cable protection effect

PendingCN111082263AMating fit is stableRealize inflation and deflationCoupling device detailsHydraulic cylinderCoil spring

The invention aims to solve the problem that the connection of the existing automobile heavy-load connector affects the protection of a cable, and discloses an improved automobile heavy-load connectorcapable of improving a cable protection effect. The connector comprises a male plug body and a female plug body. The surface of the male plug body is sleeved with a first sleeve. A first fastening screw is fastened between the first sleeve and the male plug body, a first connecting block is bonded to the surface of the first sleeve, a first cable penetrates out of the right side of the male plugbody, a first ventilation box is bonded to the right side face of the first sleeve, and the surface of the female plug body is sleeved with a second sleeve. Driving of the hydraulic cylinder is reasonably utilized; inflation and deflation of an air bag belt are realized; the male plug body and the female plug body can be plugged and unplugged through cooperation of a spiral spring, melting or adhesion caused by long-time cooperation is avoided, the male plug body and the female plug body can be conveniently and rapidly separated and closed, design is reasonable, operation is convenient and useis safe and reliable.

Owner:HUNAN AUTOMOTIVE ENG VOCATIONAL COLLEGE

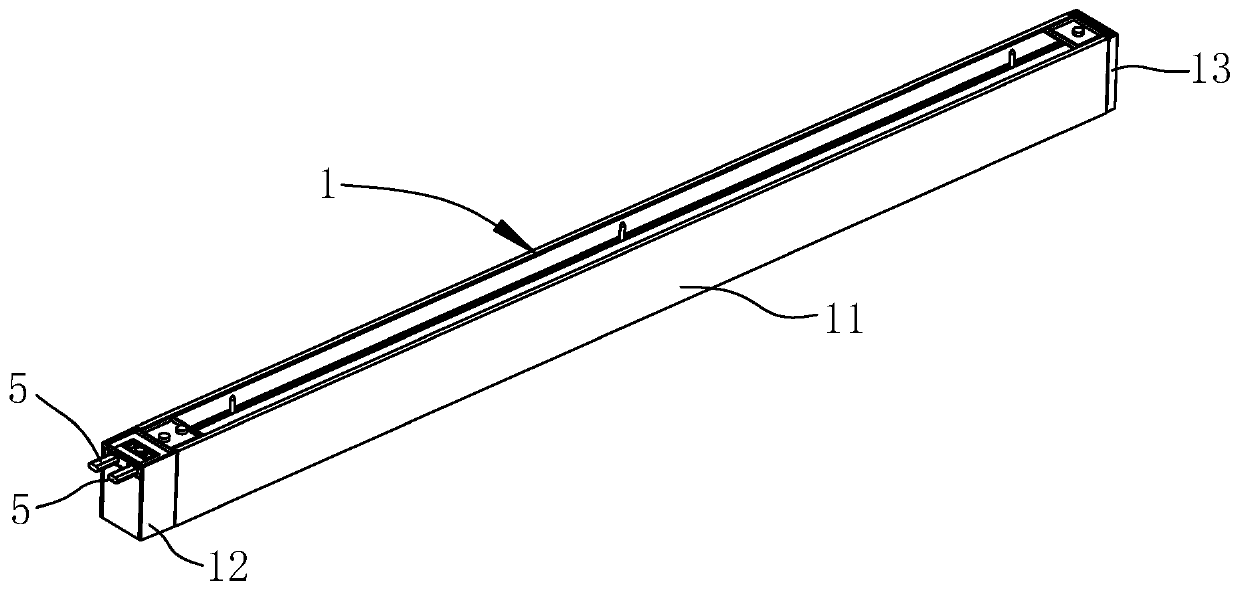

Track component of track light

PendingCN110440184AGuaranteed stabilityThe conductive structure is safe and firmLighting support devicesElectric circuit arrangementsEngineeringCopper

The invention provides a track component of a track light. The track component comprises a track bar and a track box, wherein the track bar comprises a section bar body, multiple copper bars are arranged on the inner side of the top of the section bar body, the main body of the copper bar is arc-shaped, is provided with an inner cavity, and is provided with an elastic opening at the lower part, the top of the track box is provided with an electrode inserting plate, the electrode inserting plate is inserted in the inner cavity of the copper bar from the elastic opening and clings to the edge ofthe elastic opening, the two sides of the track box are provided with elastic bulges, and inner walls of the two sides of the section bar body are provided with guide grooves corresponding to the elastic bulges. According to the track component of the track light, the conductive structure is safe and firm, multi line control can be stably carried out on the same track, and the track component iseasy to install.

Owner:中山市美棋照明科技有限公司

Linkage table rotating base

ActiveCN107364797AStable working conditionReduce wear rateLoad-engaging elementsRotation controlLimit switch

The invention discloses a linkage table rotating base. A unlocking panel is arranged in the rotating base, and is stepped to enable locking teeth of locking the rotating base to deviate from an inner gear ring; after the unlocking pedal is released, under the effect of a spring, the locking teeth and the inner gear ring are automatically engaged for locking the rotating base again, so that the rotating base cannot rotate; the rotating base is additionally provided with a driving mechanism comprising a motor, so that the rotation control of the rotating base can be realized through controlling a button; and in addition, the rotating base is provided with multiple limiting switches and limiting bolts for preventing wrong touch and overload to guarantee safe and stable system operation.

Owner:沈阳安控电气科技有限公司

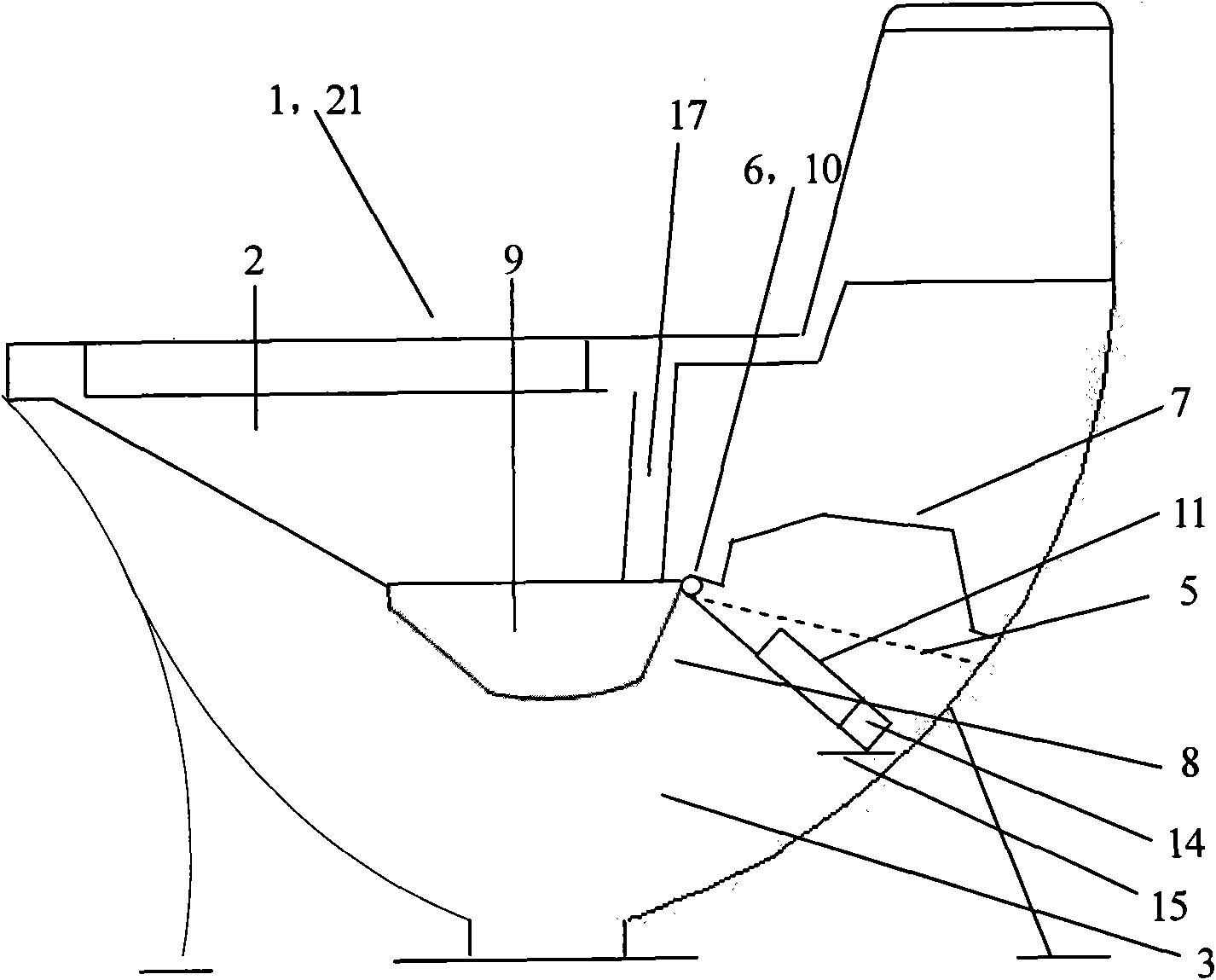

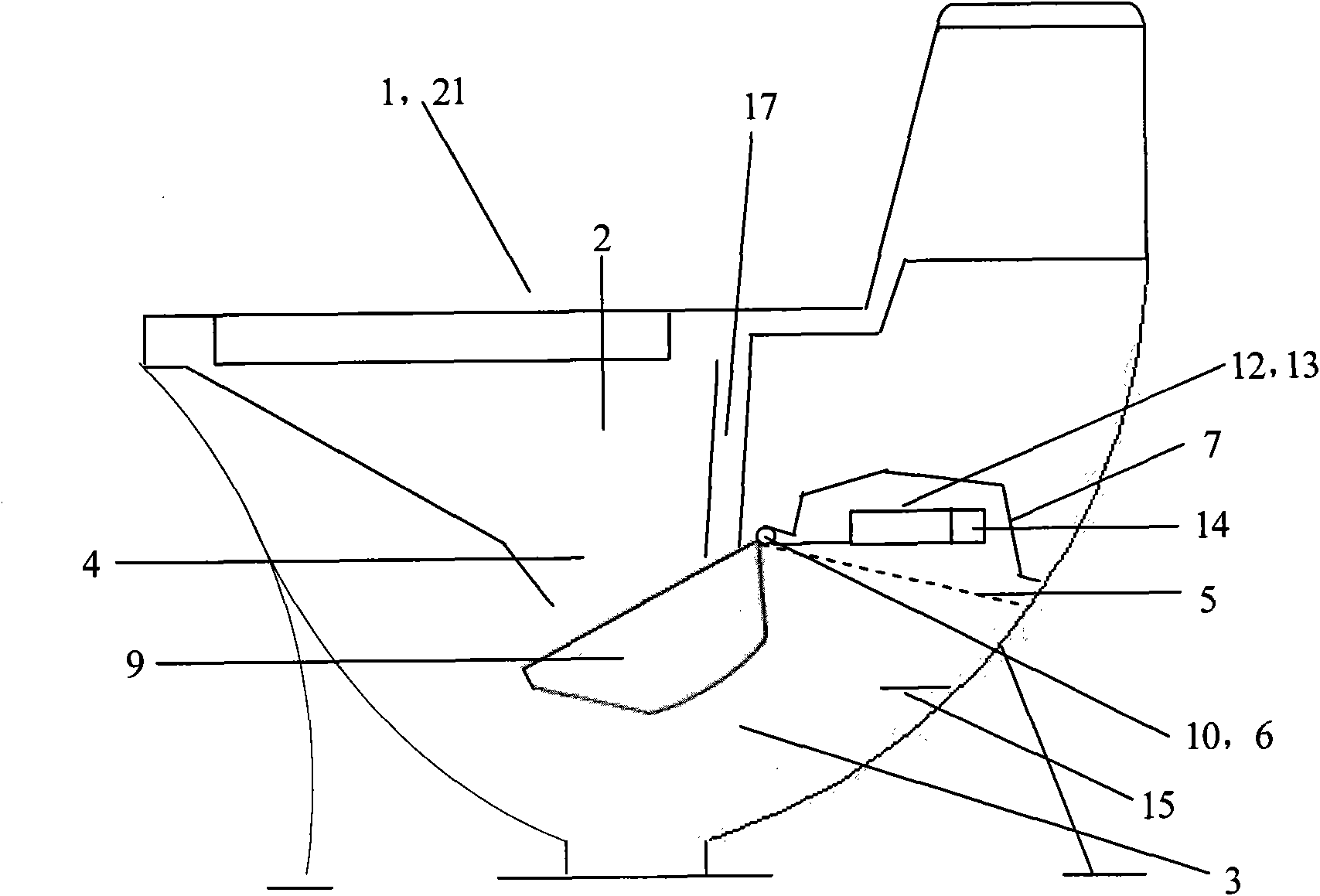

Continuous pushing molding machine for elbow

ActiveCN102744303AFit firmlyReasonable structureMetal-working feeding devicesPositioning devicesLimit switchPipe fitting

The invention relates to a continuous pushing molding machine for an elbow, which is used for processing small-size elbow pipe fittings. According to the technical scheme adopted by the invention, the continuous pushing molding machine for the elbow is characterized by comprising a frame, a pushing cylinder, an automatic chuck device, a molding mould, a cutting device and a workpiece positioning device, wherein the workpiece positioning device comprises a molding positioning part, a fixed guiding part, a resetting spring, a spring base block and a limiting mechanism; the molding positioning part comprises a workpiece pressing part and a sliding part; the sliding part is in guiding sliding fit with the fixed guiding part; one end of the resetting spring acts on the molding positioning part so as to form a restoring force of the molding positioning part; and the limiting mechanism comprises a cutting finishing limiting switch and a molding limiting switch. According to the technical scheme, the defects in the prior art are overcome, and a high-reliability and high-production-efficiency continuous pushing molding machine for the elbow is provided by the invention.

Owner:WENZHOU JIADA MACHINERY MFG

Flushing device of straight-through toilet

The invention provides a flushing device of a straight-through toilet, which comprises a fore bay, a through hole section, a sewage draining spillway and a water skip component; the fore bay is connected with the through hole section, and the through hole section and the sewage draining spillway are separated by the water skip component; the sewage draining spillway is provided with an installation hole, and the water skip component comprises a rotary shaft, a water skip and a counterweight device; and the counterweight device comprises a counterweight part, a counterweight and a magnet, the magnet can suction a conductive magnet at a position corresponding to the magnet, the suction and the separation of the magnet and the conductive magnet change the impact of a counterweight device end on the gravity of a water skip end, so that the opening and the closing of the water skip component are more stable.

Owner:张未鸣

Down feather purification device and technology

ActiveCN109827399ASolve the problem that the down can not be dried well and fluffyImprove fluffinessDrying gas arrangementsDrying machines with non-progressive movementsEngineeringDown feather

The invention relates to the related technical field of down feather purification, and discloses a down feather purification device and technology. A transverse rotation barrel is located on the innerside of a frame, and two positioning bearings are fixedly arranged on the right side end face of the transverse rotation barrel and the right side inner wall of the frame correspondingly. A hollow positioning shaft is fixedly arranged in bearing inner rings of the two positioning bearings. A torque rotation shaft is fixedly arranged on the left side end face of the transverse rotation barrel. A machine case is arranged on the left side face of the frame through bolts. The end, away from the transverse rotation barrel, of the torque rotation shaft penetrates through the inner side wall of theframe and the left side face of the machine case and is connected with a drive mechanism. An inner positioning barrel is arranged on the inner side of the transverse rotation barrel, two walking bearings are fixedly arranged on the inner walls of the left side and the right side of the transverse rotation barrel correspondingly, and the left end and the right end of the inner positioning barrel are inserted and connected in bearing inner rings of the two walking bearings correspondingly. According to the down feather purification device and technology, rotationally-dried down feather is vibrated through a vibration rope, so that the down feather drying fluffiness is improved, and the down feather drying effect is accelerated.

Owner:浙江金文纺织科技有限公司

Lamp cap capable of rotating in 360 degrees and LED (Light Emitting Diode) lamp comprising lamp cap

InactiveCN104595809AEasy to useSmooth rotationLighting support devicesPoint-like light sourceElectricityEngineering

The invention discloses a lamp cap capable of rotating in 360 degrees. The lamp cap comprises a lamp holder component connected with a lamp tube and a socket component connected with the lamp holder component in a rotating manner, wherein the lamp holder component is provided with two annular electrodes which are electrically connected with a positive electrode and a negative electrode of the lamp tube respectively; the socket component is provided with two electrode brush heads which are electrically connected with a power supply; each electrode brush head is close to the corresponding annular electrode through sliding fit respectively. The invention also discloses an LED (Light Emitting Diode) lamp provided with the lamp cap. Large-angle unlimited rotation of the lamp cap part can be realized, so that the lighting angle of the lamp tube is conveniently adjusted, the operation is easy, and components and circuits are all stably connected; compared with the prior art, the application range and quality of the LED lamp with the rotatable lamp cap are effectively improved.

Owner:ZHEJIANG SHENGKAI PHOTOELECTRIC

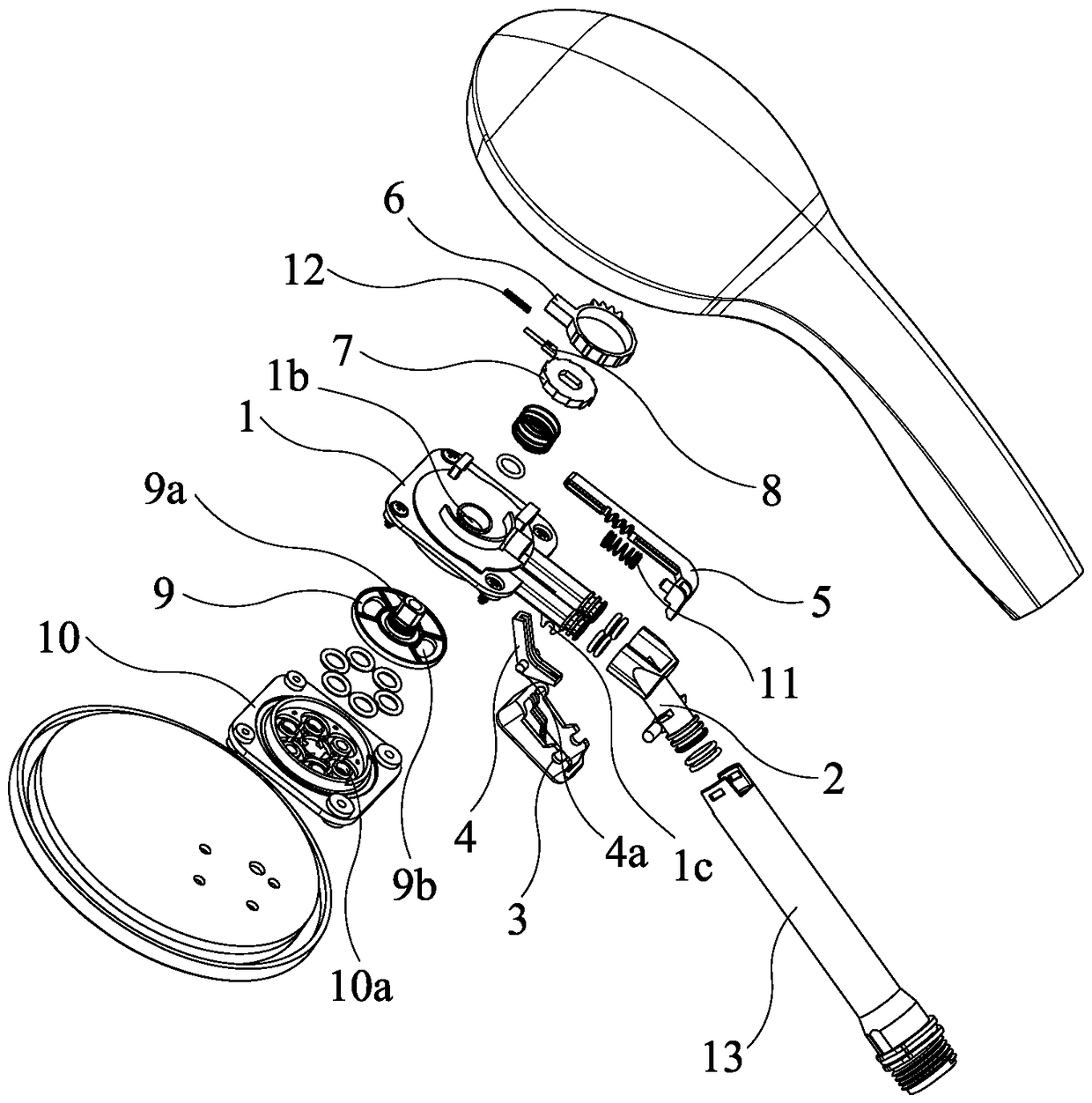

Improved shower head button switching structure

PendingCN108480073ARealization of water flow switchingAvoid getting stuckSpray nozzlesWater flowEngineering

The invention discloses an improved shower head button switching structure. The improved shower head button switching structure comprises a water sealing base, a fixed base, a button, a pushing block,a push rod, a driving disc, a driven disc, a locating block and a water sealing disc, wherein a gear part is formed on the periphery of the driving disc, a rack is formed at the front end of the pushrod, and the push rod can drive the driving disc to move in the back-and-forth reciprocating moving process; and the driven disc is nested in the driving disc, the locating block is installed in thedriving disc in an inclined manner, and a circle of ratchet teeth are formed in the periphery of the driven disc. According to the improved shower head button switching structure, a smoother and morestable water flow switching function can be achieved.

Owner:PURITY XIAMEN SANITARY WARE

Composite optical cable

ActiveCN105225746AAvoid offsetCompact structureInsulated cablesPower cablesElectrical conductorEngineering

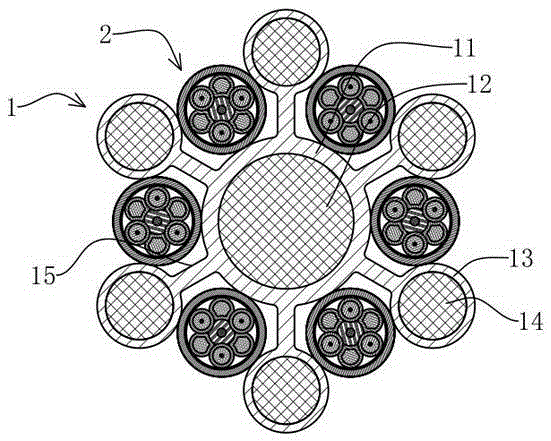

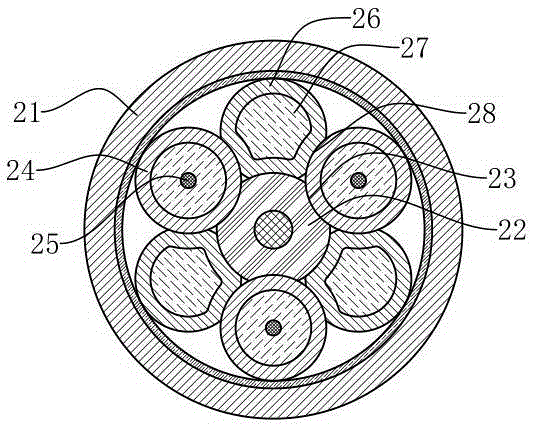

The invention provides a composite optical cable and belongs to the field of optical cables. The composite optical cable solves the problem that an existing optical cable is low in strength. The composite optical cable comprises a supporting frame and optical cable wires. The supporting frame comprises a central supporting tubes and a plurality of edge supporting tubes which are connected through fins. The central supporting tube and the edge supporting tubes are respectively and internally provided with central reinforcing ribs and edge reinforcing ribs. One optical cable wire is arranged between two adjacent fins. The central supporting tube and two edge supporting tubes are abutted against the outer wall of one optical cable wire. Each optical cable wire comprises a sheath layer and a central reinforcing member. A plurality of sleeves I and sleeves II are arranged between the sheath layer and the central reinforcing member at intervals. The sleeve I is internally provided with a conductor. The sleeve II is internally filled with a buffering material. Outer walls of the sleeves II and the central reinforcing member are respectively provided with a plurality of strip-shaped grooves I and strip-shaped grooves II. Outer walls of the sleeves I and the central reinforcing member are respectively abutted in the strip-shaped grooves I, and the outer walls of the sleeves I are further abutted in the strip-shaped grooves II. The composite optical cable is higher in strength and better in distortion resistance.

Owner:SHANDONG QUANXING YINQIAO OPTICAL & ELECTRIC CABLE SCI & TECH DEV +1

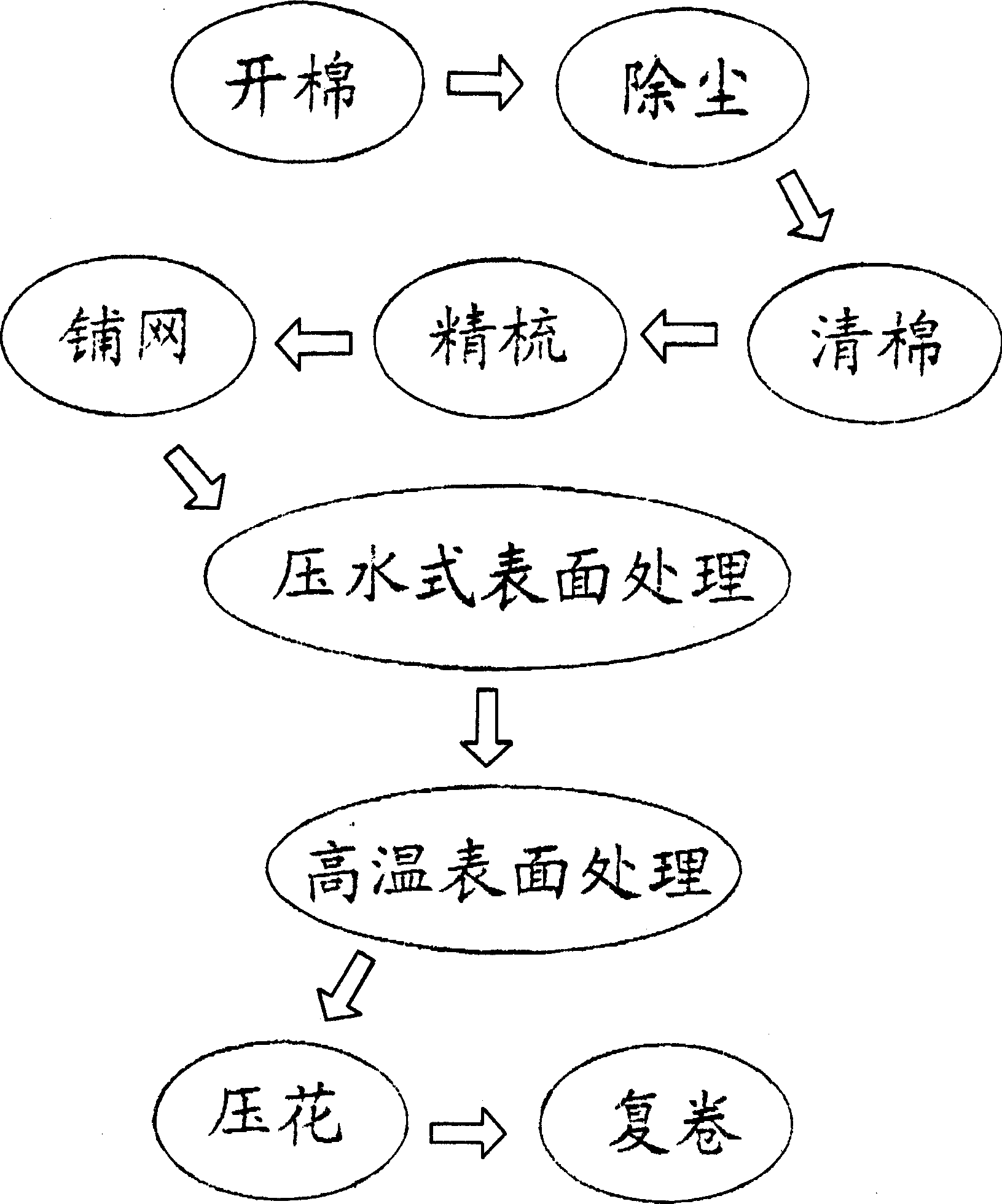

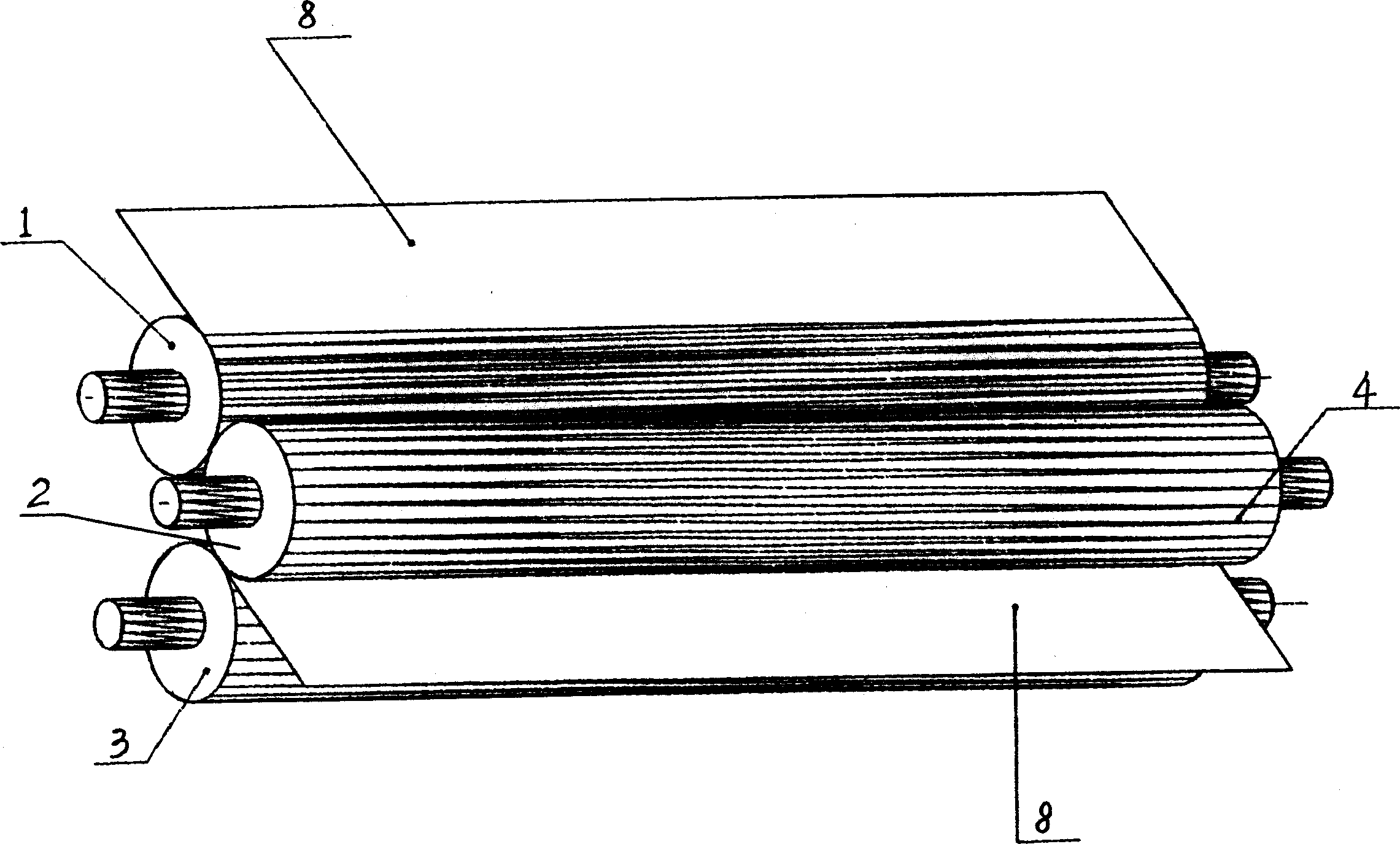

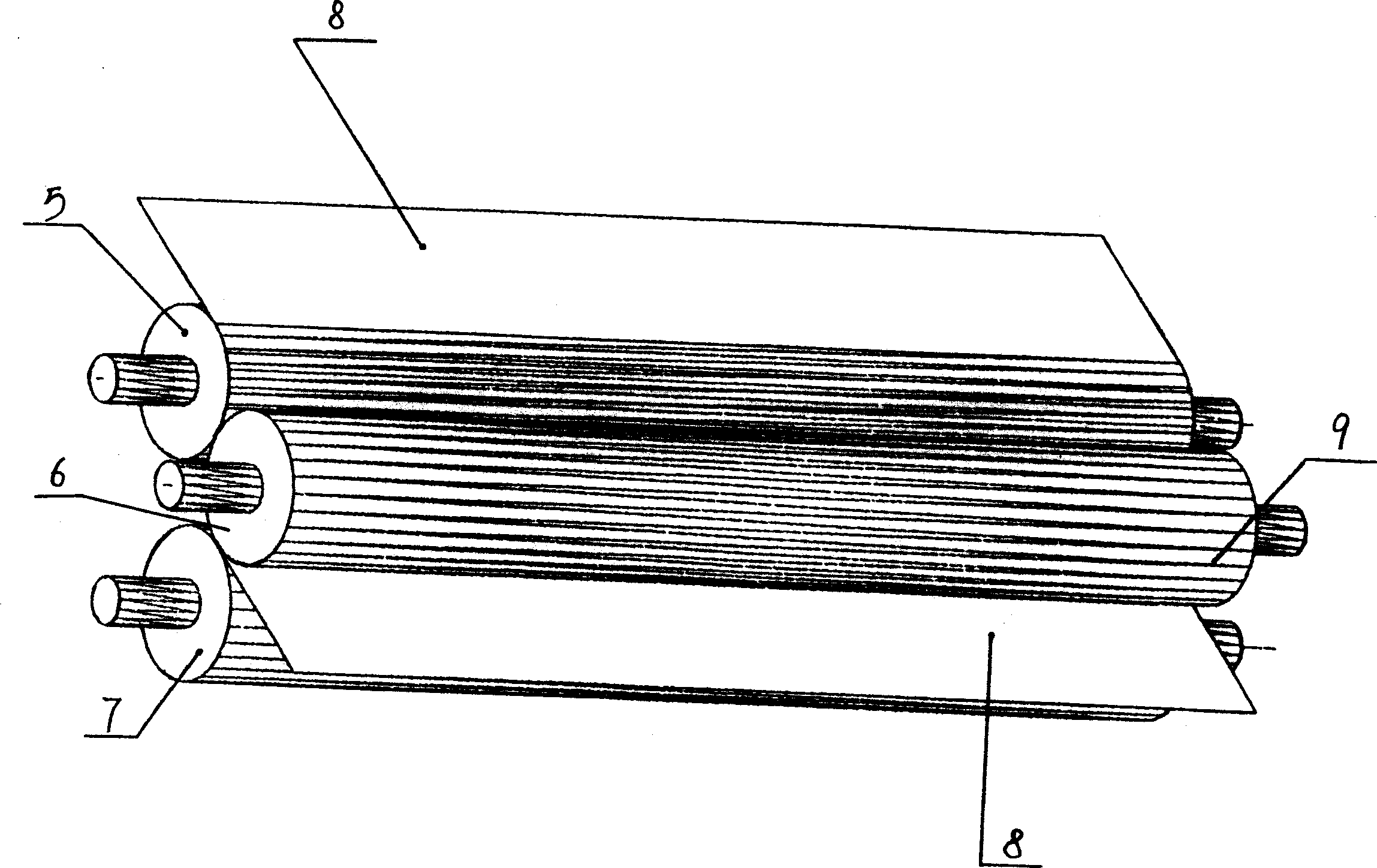

Pressurized water cosmetic cotton and method for manufacturing the same

InactiveCN1546773AFit firmlySmooth and soft surfacePackaging toiletriesPackaging cosmeticsEngineeringForming processes

Owner:杨倩红

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com