Continuous pushing molding machine for elbow

A technology for forming machines and elbows, which is applied in the direction of manufacturing tools, metal processing equipment, feeding devices, etc., and can solve problems such as difficulty in meeting factory production and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

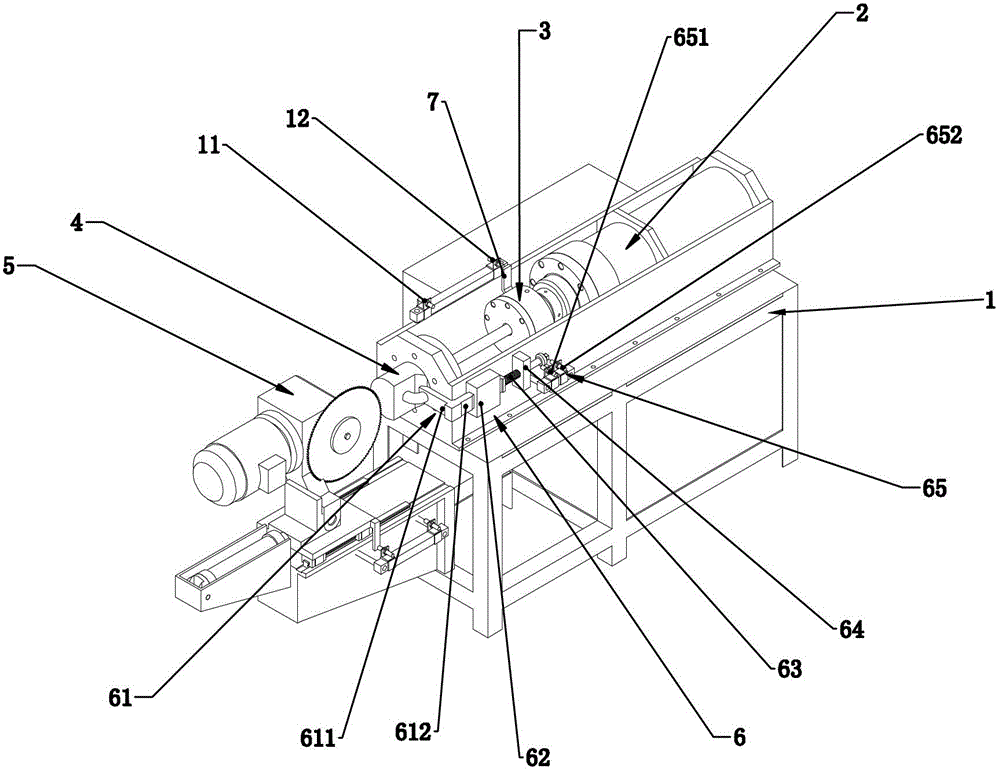

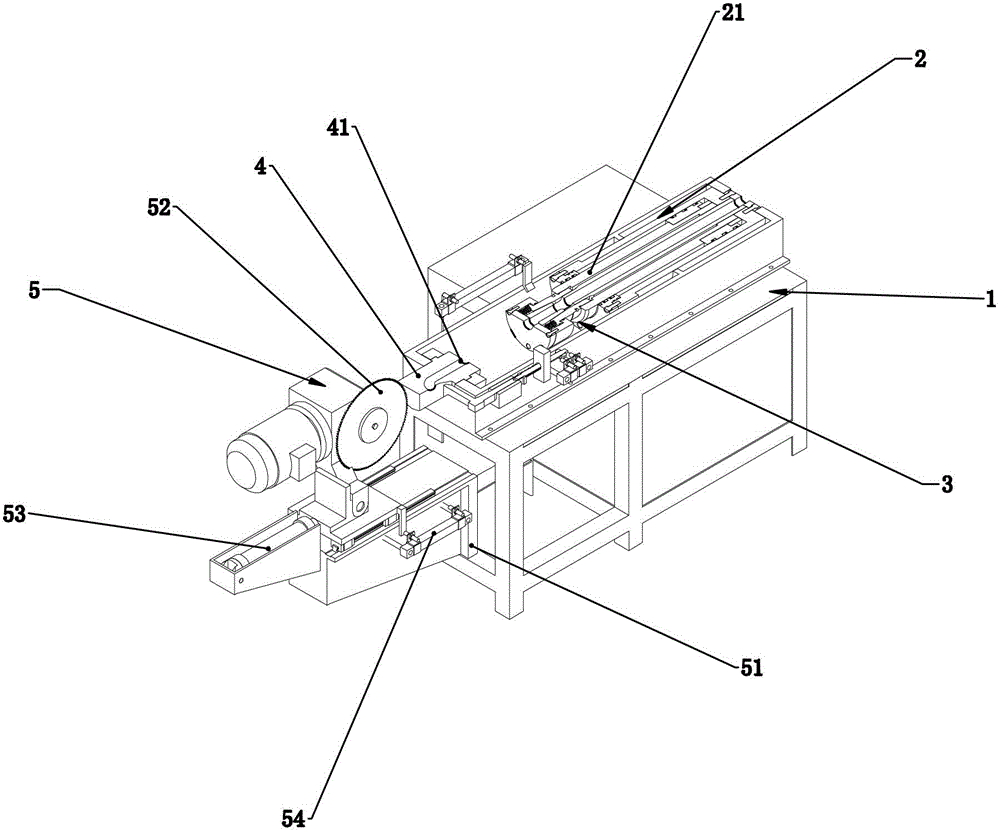

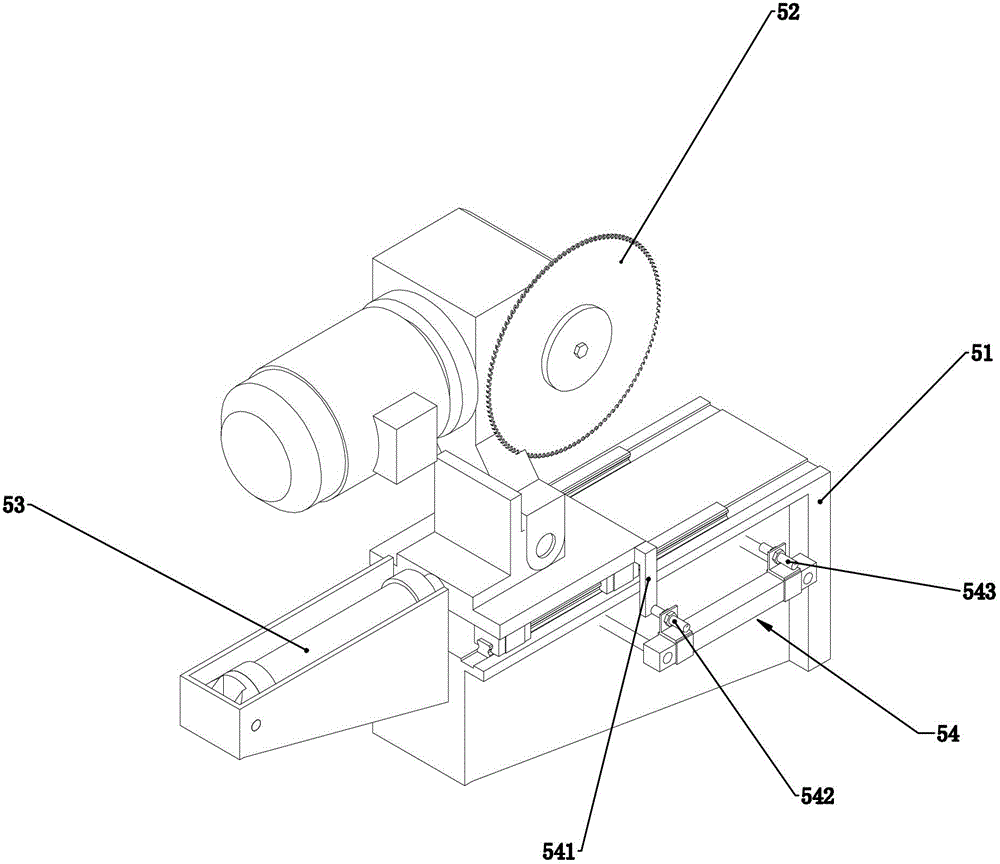

[0013] like figure 1 — Figure 5 As shown, a continuous push forming machine for elbows includes a frame 1, a propulsion cylinder 2, an automatic chuck device 3, a molding die 4, a cutting device 5 and a workpiece positioning device 6, wherein the automatic chuck device 3 includes There are a cover plate 31, a jacket 32, a return spring 33, a tapered clamping valve body 34 and a tapered push head 35, wherein the tapered clamping valve body 34 includes at least two independent cone pieces 341, and the cone pieces 341 are combined to form a cone The taper clamps the petal body 34, and the central portion of the taper clamped petal body 34 is a circular through hole 342. The taper clamped petal body 34 is inserted into the taper push head 35 from the small end 343, and the taper push head 35. The through hole 351 at the insertion end of the tapered clamping petal body 34 is trumpet-shaped. When the tapered clamping petal body 34 gradually extends into the through hole 351 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com