Down feather purification device and technology

A technology of down and horizontal rotation, which is applied in the direction of drying gas arrangement, drying solid materials, non-progressive dryers, etc., can solve the problem that the down purification device cannot dry the down and fluffy, so as to increase the fluffiness, increase the contact area, and speed up the drying process. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

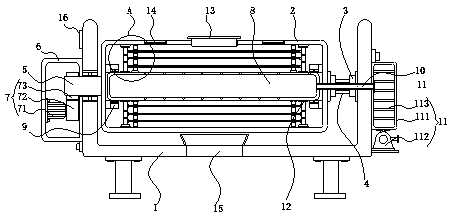

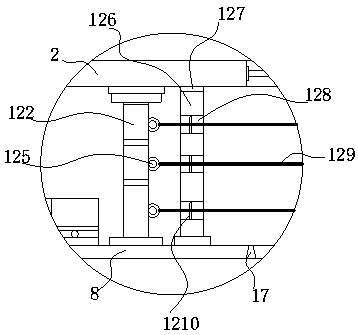

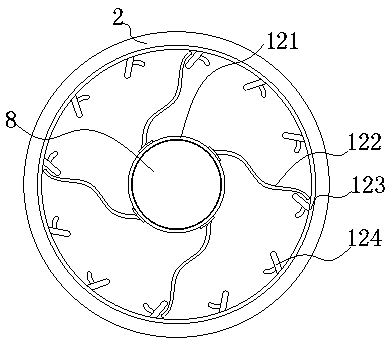

[0029] Such as Figure 1-6 As shown, the present invention provides a technical solution: a feather purification device, including a frame 1, a horizontal rotating cylinder 2, two positioning bearings 3, a hollow positioning shaft 4, a torque shaft 5, a cabinet 6, a driving mechanism 7, an internal positioning Cylinder 8, two walking bearings 9, transverse ventilation pipe 10, heating mechanism 11, inner toggle vibration mechanism 12, four introduction covers 13, two ventilation nets 14, discharge port 15, control panel 16 and ventilation holes 17, The horizontal rotating cylinder 2 is located inside the frame 1, and the two positioning bearings 3 are respectively fixedly installed on the right end surface of the horizontal rotating cylinder 2 and the right inner wall of the frame 1, and the hollow positioning shaft 4 is fixedly installed in the bearings of the two positioning bearings 3 The torque rotating shaft 5 is fixedly installed on the left side of the horizontal rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com