Acrylic and Richcel fiber florescent denim and weaving method thereof

A denim, fluorescent technology, applied in the field of clothing production, to achieve the effect of improving fluffy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The warp yarn is made of acrylic fiber and Lisa blended yarn, and the weft yarn is made of cotton yarn; among them, acrylic fiber accounts for 20% of the proportion of acrylic fiber and Lisa fiber blended yarn, and Lisa fiber accounts for 80% of the proportion of acrylic fiber and Lisa fiber blended yarn. Warp and weft density: 284×210 threads / 10cm; width: 148cm. Warp shrinkage≦-2.0% Weft shrinkage≦-1.0%.

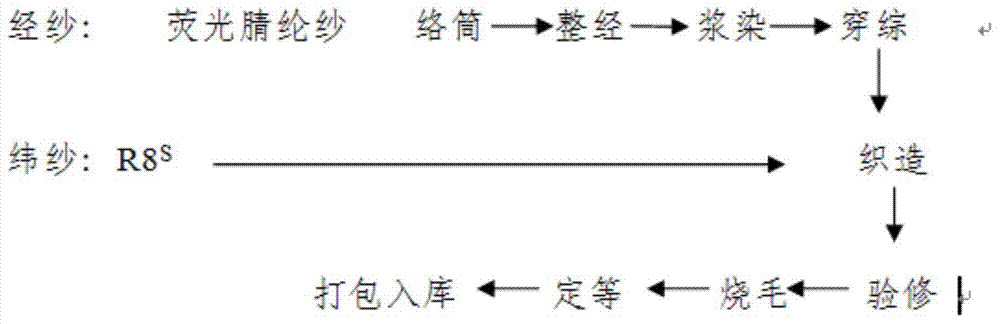

[0030] The weaving method of acrylic fiber and Lisai fiber fluorescent denim in this embodiment, the weaving process is formed by interweaving warp yarns and weft yarns, and the warp yarns go through the steps of winding, warping, sizing, threading, warp knotting, weaving, and gray cloth inspection , the weft yarn enters the weaving process with the warp yarn after being twisted through the bobbin yarn;

[0031] The main points of the production process are:

[0032] In the winding process, the loose winding machine generally adopts a linear speed of 800-1000m / min....

Embodiment 2

[0041] Weaving method Desizing process, other steps are the same as in Example 1, the warp yarn is made of acrylic fiber and Lisa blended yarn, and the weft yarn is made of cotton yarn; wherein acrylic fiber accounts for 30% of the proportion of acrylic fiber and Lisa fiber blended yarn, and Lisa fiber accounts for 30% of the proportion of acrylic fiber and Lisa fiber blended yarn. 70% of the proportion of blended yarn. . Warp and weft density: 284×210 threads / 10cm; width: 148cm. Warp shrinkage≦-2.0% Weft shrinkage≦-1.0%.

[0042] In the sizing process, if the sizing quality does not meet the requirements, it is easy to cause warp yarn breakage and "triple jump" defects to increase. The sizing adopts double sizing tanks, which should mainly improve the strength of warp yarns. The design of the sizing process follows the principles of soaking first, supplemented by covering, and enhanced elongation, and adopts the "two high and one low" sizing process. First, dye with catio...

Embodiment 3

[0044] Weaving method Desizing process, other steps are the same as in Example 1, the warp yarn adopts acrylic fiber and Lisa blended yarn, and the weft yarn adopts cotton yarn; wherein acrylic fiber accounts for 25% of the proportion of acrylic fiber and Lisa fiber blended yarn, and Lisa fiber accounts for acrylic fiber and Lisa fiber. 75% of the proportion of blended yarn. . Warp and weft density: 284×210 threads / 10cm; width: 148cm. Warp shrinkage≦-2.0% Weft shrinkage≦-1.0%.

[0045] In the sizing process, if the sizing quality does not meet the requirements, it is easy to cause warp yarn breakage and "triple jump" defects to increase. The sizing adopts double sizing tanks, which should mainly improve the strength of warp yarns. The design of the sizing process follows the principles of soaking first, supplemented by covering, and enhanced elongation, and adopts the "two high and one low" sizing process. First, dye with cationic fluorescent dye and cationic dye with fluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com