Manufacturing equipment and manufacturing method of spunbonded non-woven fabric

A technology for spunbond non-woven fabrics and manufacturing equipment, which is applied in the direction of stretch spinning, textile and papermaking, non-woven fabrics, etc. Cloth softness and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

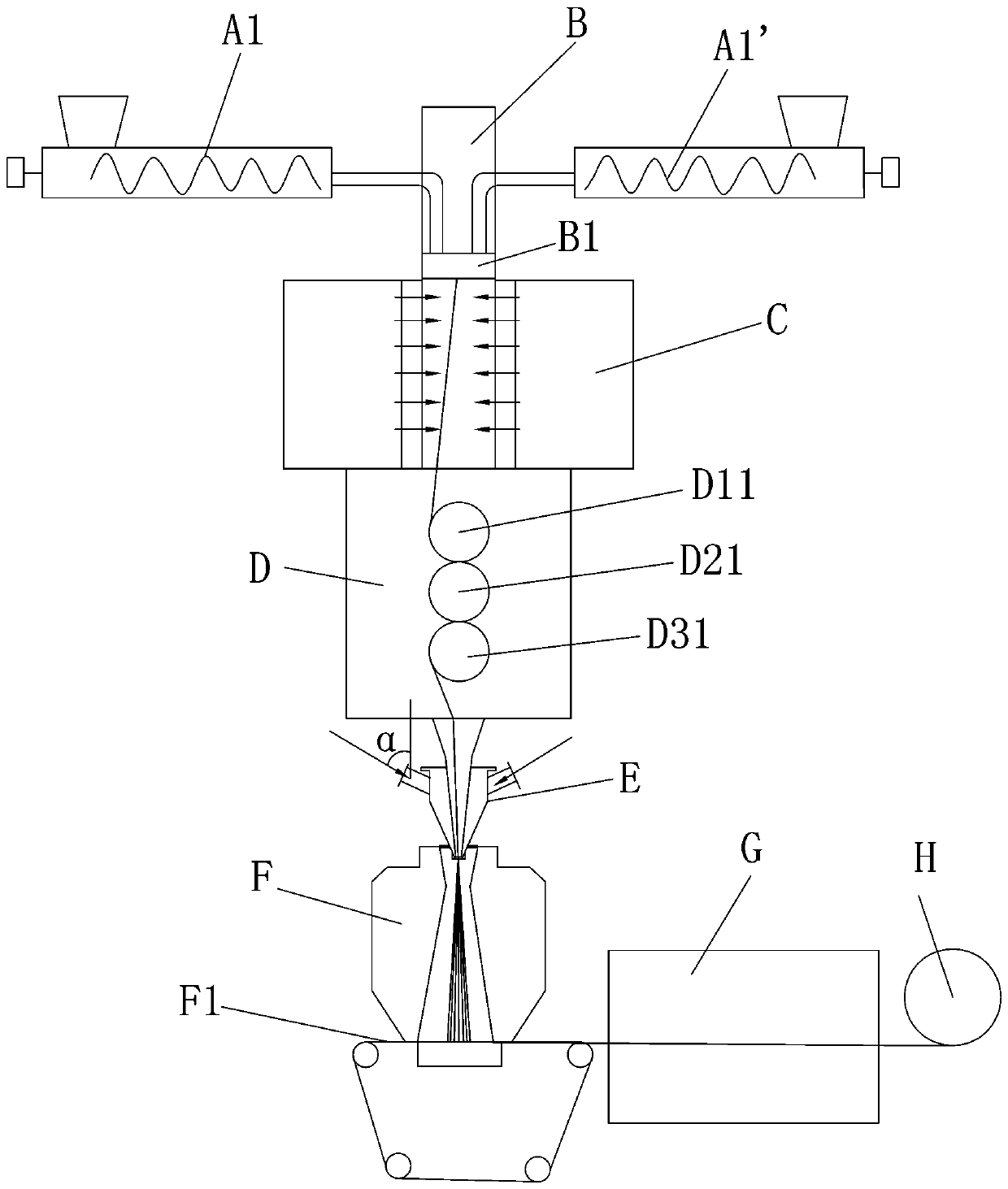

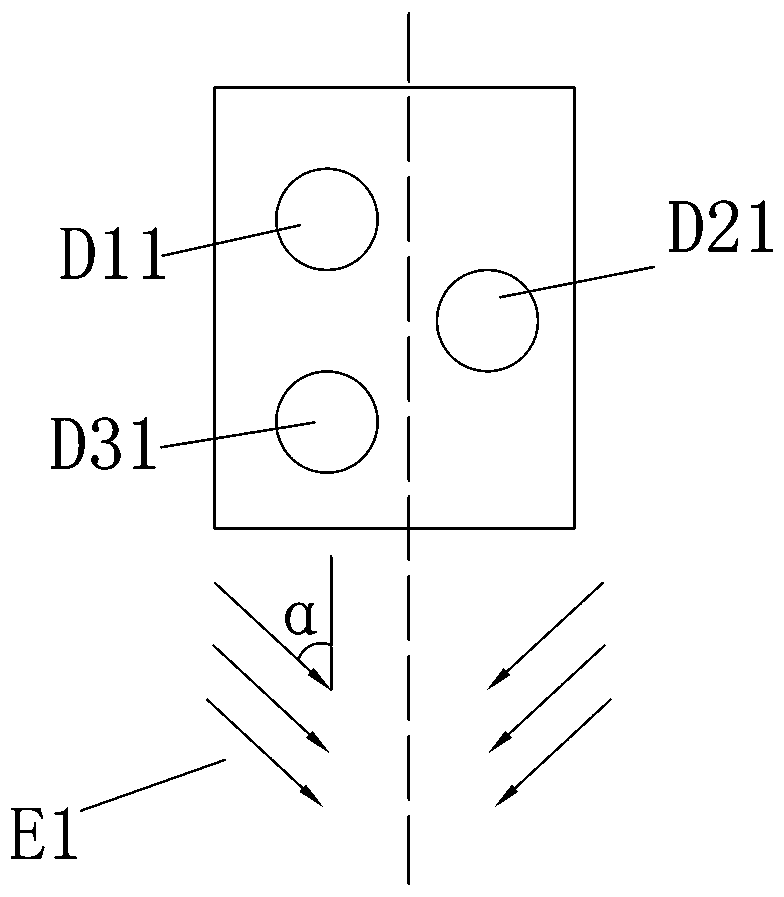

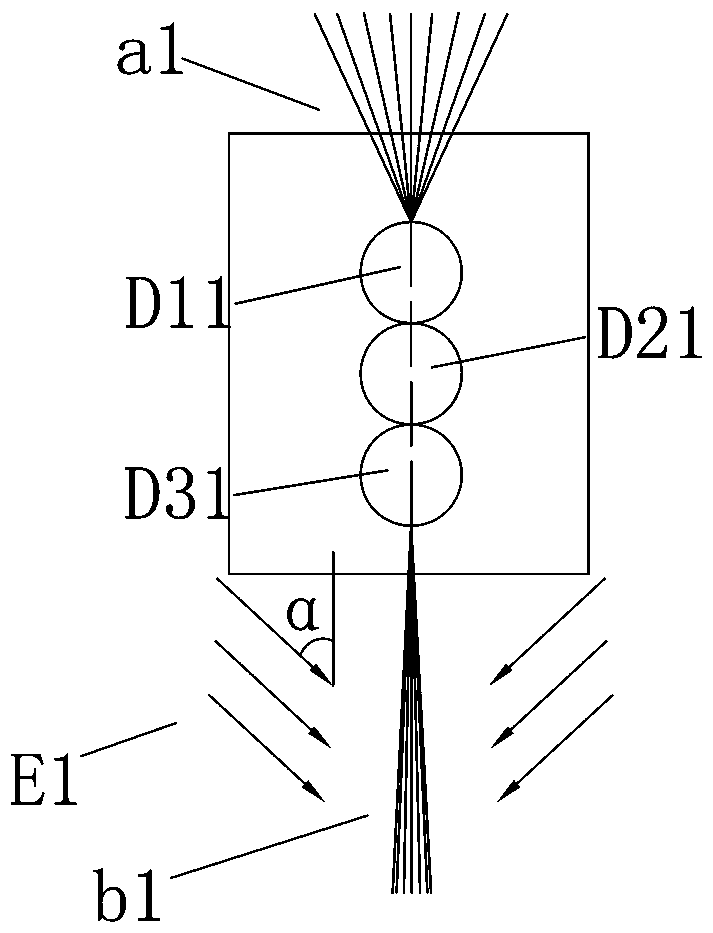

[0065] Such as Figures 1 to 4C Shown, the present invention also discloses a kind of manufacture method of spun-bonded non-woven fabric, comprises the following steps:

[0066] (1) Low-melting-point resin polyethylene and high-melting-point polypropylene resin with a difference of two melting points ≥ 20°C extrude the high-temperature melt through the hot-melt extrusion device A1 and A1' respectively and enter the spinning device B. In device B, the high-temperature melt is turned into a thin stream of melt, and then sprayed out through the spinneret B1 of the spinning device B, and the side-blown cold wind C1 cools the thin stream of the melt to form a thick two-component spunbonded long fiber a1, And the thick two-component spunbond long fiber a1 is two-component sheath-core type spunbond long fiber d, two-component orange segment type spunbond long fiber e or two-component side-by-side spunbond long fiber f; The surface layer d2 of the core type spunbond long fiber is a l...

Embodiment 2

[0072] Such as Figure 5 Shown, the present invention also discloses a kind of manufacture method of spun-bonded non-woven fabric, comprises the following steps:

[0073] (1) Low-melting-point resin polyethylene and high-melting-point polypropylene resin with a difference of two melting points ≥ 20°C extrude the high-temperature melt through the hot-melt extrusion device A2 and A2' respectively and enter the spinning device B. In the device B, the high-temperature melt is changed into a thin stream of the melt, which is then ejected through the spinneret B2 of the spinning device B, and the side-blown cold wind C2 cools the thin stream of the melt to form a woolen bonded long fiber a2, wherein the The spunbond long fiber a2 includes thick bicomponent spunbond long fiber and thick monocomponent spunbond long fiber whose fiber surface is a low-melting point resin.

[0074] (2) The formed spunbond long fibers a2 enter the mechanical drafting device D2 to mechanically stretch the...

Embodiment 3

[0079] Such as Figure 6 Shown, the present invention also discloses a kind of manufacture method of spun-bonded non-woven fabric, comprises the following steps:

[0080] (1) The difference between the two melting points ≥ 20°C. Polyethylene resin and polyester resin extrude high-temperature melts through hot-melt extrusion devices A3 and A3' respectively and enter spinning device B. In spinning device B, the high-temperature The melt becomes a thin stream of melt, and is then ejected through the spinneret B3 of the spinning device B, and the side-blown cold wind C3 is cooled to form a roving bonded long fiber a3, wherein the roving bonded long fiber a3 contains a fiber surface of Thick two-component spunbond long fibers and thick one-component spunbond long fibers of low-melting resins.

[0081] (2) The formed spunbond long fibers a3 enter the mechanical drafting device D3 to mechanically stretch the spunbond long fibers a3 to form spunbond long fibers, which include two-com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com