Pressurized water cosmetic cotton and method for manufacturing the same

A manufacturing method and technology of cosmetic cotton, which is applied in the packaging of cosmetics, cosmetic powder containers, non-woven fabrics, etc., can solve the problems of unsatisfactory texture and softness, unreliable bonding of cotton and wool fibers, and rough product surfaces. Achieve the effect of smooth and soft surface, reduced power consumption, and firm fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: The water-pressing cotton pad involved in this embodiment is composed of an ultra-thin surface layer and an elastic middle layer, the ultra-thin surface layer is dense, soft, and flexible, and the middle layer is elastic; the ultra-thin surface layer covers the surface of the middle layer .

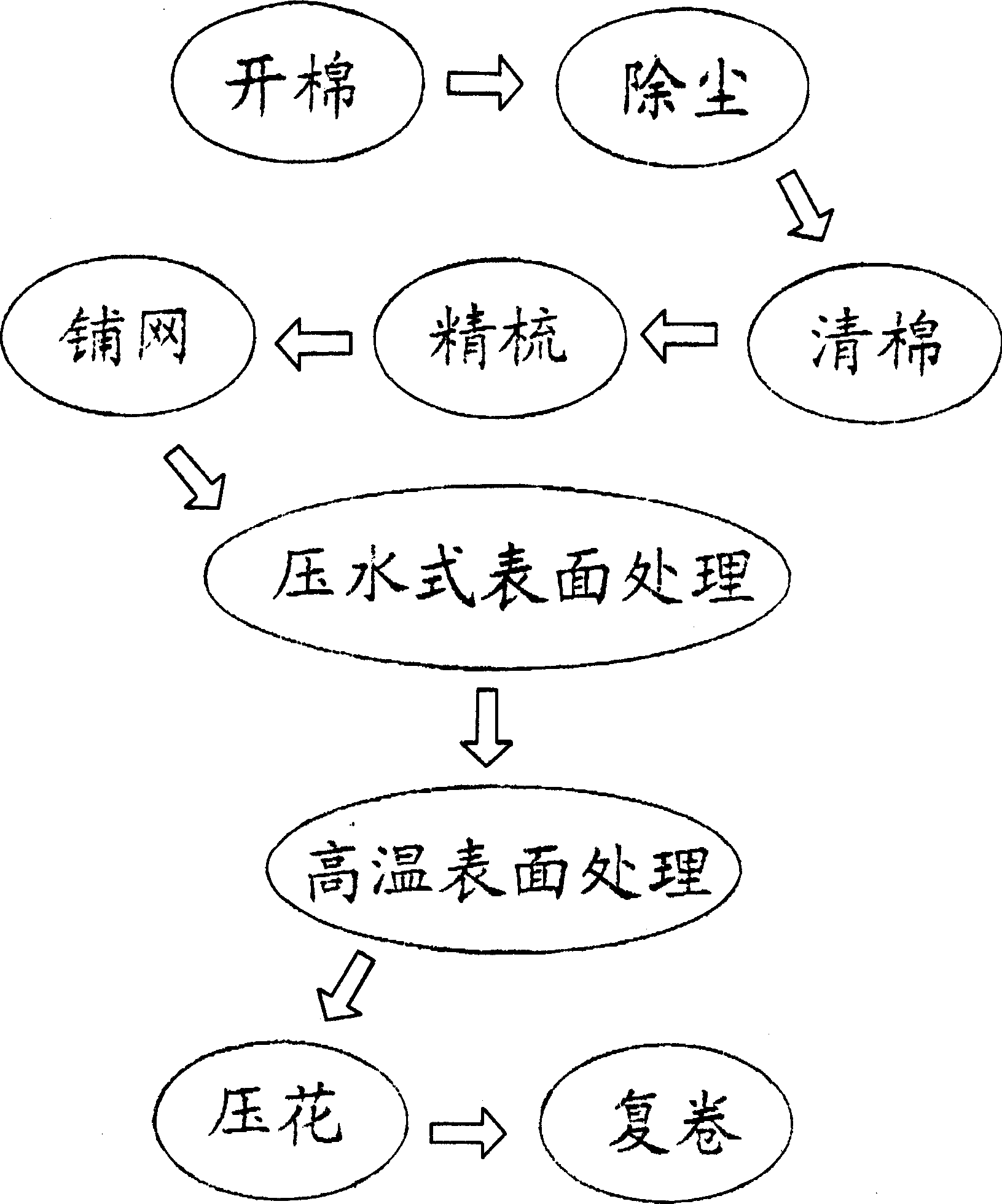

[0025] From figure 1 As can be seen, the technological process of the present embodiment is as follows:

[0026] 1) Open the cotton through the cotton opener;

[0027] 2) Carry out dust removal treatment, cotton cleaning treatment, and remove dust and cotton grains trapped in the cotton;

[0028] 3) Send the dust-removed and sorted cotton to the carding machine for combing, and then enter the web-laying machine to form a cotton thin layer and core layer;

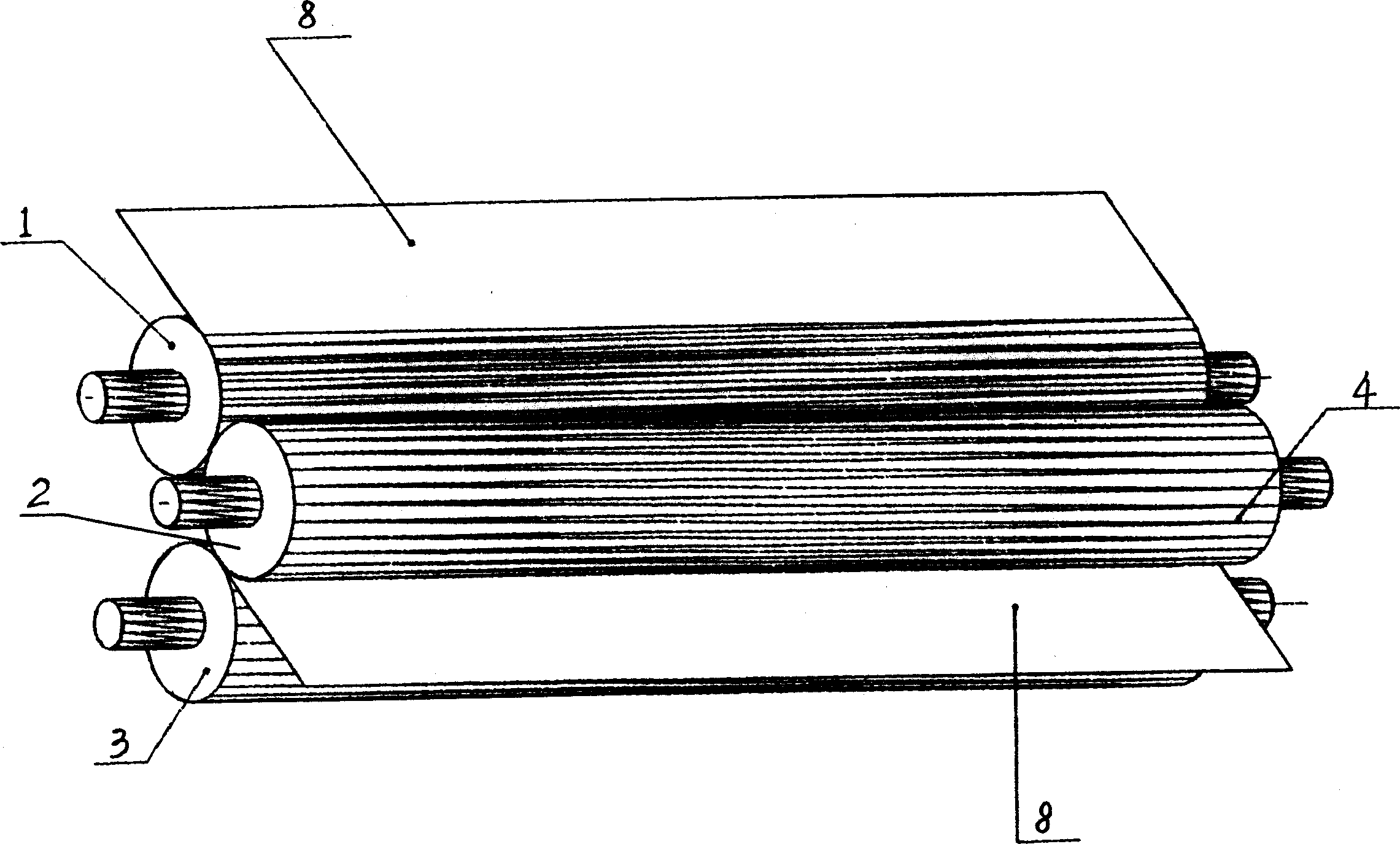

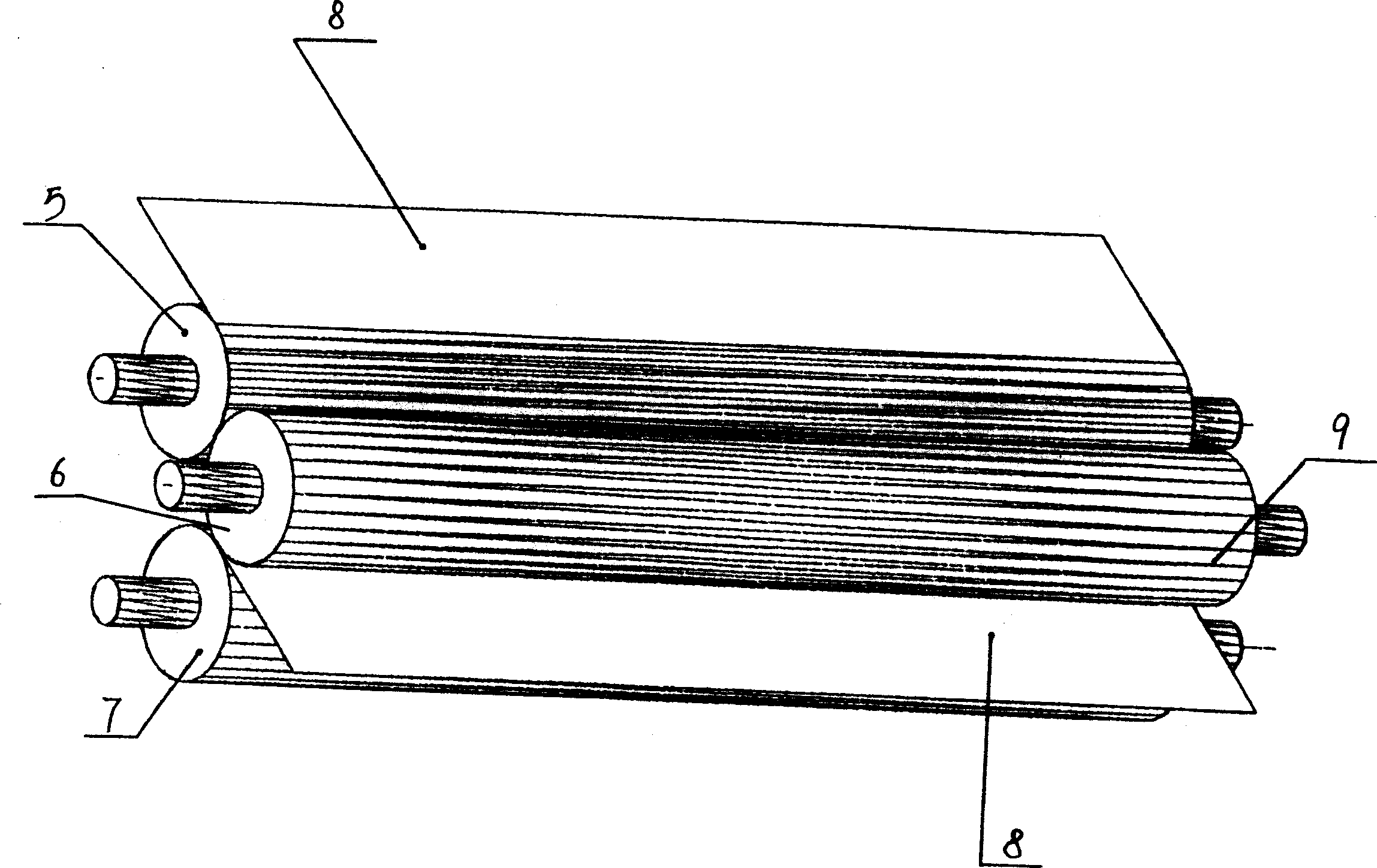

[0029] 4) After the aforementioned thin layer of cotton is sprayed with water, the thin layer of cotton and the core layer of cotton are subjected to water pressure treatment by using a special water pressing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com