Track component of track light

A track light and track technology, which is applied to the components of lighting devices, semiconductor devices of light-emitting elements, lighting and heating equipment, etc., can solve problems such as unstable contact of electrodes and wires, and achieve a safe and firm conductive structure, simple and convenient installation, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

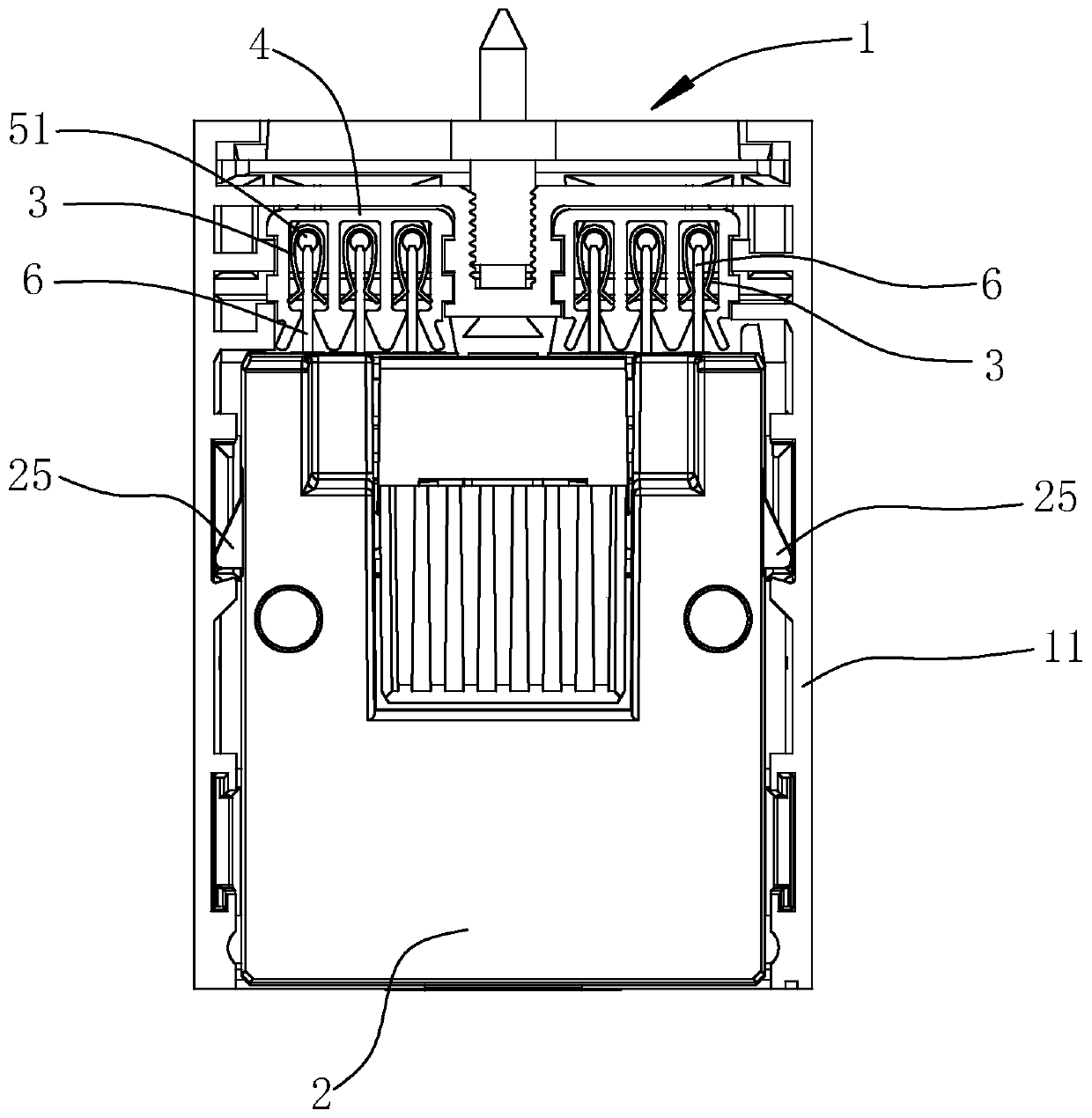

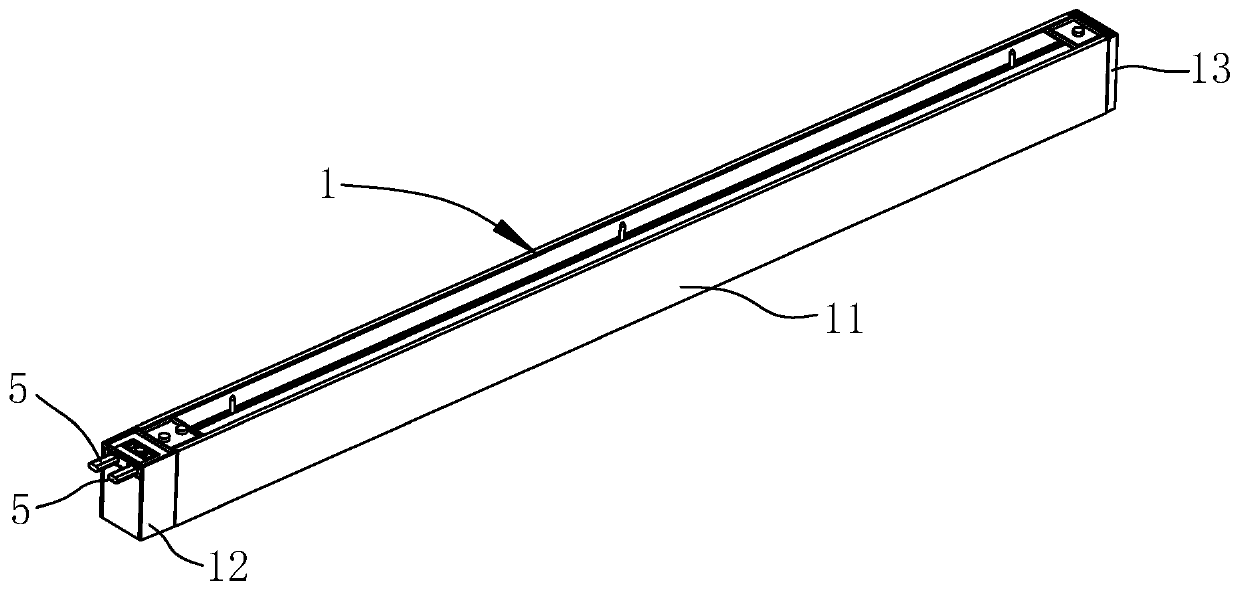

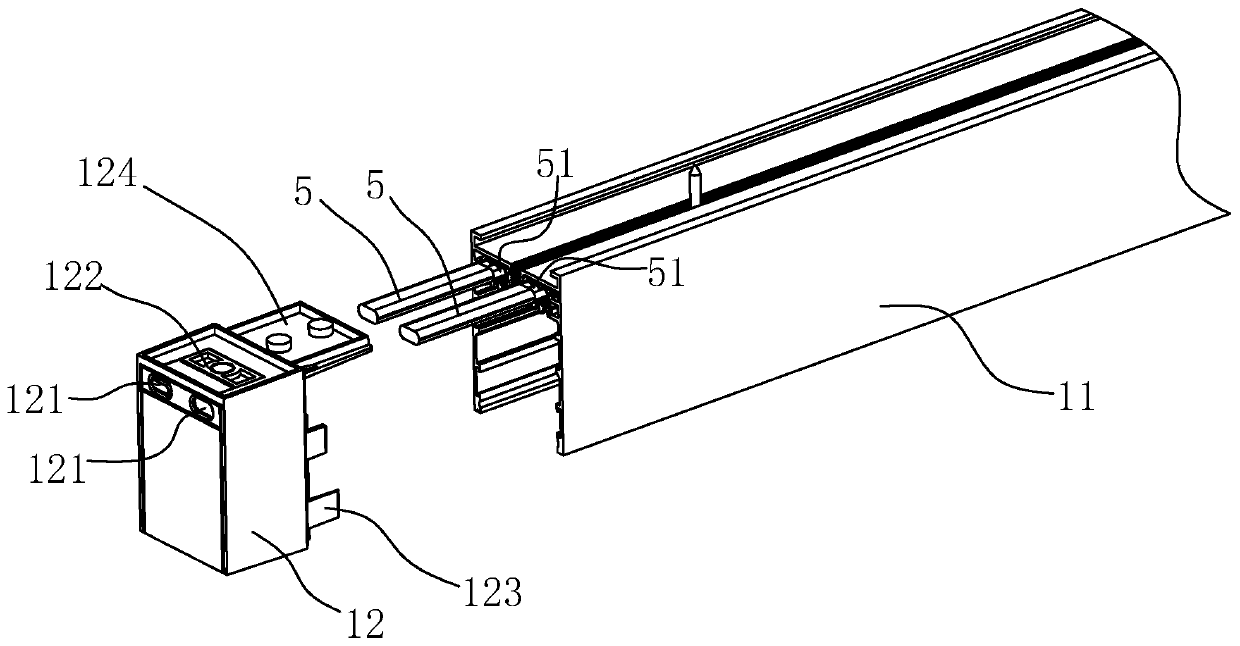

[0027] The solution of this application is further described in conjunction with the drawings as follows:

[0028] See attached Figure 1-8 , A track assembly of a track light, comprising a track bar 1 and a track box 2. The track bar 1 includes a profile body 11 in the shape of a trough, and a first end cover 12 and a second end cover 13 at both ends of the profile body 11. The notch of the profile main body 1 faces downwards, and six copper bars 3 are arranged inside the top. The main body of the copper bar 3 is arc-shaped with an inner diameter gradually narrowing from top to bottom. It has an inner cavity and an elastic opening 31 at the bottom. , The edge of the elastic opening 31 is provided with a folded edge 32 that is turned outward. The overall cross section of the copper strip 3 is in the shape of a clamp. Before installation, the elastic opening 31 is in an elastic closed state. The top of the track box 2 is provided with an electrode insert 6, and the electrode i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com