Floating connector

A floating connector and connector technology, which is applied in the direction of connection, two-part connection device, and parts of the connection device, can solve the problems of increased resistance, poor workability, and difficulty in absorbing deviation, and achieves absorption of relative position deviation, The effect of strong self-reliance and simple manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] specific implementation

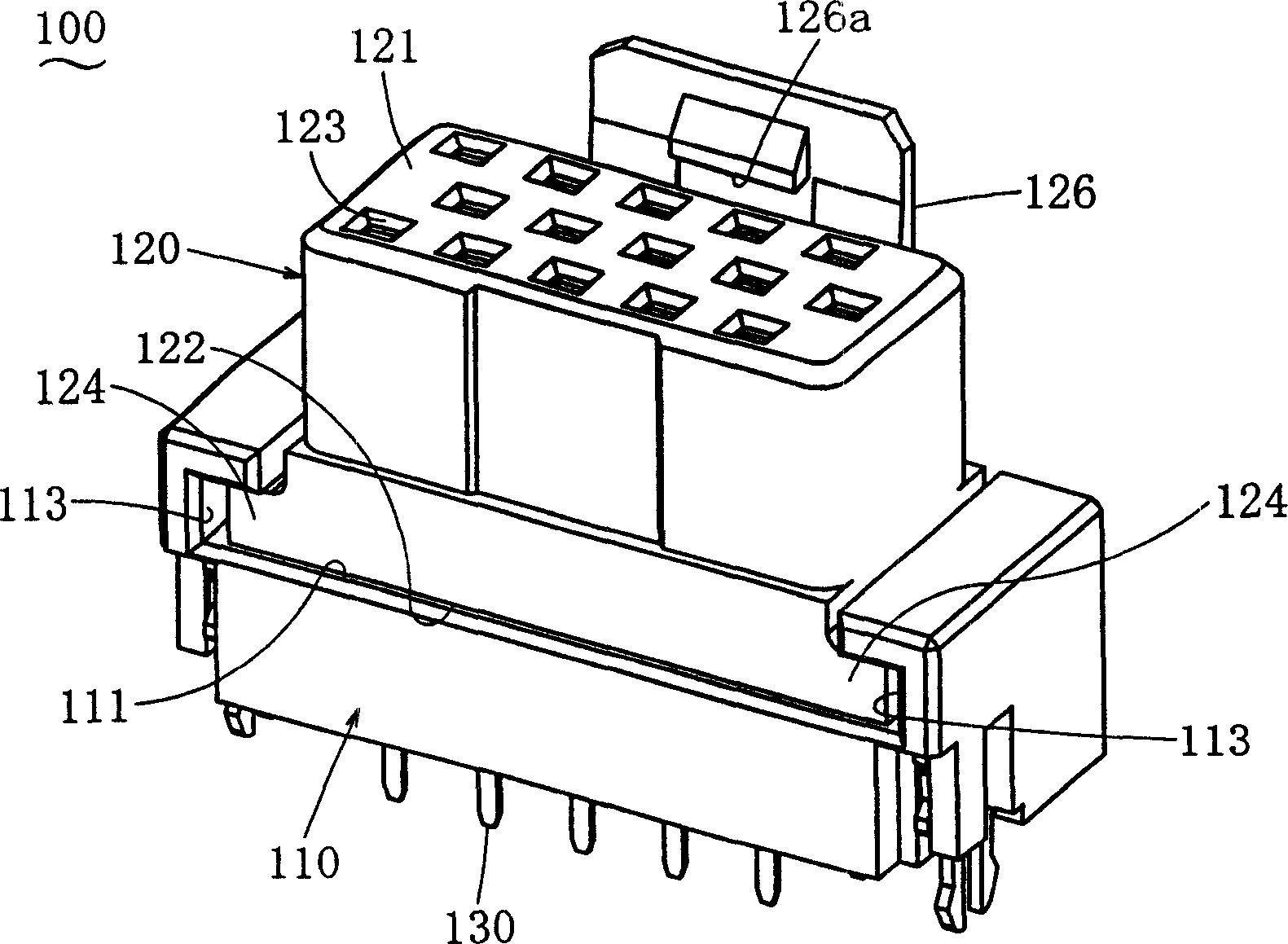

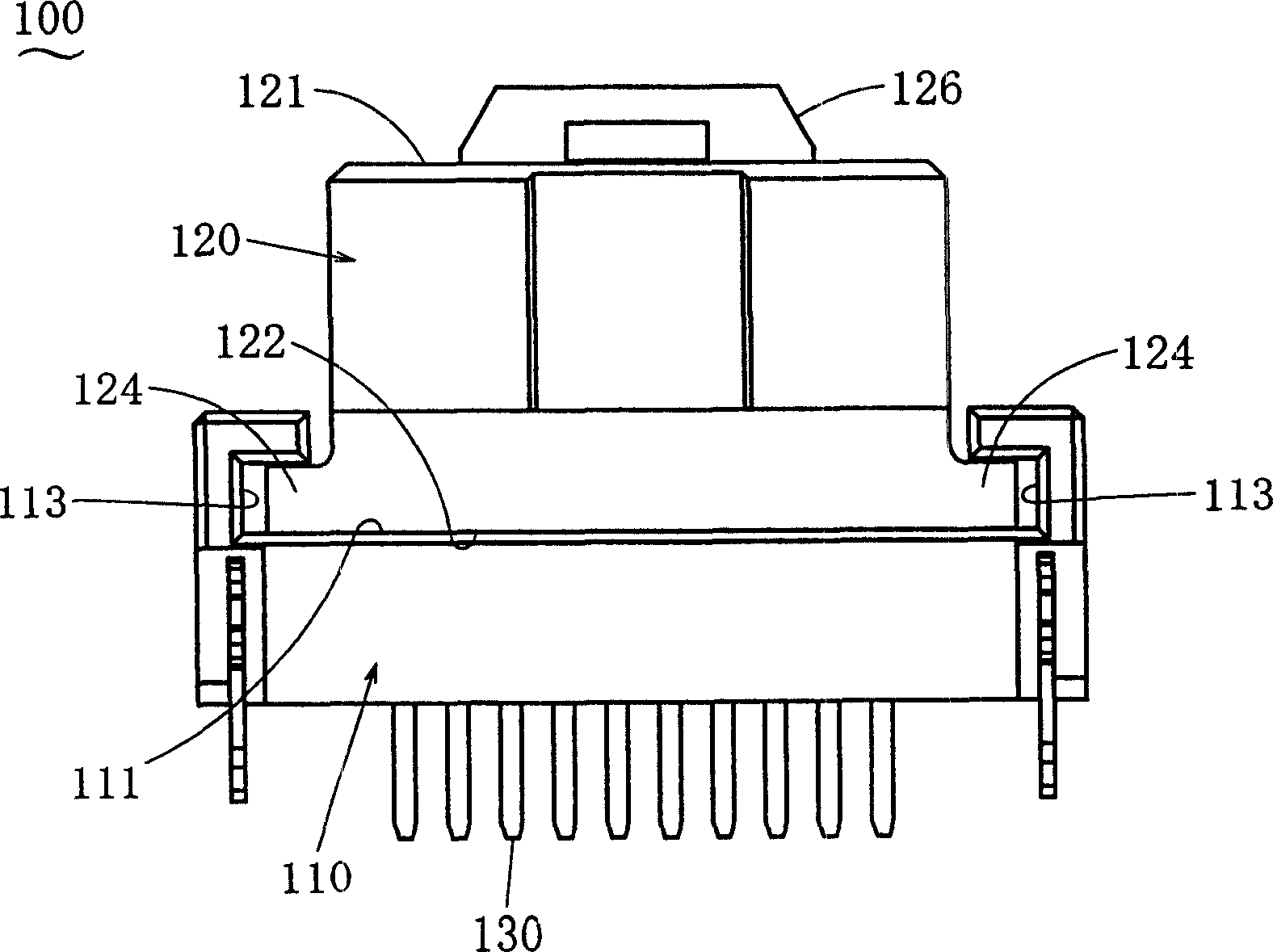

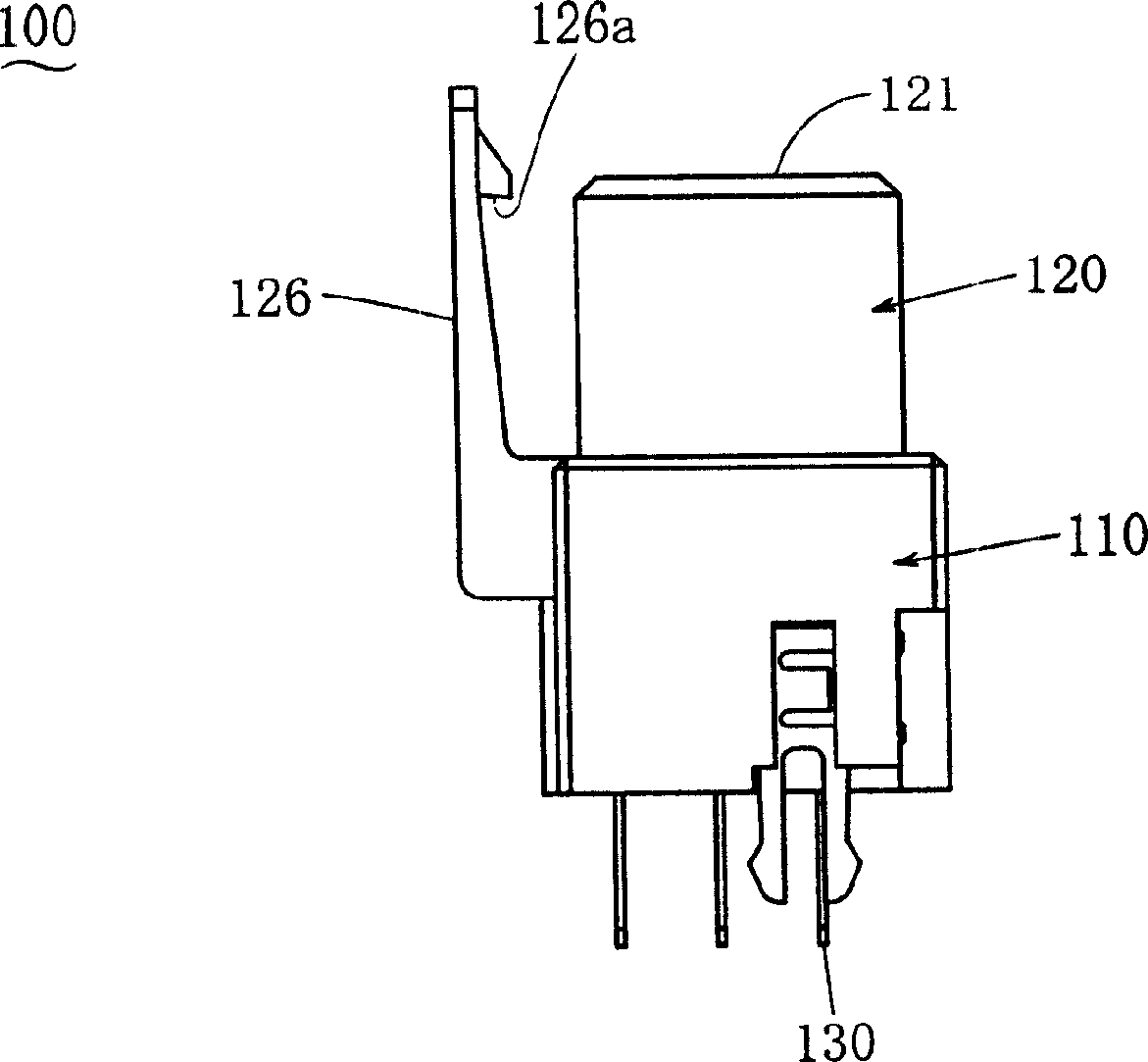

[0034] Embodiments of the present invention will be described below. Figure 1 to Figure 7 A floating connector 100 in an embodiment of the invention is shown. The floating connector 100 with Figure 11 and Figure 12 The opposite side connector 200 is shown mated or unplugged from the opposite side connector 200 . Fitting and extraction are performed along the height direction. The floating connector 100 of this embodiment has the convex portion 121 which is fitted by being fitted into the concave portion 211 of the opposite-side connector 200 , but this relationship is also possible in reverse. In addition, the floating connector 100 of this embodiment has a female contact (female contact) 130 by fitting with a male contact (male contact) 220 of the connector 200 on the opposite side. To achieve the connection, and this relationship is also possible in reverse. The description will be given using the mutually orthogonal depth direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com