High-precision RV speed reducer comprehensive testing device

A comprehensive testing and reducer technology, applied in the direction of measuring devices, testing of machine/structural components, testing of mechanical components, etc., can solve the problem of decreased accuracy, low accuracy of assembly process, failure to obtain backlash, backlash and torsion Rigidity and other issues to achieve the effect of simplifying assembly, assembly and disassembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

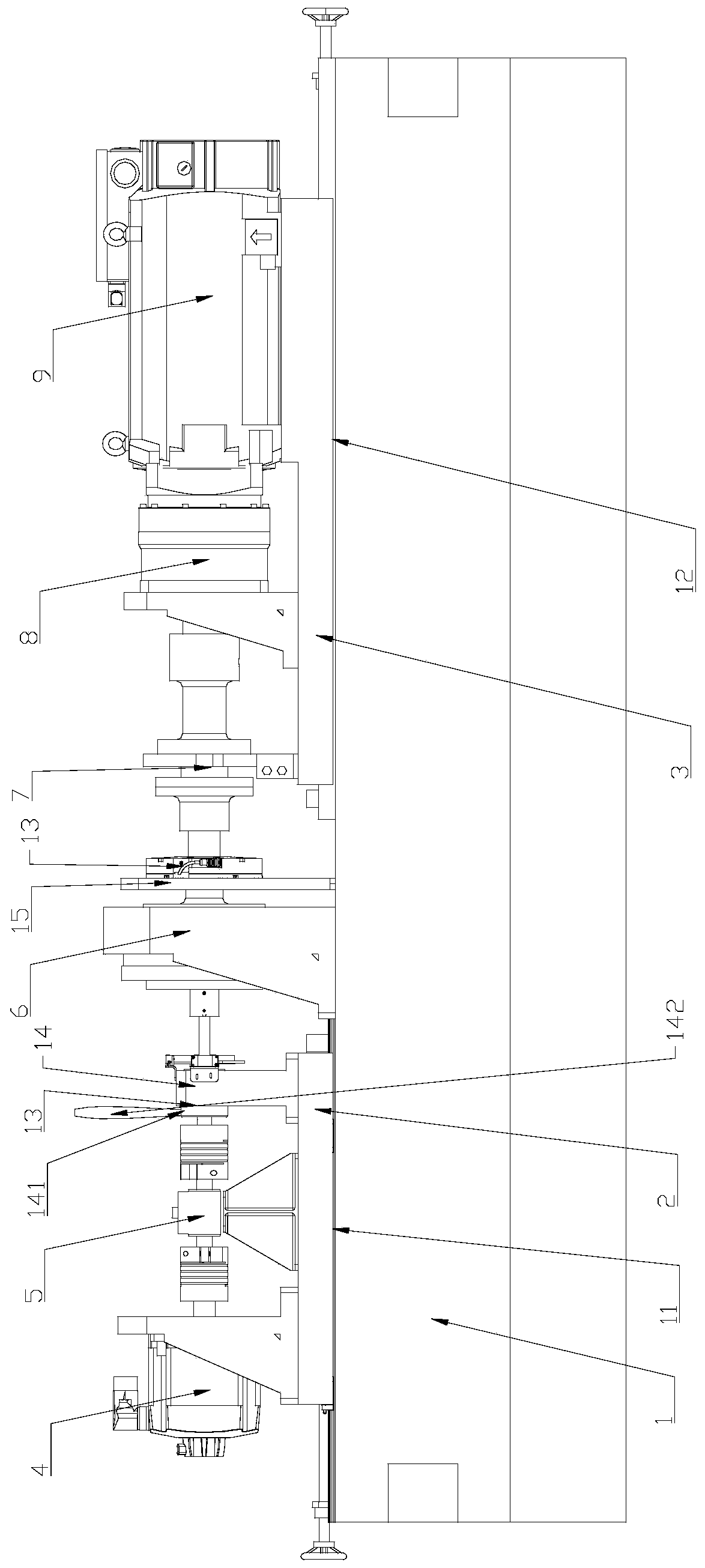

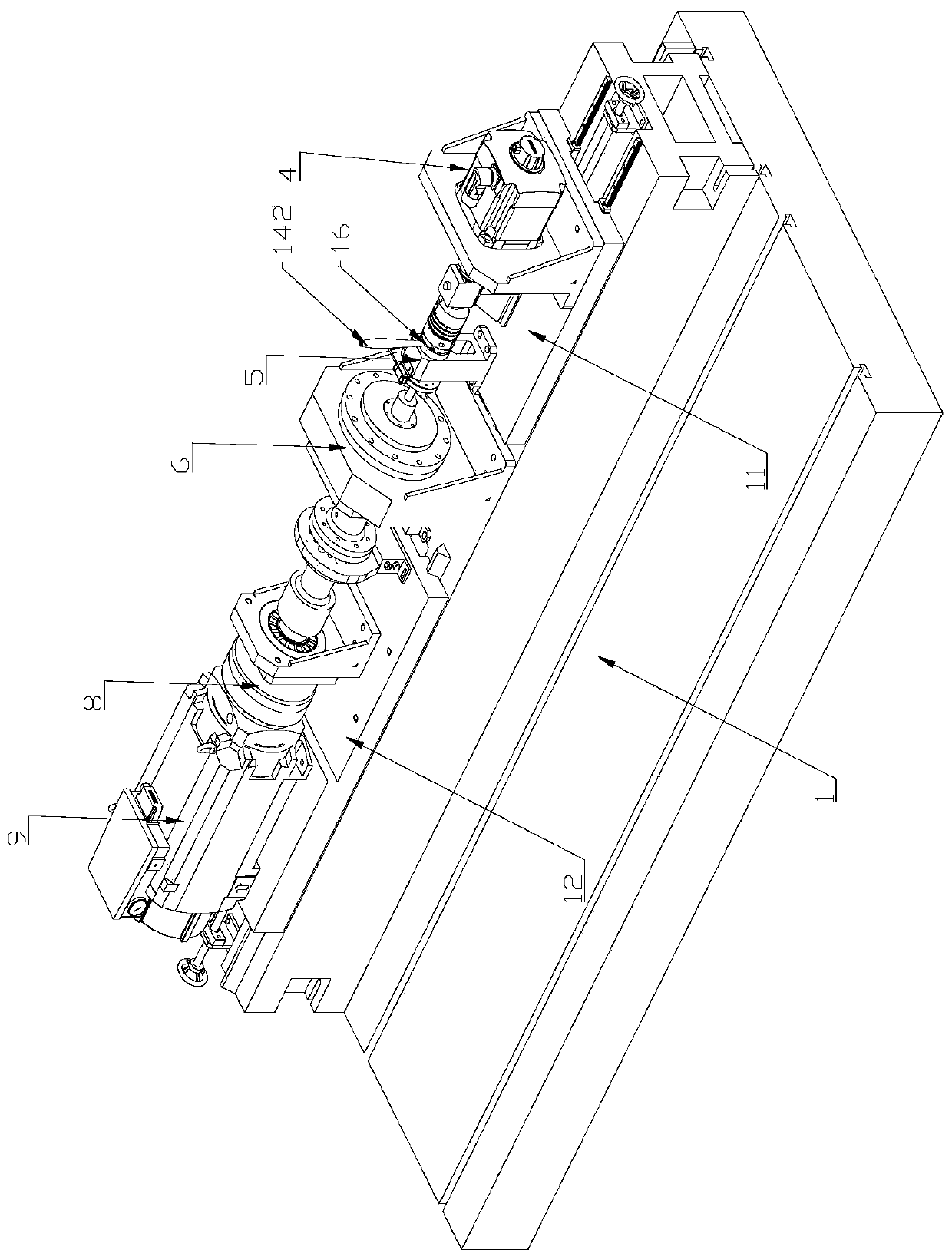

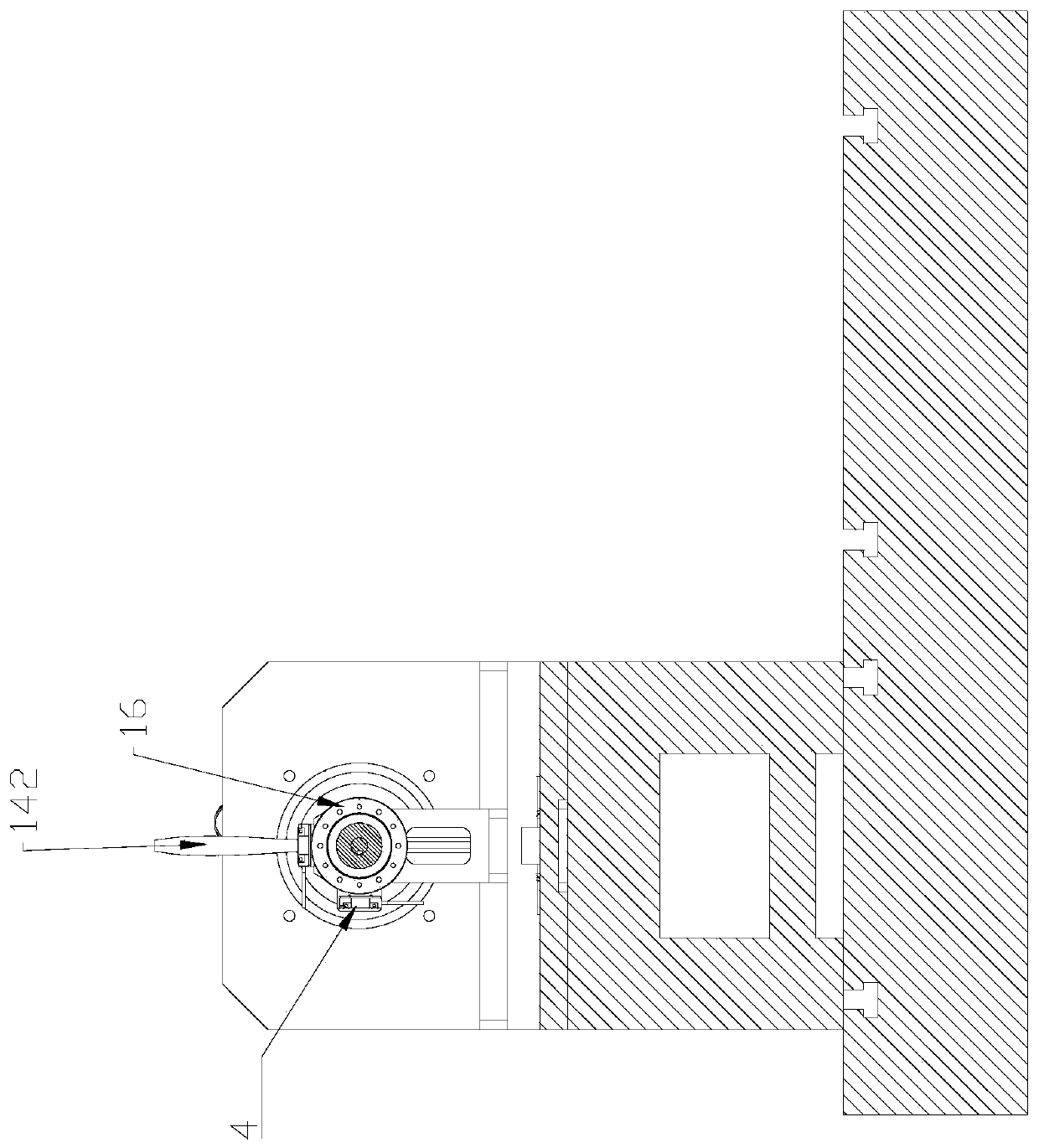

[0046] The high-precision RV reducer comprehensive test device in the present invention includes the following parts:

[0047] Part 1 of the base: a first slide rail 11 and a second slide rail 12 are arranged on it. The first sliding platform 2 is arranged on the first linear slide rail 11, and can be linearly displaced along the first linear slide rail 11; the second sliding platform 3 is arranged on the second linear slide rail 12, and can move along the second straight line The slide rail 12 is linearly displaced, and the RV speed reducer 6 to be tested is arranged between the first sliding platform 2 and the second sliding platform 3 . Both ends of the base 1 are respectively provided with a shaft rod assembly, which realizes the horizontal position adjustment of the first sliding platform 2 and the second sliding platform 3 respectively, and its rod is provided with an external thread, which is compatible with the first sliding platform 2 and the second sliding platform. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com