Bridge wet joint cast-in-place concrete automatic vibration compacting device

A technology of vibratory compaction and wet joints, which is applied in the direction of bridge construction, bridge erection/assembly of bridges, etc. It can solve the problems of inability to ensure the compactness of concrete, holes in concrete, and inability to vibrate concrete, so as to achieve stable work and low labor intensity. Small, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

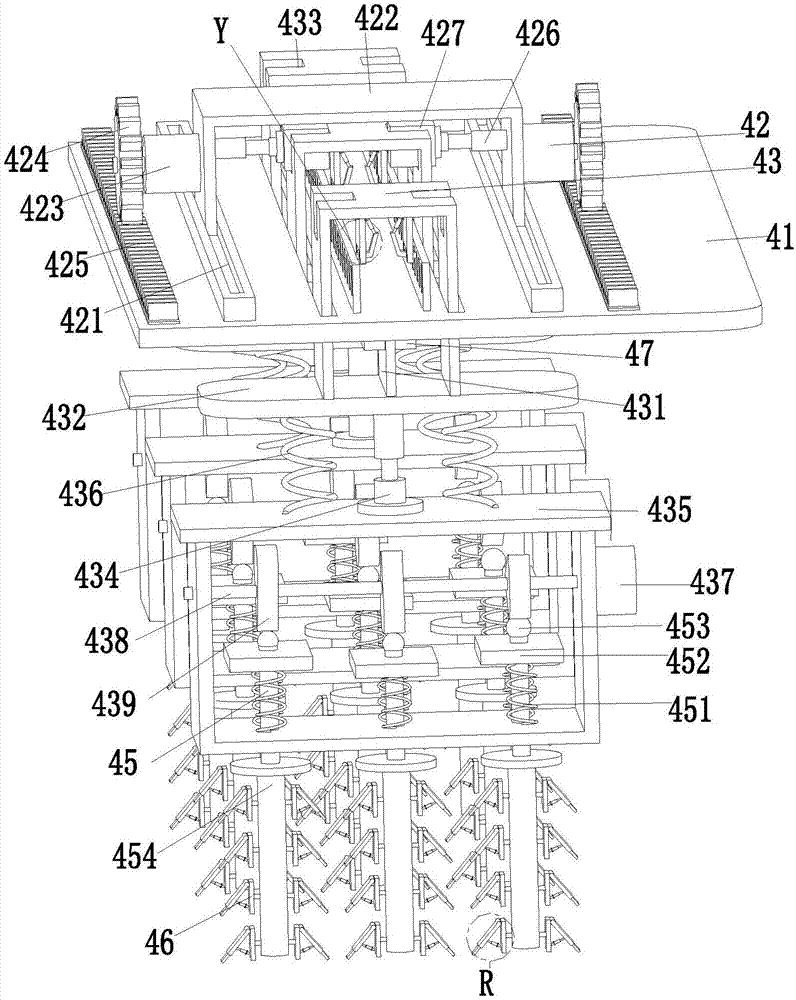

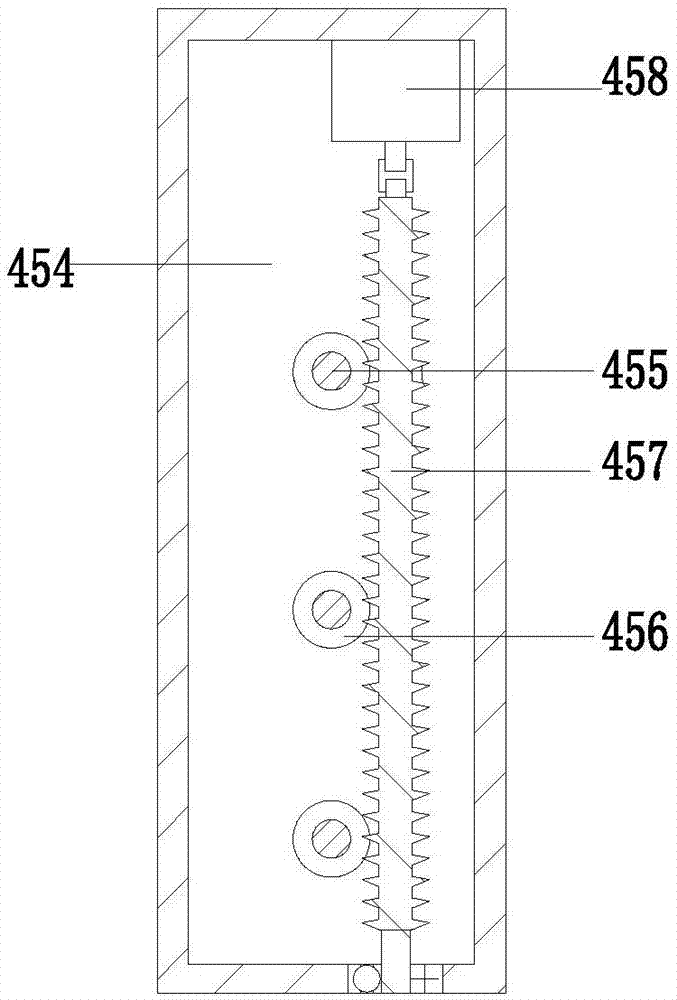

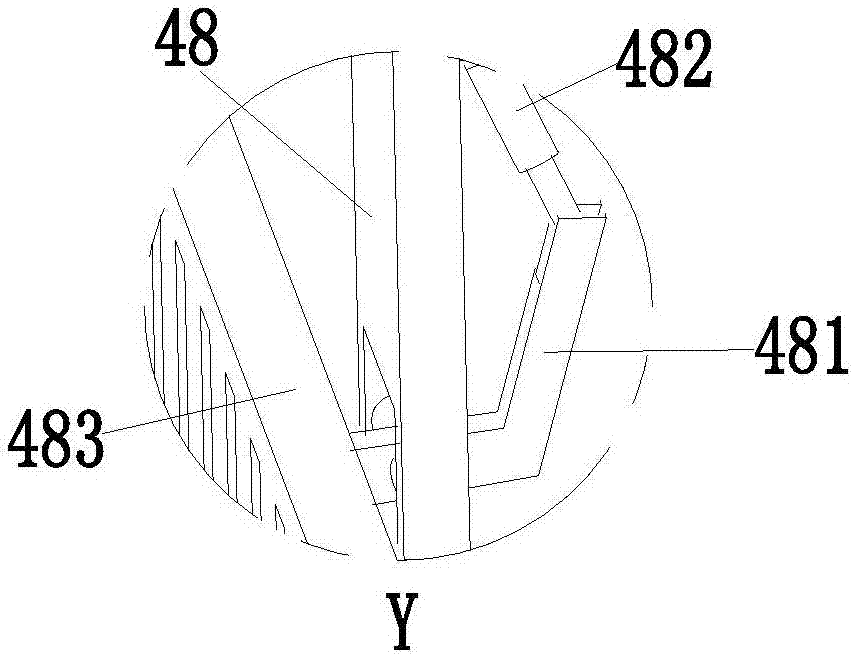

[0020] Such as Figure 1 to Figure 4 As shown, a bridge wet joint cast-in-place concrete automatic vibration compaction equipment includes a vibration support frame 41, a vibration movement mechanism 42 is arranged on the vibration support frame 41, a vibration movement groove is arranged on the vibration support frame 41, and the vibration support frame The lower end of 41 is equipped with a vibration support groove 47, and the vibration displacement mechanism 43 is arranged at equal intervals from left to right in the vibration support groove 47 through a sliding fit mode. The mechanism 42 drives the vibration-displacement mechanism 43 to make appropriate adjustments, which eliminates the need for manual vibratory compaction operations with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com