Extremely temperature sensitive halogen-free and low smoke flame retardant plastic alloy for cables and preparation method thereof

A low-smoke flame-retardant, plastic alloy technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of unsatisfactory mechanical properties of materials, poor thermal deformation properties of materials at high temperature, and high manufacturing costs, and achieves a large amount of glue, The effect of good fluidity and good thermal deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

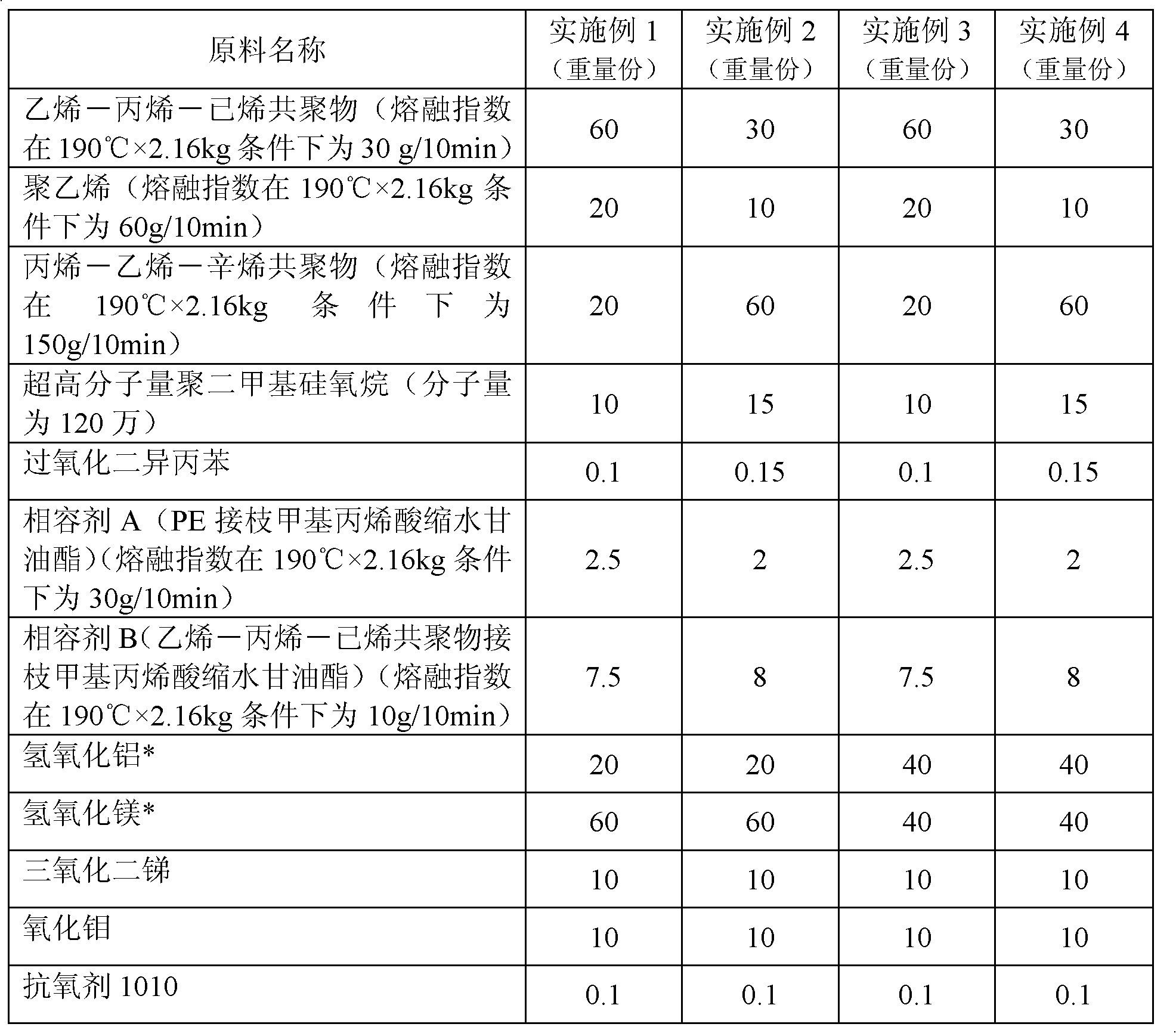

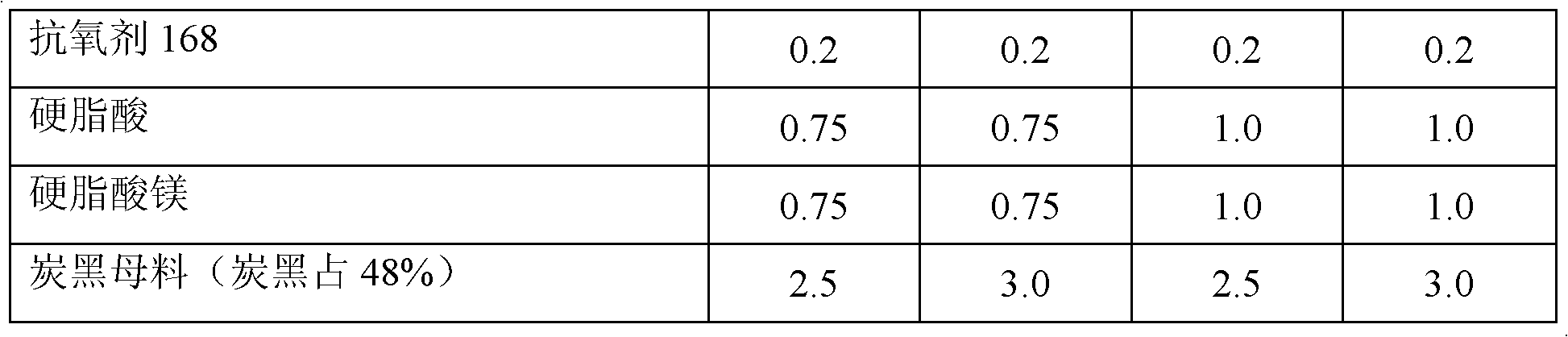

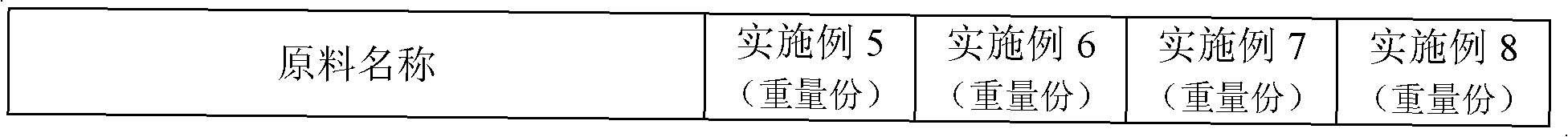

Embodiment 1

[0044] The raw materials of halogen-free plastic alloys for cables that are extremely sensitive to temperature are: ethylene-propylene-hexene copolymer, polyethylene, propylene-ethylene-octene copolymer, ultra-high molecular weight polydimethylsiloxane, dimethicone peroxide Cumene, compatibilizers, inorganic flame retardants, flame retardant synergists, smoke suppressants, antioxidants, processing lubricants and UV-resistant masterbatches. Its specific formula is shown in Table 1, and the performance of the obtained halogen-free plastic alloy for cables which is extremely sensitive to temperature is shown in Table 2.

[0045] Its preparation method is as follows: (1) After fully mixing ultra-high molecular weight polydimethylsiloxane in an internal mixer at 130°C, adding dicumyl peroxide and mixing for 2 minutes; (2) mixing other The raw material components are mixed evenly through a high-speed mixer (rotating speed: 400-800rpm) according to the proportion; (3) the mixed mater...

Embodiment 2

[0047] The raw materials of halogen-free plastic alloys for cables that are extremely sensitive to temperature are: ethylene-propylene-hexene copolymer, polyethylene, propylene-ethylene-octene copolymer, ultra-high molecular weight polydimethylsiloxane, dimethicone peroxide Cumene, compatibilizers, inorganic flame retardants, flame retardant synergists, smoke suppressants, antioxidants, processing lubricants and UV-resistant masterbatches. Its specific formula is shown in Table 1, and the performance of the obtained halogen-free plastic alloy for cables which is extremely sensitive to temperature is shown in Table 2.

[0048] Its preparation method is identical with embodiment 1.

Embodiment 3

[0050] The raw materials of halogen-free plastic alloys for cables that are extremely sensitive to temperature are: ethylene-propylene-hexene copolymer, polyethylene, propylene-ethylene-octene copolymer, ultra-high molecular weight polydimethylsiloxane, dimethicone peroxide Cumene, compatibilizers, inorganic flame retardants, flame retardant synergists, smoke suppressants, antioxidants, processing lubricants and UV-resistant masterbatches. Its specific formula is shown in Table 1, and the performance of the obtained halogen-free plastic alloy for cables which is extremely sensitive to temperature is shown in Table 2.

[0051] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com