Disclosed is method for producing composition for heavy-duty forklift tire

A technology for forklift tires and manufacturing methods, applied in the field of polyurethane materials, can solve problems such as hardness, strength and modulus performance decline, and achieve the effects of improving heat resistance, improving uniform dispersion, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

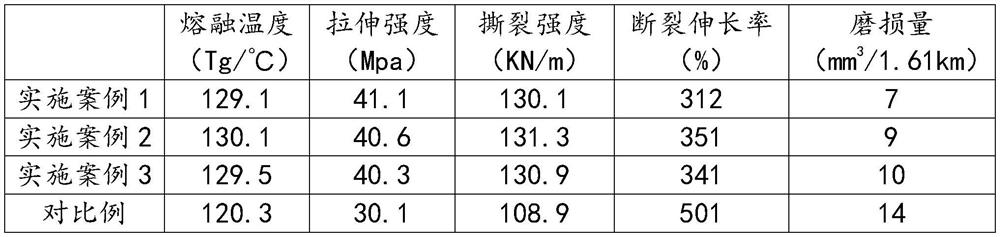

Examples

Embodiment example 1

[0024] A composition for heavy-duty forklift tires, made of the following raw materials in parts by weight: 30 parts of polyether polyol, 70 parts of polyester polyol, 15 parts of isocyanate, 5 parts of 3,5-diethyltoluenediamine, three 1 part of methylolpropane, 4 parts of modified graphene oxide, 0.1 part of dibutyltin dilaurate, 0.1 part of polysiloxane-oxyalkylene block copolymer, 3 parts of water;

[0025] The manufacture of the composition for heavy-duty forklift truck tires consists of the following steps:

[0026] Step S1: polyether polyol, polyester polyol, isocyanate, 3,5-diethyltoluenediamine, trimethylolpropane, dibutyltin dilaurate, polysiloxane-oxyalkylene block copolymer 1. Water is added to the mixer, the temperature is 25°C, and the stirring speed is 4000r / min. Stir for 15s. The functionality of polyether polyol is 2, the number average molecular weight is 2000, and the functionality of polyester polyol is 3. , the number average molecular weight is 5500, and ...

Embodiment example 2

[0034] A composition for heavy-duty forklift tires, made of the following raw materials in parts by weight: 35 parts of polyether polyol, 65 parts of polyester polyol, 10 parts of isocyanate, 6 parts of 3,5-diethyltoluenediamine, three 2 parts of methylolpropane, 6 parts of modified graphene oxide, 0.3 part of dibutyltin dilaurate, 0.2 part of polysiloxane-oxyalkylene block copolymer, 4 parts of water;

[0035] The manufacture of the composition for heavy-duty forklift truck tires consists of the following steps:

[0036] Step S1: polyether polyol, polyester polyol, isocyanate, 3,5-diethyltoluenediamine, trimethylolpropane, dibutyltin dilaurate, polysiloxane-oxyalkylene block copolymer 1. Water is added to the mixer, the temperature is 25°C, and the stirring speed is 4000r / min. Stir for 15s. The functionality of polyether polyol is 2, the number average molecular weight is 2000, and the functionality of polyester polyol is 3. , the number average molecular weight is 5500, and...

Embodiment example 3

[0044] A composition for heavy-duty forklift tires, made of the following raw materials in parts by weight: 40 parts of polyether polyol, 60 parts of polyester polyol, 15 parts of isocyanate, 10 parts of 3,5-diethyltoluenediamine, three 3 parts of methylolpropane, 9 parts of modified graphene, 0.5 part of dibutyltin dilaurate, 0.3 part of polysiloxane-oxyalkylene block copolymer, 6 parts of water;

[0045] The manufacture of the composition for heavy-duty forklift truck tires consists of the following steps:

[0046] Step S1: polyether polyol, polyester polyol, isocyanate, 3,5-diethyltoluenediamine, trimethylolpropane, dibutyltin dilaurate, polysiloxane-oxyalkylene block copolymer 1. Water is added to the mixer, the temperature is 25°C, and the stirring speed is 4000r / min. Stir for 15s. The functionality of polyether polyol is 2, the number average molecular weight is 2000, and the functionality of polyester polyol is 3. , the number average molecular weight is 5500, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com