Patents

Literature

40results about How to "High heat deformation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic silica gel packaging material of large-power LED and preparation method thereof

InactiveCN101717584AHigh heat deformation resistanceReasonable distribution of cross-linking pointsSemiconductor devicesPtru catalystOptical transmittance

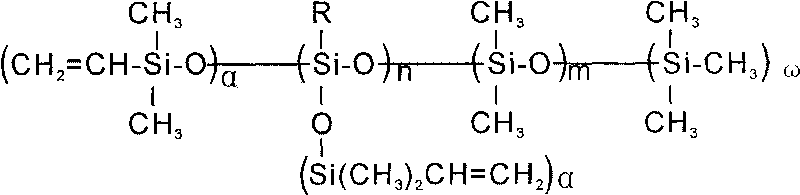

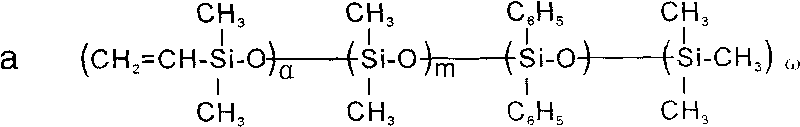

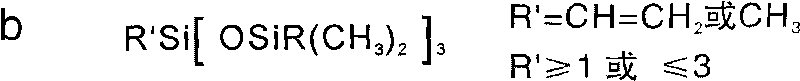

The invention relates to organic silica gel for packaging a large-power LED and a preparation method thereof. The gel is prepared by mixing a component A of vinyl-contained polysiloxane, a silicon resin component B, a component C of hydrogen-contained polymethylsiloxane, a platinum catalyst component D, a catalytic inhibiting agent component E and a thickening agent component F, and the obtained packaging gel with different refractive rates of 1.4 grade, 1.5 grade, and the like is used for packaging various types of large-power LEDs or is used as other optical purposes. By adopting the component B as a filling material, the invention solves the problems of temperature resistance, color change, light transmittance and needle penetration reduction of the large-power LED product, can be made into two packaging types of a single component and double components, improves the adaptability on packaging equipment and the manufacture procedure and the efficiency, reduces the cost and is convenient for use.

Owner:陈俊光

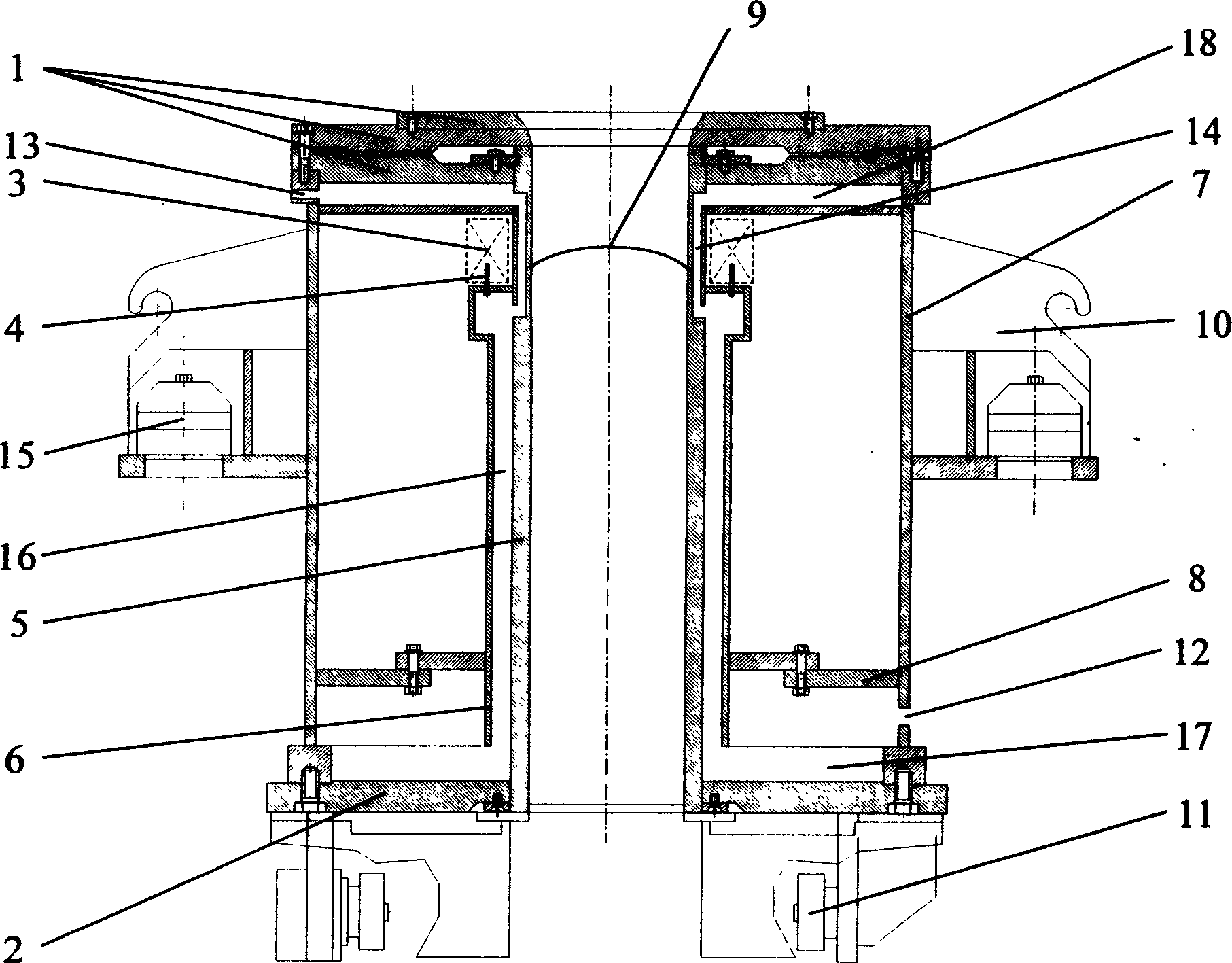

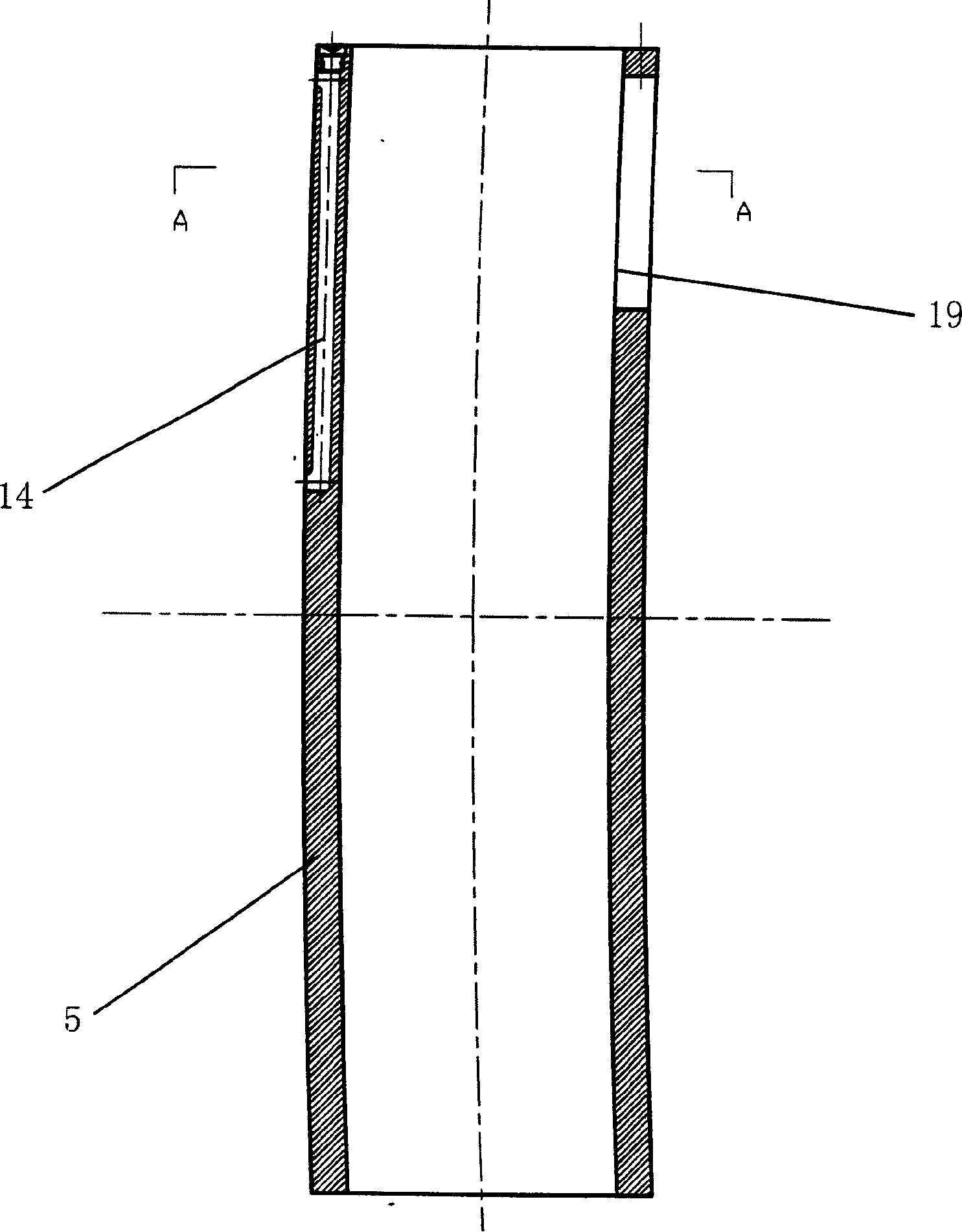

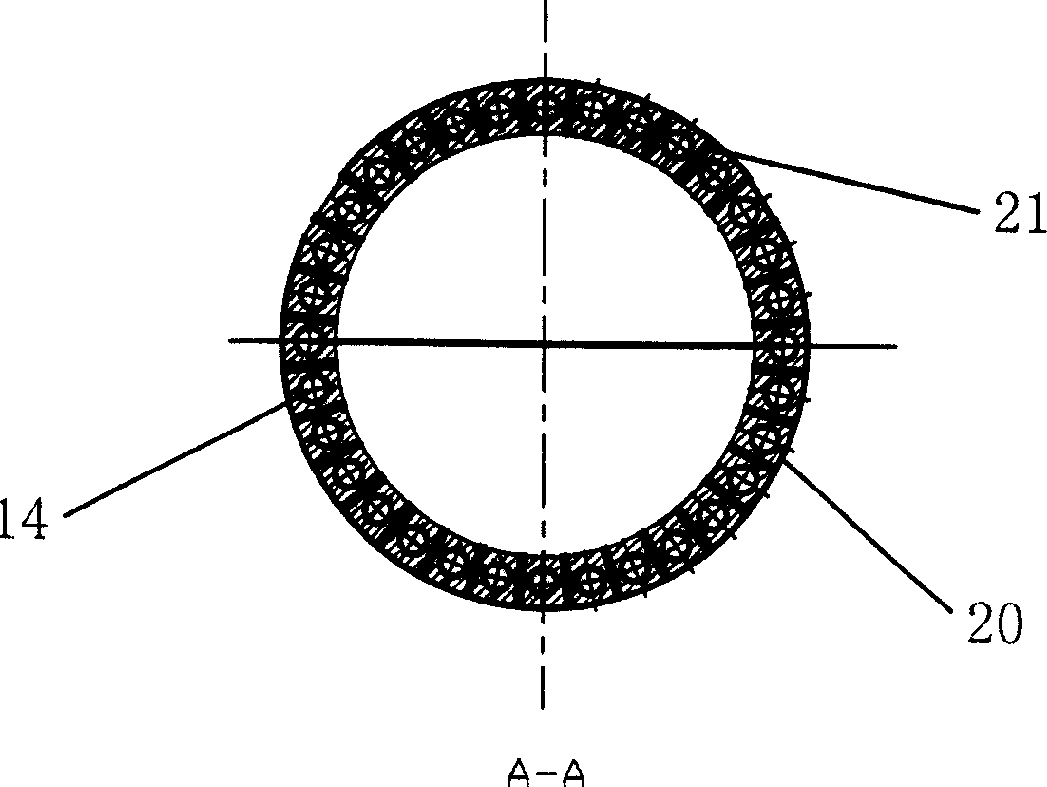

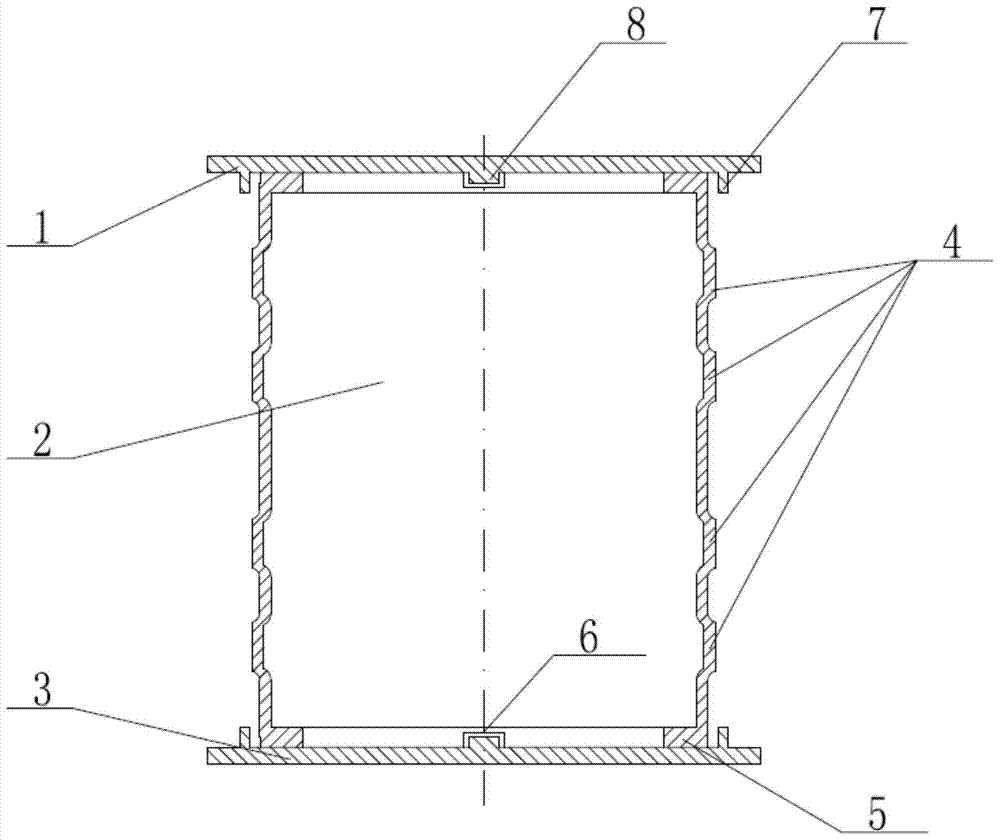

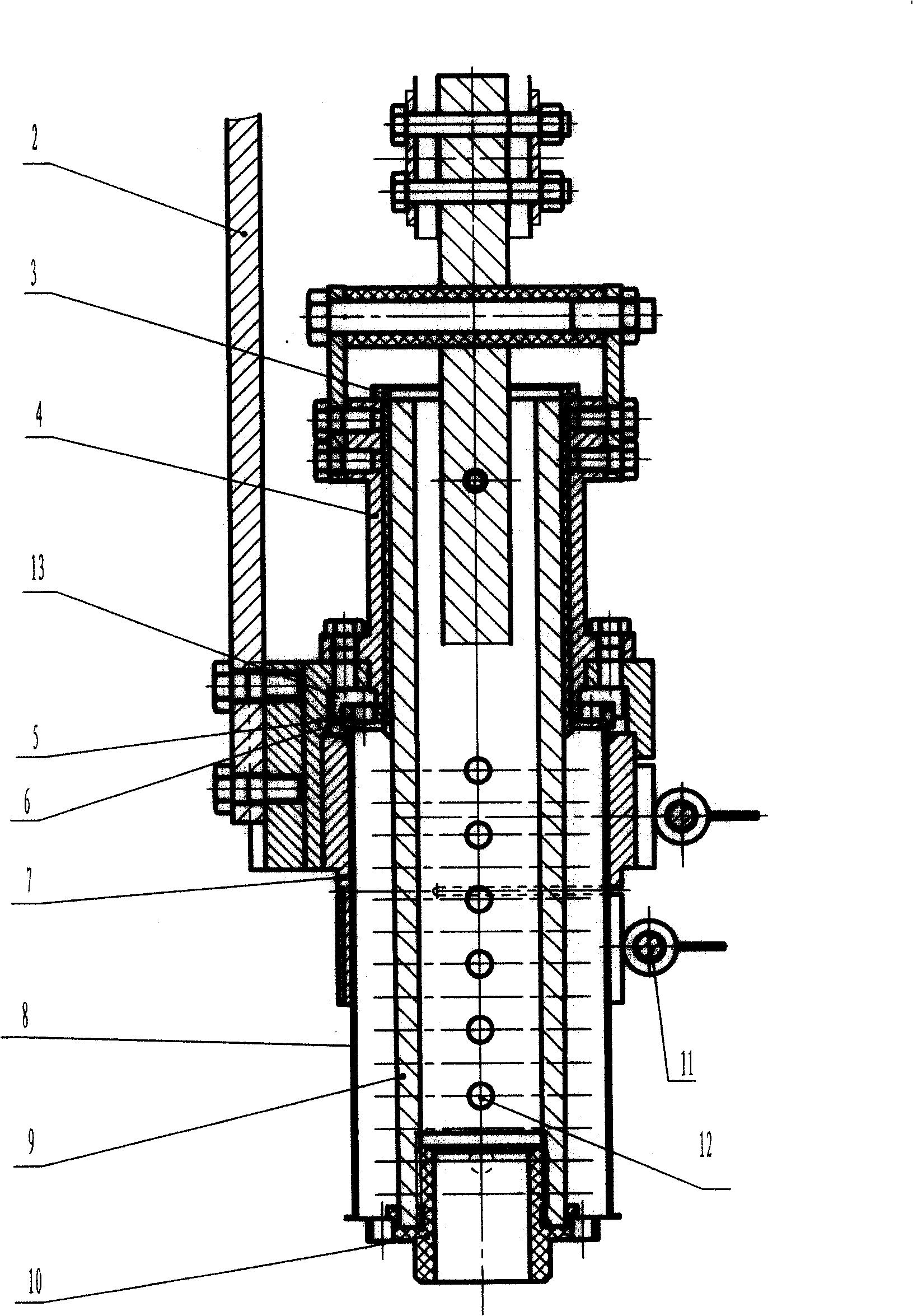

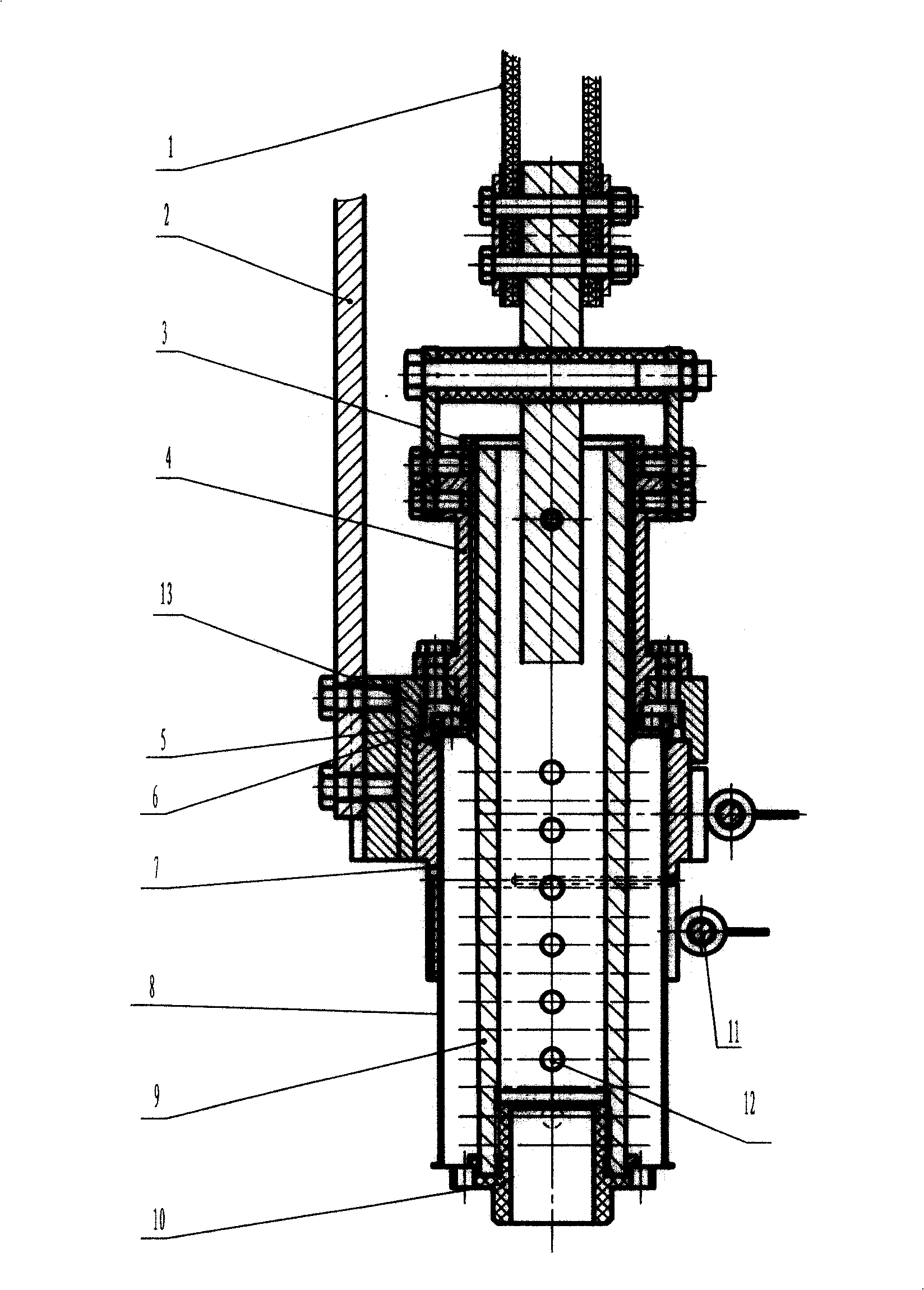

Water seam-split body internal water cooling type flexible contact electromagnetic continuous casting crystallizer

A water cooled electromagnetic crystallizer for conticasting is composed of upper and lower flanges, coil, sleeve pipe of crystallizer, cooling water jacket, cooling water tube, connection part and lifting gear. It features that the upper part of said sleeve pipe has local slit structure, the cooling water tube is arranged in split body and a water seam structure is formed between the lower part of said sleeve pipe and cooling water jacket.

Owner:NORTHEASTERN UNIV

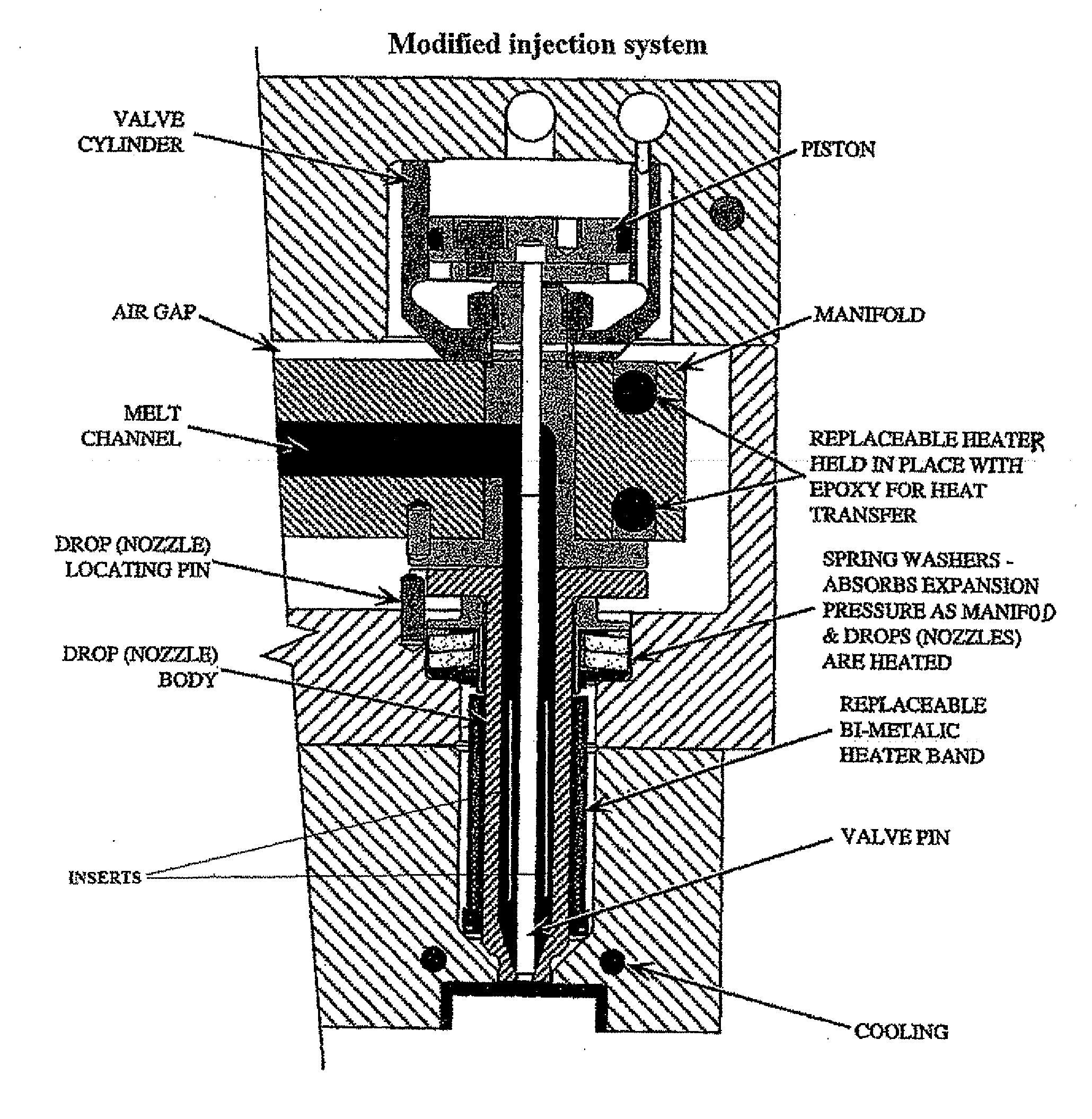

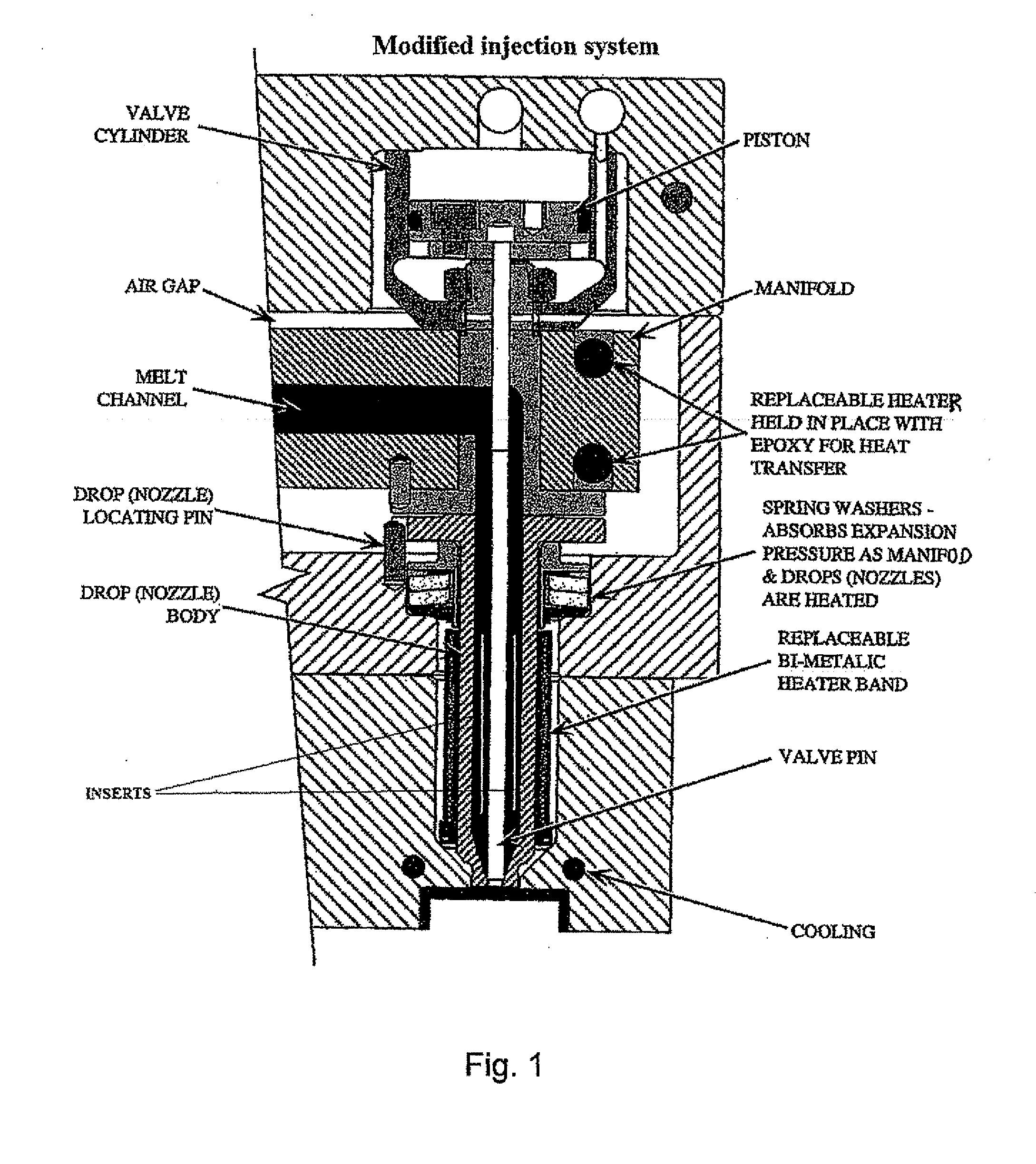

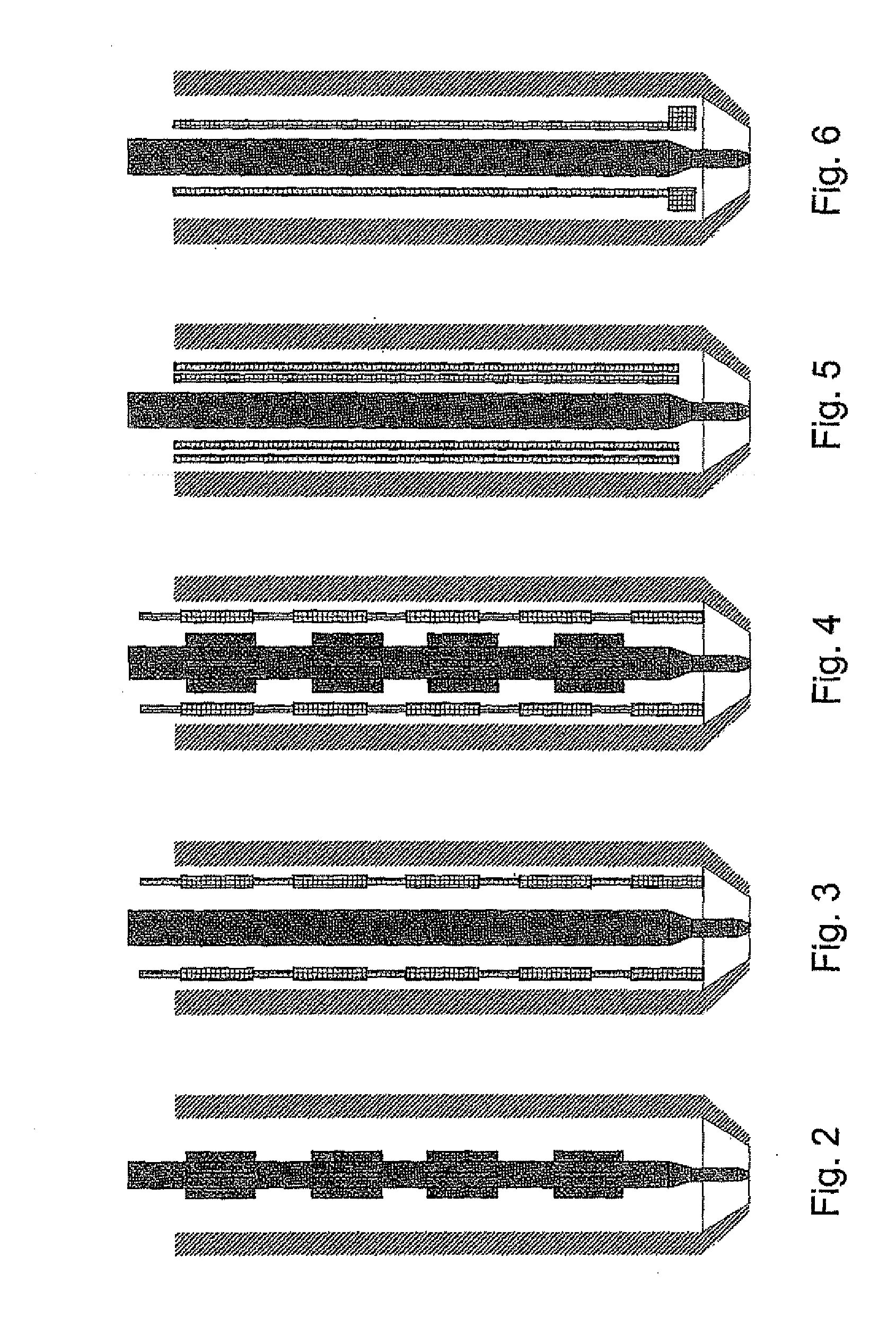

Modified hot runner systems for injection blow molding

ActiveUS20130029067A1Optimize wall thicknessImproved performance characteristicsSynthetic resin layered productsThin material handlingBlow moldingHot runner

An injection blow molding method for making a container having the steps of injecting a molten crystallizable polymer in a preform mold via a hot runner system and biaxially stretching the preform by blowing to form a container. The method further having the step to selectively modify the flow path of the molten crystallizable polymer within the hot runner system.

Owner:KEIRYO PACKAGING

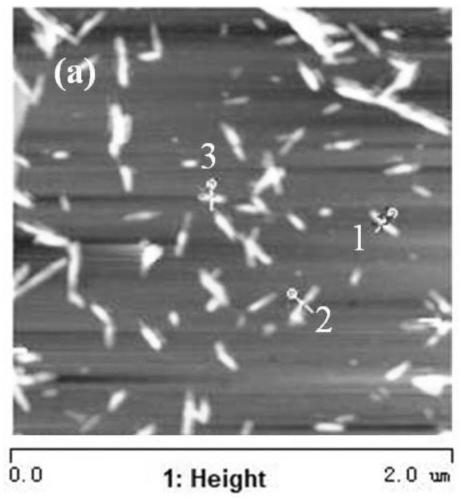

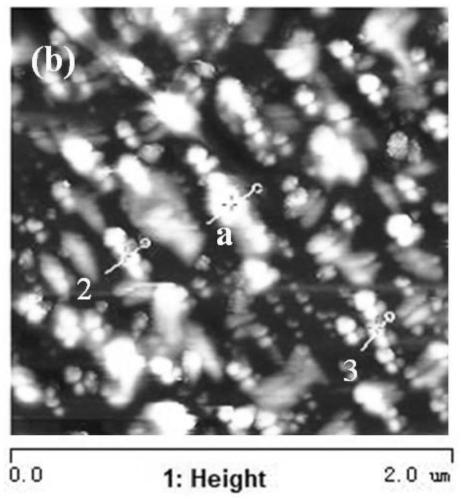

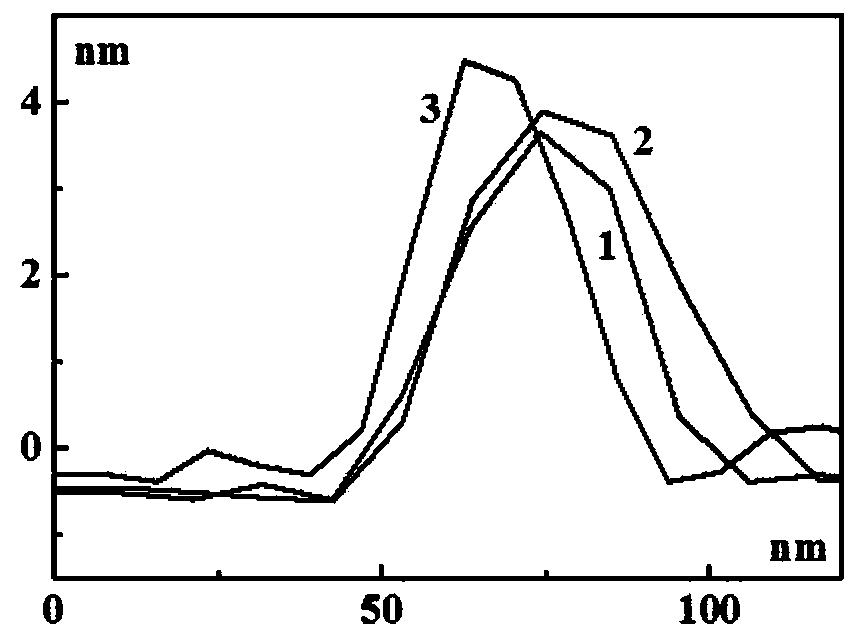

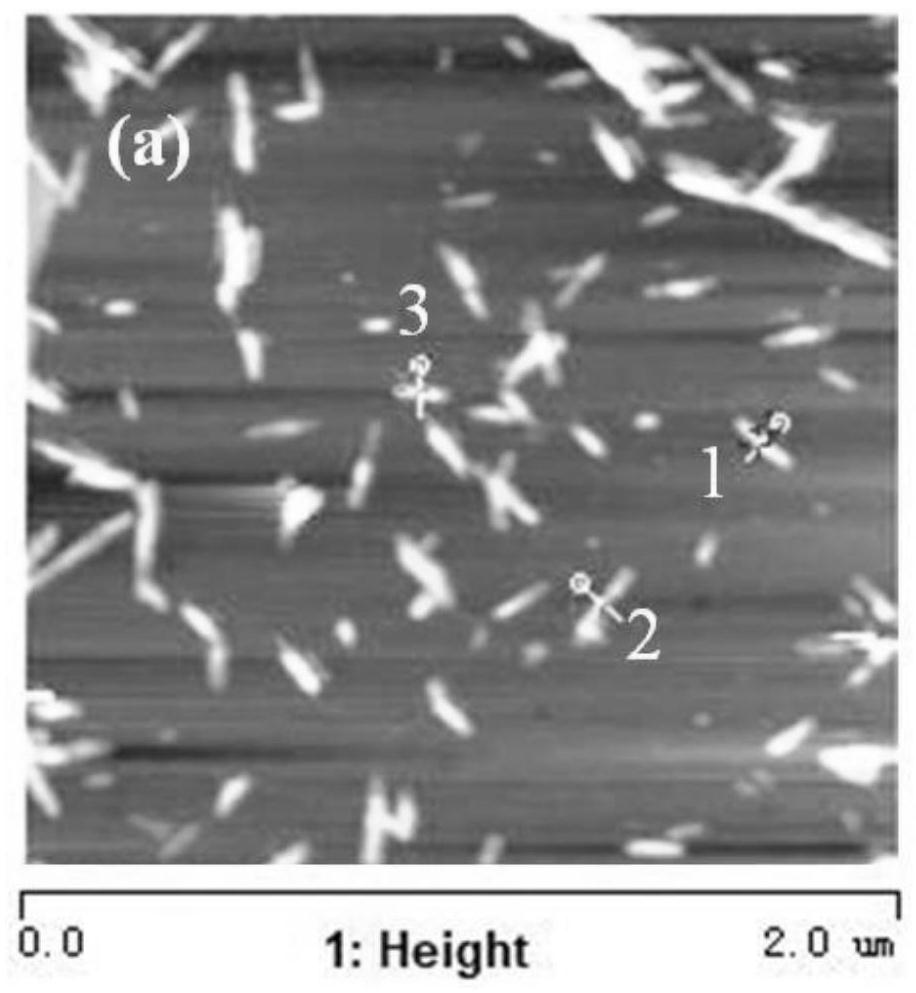

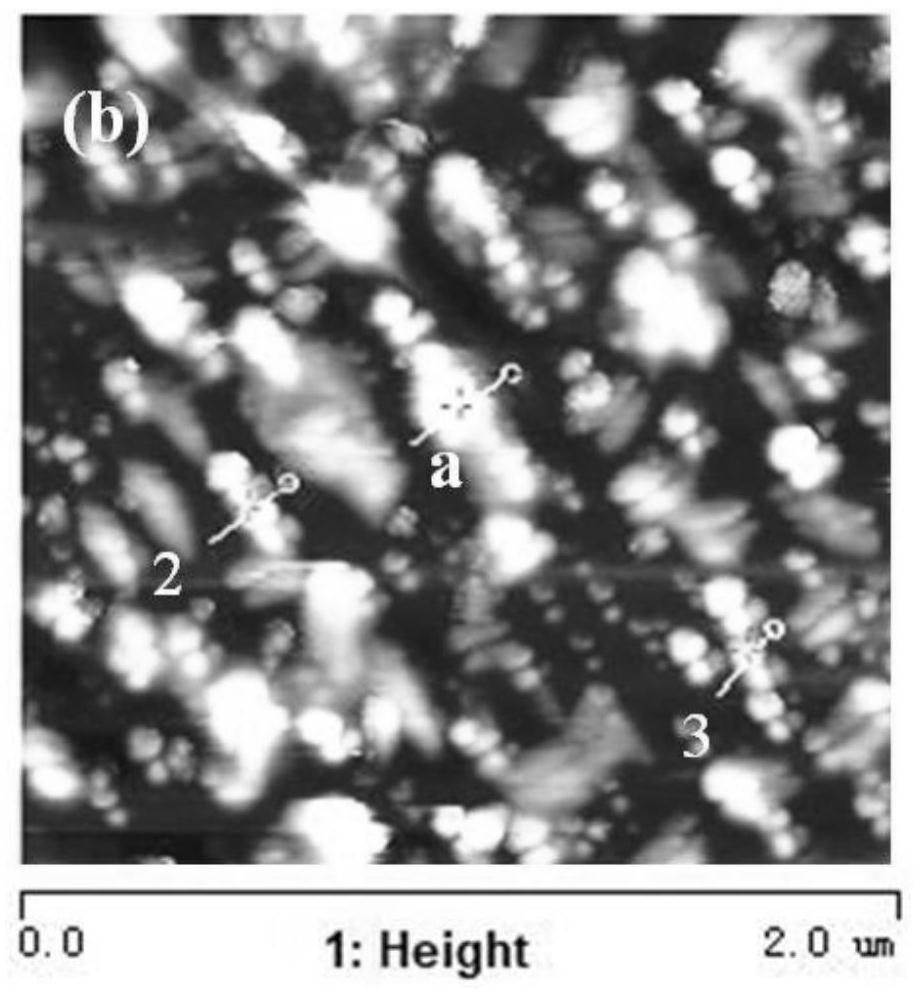

Polylactic acid/nucleating agent modified cellulose nanocrystalline composite material and method

The invention discloses a polylactic acid / nucleating agent modified cellulose nanocrystalline composite material and a method. The preparation method is characterized by comprising the following steps: modifying cellulose nanocrystals by using a polyamides nucleating agent with a self-assembly capability to obtain modified cellulose nanocrystals with a needle-like or rod-like self-assembly structure, and compounding the modified cellulose nanocrystals with polylactic acid to obtain the polylactic acid / cellulose interface structure with a shish-kebab form. The nucleating agent with self-assembly capability and capable of forming rod-like and needle-like structures is selected, and hydroxyl of cellulose and amino of the nucleating agent form hydrogen-bond interaction, so that adsorption of the nucleating agent on the surface of the cellulose is realized, damage to a cellulose structure is avoided, and excellent performance of the cellulose is reserved to the greatest extent.

Owner:SHANDONG UNIV OF SCI & TECH

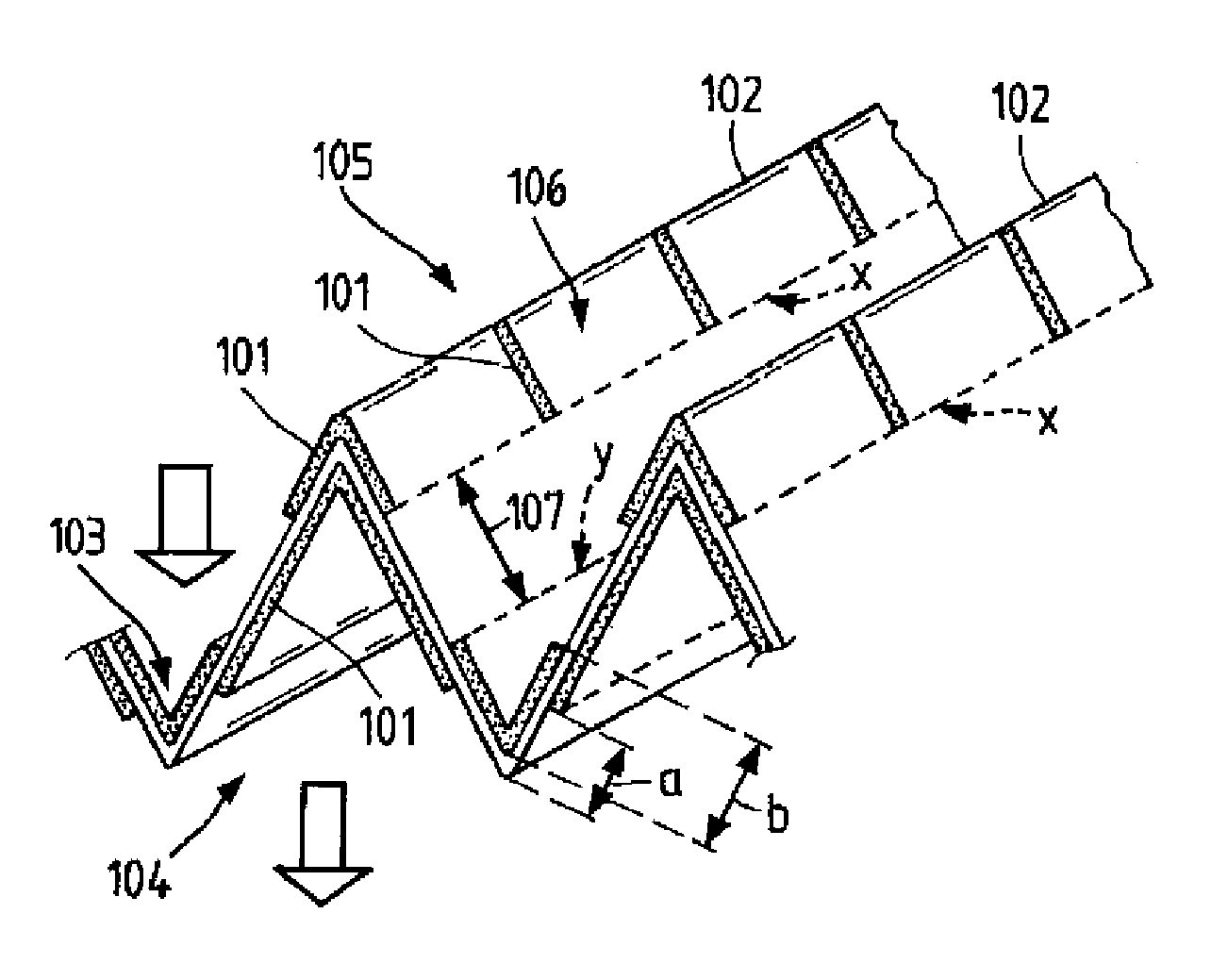

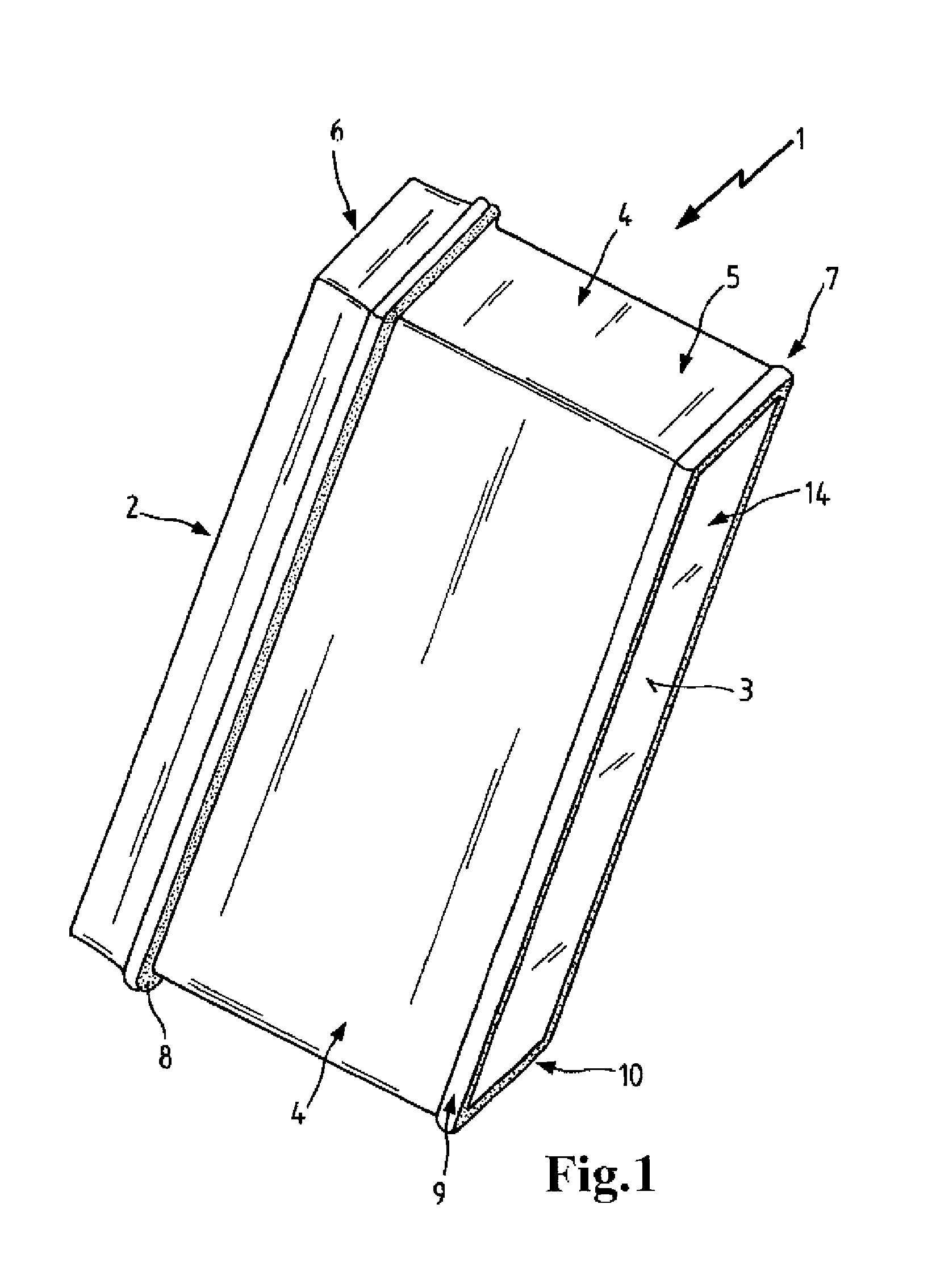

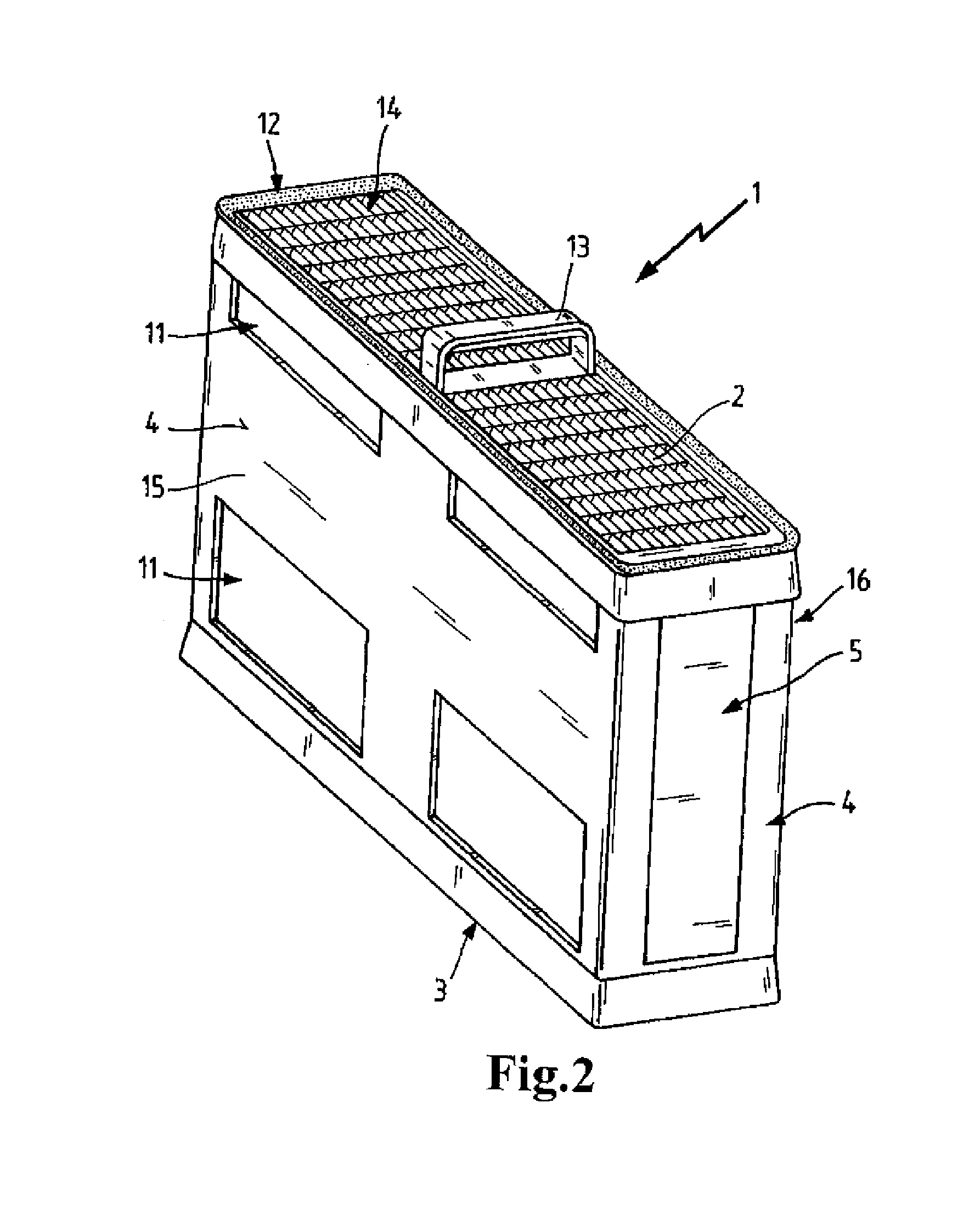

Filter Element and Process for Producing a Filter Element

InactiveUS20130133517A1High heat deformation resistanceReducing stringing tendencyDispersed particle filtrationMembrane filtersChemistryPolyamide

Owner:MANN HUMMEL GMBH

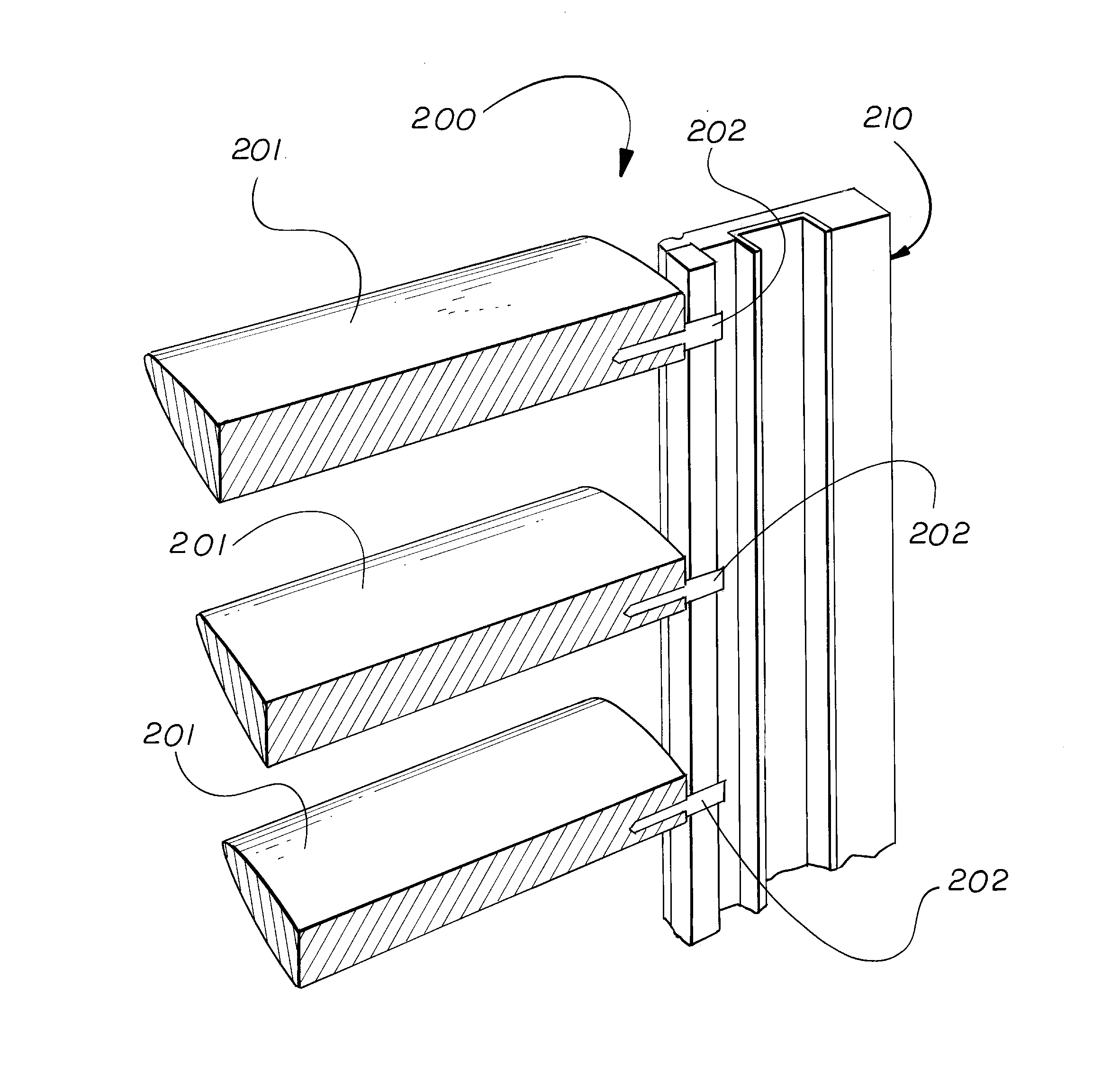

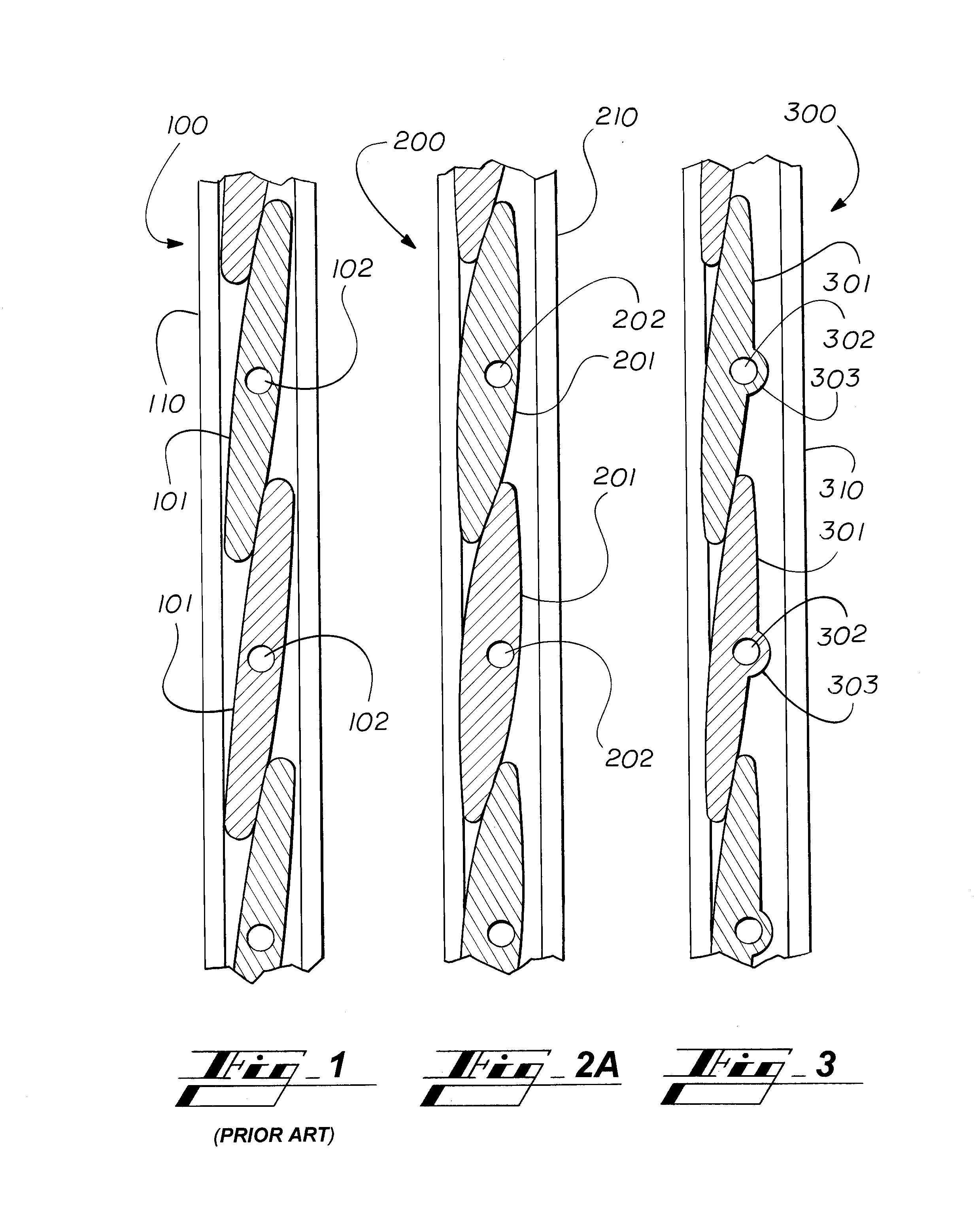

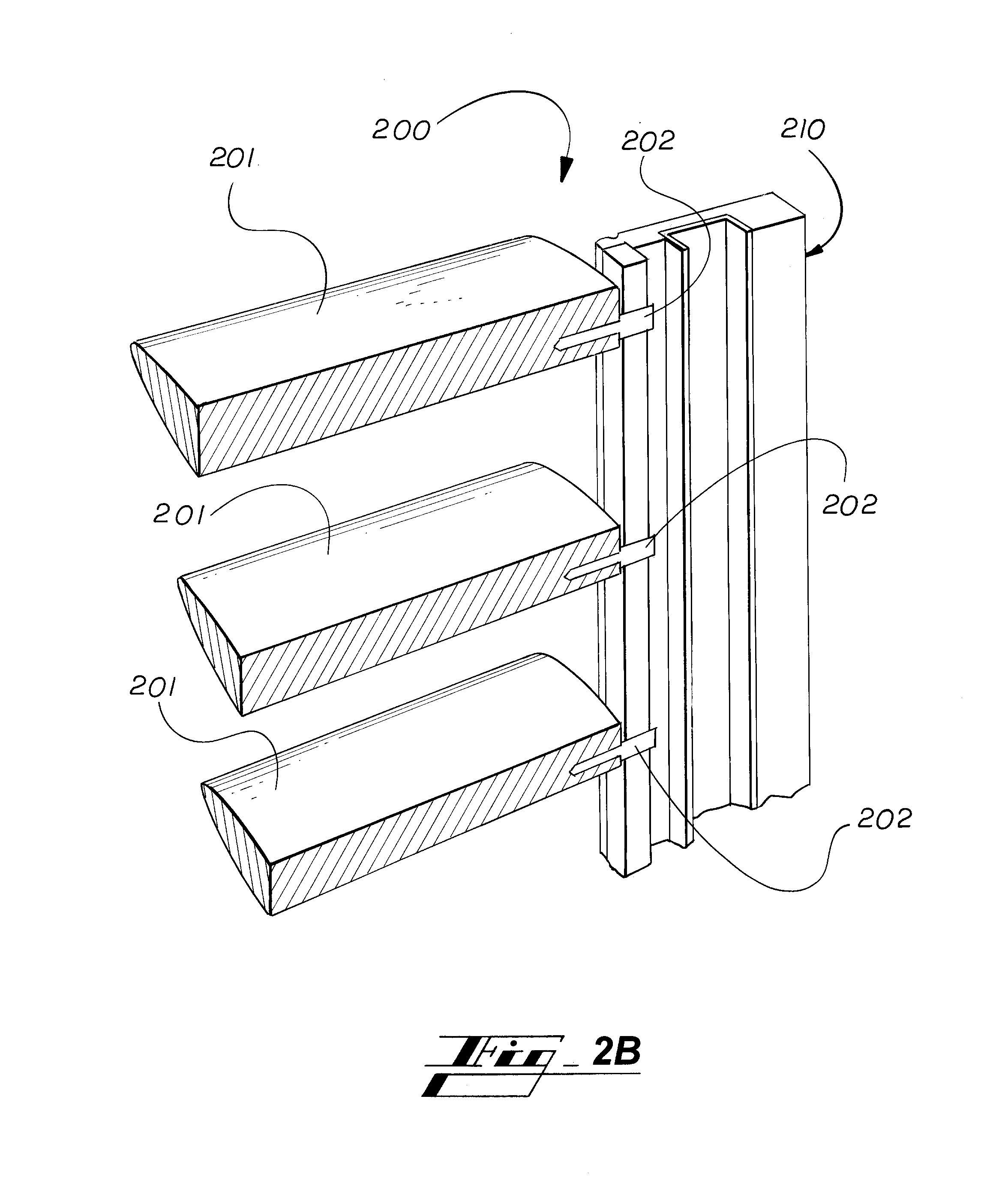

Wide-span louver

InactiveUS20140259932A1Increase moment of inertiaLarge spanVentilation arrangementHorizontal axisEngineering

Wide span louvers including elongated oval bodies with a thickness to width ratio between 0.14 to 0.25, and a pivot / attachment point offset below the horizontal axis, and other improvements to improve resistance to weight and / or thermal sag in long span shutter assemblies and the like.

Owner:ROYAL GROUP

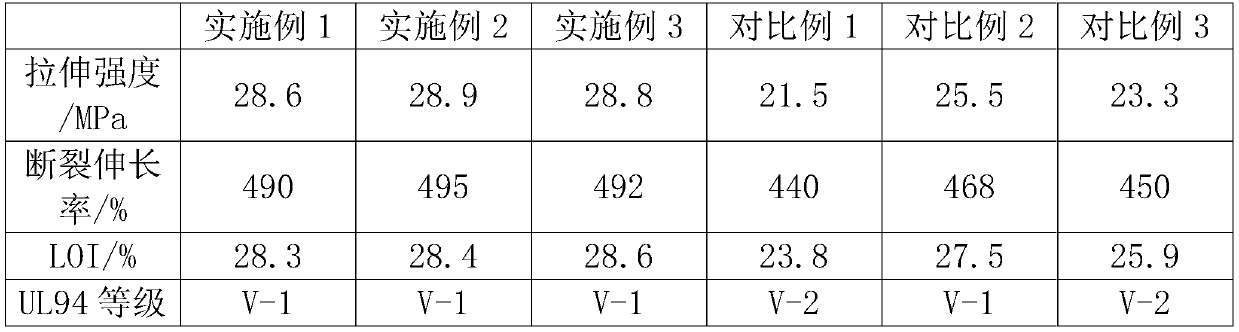

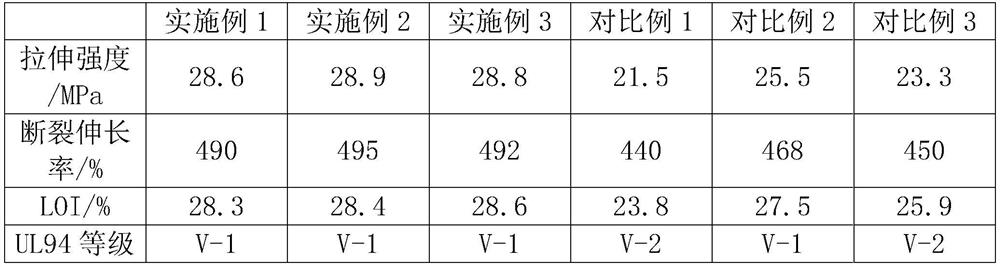

Flame-retardant environment-friendly polyurethane material and preparation method thereof

ActiveCN111548476AImprove flame retardant performanceInhibit migrationDiphenylmethanePolymer science

The invention discloses a flame-retardant environment-friendly polyurethane material, which is prepared from the following raw materials in parts by weight: 50-60 parts of diphenylmethane diisocyanate, 12-15 parts of polycaprolactone, 6-8 parts of a flame retardant and 1-2 parts of modified diatomite. The polyurethane material is prepared by the following method: 1, preparing a polyurethane prepolymer; and 2, performing a reaction on the prepolymer with a flame retardant to obtain the polyurethane material. According to the invention, a self-made flame retardant is used as one of polyurethanecopolymerization raw materials, so that flame retardant molecules are grafted to a polyurethane molecular chain in a chemical bonding manner to form a part of a main chain structure; in addition, themodified diatomite is added into the raw materials, so that the compatibility and dispersity of the polymer in a polymer matrix are improved, and the reinforcing effect is better exerted; the diatomite can play a synergistic effect on the flame retardant, so that the flame retardant property of the polyurethane material is further enhanced; the obtained polyurethane material not only has high comprehensive mechanical properties, but also has greatly improved flame retardancy.

Owner:广东裕泰实业集团有限公司

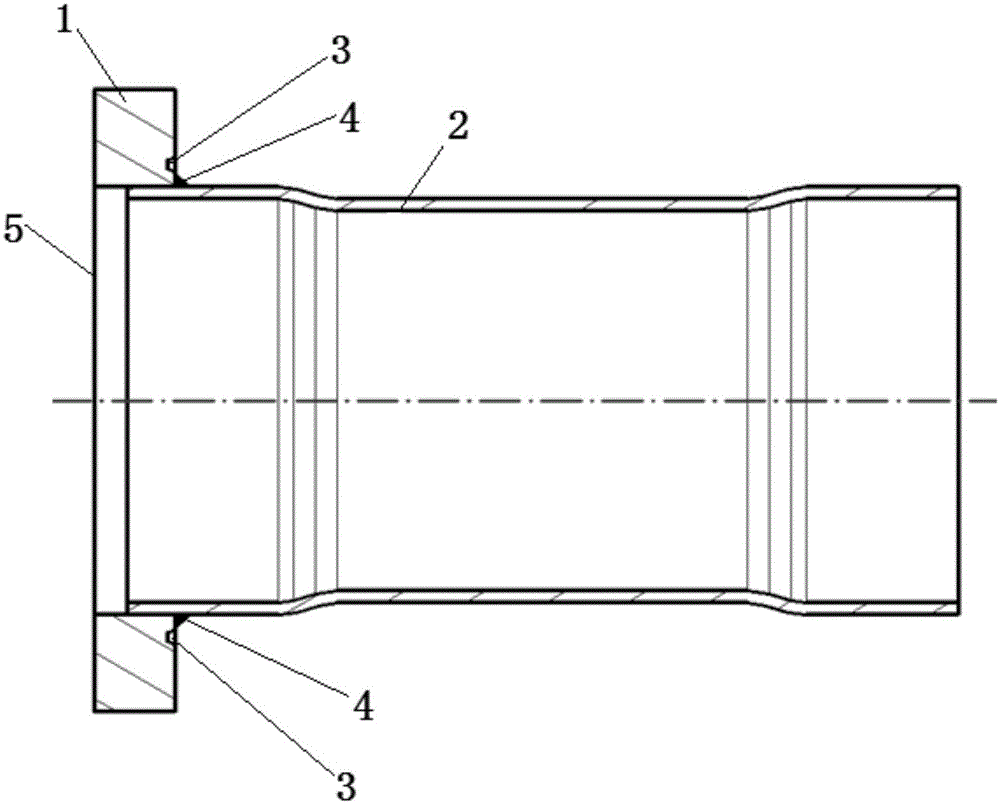

Connecting flange for exhaust system of passenger car and method for preventing welding deformation

InactiveCN105020507AIncrease packing densityHigh heat deformation resistanceFlanged jointsMetal working apparatusVolumetric Mass DensityWelding deformation

The invention discloses a connecting flange for an exhaust system of a passenger car and a method for preventing welding deformation. One end of the connecting flange is welded with a connecting pipe of the exhaust system; the end surface of the other end of the connecting flange serves as a flange connecting end surface; the flange connecting end surface is a plane; and a deformation preventing groove is formed in the periphery of a welding line on the end surface of one end, welded with the connecting pipe, of the connecting flange. As one groove is punched in the welding edge of the connecting flange with the connecting pipe by using a mold, the filling density of the welding edge of the flange is increased, the material heat deformation resistance is enhanced, the deformation quantity of the connecting flange after the welding is reduced, the planeness of the connecting end surface of the flange is guaranteed, the connecting sealing performance of the plane flange is guaranteed, and the sealing performance of the exhaust system is guaranteed.

Owner:CHERY COMML VEHICLE ANHUI

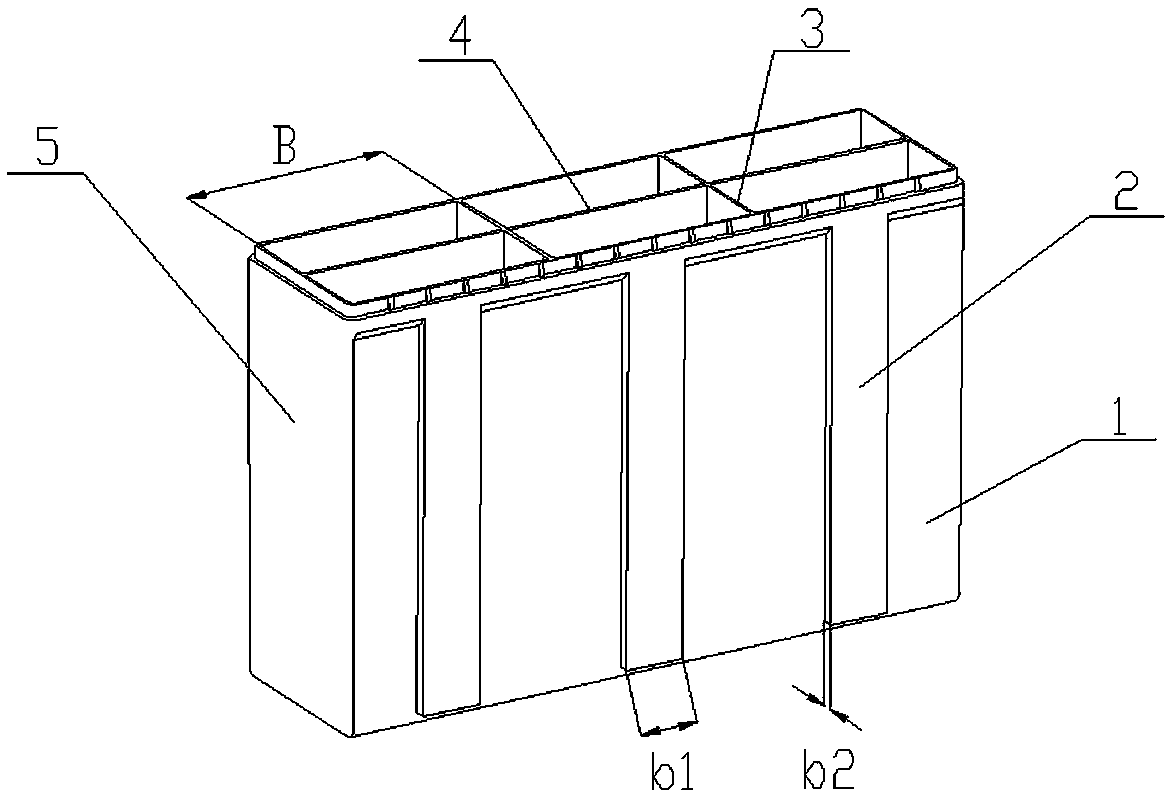

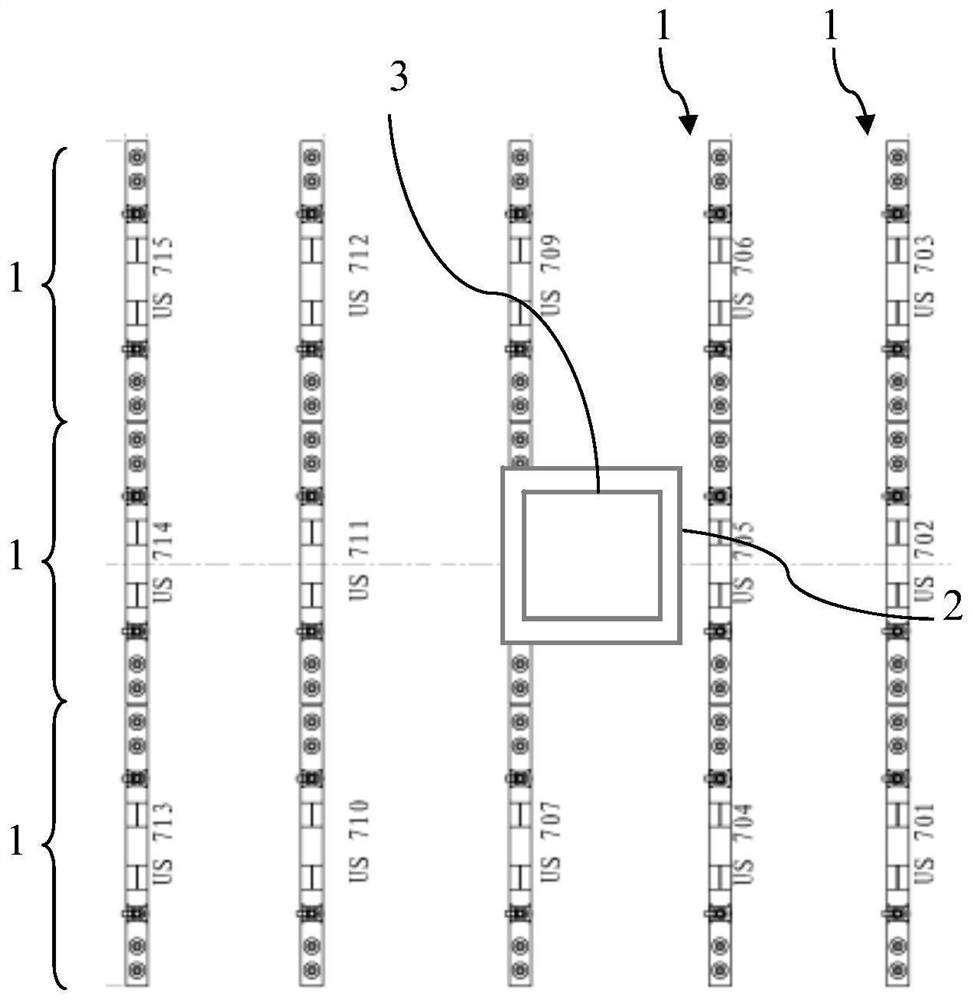

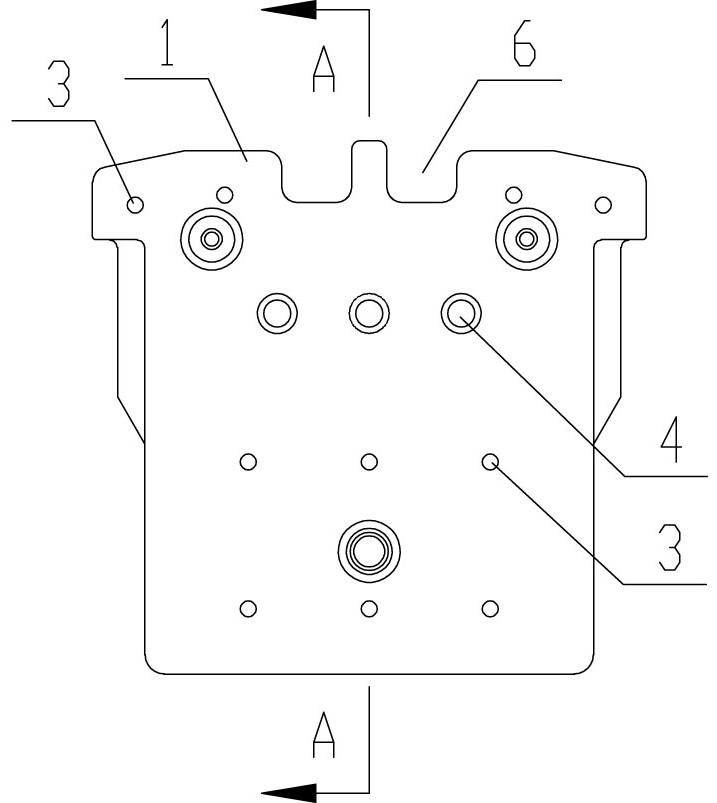

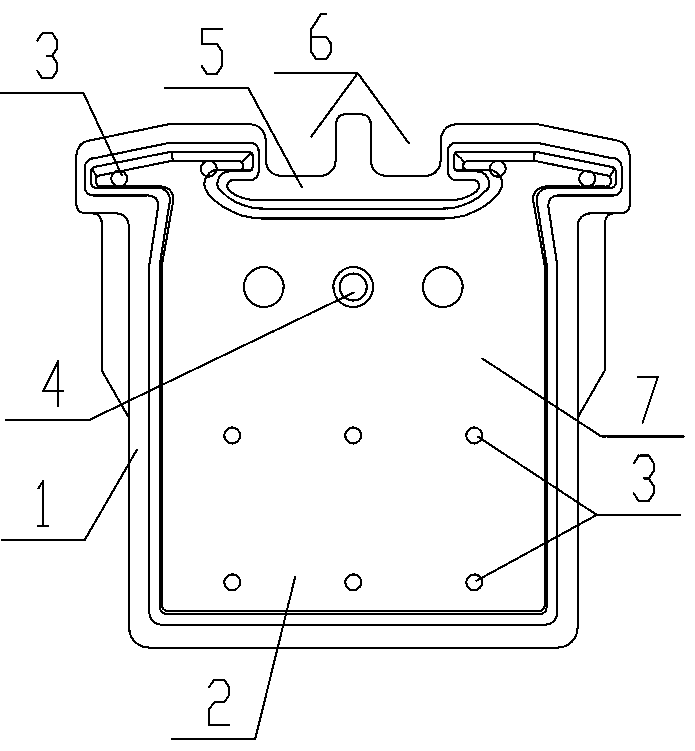

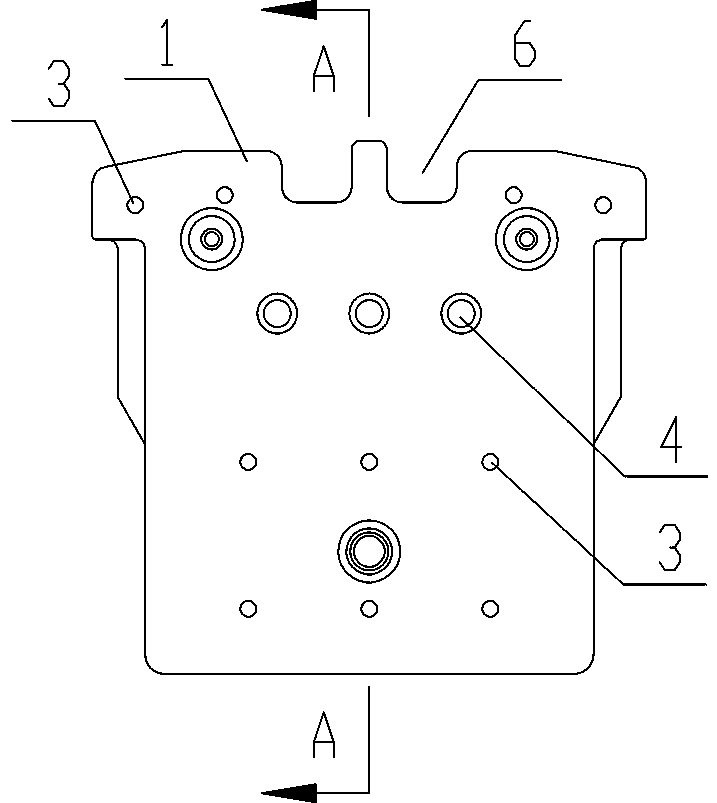

Strengthening structure for bottom shell of lead-acid storage battery

InactiveCN108598599ASimple structureEasy to makeFinal product manufactureCell component detailsThermal deformationEnergy storage

The invention discloses a strengthening structure for a bottom shell of a lead-acid storage battery. The strengthening structure comprises face wall plates, ribs, transverse partition plates, longitudinal partition plates and side wall plates, wherein a rectangular cavity with internal grids is formed by the transverse partition plates and the longitudinal partition plates, and an opening of the cavity is upward. The entity rectangular ribs which are vertical and convex are arranged on the outer walls of the face wall plates at equal intervals. The convex ribs are additionally arranged on theouter walls of the face wall plates at the two sides of the bottom shell, and the external ribs are directly arranged in a thermal deformation weak region, a structure strengthening effect is good, and the heat deformation resistance of the bottom shell can be remarkably improved. The strengthening structure is particularly suitable for being matched with the bottom shell of an energy-storage lead-acid storage battery.

Owner:SHUANGDENG GRP

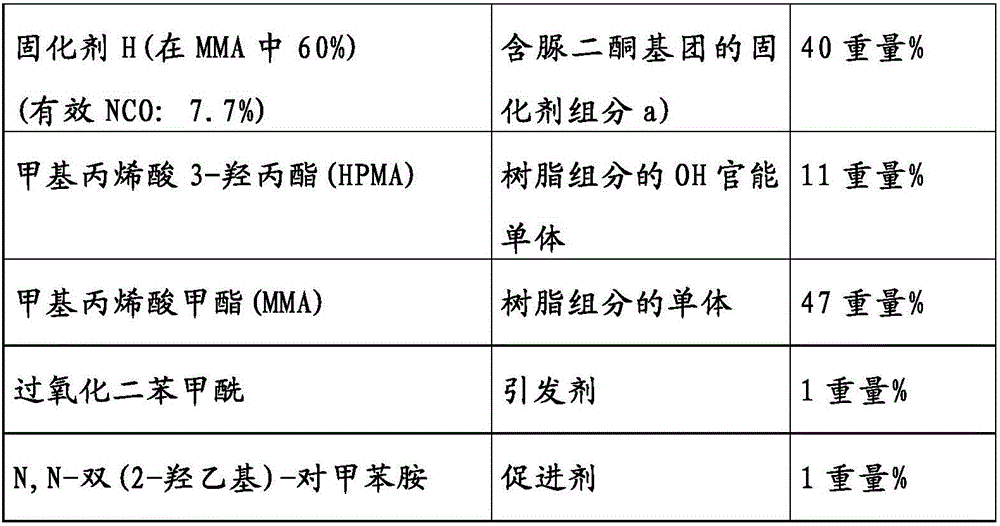

Efficient production of composite semifinished products and components in a wet pressing method using hydroxy functionalized (meth)acrylates which are duroplastically crosslinked using isocyanates or uretdiones

InactiveCN106573441AStable storageHigh heat deformation resistanceLayered product treatmentSynthetic resin layered productsThermoplasticFiber

The invention relates to a method for producing composite semi-finished products and components. In order to produce the semifinished products or components, (meth)acrylate monomers, (meth)acrylate polymers, multi-functionalized (meth)acrylates, hydroxy functionalized (meth)acrylate monomers, and / or hydroxy functionalized (meth)acrylate polymers are mixed with di- or poly isocyanates or uretdione materials. The liquid mixture is applied onto fiber materials, such as carbon fibers, glass fibers, or polymer fibers for example, using known methods and polymerized using a first temperature increase, a redox accelerator, or a photo-initiation. After the polymerization process, for example at room temperature or a temperature of up to 120 DEG C, thermoplastics are produced which can then still be deformed. The hydroxy functionalized (meth)acrylate components can then be crosslinked with the isocyanates or uretdiones which are already present in the system in a press at a second temperature which is at least 20 DEG C higher than the polymerization temperature. At the same time, the final component is shaped in said press. In this manner, dimensionally stable duroplastics or crosslinked composite components can be produced.

Owner:EVONIK DEGUSSA GMBH

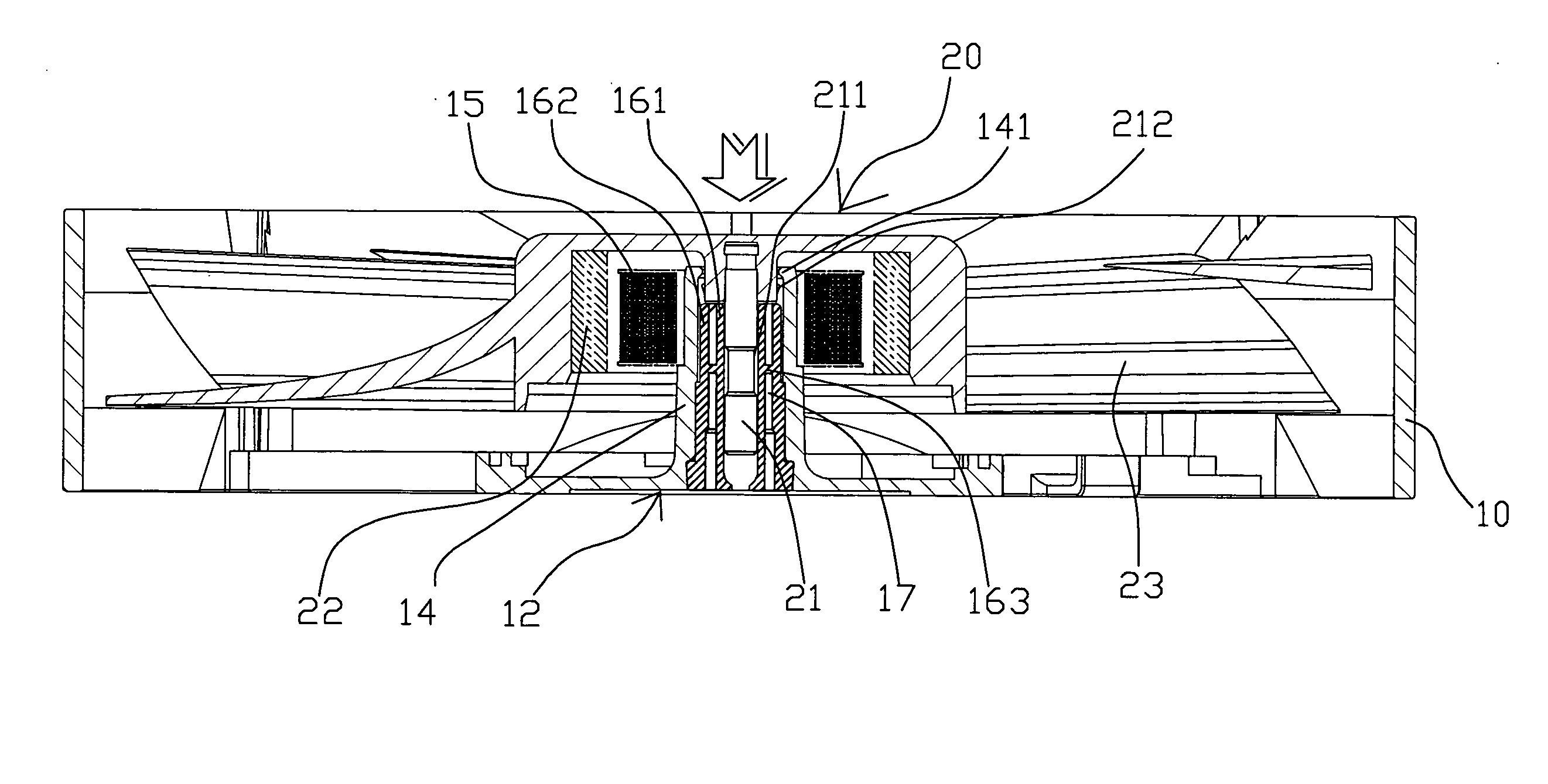

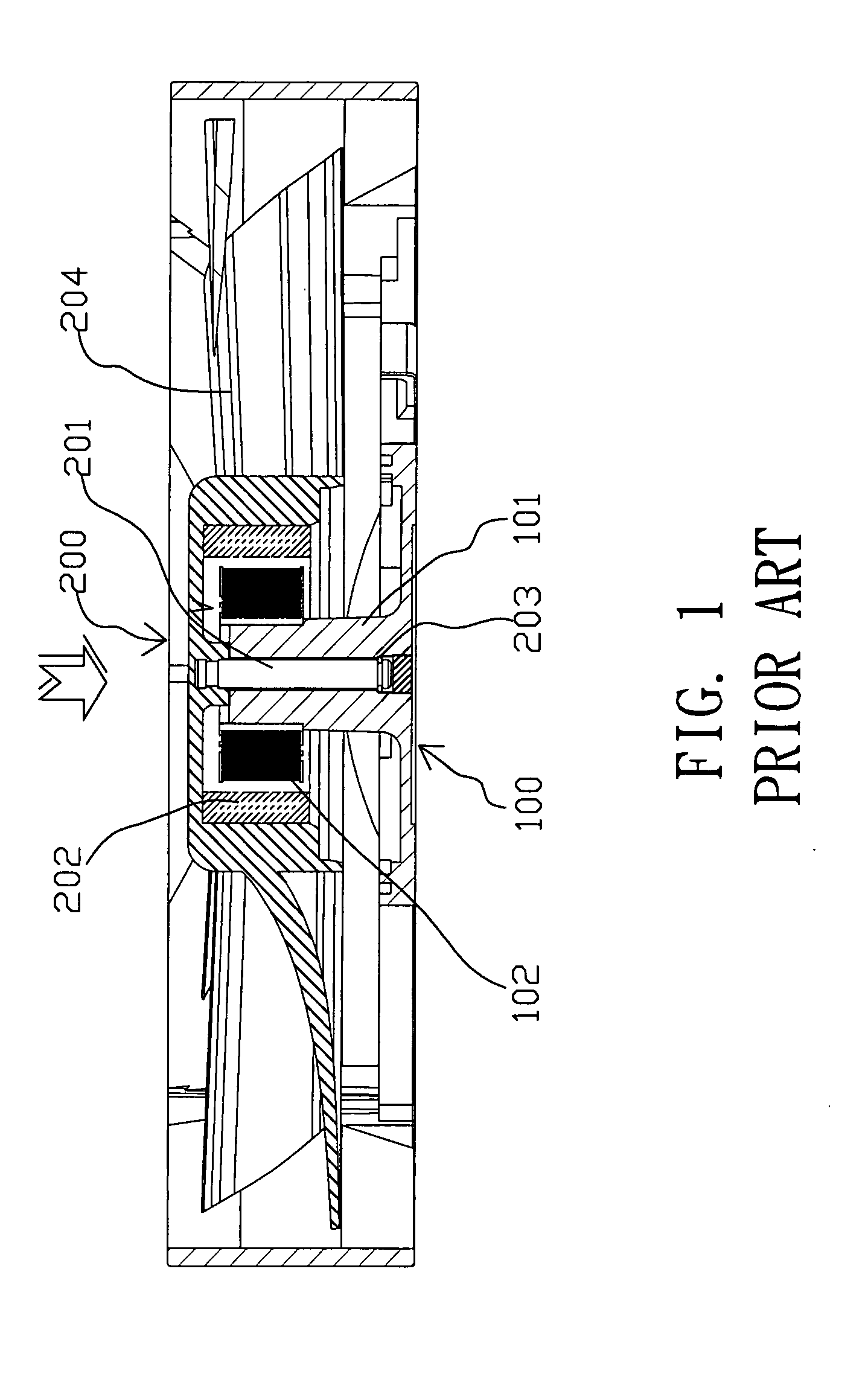

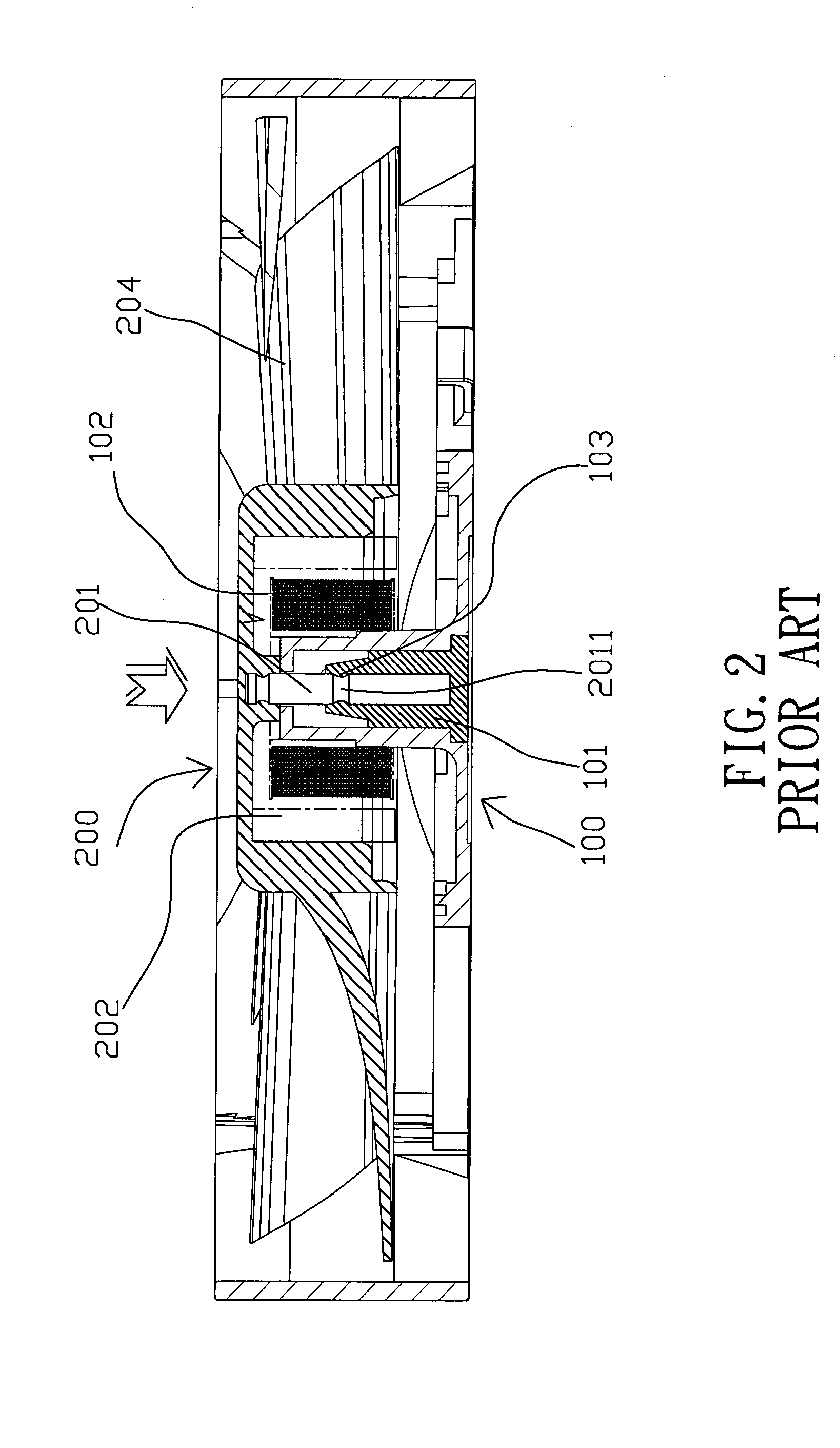

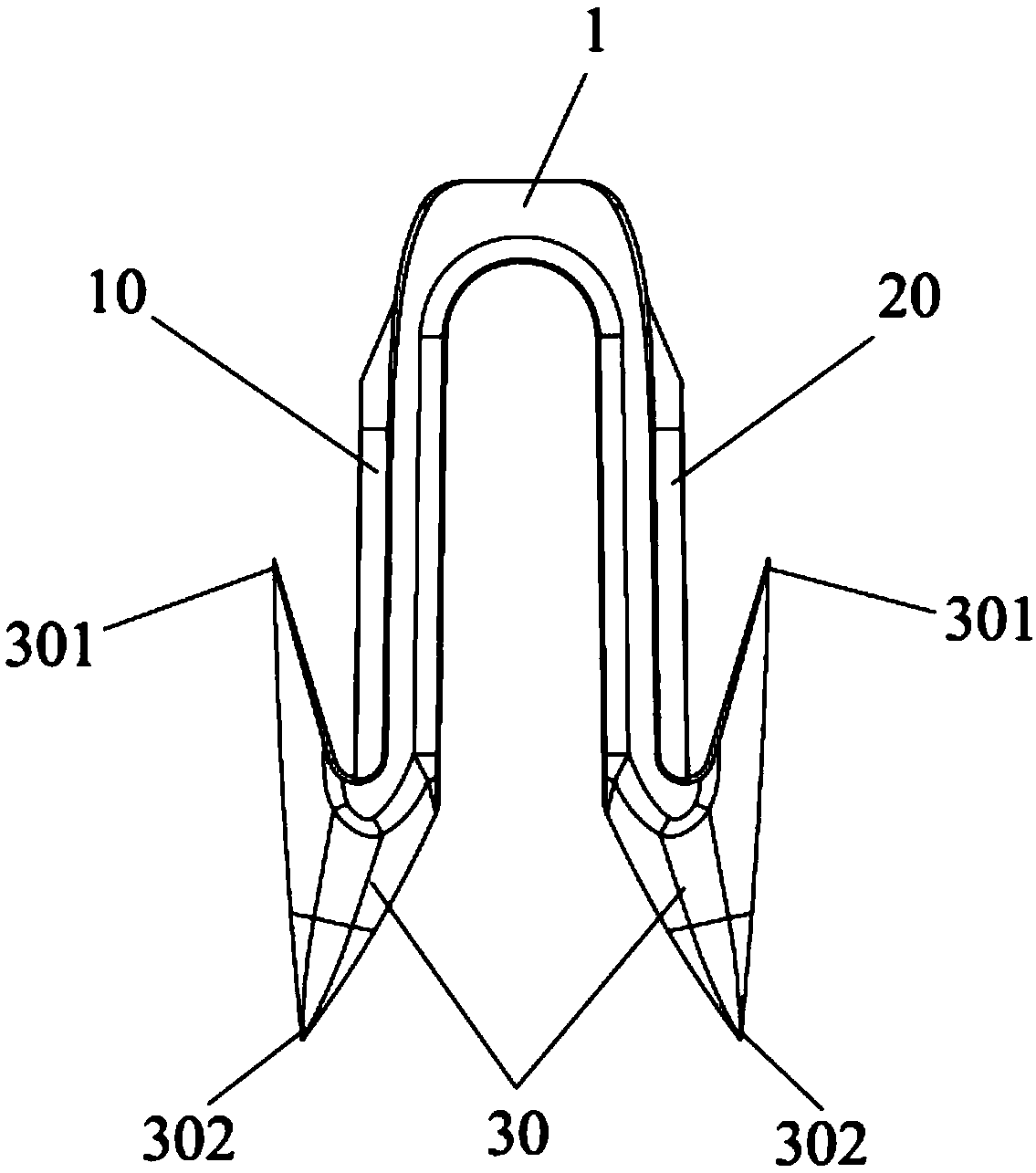

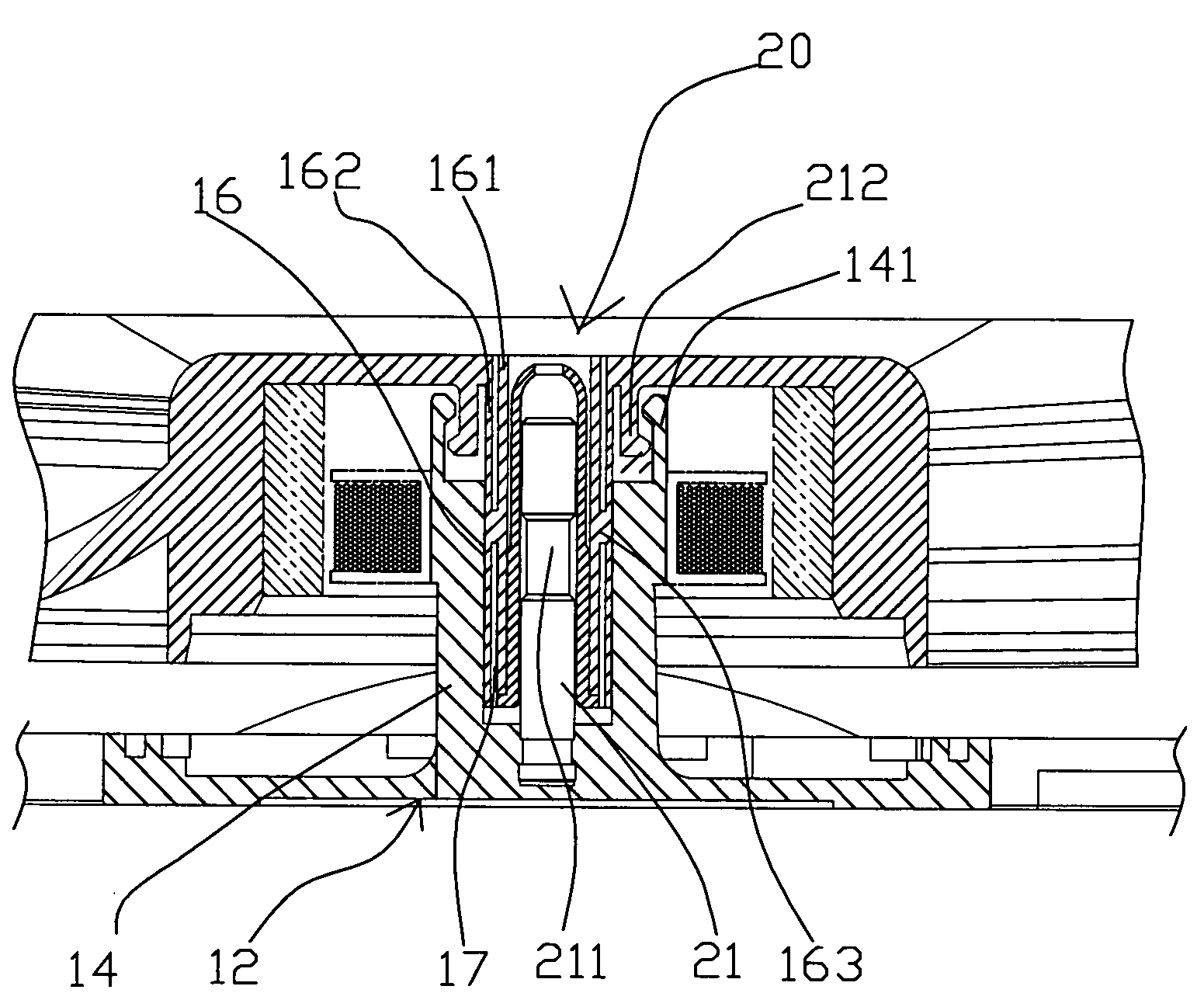

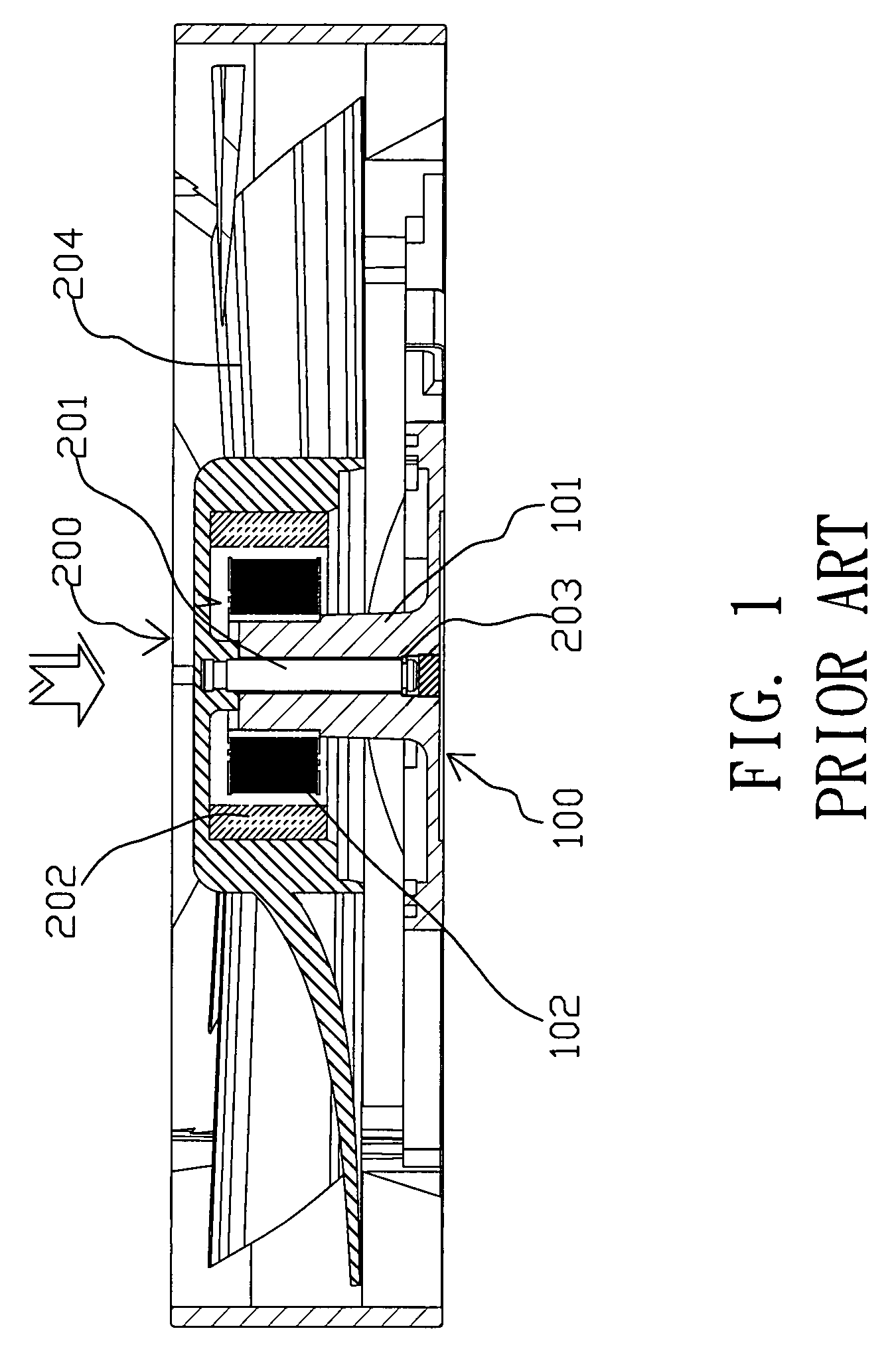

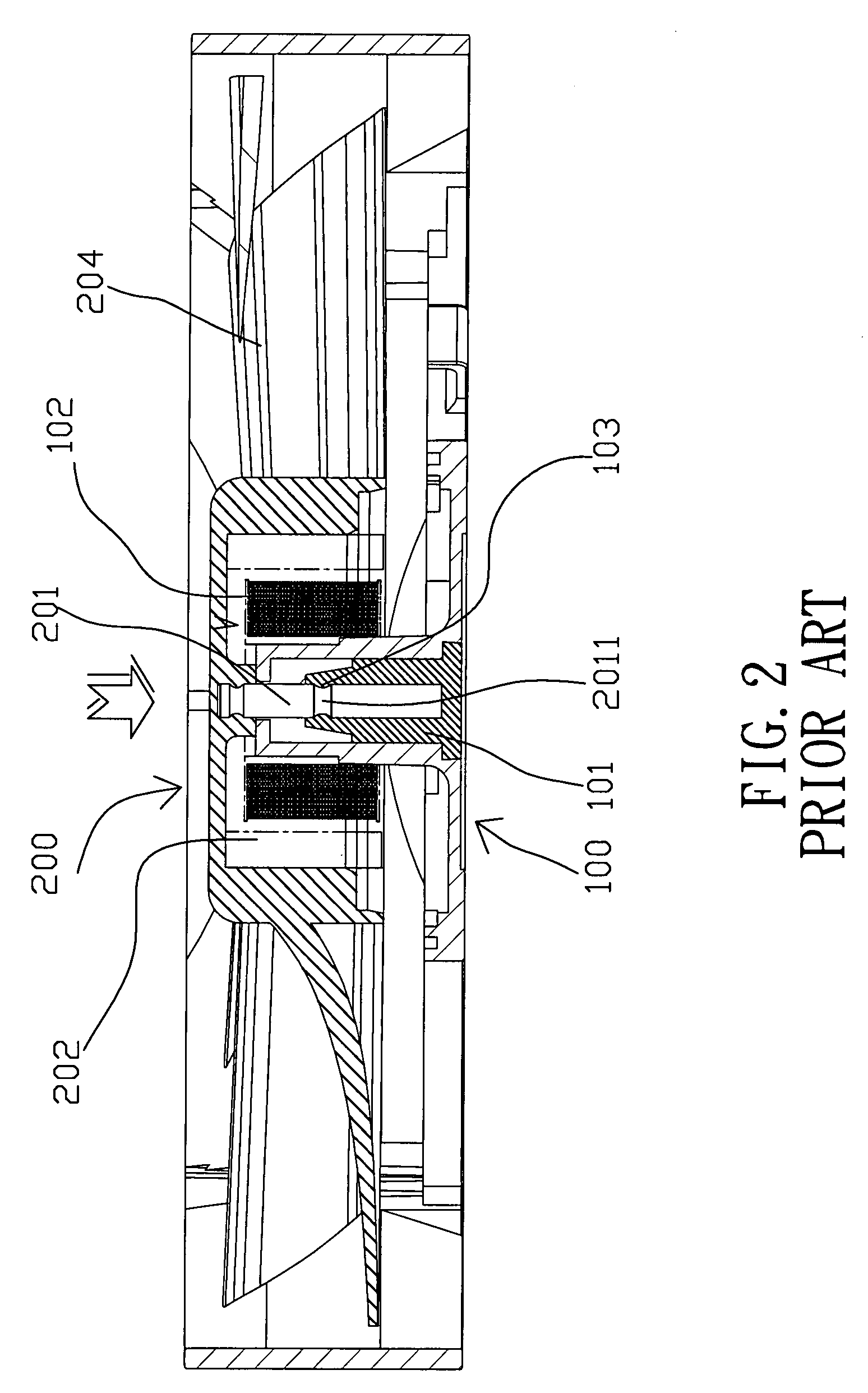

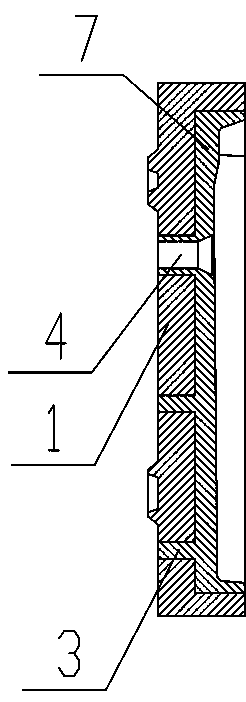

Enhanced thermal deformation resisting bearing of electric motor

InactiveUS20080218017A1Enhance thermal deformation resistImprove lubricate effectPump componentsBearing componentsThermal deformationStator

This invention discloses an enhanced thermal deformation resisting bearing of an electric motor. The bearing includes a frame for containing a stator and a rotor. The stator has an axle sleeve sheathed with a bearing. The bearing has a hole groove for dividing the bearing into inner and outer layers. A connecting portion maintains an appropriate interval between the inner and outer layers. An embedded groove is extended inward and disposed at a free end of the axle sleeve. The rotor has an axle, and the periphery of the axle has a groove. The groove corresponds with the connecting portion of the bearing. The rotor has a protruding latch disposed proximate to the axle and embedded into the embedded groove. If the axle rotates in the bearing, the thinner inner layer will be expanded by high temperature, but the thicker connecting portion still maintains the bearing in its position.

Owner:TEK CHAIN TECH

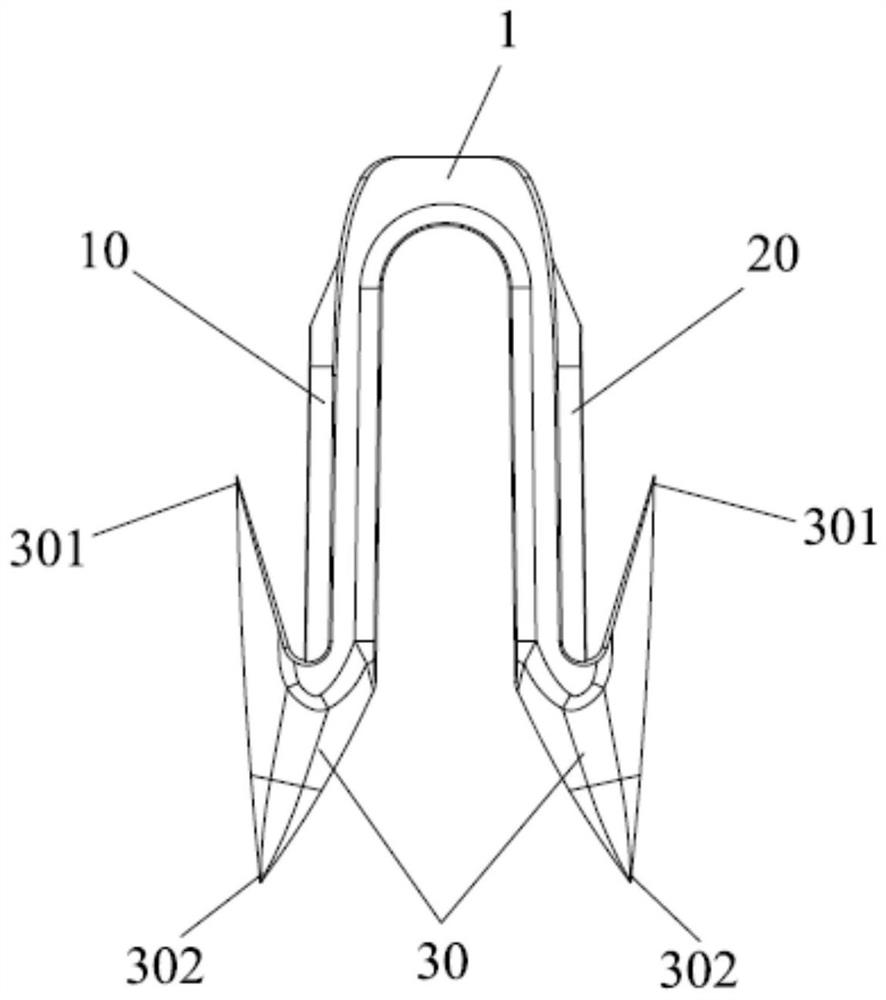

Hernia patch fixing nail and preparation method thereof

The invention relates to the technical field of absorbable biological materials and medical devices, in particular to a hernia patch fixing nail. The hernia patch fixing nail is obtained through injection molding of an absorbable biological material, the absorbable biological material is a blend formed by a composition of a heterogeneous polymer, the blend comprises, by molar ratio, 70-90% of lactide and 30-10% of glycolide; the preparation method of the hernia patch fixing nail comprises the steps that a general molecular weight and low molecular weight of rich lactide and rich glycolide arefirstly prepared, then melt mixing, dyeing, prilling, drying, injection molding and annealing are carried out in sequence to obtain the fixing nail. The prepared fixing nail has excellent comprehensive properties such as high strength, good toughness, strong resistance to heat deformation and high dimensional stability in the early stage and the initial stage of application; degradation is in a continuous state when carried out, the polymer is significantly degraded in an important period of internal tissue recovery and adjustment and is basically absorbed by the human body within 10-20 months; mixing is simple and the synthesis cost is low.

Owner:广东晨曦医疗科技有限公司

Enhanced thermal deformation resisting bearing of electric motor

InactiveUS7535142B2High heat deformation resistanceProvide flexibilityPump componentsBearing componentsThermal deformationEngineering

This invention discloses an enhanced thermal deformation resisting bearing of an electric motor. The bearing includes a frame for containing a stator and a rotor. The stator has an axle sleeve sheathed with a bearing. The bearing has a hole groove for dividing the bearing into inner and outer layers. A connecting portion maintains an appropriate interval between the inner and outer layers. An embedded groove is extended inward and disposed at a free end of the axle sleeve. The rotor has an axle, and the periphery of the axle has a groove. The groove corresponds with the connecting portion of the bearing. The rotor has a protruding latch disposed proximate to the axle and embedded into the embedded groove. If the axle rotates in the bearing, the thinner inner layer will be expanded by high temperature, but the thicker connecting portion still maintains the bearing in its position.

Owner:TEK CHAIN TECH

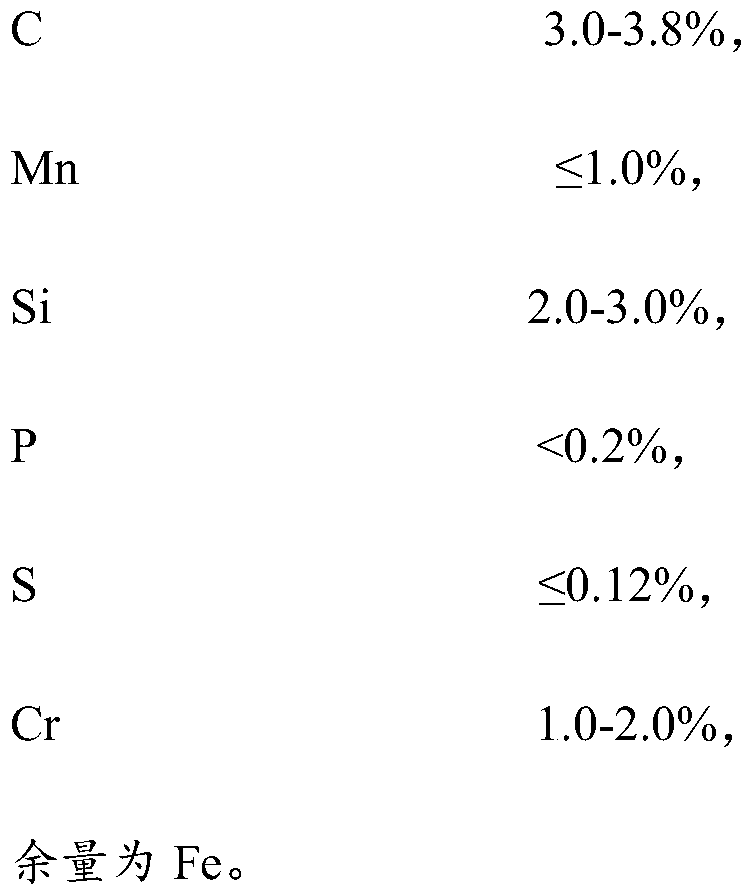

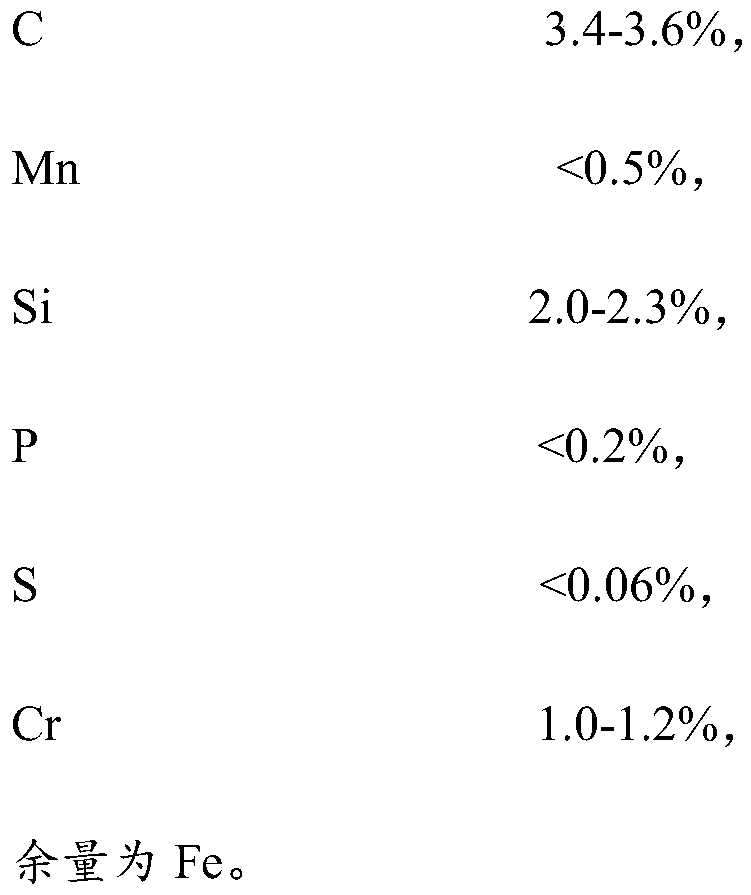

Heat-resistant medium-chromium vermicular graphite cast iron glass mold material and preparation method thereof

InactiveCN110079727AHigh hardnessImprove wear resistanceProcess efficiency improvementHeat resistanceGraphite

The invention provides a heat-resistant medium-chromium vermicular graphite cast iron glass mold material. The glass mold material comprises the following components of 3.0%-3.8% of C, less than or equal to 1.0% of Mn, 2.0-3.0% of Si, less than 0.2% of P, less than or equal to 0.12% of S, 1.0%-2.0% of Cr, and the balance Fe, wherein the total mass of all the components is 100%. The heat-resistantmedium-chromium vermicular graphite cast iron glass mold material has relatively high hardness, abrasive resistance and heat resistance, thus improving the heat and deformation resistance and the oxidation resistance of the glass mold as well as prolonging the service life of the glass mold.

Owner:CHENGDU XINZHI IND

Thin-walled part processing process

The invention discloses a thin-walled part processing process, comprising the steps of S1, annealing of raw materials; S2, rough processing of raw materials with reserved machining allowance during processing; S3, quenching and tempering the workpieces subjected to rough processing; S4, finishing the workpieces subjected to quenching and tempering; S5, carrying out vacuum quenching on the workpieces subjected to finishing to form finished products. The thin-walled member processed by the process of the invention can effectively reduce the deformation amount thereof and ensure the precision ofthe finished products.

Owner:安徽宁国中鼎模具制造有限公司

Uptake flue roof for copper smelting of flash furnace

PendingCN112378263AImprove cooling effectCool evenlyCharge composition/stateIncreasing energy efficiencyThermal deformationCooling effect

The invention provides an uptake flue roof for copper smelting of a flash furnace. The uptake flue roof for copper smelting of the flash furnace is characterized in that a plate-type copper water jacket is arranged in an area, close to a furnace side, of a middle-portion square water jacket, a plate surface of the plate-type copper water jacket is horizontally arranged, the plate-type copper waterjacket is formed by copper water jacket units with plate edges closely arranged, cooling water paths are arranged in plate bodies of the copper water jacket units, flame-retardant layers are arrangedon lower plate surfaces of the copper water jacket units, water inlet pipes and water outlet pipes of the cooling water paths extend to upper plate surfaces of the copper water jacket units, and lifting eyes are arranged on the upper plate surfaces of the copper water jacket units. In the technical scheme, the cooling water paths are arranged in the plate bodies of the copper water jacket units with the plate bodies horizontally arranged, thus the uptake flue roof for copper smelting of the flash furnace has an excellent cooling effect, the flame-retardant layers arranged on the lower plate surfaces of the copper water jacket units in an attached mode can also be cooled effectively and evenly in time, the thermal deformation resistance capability of the uptake flue roof for copper smelting of the flash furnace is significantly enhanced, the structural strength of the flue roof of the smelting furnace is improved, and the service life is prolonged.

Owner:TONGLING NON FERROUS METAL GROUP CORP

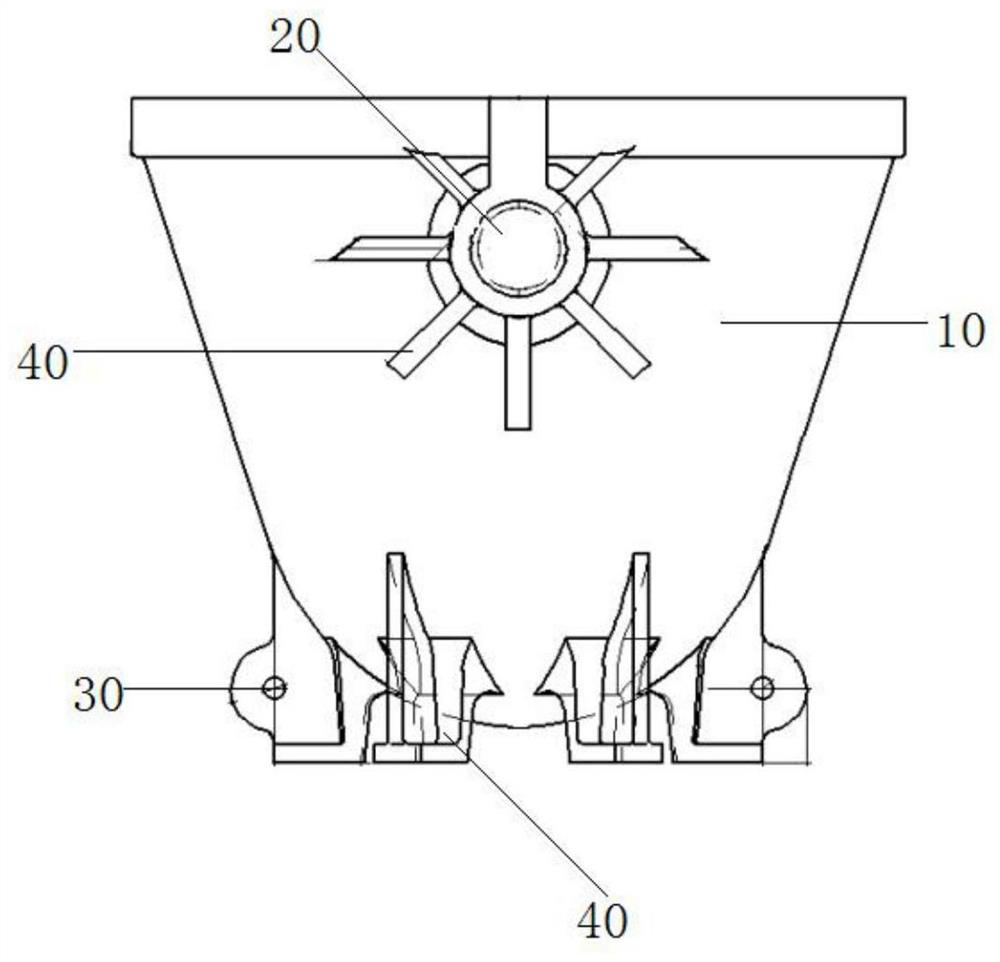

Composite copper anode mold with improved service life and production method thereof

ActiveCN109853004BHigh mechanical strengthImprove thermal fatigue resistancePhotography auxillary processesProcess efficiency improvementChemical compositionCopper anode

The invention relates to the technical field of mold production in the metallurgical industry, in particular to a composite copper anode mold with improved service life, which includes a mold body on which a copper pouring cavity is opened, and the mold body is located on the upper part of the copper pouring cavity and is provided with a mold lifter The top mold hole, the mold body is located in the copper pouring cavity and is compounded with a layer of chromium-zirconium-copper alloy. The chemical composition weight percentage of the chromium-zirconium-copper alloy is: Cr:0.75-0.85, Zr:0.15-0.25, Mn< 0.0013, Mo<0.0003, Ni<0.0005, Fe<0.037, and the balance is Cu; the service life of the copper anode mold of the present invention is greatly extended, and the average copper pouring amount can reach more than 1000 tons / block.

Owner:湖北钜神材料科技有限责任公司

A hernia patch fixing nail and its preparation method

The invention relates to the technical field of absorbable biological materials and medical devices, in particular to a hernia patch fixing nail. The hernia patch fixing nail is obtained through injection molding of an absorbable biological material, the absorbable biological material is a blend formed by a composition of a heterogeneous polymer, the blend comprises, by molar ratio, 70-90% of lactide and 30-10% of glycolide; the preparation method of the hernia patch fixing nail comprises the steps that a general molecular weight and low molecular weight of rich lactide and rich glycolide arefirstly prepared, then melt mixing, dyeing, prilling, drying, injection molding and annealing are carried out in sequence to obtain the fixing nail. The prepared fixing nail has excellent comprehensive properties such as high strength, good toughness, strong resistance to heat deformation and high dimensional stability in the early stage and the initial stage of application; degradation is in a continuous state when carried out, the polymer is significantly degraded in an important period of internal tissue recovery and adjustment and is basically absorbed by the human body within 10-20 months; mixing is simple and the synthesis cost is low.

Owner:广东晨曦医疗科技有限公司

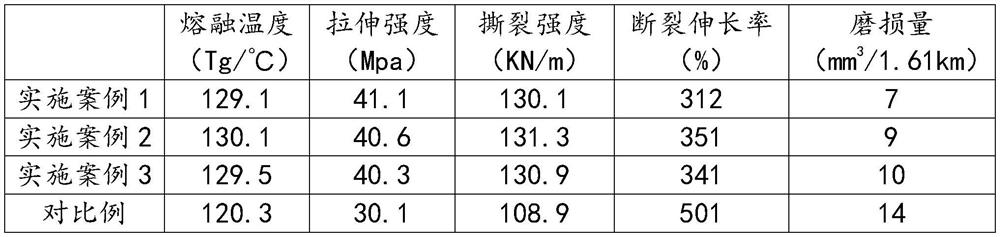

Disclosed is method for producing composition for heavy-duty forklift tire

The invention discloses a manufacturing method of a composition for a tire of a load-bearing forklift. The manufacturing method comprises the following steps: preparing a polyurethane prepolymer and preparing a polyurethane composition. The composition for the loaded forklift tire is prepared from the following raw materials in parts by weight: 30-40 parts of polyether polyol, 60-70 parts of polyester polyol, 5-15 parts of isocyanate, 5-15 parts of a chain extender, 1-3 parts of a cross-linking agent, 4-8 parts of modified inorganic filler, 0.1-0.5 part of a catalyst, 0.1-0.3 part of a stabilizer and 3-6 parts of a foaming agent. The modified graphene oxide is added, the uniform dispersity of the modified graphene oxide in a polyurethane matrix is utilized, and a net-shaped structure formed by the modified graphene oxide in the polyurethane matrix is also utilized, so that the composition for the load-bearing forklift tire is obtained; and meanwhile, the composite material has the advantages of high bearing capacity, high strength, good toughness, impact resistance, wear resistance and high thermal stability.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

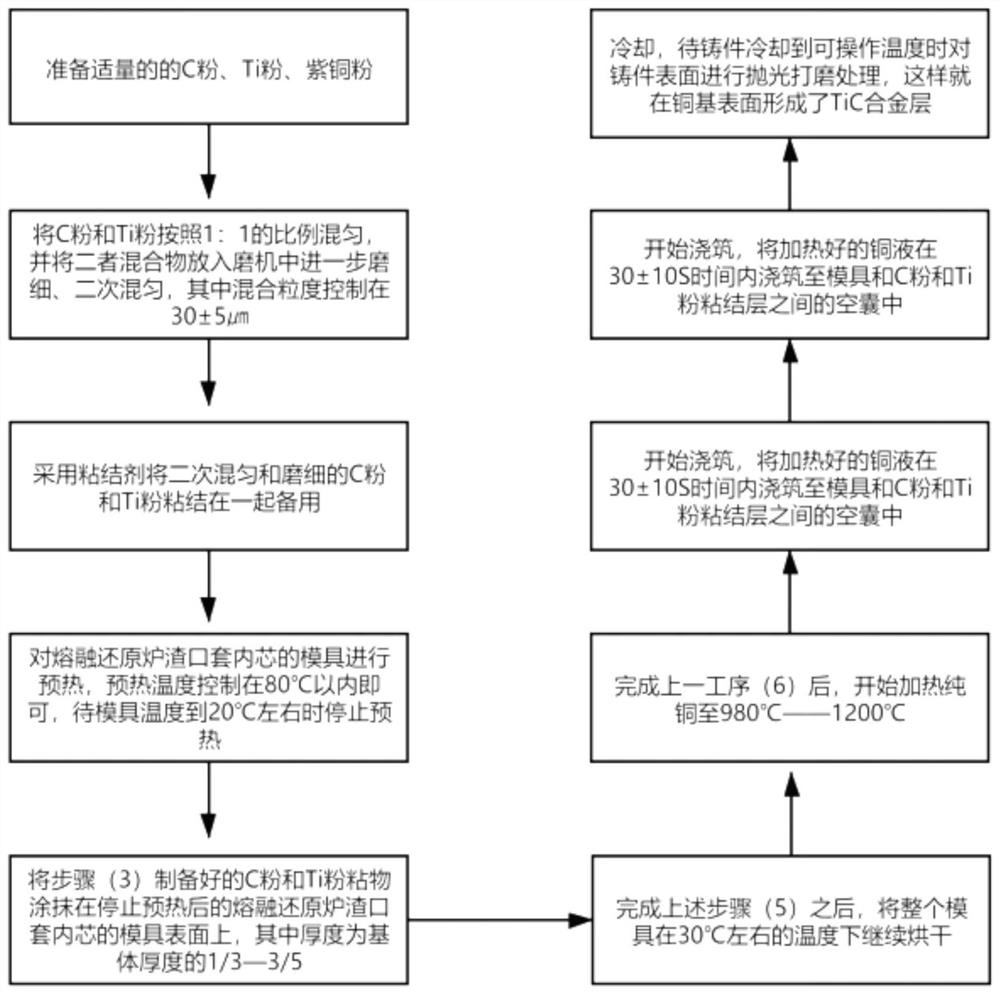

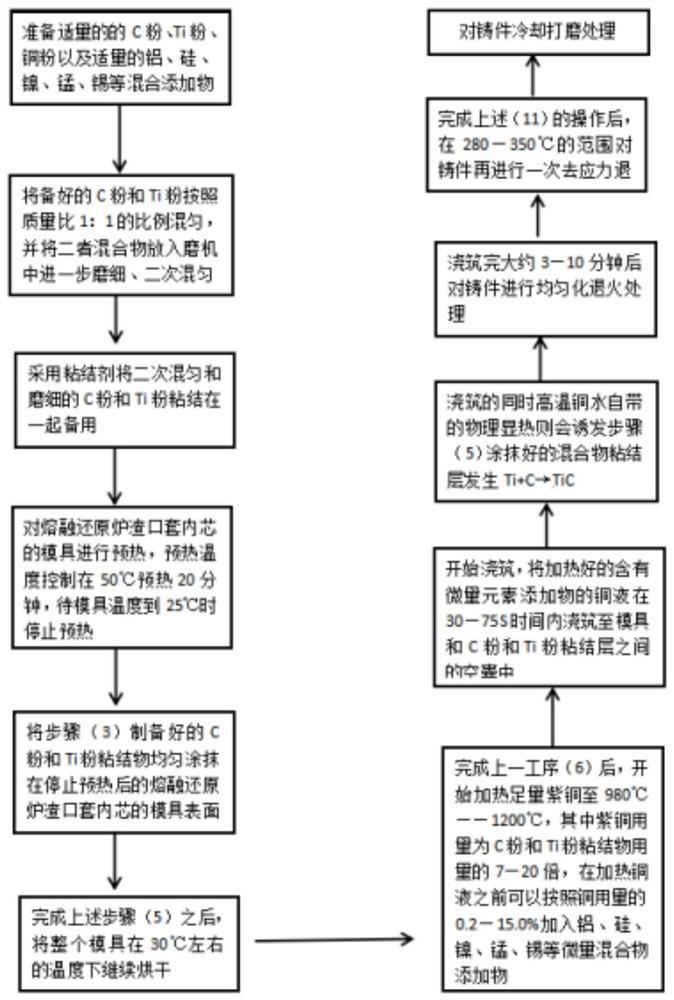

Manufacturing method of copper-based slag notch sleeve inner core suitable for smelting reduction furnace

InactiveCN113798477AImprove thermal conductivityImprove wear resistanceSmelting processWorking environment

The invention discloses a manufacturing method of a slag notch sleeve inner core suitable for a smelting reduction furnace. The manufacturing method comprises the following process steps that C powder and Ti powder are uniformly mixed according to a ratio of (1-2): (1-2), the mixture of the C powder and the Ti powder is further ground in a mill, and uniformly mixing is carried out for the second time; the C powder and the Ti powder which are evenly mixed and ground for the second time are bonded together through a binding agent for standby application; the prepared C powder and Ti powder stickies are smeared on the surface of a mold of the smelting reduction furnace slag notch sleeve inner core after preheating is stopped, and pure copper starts to be heated to be melted; the heated copper liquid is poured into an empty bag between the mold and the bonding layer of the C powder and the Ti powder within 30 seconds; and cooling is carried out. The obtained copper-based slag notch sleeve inner core is good in heat conduction effect and capable of meeting the complex working environment in the smelting reduction smelting process, the wear resistance is greatly improved, and the thermal deformation resistance is improved.

Owner:内蒙古赛思普科技有限公司

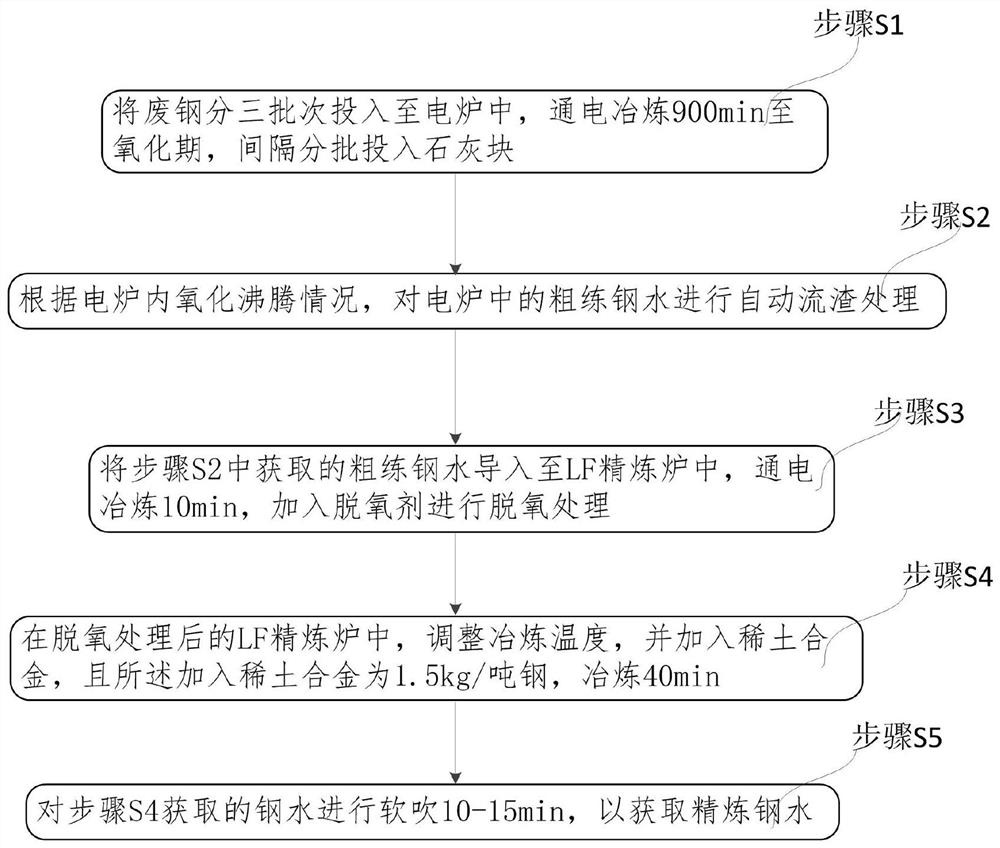

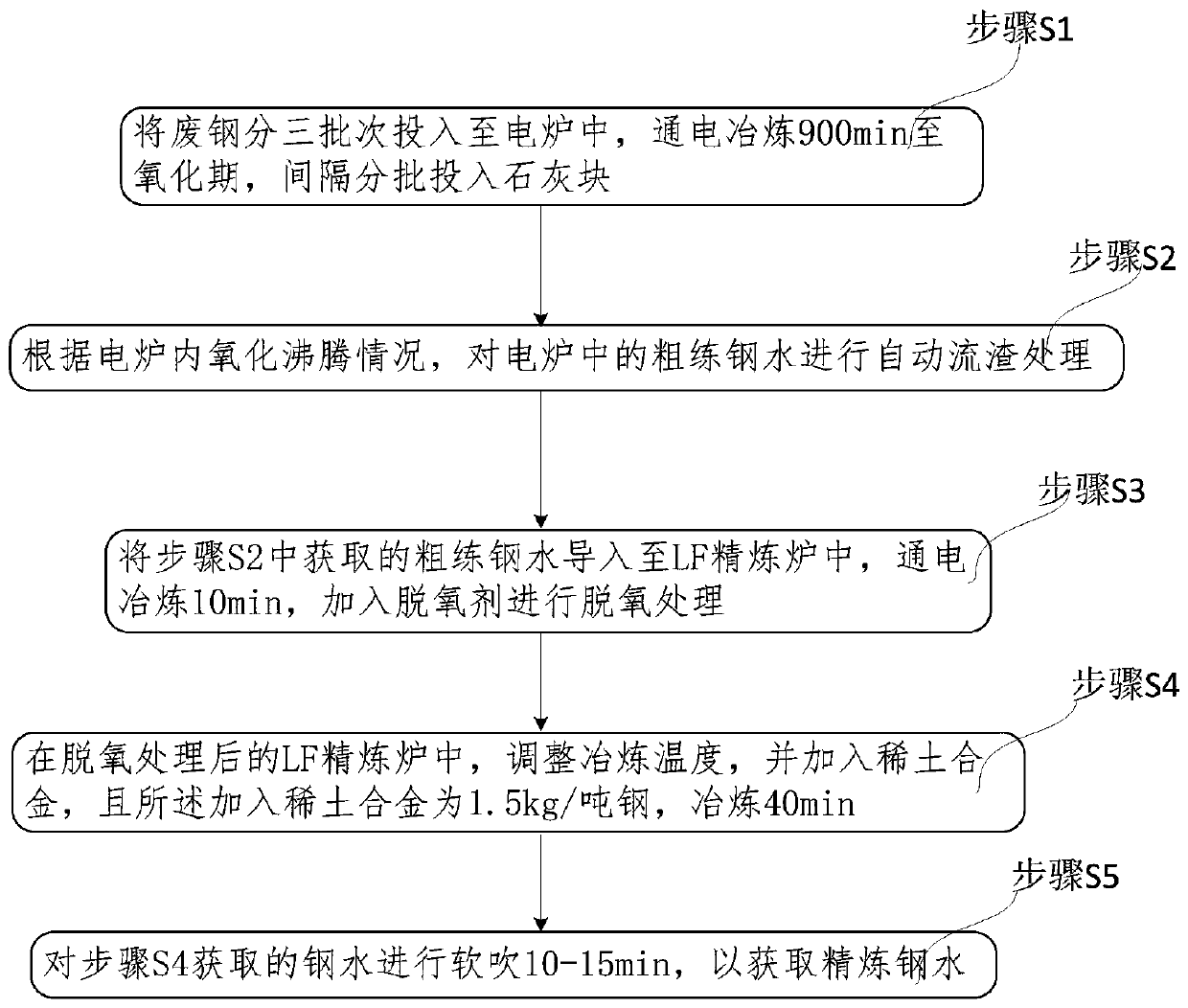

A slag ladle raw material processing method suitable for copper smelting working conditions

ActiveCN110527781BAlleviate the problem of prone to crackingCrack reliefMelt-holding vesselsProcess efficiency improvementSteelmakingMolten steel

A slag ladle raw material processing method suitable for copper smelting working conditions of the present invention controls the processing of slag ladle raw materials to improve the flexibility of slag ladle raw materials, thereby effectively relieving the slag ladle from being subjected to high temperature for a long time. Next, the problem of cracks that are prone to occur. A slag ladle raw material processing method suitable for copper smelting working conditions of the present invention can effectively reduce the content of harmful elements and residual elements and improve the purity of molten steel by adopting electric furnace steelmaking and LF furnace refining, wherein P, S content < 0.020%, lower than the national standard ≤ 0.040%. It can effectively reduce the crack tendency of the slag bag under high temperature conditions. The molten steel undergoes metamorphic treatment (rare earth re), which can refine the crystal grains and improve the comprehensive physical properties of the material. Single ladle casting, on-site temperature measurement before pouring, the pouring temperature can be controlled within the range of ±3°C required by the process, and the crystal grains of the slag ladle The particles are relatively uniform and fine, which can effectively improve its physical properties.

Owner:武汉恒威宸装备制造有限公司

Cinder ladle raw material processing method suitable for copper smelting working conditions

ActiveCN110527781AAlleviate the problem of prone to crackingCrack reliefMelt-holding vesselsProcess efficiency improvementSteelmakingRare earth

According to a cinder ladle raw material processing method suitable for the copper smelting working conditions, the flexibility of cinder ladle production raw materials is improved by controlling processing of the cinder ladle raw materials, and therefore the problem that cracks are likely to be generated when cinder ladles are subjected to the high-temperature action for a long time is effectively solved. According to the cinder ladle raw material processing method suitable for the copper smelting working conditions, by means of electric furnace steelmaking and LF furnace refining, the content of harmful elements and residual elements can be effectively reduced, the purity of molten steel is improved, and the content of P and S is smaller than 0.020% and lower than or equal to 0.040% of the national standard. The cracking tendency of the cinder ladle under the high-temperature condition can be effectively reduced. The molten steel is subjected to modification treatment (rare earth re), so that grains can be refined, the physical comprehensive performance of the material can be improved, through single-ladle pouring, on-site temperature measurement is performed before pouring and pouring temperature can be controlled within the range of + / -3 DEG C required by the process, the grains of the slag ladle are relatively uniform and fine, and the physical performance of the slag ladle can be effectively improved.

Owner:武汉恒威宸装备制造有限公司

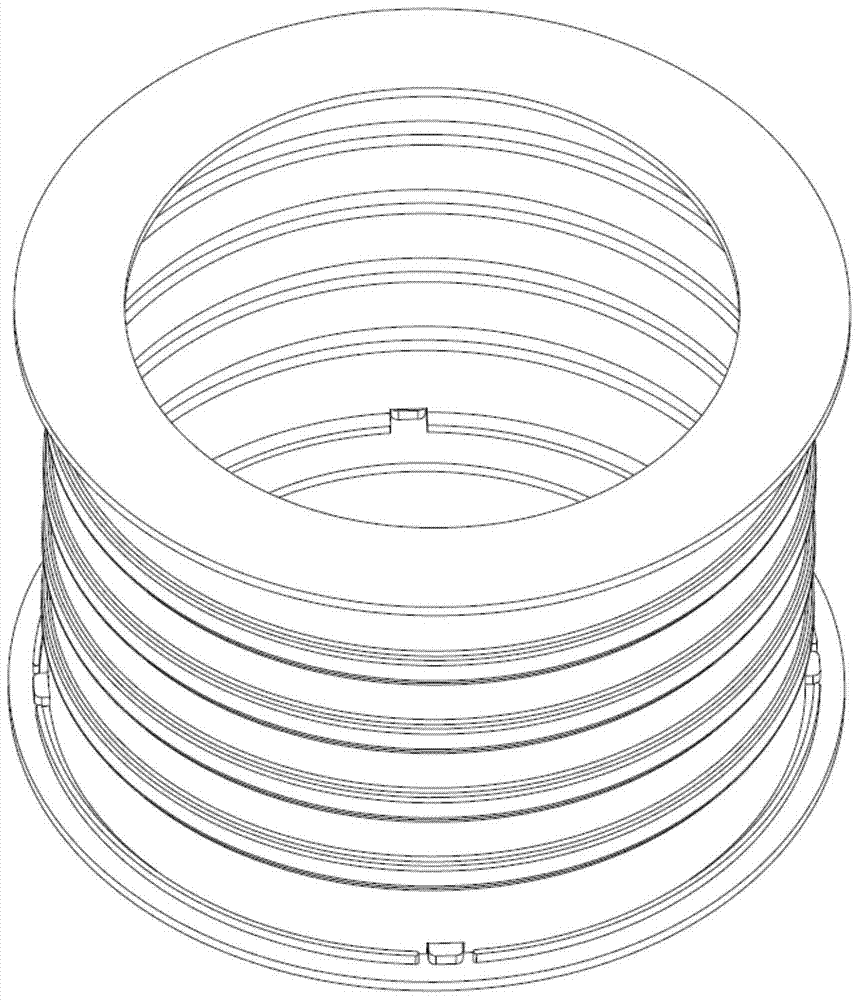

A High Thermal Stability Ion Thruster Screen Barrel

ActiveCN105020112BReduced risk of structural failureImprove structural rigidityMachines/enginesUsing plasmaVertical projectionThermal deformation

The invention discloses a grid cylinder of an ion thruster, which overcomes the deficiency of thermal stability of the existing grid cylinder and can meet the requirements of structural stability and thermal deformation resistance of a high-power ion thruster in a high-temperature environment. The screen cylinder body adopts a cylindrical thin-walled structure, and outwardly protruding reinforcing ribs with the same wall thickness as the cylinder are processed on the circumference of the screen cylinder body, and the reinforcement ribs are integrated with the screen grid cylinder body. Both ends of the screen cylinder body are bent inwardly to form annular inner folds; the screen cylinder body connects the upper fixed structure and the lower fixed structure through the annular inner folds at both ends. Positioning structures are designed at the contact surface between the screen cylinder and the upper fixed structure and at the contact surface between the screen cylinder and the lower fixed structure; the positioning structure includes a positioning boss and a positioning groove that cooperate with each other; the positioning groove Located at the two ends of the screen cylinder, the positioning bosses are located at the upper and lower fixing structures, and a limiting ring-shaped boss is designed on the upper and lower fixing structures.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

A kind of flame-retardant and environment-friendly polyurethane material and preparation method thereof

ActiveCN111548476BImprove flame retardant performanceInhibit migrationDiphenylmethanePolymer science

The invention discloses a flame-retardant environment-friendly polyurethane material, which is prepared from the following raw materials in parts by weight: 50-60 parts of diphenylmethane diisocyanate, 12-15 parts of polycaprolactone, 6-8 parts of a flame retardant and 1-2 parts of modified diatomite. The polyurethane material is prepared by the following method: 1, preparing a polyurethane prepolymer; and 2, performing a reaction on the prepolymer with a flame retardant to obtain the polyurethane material. According to the invention, a self-made flame retardant is used as one of polyurethanecopolymerization raw materials, so that flame retardant molecules are grafted to a polyurethane molecular chain in a chemical bonding manner to form a part of a main chain structure; in addition, themodified diatomite is added into the raw materials, so that the compatibility and dispersity of the polymer in a polymer matrix are improved, and the reinforcing effect is better exerted; the diatomite can play a synergistic effect on the flame retardant, so that the flame retardant property of the polyurethane material is further enhanced; the obtained polyurethane material not only has high comprehensive mechanical properties, but also has greatly improved flame retardancy.

Owner:广东裕泰实业集团有限公司

Composite copper anode mold capable of prolonging service life and production method thereof

ActiveCN109853004AHigh mechanical strength and thermal fatigue resistanceHigh hardness and thermal deformation resistancePhotography auxillary processesProcess efficiency improvementChromiumChemical composition

The invention relates to the technical field of metallurgy industrial production molds, in particular to a composite copper anode mold capable of prolonging the service life. The composite copper anode mold comprises a mold body; a copper casting cavity is formed in the mold body; a mold drawing and ejecting hole is formed in the mold body at the upper part of the copper casting cavity; a layer ofchromium zirconium copper alloy is compounded on the mold body in the copper casting cavity; and the chromium zirconium copper alloy has the following chemical components in percentage by weight: 0.75-0.85 of Cr, 0.15-0.25 of Zr, Mn less than 0.0013, Mo less than 0.0003, Ni less than 0.0005, Fe less than 0.037, and the balance of Cu. The service life of the copper anode mold is greatly prolonged;and the average copper casting quantity can reach above 1000 t / p.

Owner:湖北钜神材料科技有限责任公司

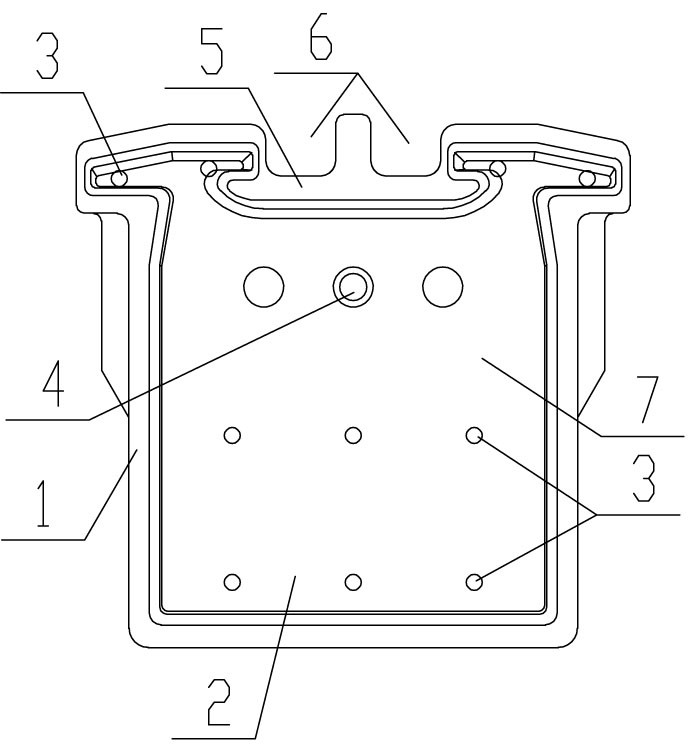

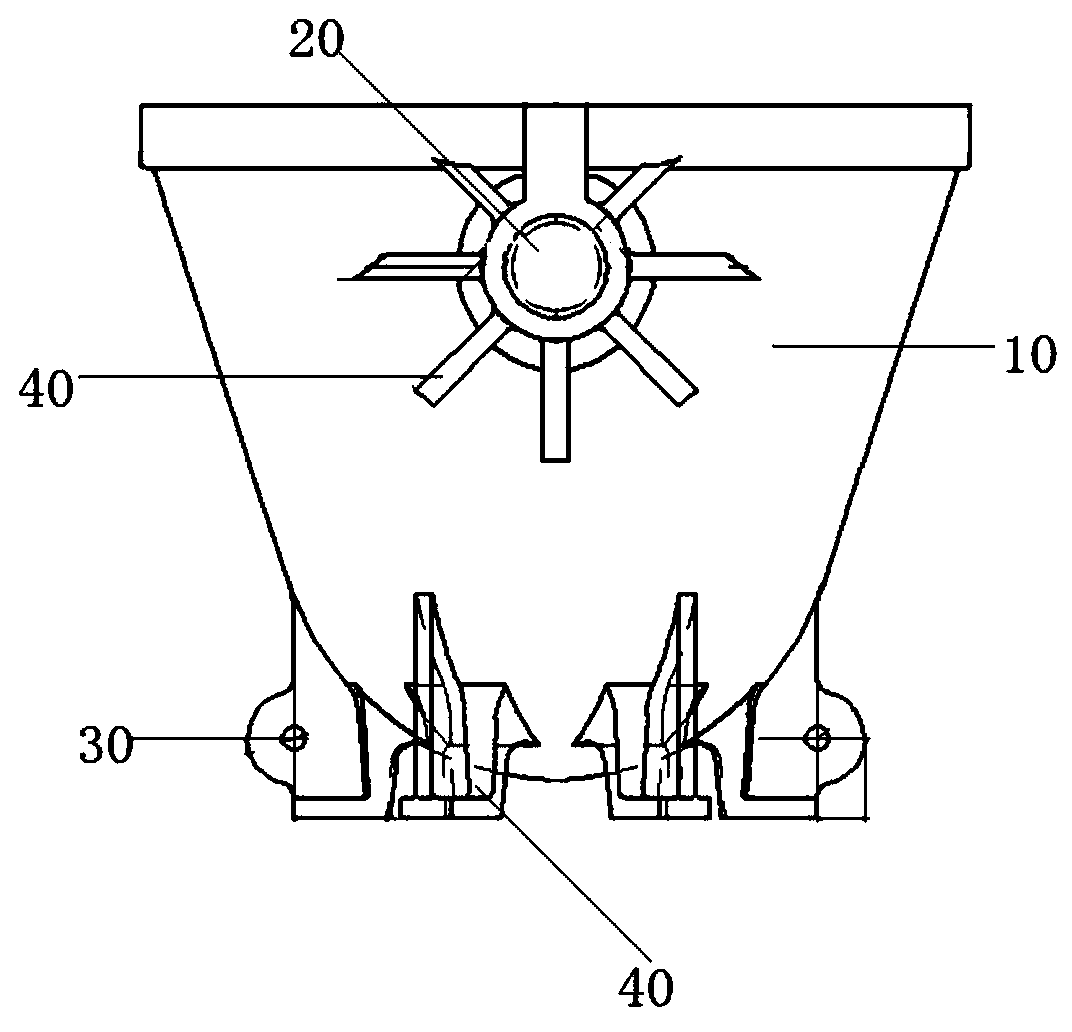

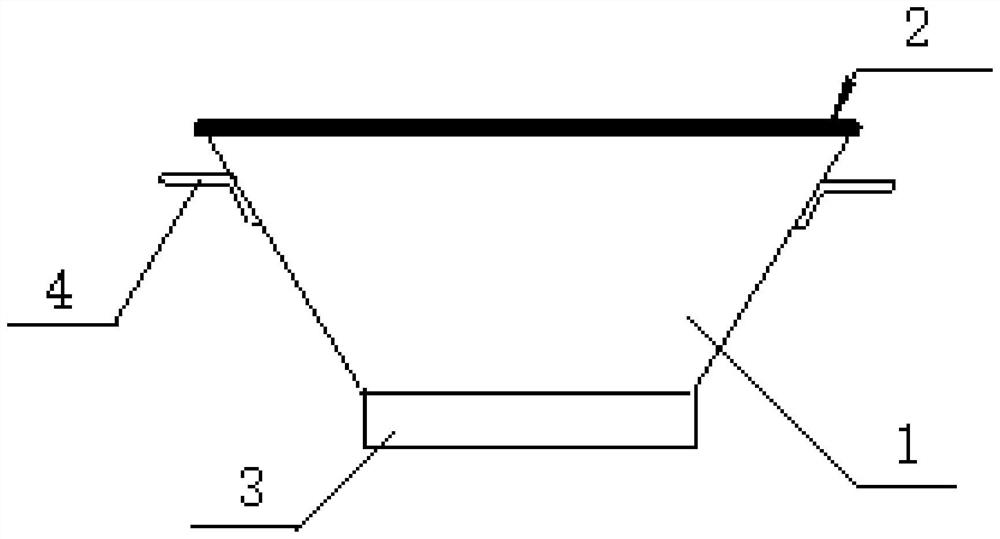

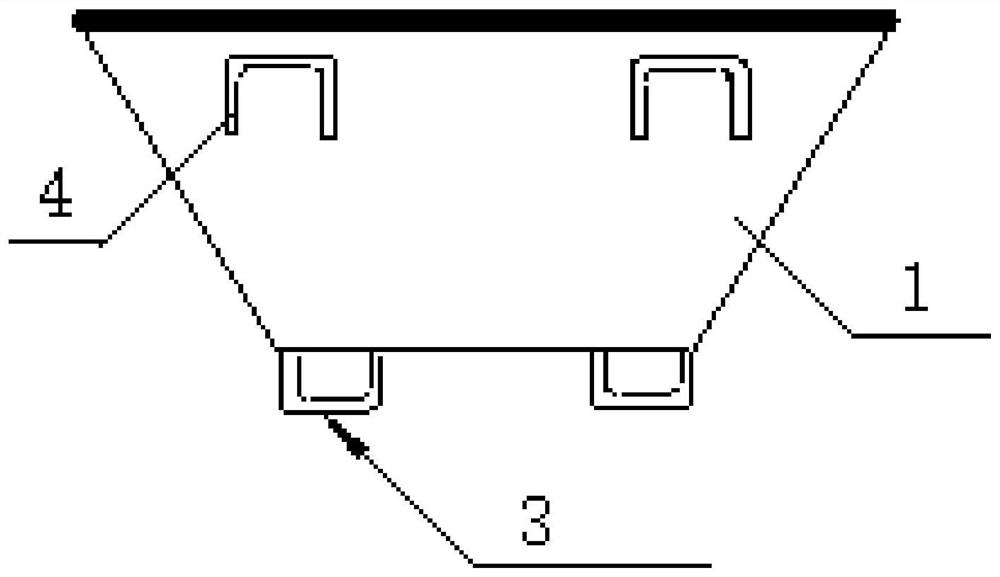

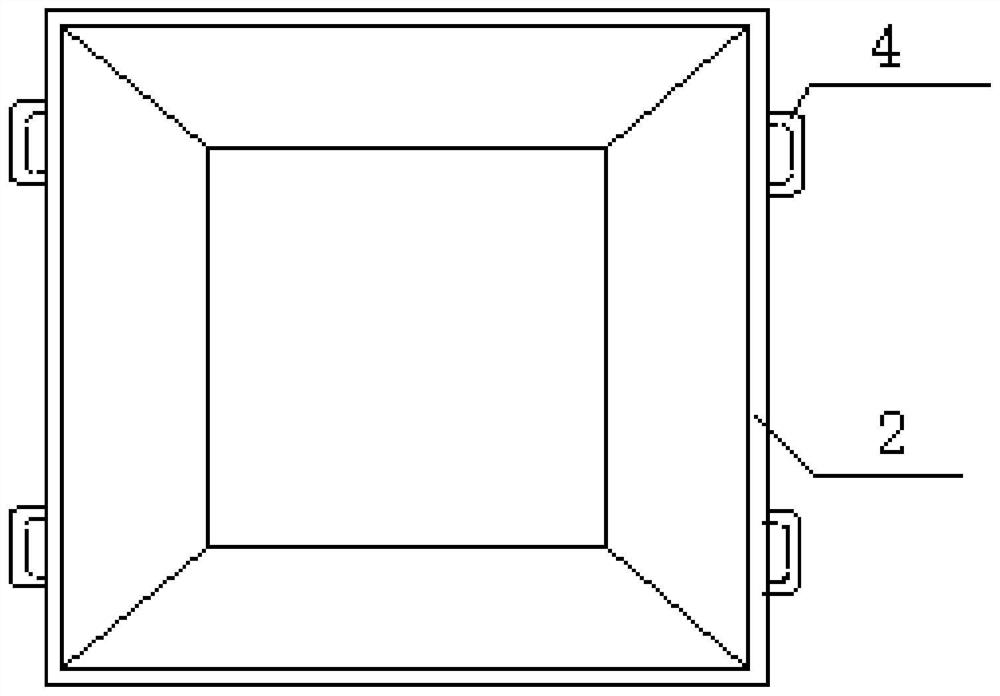

Anti-deformation carbon residue box

PendingCN114684476AHigh strengthHigh heat deformation resistanceRigid containersContainer handlesElectrolysisThermal deformation

The invention relates to the field of electrolysis production, in particular to an anti-deformation carbon residue box which comprises a box body with an upward opening, the box body is in a quadrangular frustum pyramid shape, the bottom face and the top opening of the box body are rectangles with the same shape, and the area of the top opening of the box body is larger than that of the bottom face of the box body; the reinforcing part is arranged at an opening in the top of the box body, the reinforcing part comprises four reinforcing strips, each reinforcing strip is fixedly connected with the top edge of one side wall of the box body, and the four reinforcing strips are fixedly connected end to end to form the annular reinforcing part; the supporting seat is arranged below the bottom surface of the box body; compared with the prior art, the overall strength and thermal deformation resistance of the upper opening of the box body are greatly improved, the bottom strength of the box body is effectively enhanced, the overall supporting effect of the box bottom is formed, the service life of the carbon residue box is effectively prolonged, and carrying by workers is greatly facilitated.

Owner:NAT ELECTRIC POWER INVESTMENT GRP YELLOW RIVER UPSTREAM HYDROPOWER DEV CO LTD +2

Chromium plating rack for cylinder liner bore

InactiveCN100449134CUniform thicknessReduce volatilityElectrolysis componentsMolten spray coatingEngineeringRudder

The invention relates to a device to measure and regulate micro aeroboat engine, including engine speed measuring and sensing device, control box and rudder, and its character: the measuring and sending device has the structure: there is a magnet block fixed on the rotating shaft of the engine, there is a Hall sensor probe installed near the magnet, the output of the Hall sensor probe is connected to the control box through lead wires and that of the control box is connected to the rudder through lead wires. It can measure and control left and right engines of the aeroboat to make their speed consistent in a certain range, without manual operation and control, thus reducing labor strength of operators.

Owner:烟台万斯特有限公司

A kind of cellulose nanocrystal composite material and method modified by polylactic acid/nucleating agent

Owner:SHANDONG UNIV OF SCI & TECH

High-strength engine cylinder cover

InactiveCN104611621AImprove reliabilityImprove thermal fatigue strengthCylinder headsCylindersThermal fatigueThermal deformation

The invention discloses a high-strength engine cylinder cover. The high-strength engine cylinder cover is manufactured from a gray cast iron material added with modified nano-ceramic powder. According to the high-strength engine cylinder cover, the original material components and production process are basically not changed on the basis of the original gray cast iron material; through addition of trace nano-modified powder, the uniformity and the continuity of a metallographic structure of the material are improved and the thermal fatigue strength of a gray iron material is remarkably improved; furthermore, a process for forming an unload groove in a base plate of the cylinder cover is omitted; by adding the nanopowder, the thermal fatigue strength and thermal deformation resistance of the gray iron material are obviously improved; the process for forming an unload groove in the base plate of the cylinder cover is omitted, so that the surface machining stress of the base plate is relatively low, the rigidity is relatively high and the flatness is relatively good; by virtue of the technical route, the reliabilities of the cylinder cover and a cylinder gasket can be effectively improved, and the risks of cracking, deformation and cylinder gasket impact can be reduced.

Owner:GUANGXI YUCHAI MASCH CO LTD

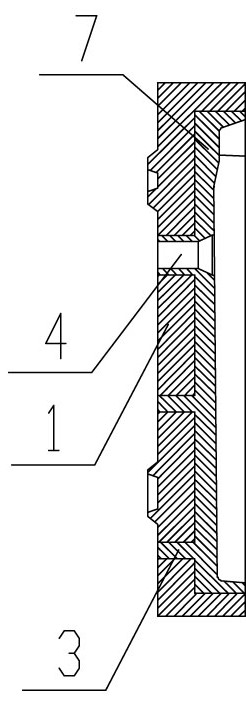

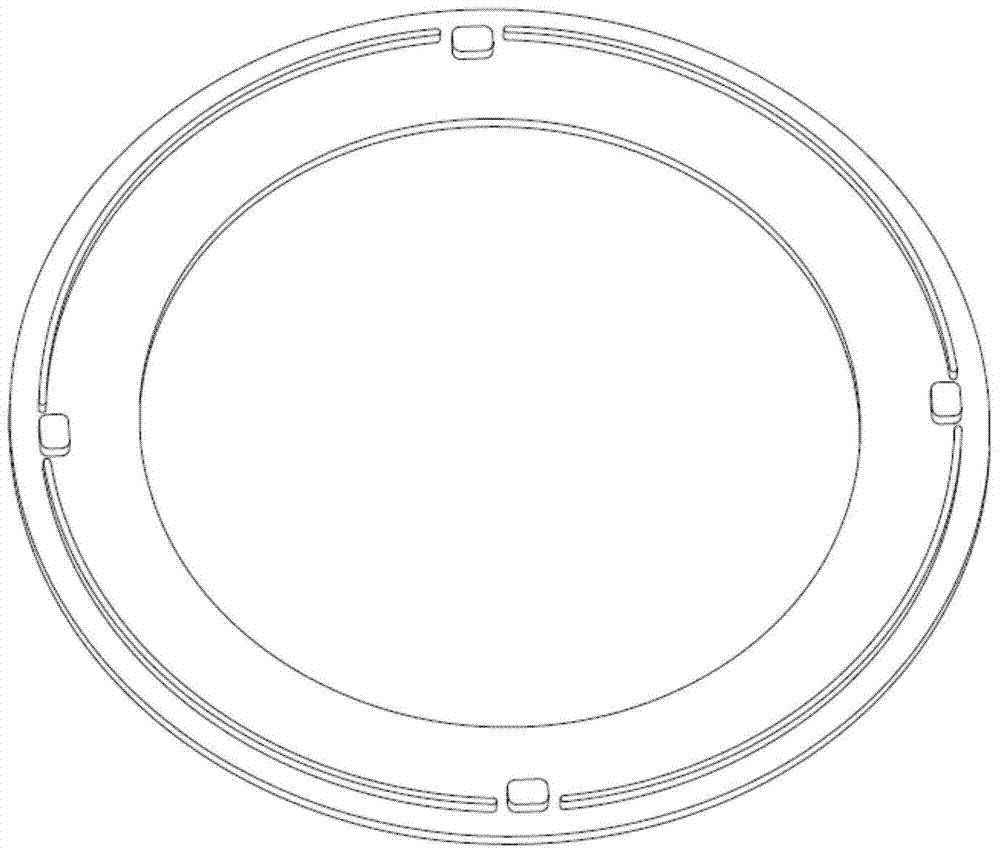

Anti-air backflow and anti-deformation liquid viscous clutch dual plate

InactiveCN107676402BHigh torque transmissionHigh heat deformation resistanceCouplingsFluid clutchesViscous liquidAir volume

The invention provides an anti-air-backflow and anti-deformation dual disc of a liquid viscous speed-regulating clutch. The clutch dual disc is an annular steel disc. An inner annular ring of the annular steel disc is provided with a spline tooth. The outer surface of the clutch dual disc is a plane. The inner surface of the clutch dual disc is an inclined plane. The thickness of the clutch dual disc is gradually increased in the direction from the inner diameter to the outside diameter. The thickness variation of the clutch dual disc meets the formula of h2-h1=l*tangent alpha= (omega2 / omega1)*n. The included angle alpha between the inner surface and the upper surface of the clutch dual disc is more than 0 degree and no more than 2 degrees. The dual disc reduces the air volume of frictionpairs, increases the effective contact area of the friction pairs, enhances the film forming ability and the dynamic pressure bearing capacity of a viscous liquid between the friction pairs, enhancesthe non-deformability of the dual disc, improves the working performance of the liquid viscous speed-regulating clutch, and prolongs the service life of the liquid viscous speed-regulating clutch.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com