Manufacturing method of copper-based slag notch sleeve inner core suitable for smelting reduction furnace

A production method and reduction furnace technology are applied in the production of copper-based slag mouth sleeve inner core and the production field of copper-based slag mouth inner core, which can solve the problems of easy deformation, poor high temperature resistance, easy burning and the like, and achieve heat resistance. Enhanced deformation performance, enhanced wear resistance, and shortening of the effect of the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

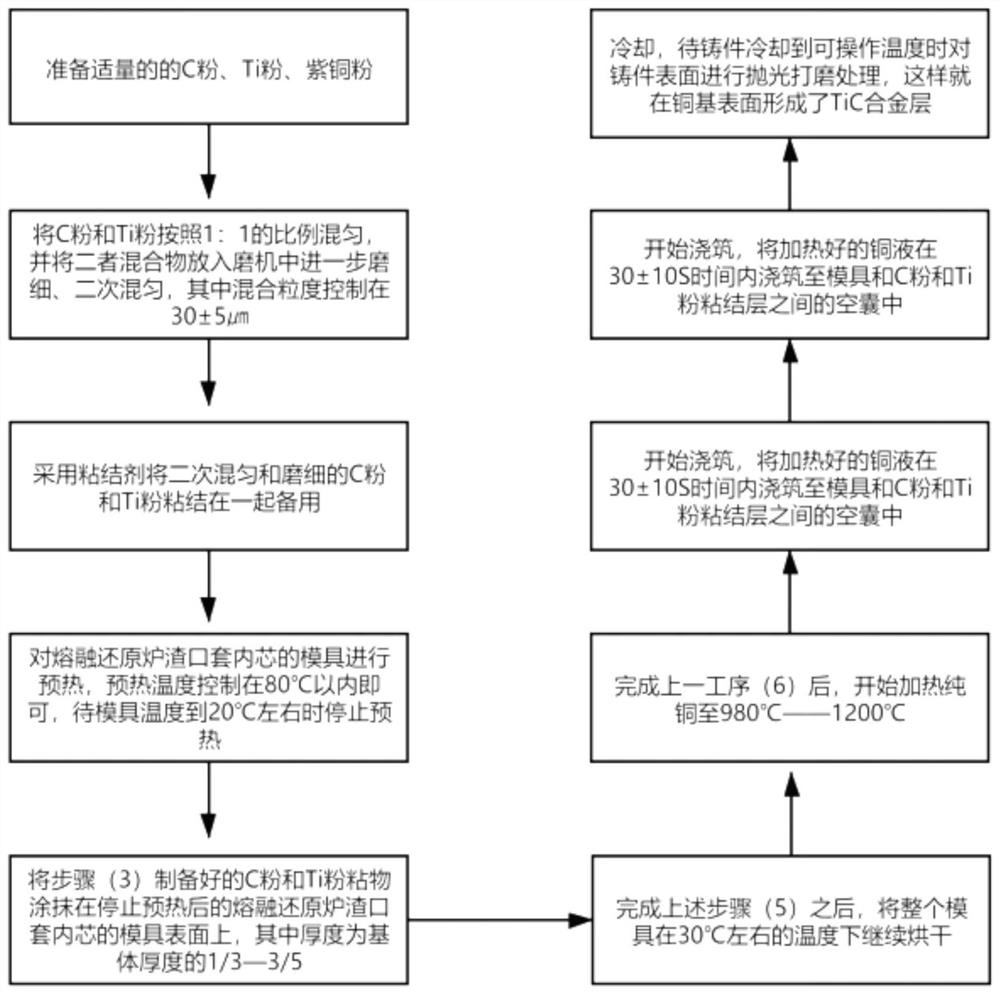

[0050] A method for manufacturing the inner core of a slag mouth sleeve suitable for a smelting reduction furnace includes the following process steps:

[0051] (1) Prepare an appropriate amount of C powder, Ti powder and red copper;

[0052] (2) Mix C powder and Ti powder according to the ratio of 1:1, and put the mixture of the two into the mill for further grinding and secondary mixing, wherein the mixing particle size is controlled at 30±5μm, and the mixing particle size of the output Controlled at 20±5μm;

[0053](3) Use a binder to bond the secondary mixed and finely ground C powder and Ti powder together for later use. 30% of the mass of the powder mixture;

[0054] (4) Preheating the mold of the inner core of the slag mouth sleeve of the smelting reduction furnace, the preheating temperature is controlled at 50°C for 20 minutes, and the preheating is stopped when the mold temperature reaches 25°C;

[0055] (5) C powder and Ti powder sticky matter prepared by step (3...

Embodiment 2

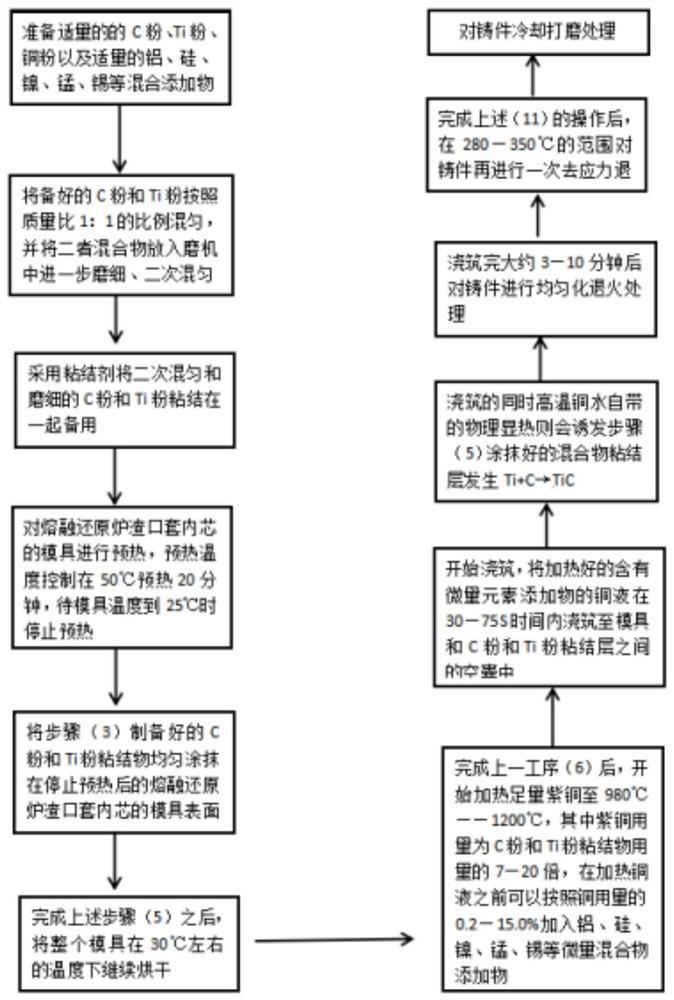

[0062] A method for manufacturing the inner core of a slag mouth sleeve suitable for a smelting reduction furnace, comprising the following process steps:

[0063] (1) Prepare appropriate amount of C powder, Ti powder and brass;

[0064] (2) Mix the prepared C powder and Ti powder according to the mass ratio of 1:1, and put the mixture of the two into the mill for further grinding and secondary mixing, wherein the mixing particle size is controlled at 30±5μm , the output mixing particle size is controlled at 20±5μm;

[0065] (3) Use a binder to bond the secondary mixed and ground C powder and Ti powder together for later use. The binder is polyvinyl alcohol (PVA), and the amount of the binder is 50% of the quality of the mixture. % ratio, so that the bonding effect is better for later use;

[0066] (4) Preheating the mold of the inner core of the slag mouth sleeve of the smelting reduction furnace, the preheating temperature is controlled at 50°C for 20 minutes, and the preh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com