Anti-air backflow and anti-deformation liquid viscous clutch dual plate

An air return and clutch technology, applied in the field of friction components, can solve the problems of reduced clutch working efficiency, reduced clutch service life, reduced clutch efficiency, etc., and achieves the effect of enhancing thermal deformation resistance, prolonging working life, and reducing air volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

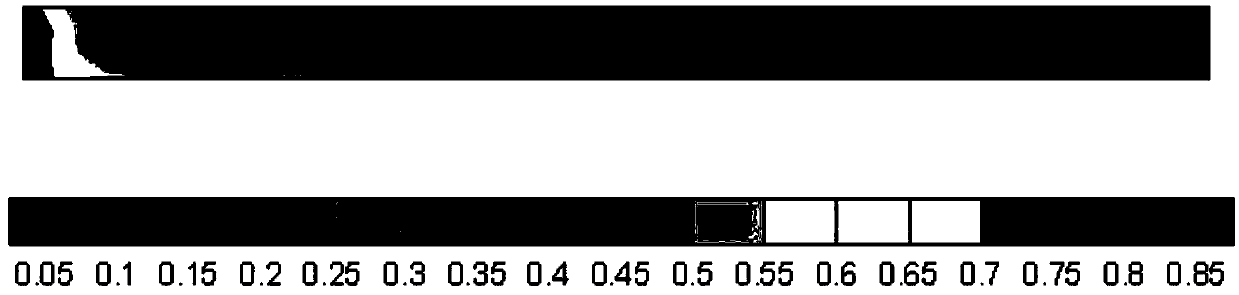

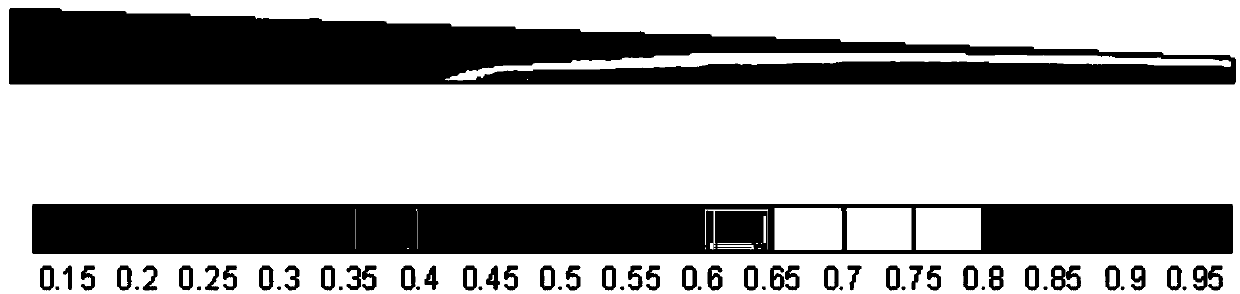

[0031] In the anti-air backflow and anti-deformation anti-air backflow and anti-deformation liquid viscous clutch dual plate, the clutch dual plate 1 is an annular steel plate, and the material of the annular steel plate is 45 # steel. Spline teeth 2 are arranged on the inner ring of the annular steel plate, the outer surface of the clutch pair 1 is a plane, and the inner surface is an inclined plane, and the thickness of the clutch pair 1 gradually increases from the inner diameter to the outer diameter. ; In this embodiment, the inner diameter of the clutch pair plate 1 and the friction plate is 130mm, and the outer diameter is 180mm, the angle α=0.1° between the inner surface and the upper surface of the clutch pair plate 1, and the oil film thickness h 1 0.3mm, oil film thickness h at outer diameter 2 is 0.1mm, when the clutch is working, the volume fraction of viscous oil between the friction pairs is as follows figure 2 As shown, it is possible to reduce figure 1 The...

Embodiment 2

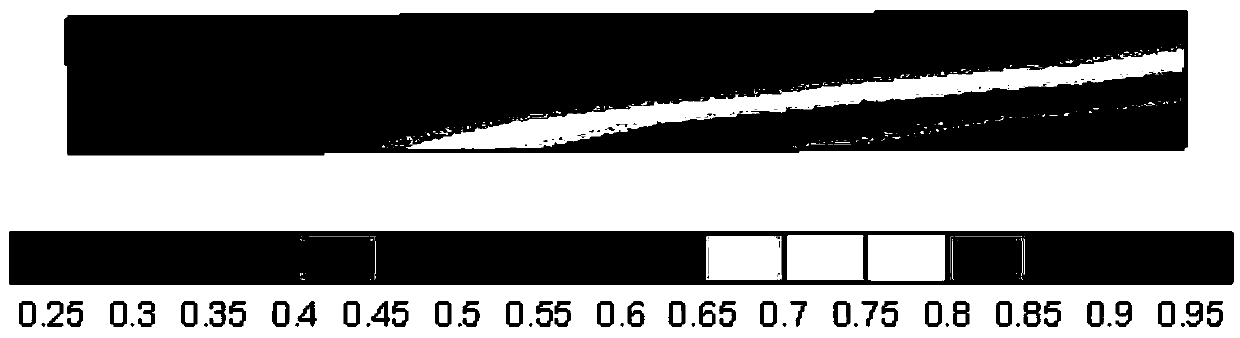

[0033] In the anti-air backflow and anti-deformation anti-air return and anti-deformation fluid viscous speed-regulating clutch dual plate, the clutch dual plate 1 is an annular steel plate, and the material of the annular steel plate is 65Mn steel. Spline teeth 2 are arranged on the inner ring of the annular steel plate, the outer surface of the clutch pair 1 is a plane, and the inner surface is an inclined plane, and the thickness of the clutch pair 1 gradually increases from the inner diameter to the outer diameter. ; In this embodiment, the inner diameter of the clutch pair plate 1 and the friction plate is 90mm, and the outer diameter is 110mm, the angle α=2° between the inner surface and the upper surface of the clutch pair plate 1, and the oil film thickness h at the inner diameter 1 0.5mm, oil film thickness h at outer diameter 2 is 0.3mm, when the clutch is working, the volume fraction of viscous oil between the friction pairs is as follows Figure 4 As shown, it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com