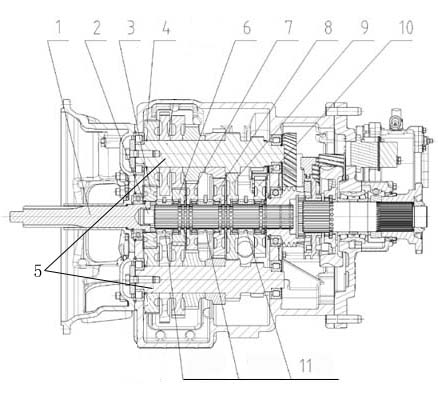

Heavy ten-gear speed changer assembly

A transmission, heavy-duty technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem that the transmission cannot meet the output torque and speed ratio range, so as to reduce the failure rate of the whole vehicle, increase the service life, The effect of increased transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

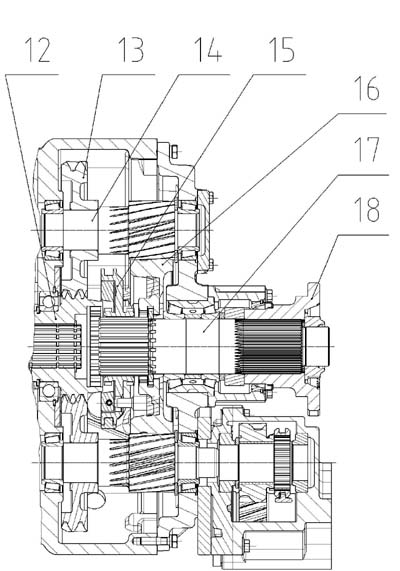

[0014] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 As shown, the heavy-duty 10-speed transmission assembly is composed of the main box and the auxiliary box. It is characterized in that: the main box manually controls the 5 gears and adopts the gear shifting of the combination sleeve, and the auxiliary box pneumatically controls the 2 gears and uses the synchronizer to change gears. A total of 10 forward gears are formed; the 10-speed double countershaft transmission is equipped with a full helical gear structure for the auxiliary box, and the transmission can take power from the side, bottom of the main box or the rear end of the two intermediate shafts of the auxiliary box.

[0015] The tail end of the first shaft in the main box is connected with two shafts. The lower left and upper right positions of the second shafts are two identical and symmetrical intermediate shafts. The reduction gear on the intermediate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com