Gear rack drive revolving worktable

A technology of rotary table and rack and pinion, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of not applying high-precision rotary table, transmission torque limit, etc., and achieve simple structure, eliminate Clearance, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

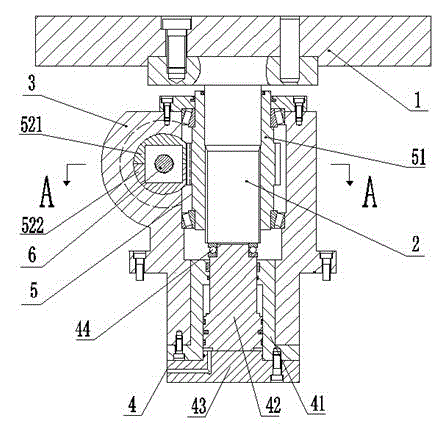

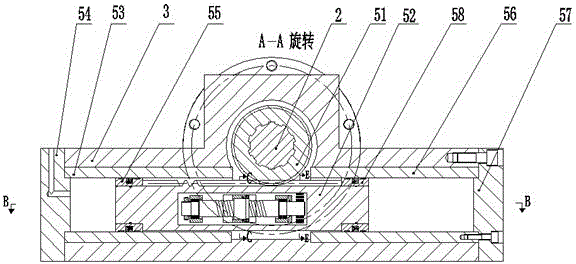

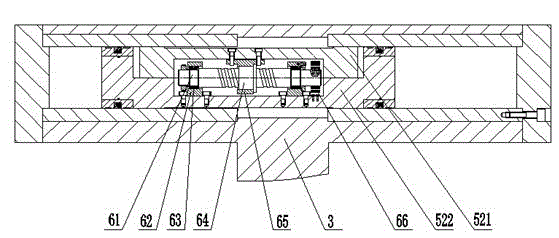

[0044] Such as Figure 1 to Figure 5 As shown, the rack and pinion drive rotary table of the present invention is hydraulically driven, and includes the table 1, the box body 3, the lifting drive mechanism 4, the rotary drive mechanism 5 and the anti-backlash mechanism 6; wherein the table 1 passes through the spline shaft 2 is assembled and connected to the box body 3, and is supported and limited by the spline shaft 2, and the worktable 1 is fixedly connected to the spline shaft 2 by screws; the rotary drive mechanism 4, the lift drive mechanism 5 and the anti-backlash mechanism 6 are installed in Inside the box 3, the rotary drive mechanism 3 and the lift drive mechanism 4 are respectively assembled and connected with the spline shaft 2 and drive the spline shaft 2;

[0045] Figure 1 to Figure 5 in, figure 1 Shows the lifting drive mechanism of the rack and pinion drive rotary table and the installation relationship of the various parts in the box; figure 2 Shows the rotary d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com