A kind of flame-retardant and environment-friendly polyurethane material and preparation method thereof

A polyurethane material and environmentally friendly technology, applied in the field of polyurethane materials, can solve the problems affecting the flame retardancy and mechanical properties of polyurethane materials, poor compatibility, difficulty in uniform dispersion of flame retardants and other additives, etc., to avoid migration and rich Set, improve flame retardant performance, improve compatibility and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

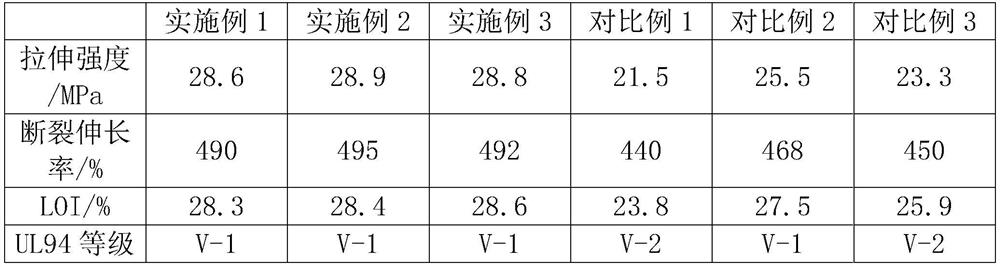

Examples

Embodiment 1

[0041] A flame-retardant and environment-friendly polyurethane material, comprising the following raw materials in parts by weight: 50 parts of diphenylmethane diisocyanate, 12 parts of polycaprolactone, 6 parts of flame retardant, and 1 part of modified diatomite;

[0042] Described polyurethane material is prepared by following method:

[0043] The first step is to place the modified diatomite in a beaker, add diphenylmethane diisocyanate and polycaprolactone in sequence, heat to 75°C, and react at a constant temperature for 120 minutes to obtain a prepolymer terminated with isocyanate groups;

[0044] Step 2: Weigh the prepolymer, preheat it to 65°C and carry out vacuum defoaming. After the prepolymer has no bubbles, quickly pour the flame retardant into the prepolymer, and place it in a 75°C water bath for mechanical stirring 2min, pour into the mold, vacuum degassing for 70s, and finally put it into a 120°C oven for 10h to make the polyurethane material.

Embodiment 2

[0046] A flame-retardant and environment-friendly polyurethane material, comprising the following raw materials in parts by weight: 55 parts of diphenylmethane diisocyanate, 13 parts of polycaprolactone, 7 parts of flame retardant, and 1.5 parts of modified diatomite;

[0047] Described polyurethane material is prepared by following method:

[0048] The first step is to place the modified diatomite in a beaker, add diphenylmethane diisocyanate and polycaprolactone in sequence, heat to 78°C, and react at a constant temperature for 135 minutes to obtain a prepolymer terminated with isocyanate groups;

[0049] Step 2: Weigh the prepolymer, preheat it to 68°C and carry out vacuum defoaming. After the prepolymer has no foam, quickly pour the flame retardant into the prepolymer, and place it in a 78°C water bath for mechanical stirring After 2.5 minutes, it was poured into a mold, vacuum defoamed for 75 seconds, and finally placed in an oven at 120° C. for 11 hours to prepare the po...

Embodiment 3

[0051] A flame-retardant and environment-friendly polyurethane material, comprising the following raw materials in parts by weight: 60 parts of diphenylmethane diisocyanate, 15 parts of polycaprolactone, 8 parts of flame retardant, and 2 parts of modified diatomite;

[0052] Described polyurethane material is prepared by following method:

[0053] The first step is to place the modified diatomite in a beaker, add diphenylmethane diisocyanate and polycaprolactone in sequence, heat to 80°C, and react at a constant temperature for 150 minutes to obtain a prepolymer terminated with isocyanate groups;

[0054] Step 2: Weigh the prepolymer, preheat it to 70°C and carry out vacuum defoaming. After the prepolymer has no bubbles, quickly pour the flame retardant into the prepolymer, and place it in a water bath of 80°C for mechanical stirring. After 3 minutes, pour it into a mold, vacuum defoam for 80 seconds, and finally place it in a 120°C oven for 12 hours to prepare the polyurethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com