Patents

Literature

47results about How to "Optimize wall thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

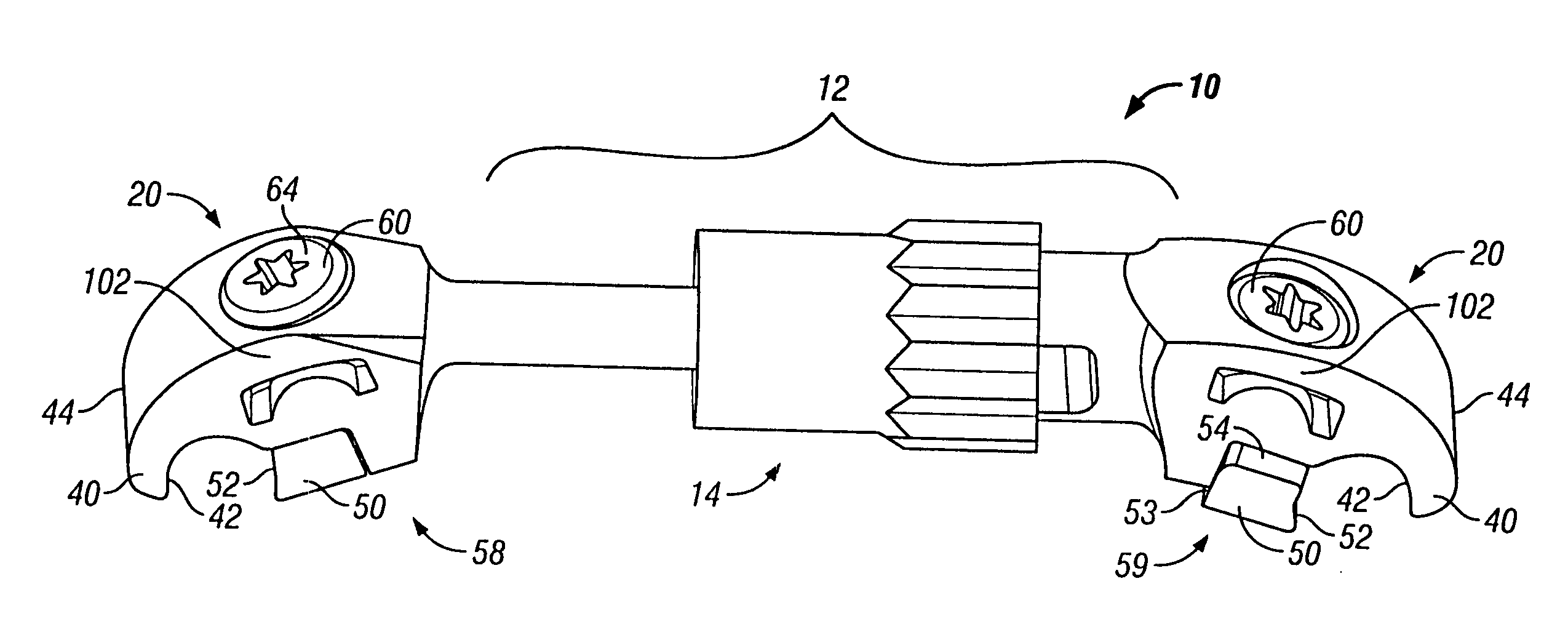

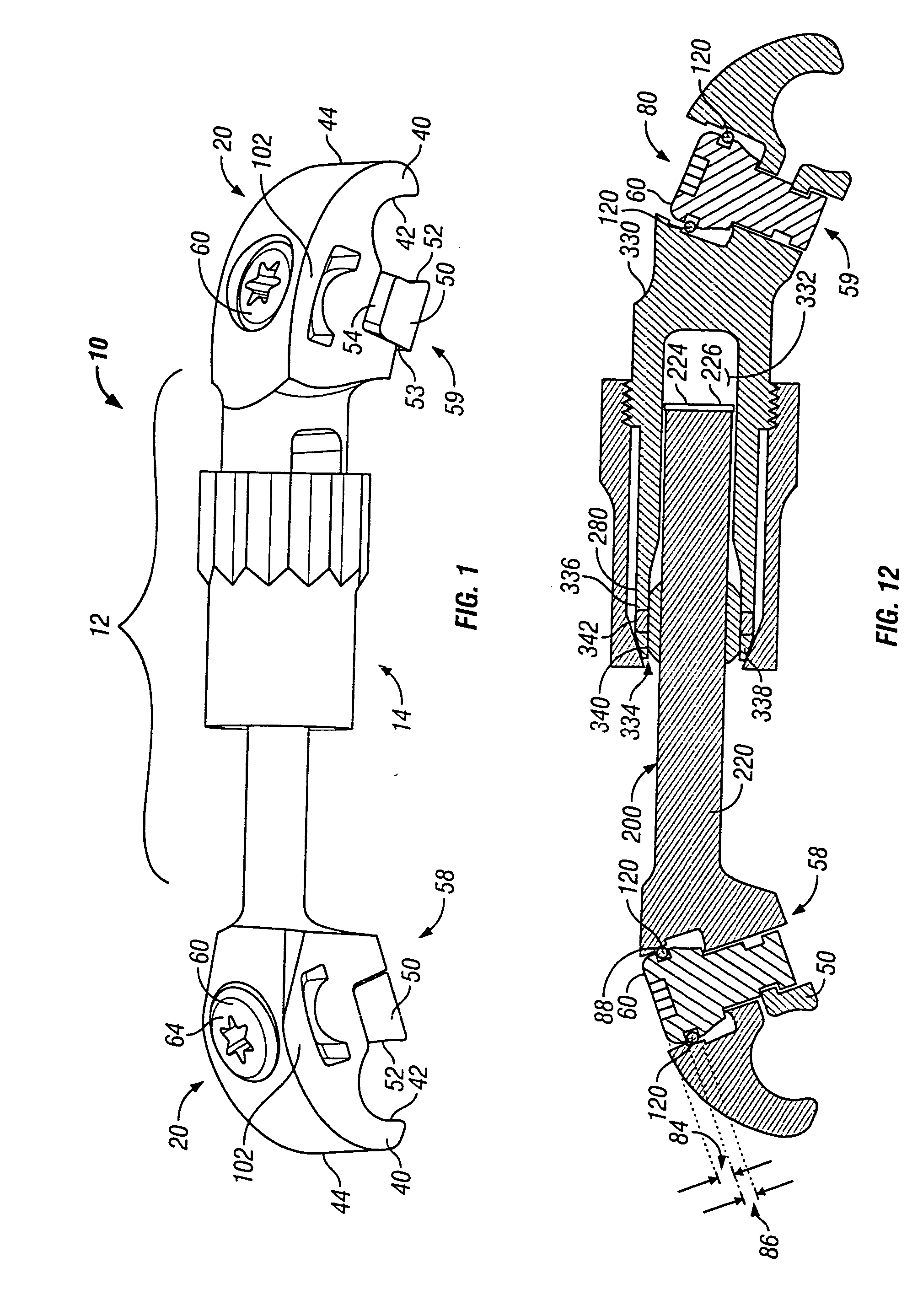

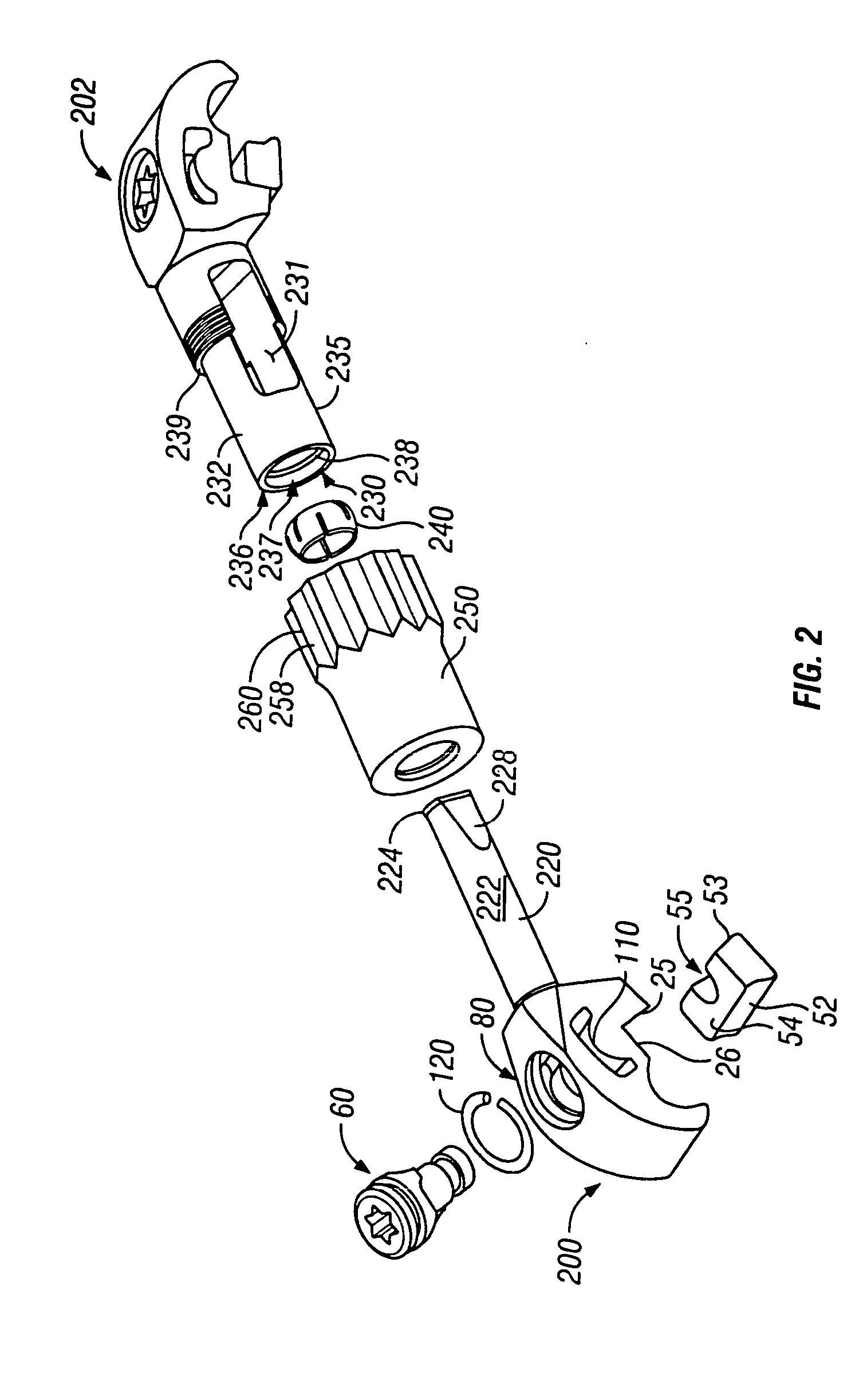

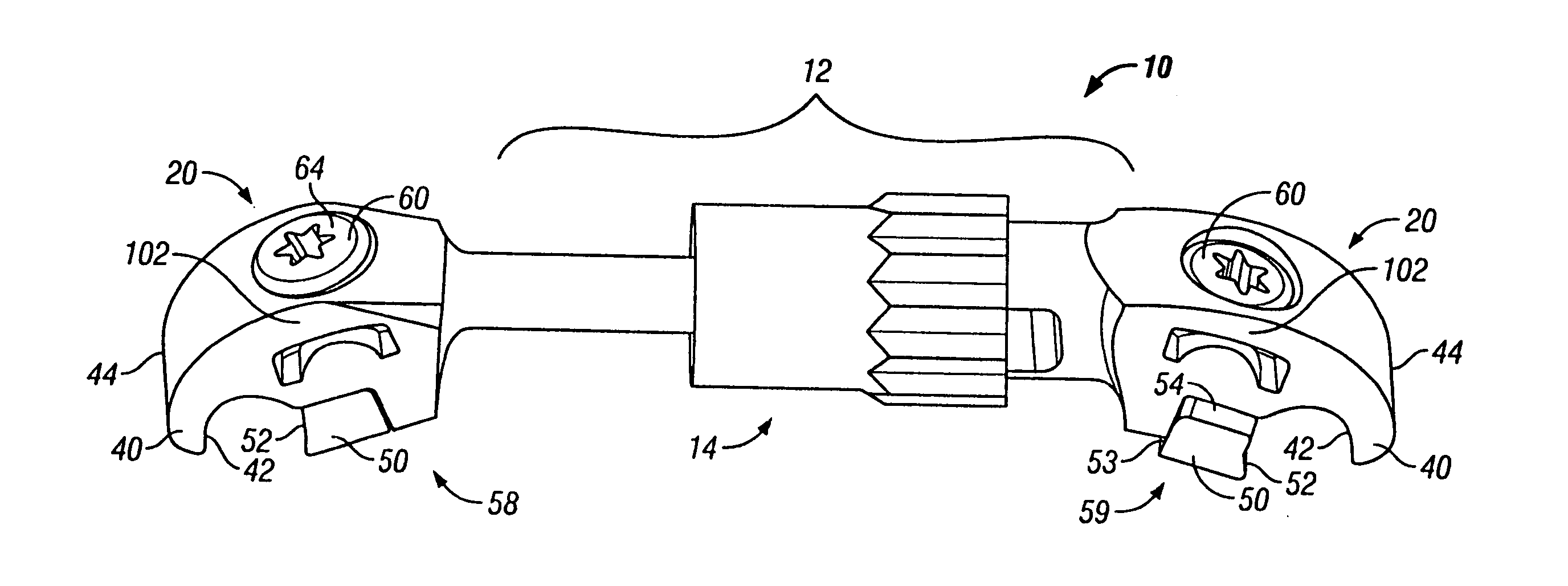

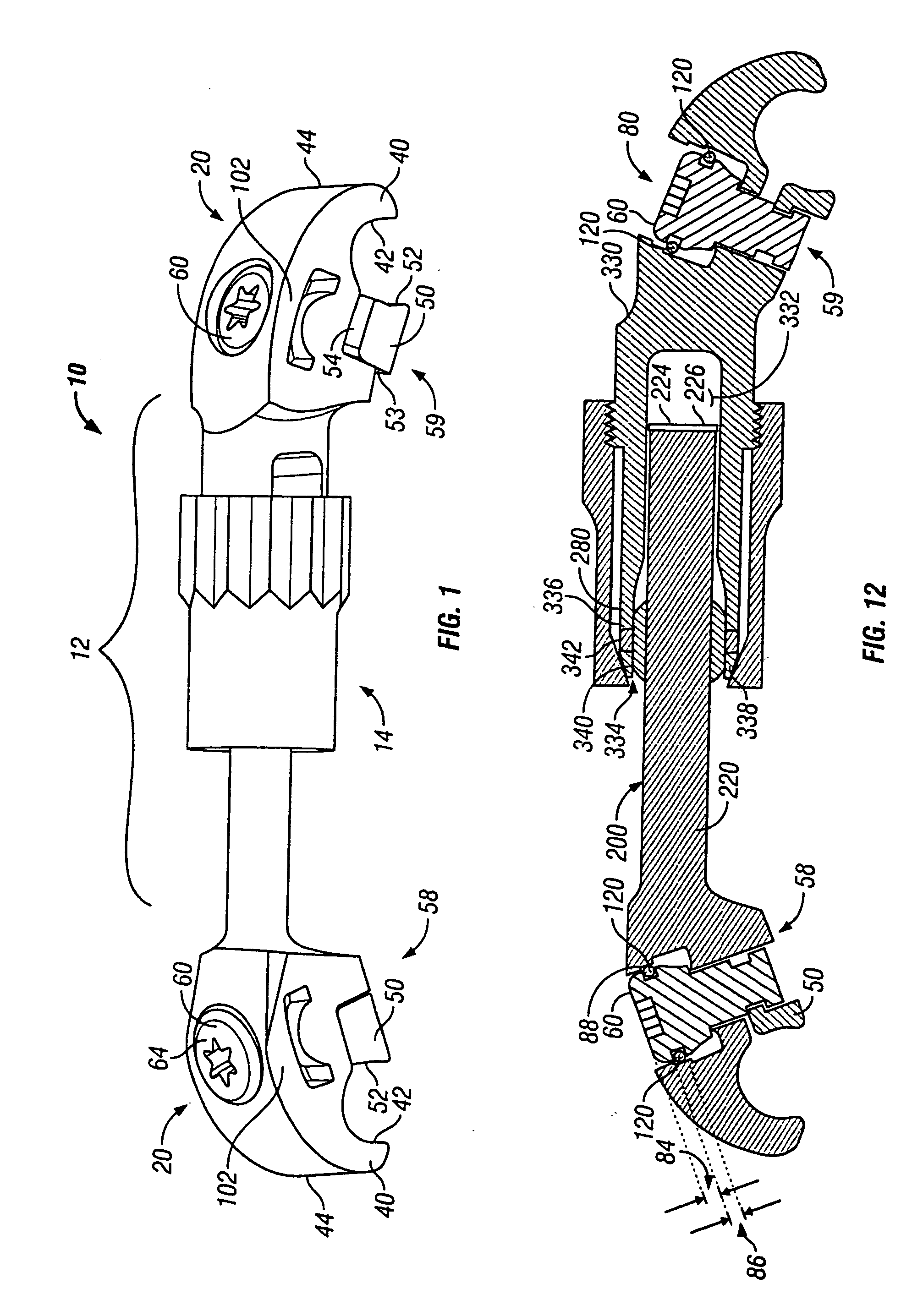

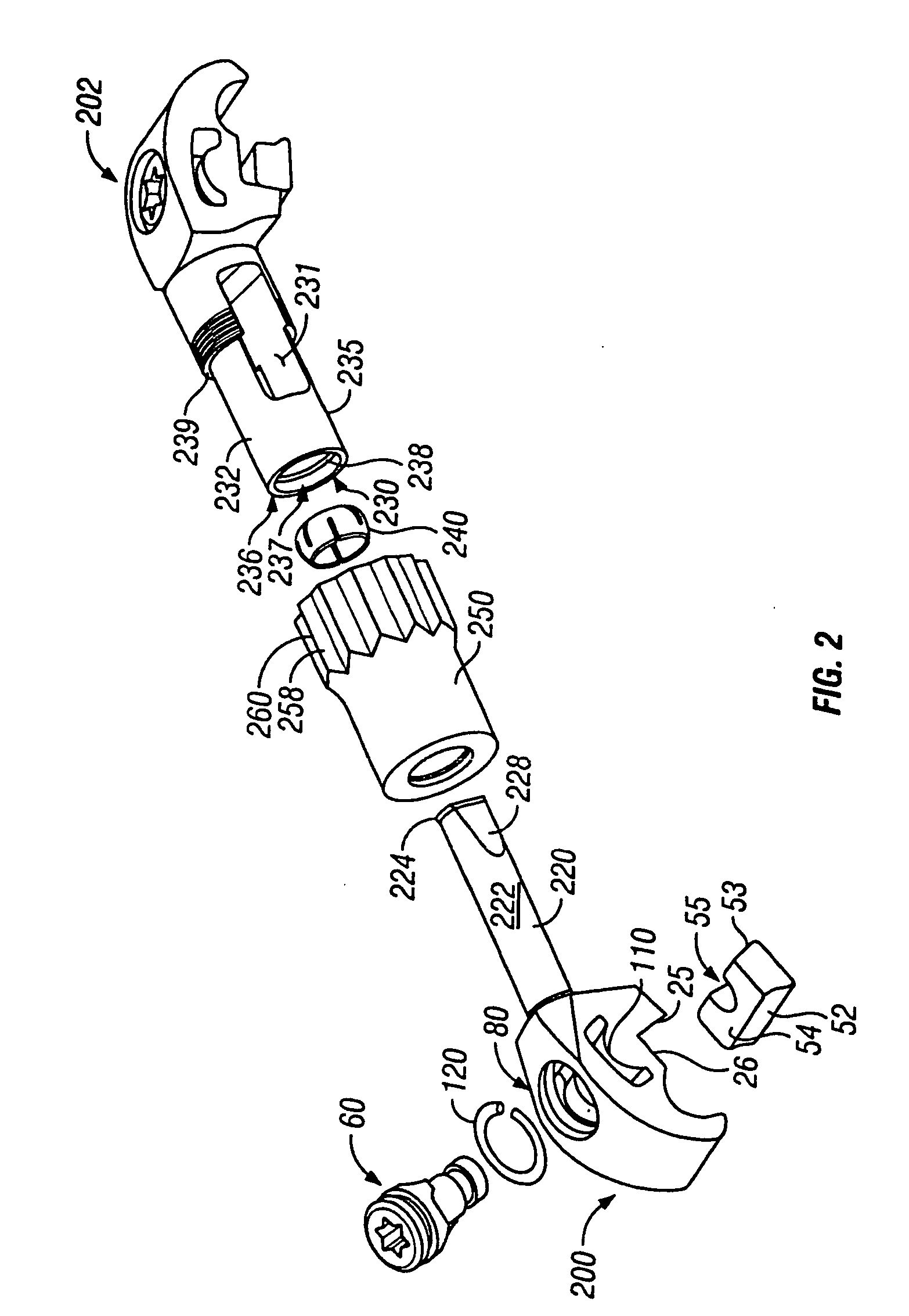

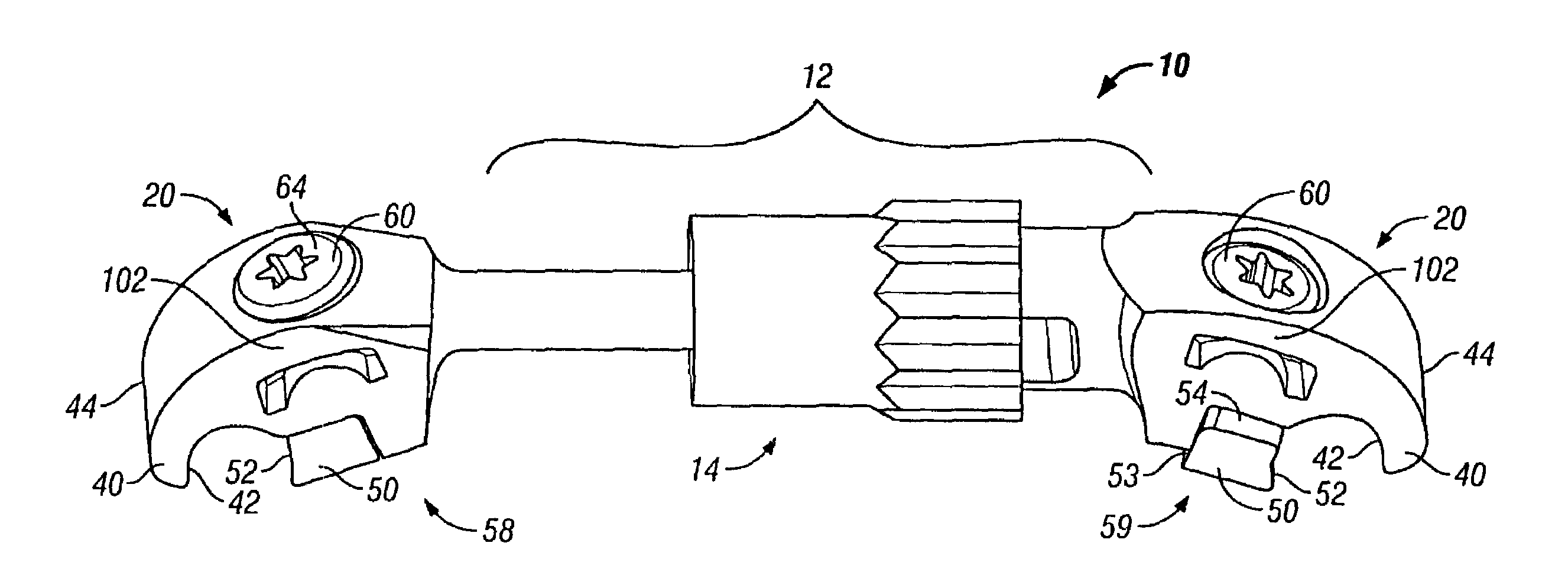

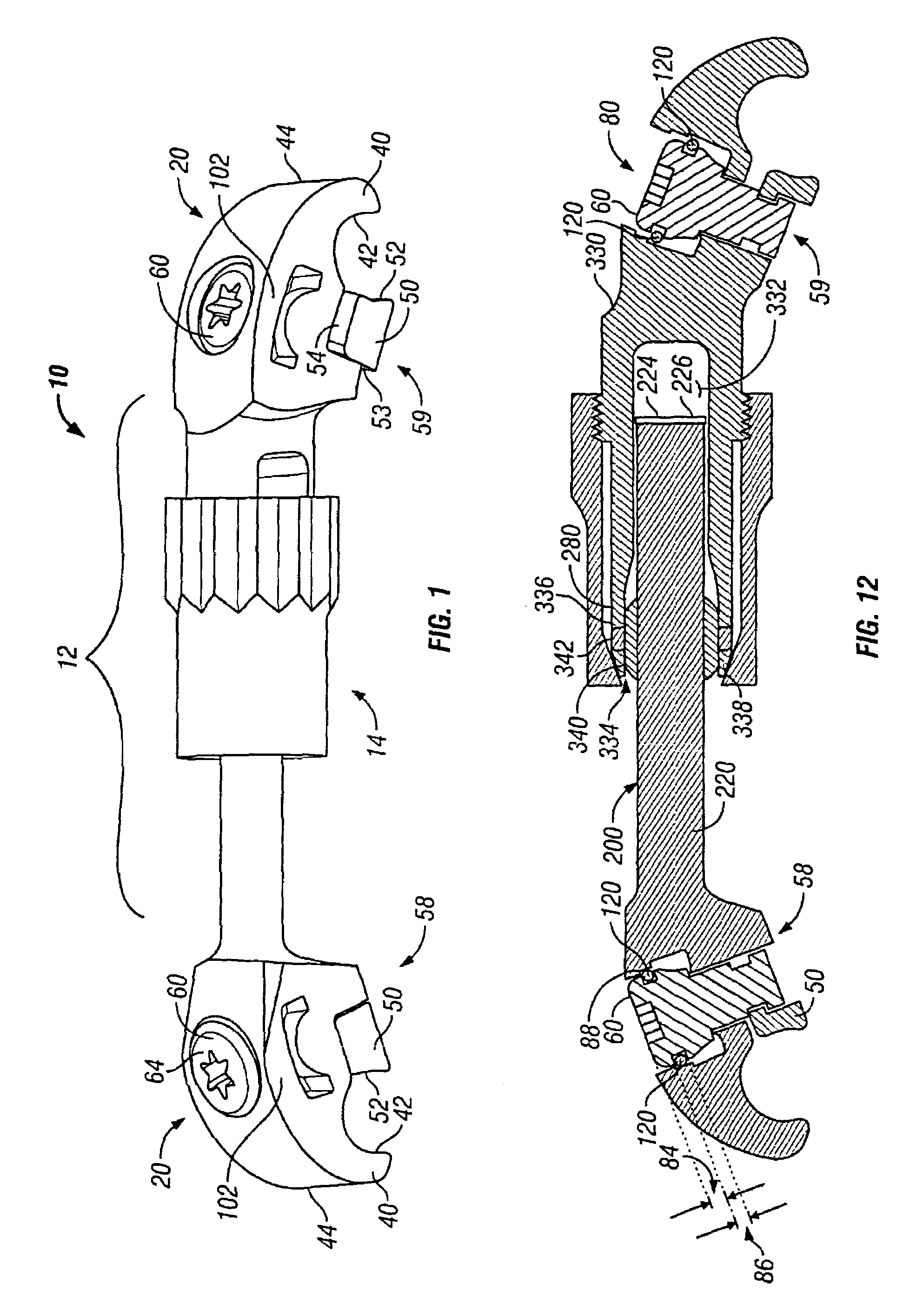

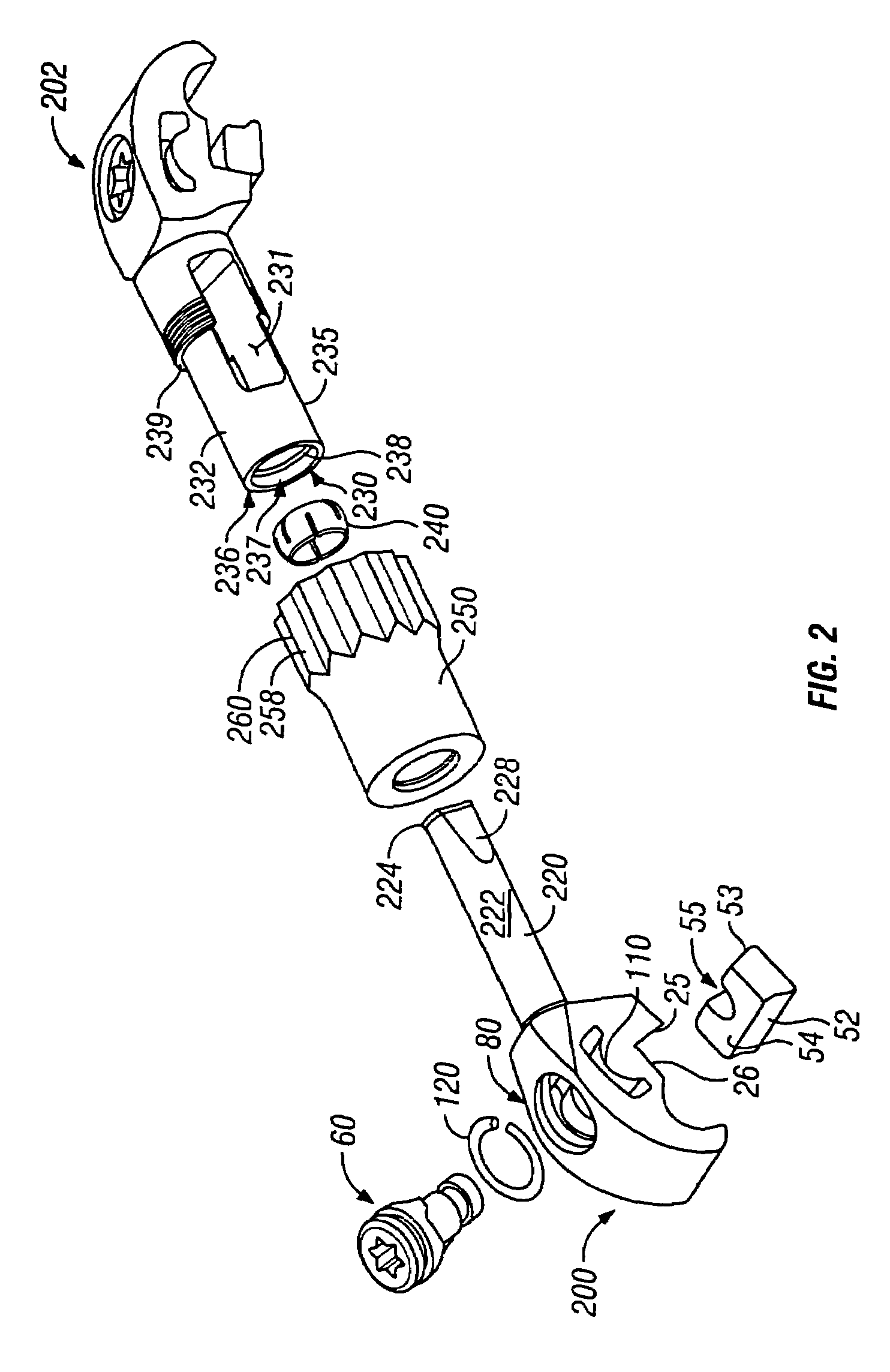

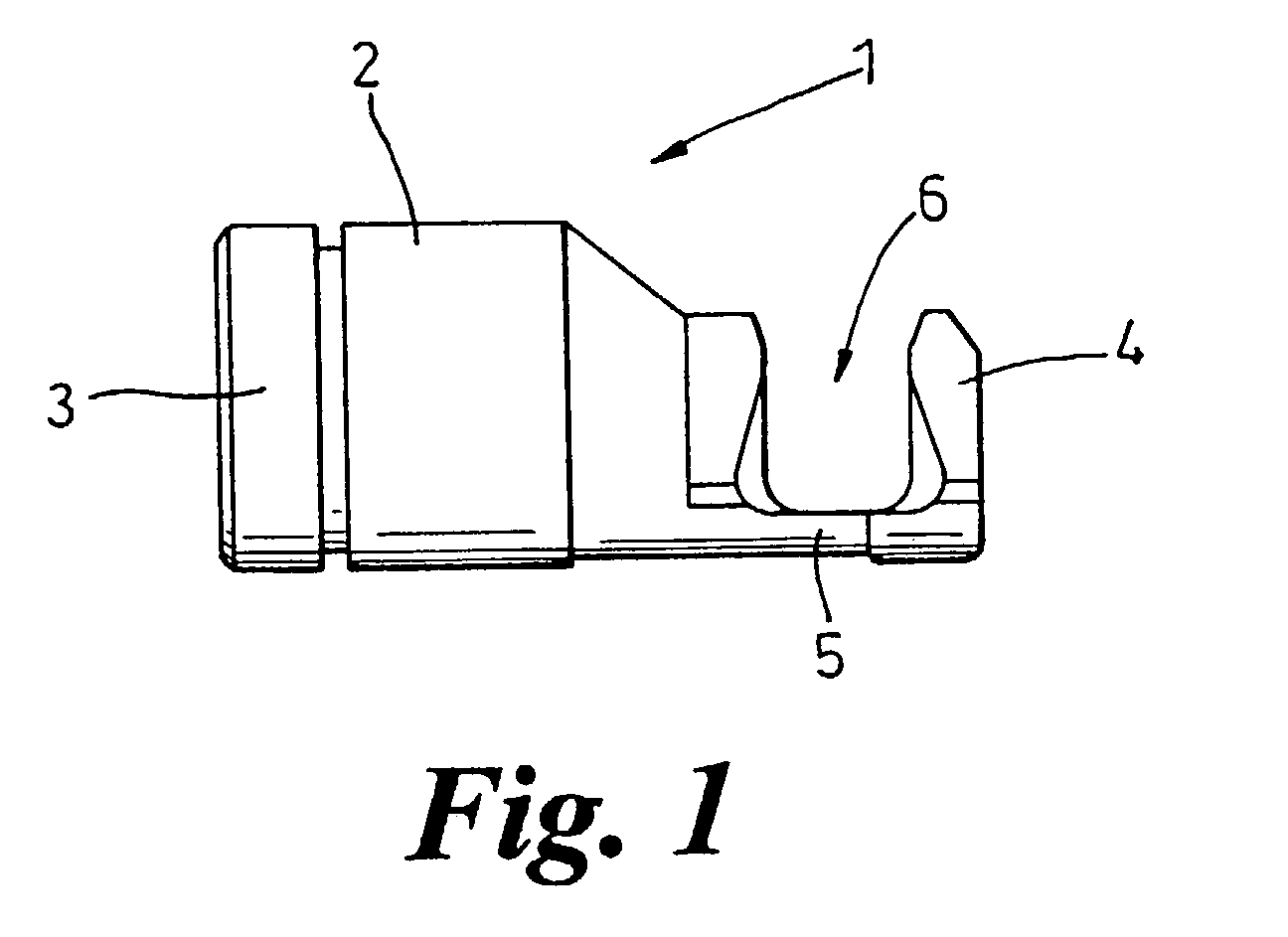

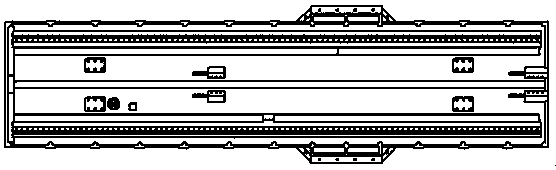

Crosslink for securing spinal rods

InactiveUS20050090821A1High strengthGap minimizationInternal osteosythesisJoint implantsCross connectionEngineering

A crosslink member for securing spinal rods is disclosed having connector ends that include a brace and a locking member, each having an arcuate face resting on and securing a spinal rod. The locking member is secured by a cam member that rotates relative to the locking member and that cams against the connector to displace the cam member. The crosslink includes a male connector with a cylindrical cross rod received by a cavity in a female connector. The cross rod is secured by a pivotable clamp device in the female connector, and the cross rod connector and female connector may pivot, rotate, and telescope relative to each other. To reduce size without sacrificing pivot sweep, the cross rod has beveled edges, and the cavity of the female connector has windows to provide pivot clearance.

Owner:PIONEER SURGICAL TECH INC

Crossllink for securing spinal rods

InactiveUS20060271051A1High strengthGap minimizationInternal osteosythesisJoint implantsEngineeringMechanical engineering

A crosslink member for securing spinal rods is disclosed having connector ends that include a brace and a locking member, each having an arcuate face resting on and securing a spinal rod. The locking member is secured by a cam member that rotates relative to the locking member and that cams against the connector to displace the cam member. The crosslink includes a male connector with a cylindrical cross rod received by a cavity in a female connector. The cross rod is secured by a pivotable clamp device in the female connector, and the cross rod connector and female connector may pivot, rotate, and telescope relative to each other. To reduce size without sacrificing pivot sweep, the cross rod has beveled edges, and the cavity of the female connector has windows to provide pivot clearance.

Owner:PIONEER SURGICAL TECH INC

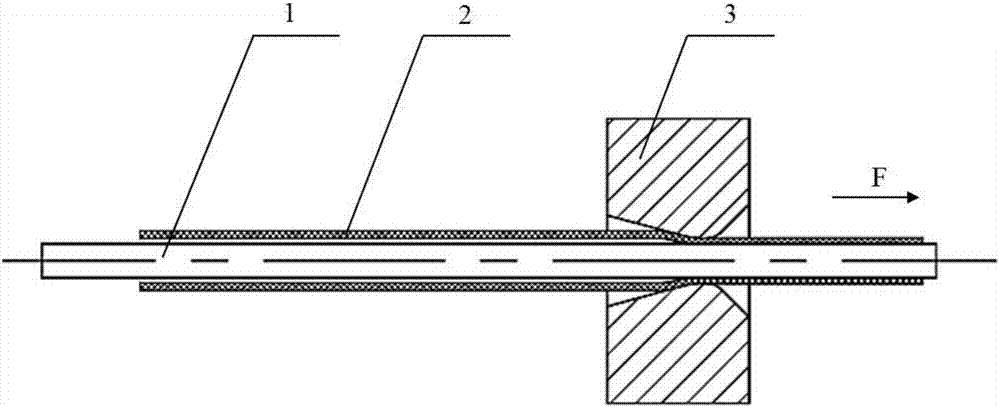

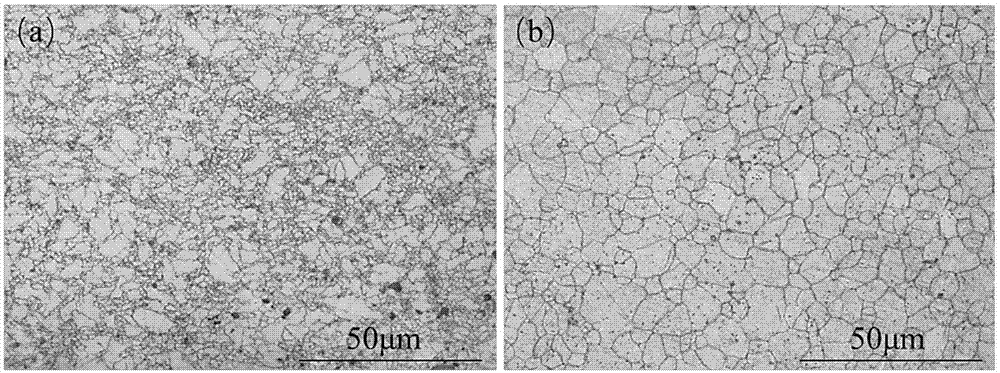

Magnesium alloy microcapillary and preparation method thereof

The invention discloses a magnesium alloy microcapillary and a preparation method thereof and belongs to the field of metal material precision machining. The method comprises the following steps that(1) a magnesium alloy blank is extruded to obtain a seamless extruded pipe blank; (2) the obtained seamless extruded pipe blank is subjected to stress relief annealing; and (3) the annealed seamless extruded pipe blank is subjected to multiple passes of drawing and intermediate annealing, and the magnesium alloy microcapillary is obtained. The magnesium alloy microcapillary prepared through the preparation method provided by the invention is good in surface quality, precise in size, uniform in wall thickness and excellent in mechanical property; the machining method is simple in process, low in cost, high in machining efficiency, and capable of performing large-scale production; and the magnesium alloy microcapillary can be used as a structural component to be applied to the fields of automobiles and electronics, and can also be used as a medical implant used for preparing an intravascular stent.

Owner:BEIJING UNIV OF TECH

Crosslink for securing spinal rods

InactiveUS7744633B2High strengthGap minimizationInternal osteosythesisJoint implantsCross connectionEngineering

A crosslink member for securing spinal rods is disclosed having connector ends that include a brace and a locking member, each having an arcuate face resting on and securing a spinal rod. The locking member is secured by a cam member that rotates relative to the locking member and that cams against the connector to displace the cam member. The crosslink includes a male connector with a cylindrical cross rod received by a cavity in a female connector. The cross rod is secured by a pivotable clamp device in the female connector, and the cross rod connector and female connector may pivot, rotate, and telescope relative to each other. To reduce size without sacrificing pivot sweep, the cross rod has beveled edges, and the cavity of the female connector has windows to provide pivot clearance.

Owner:PIONEER SURGICAL TECH INC

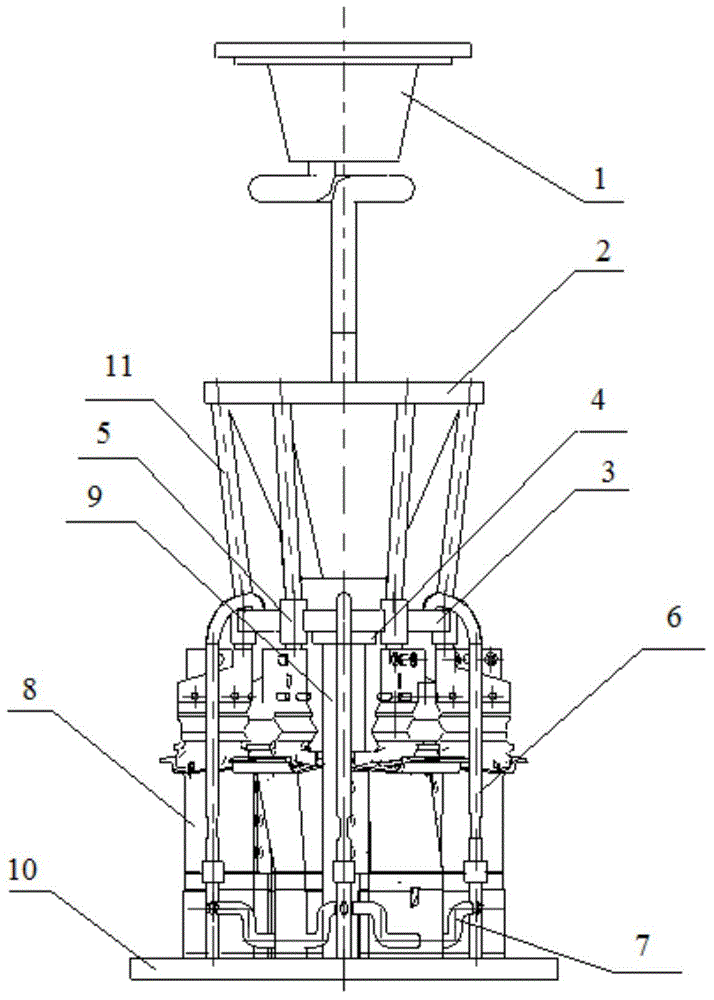

Double-buffering casting system for directional hollow turbine work blade

ActiveCN104384485AShorten speedReduce shockMolten metal conveying equipmentsCircular discInvestment casting

By aiming at the problem of core fracture and leakage occurring in the casting process of a hollow turbine work blade and the problem of wall thickness due to eccentricity, the invention provides a double-buffering casting system for a directional hollow turbine work blade, and belongs to the field of directional solidification of investment casting. The casting system consists of a circuitous casting funnel, a sprue cup, an upper part filter screen, an upper circular disc, a solid plug sheet, a hollow pipe, a vertical sprue, a lower part filter screen, a transverse straight sprue, a blade die case cavity, a middle post pipe, a bottom disc and an exhaust passage, wherein through the buffering effect of the circuitous casting funnel, the upper circular disc, the vertical sprue, the transverse sprue and the filter screens on metal liquid, the flowing speed of the metal liquid can be decelerated, so the impact of the metal liquid on a ceramic die core arranged in the die case cavity is greatly reduced, the problem of core fracture and leakage easily occurring in the casting process and the problem of wall thickness due to eccentricity can be greatly solved, the rejection rate is reduced, and the cost is reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

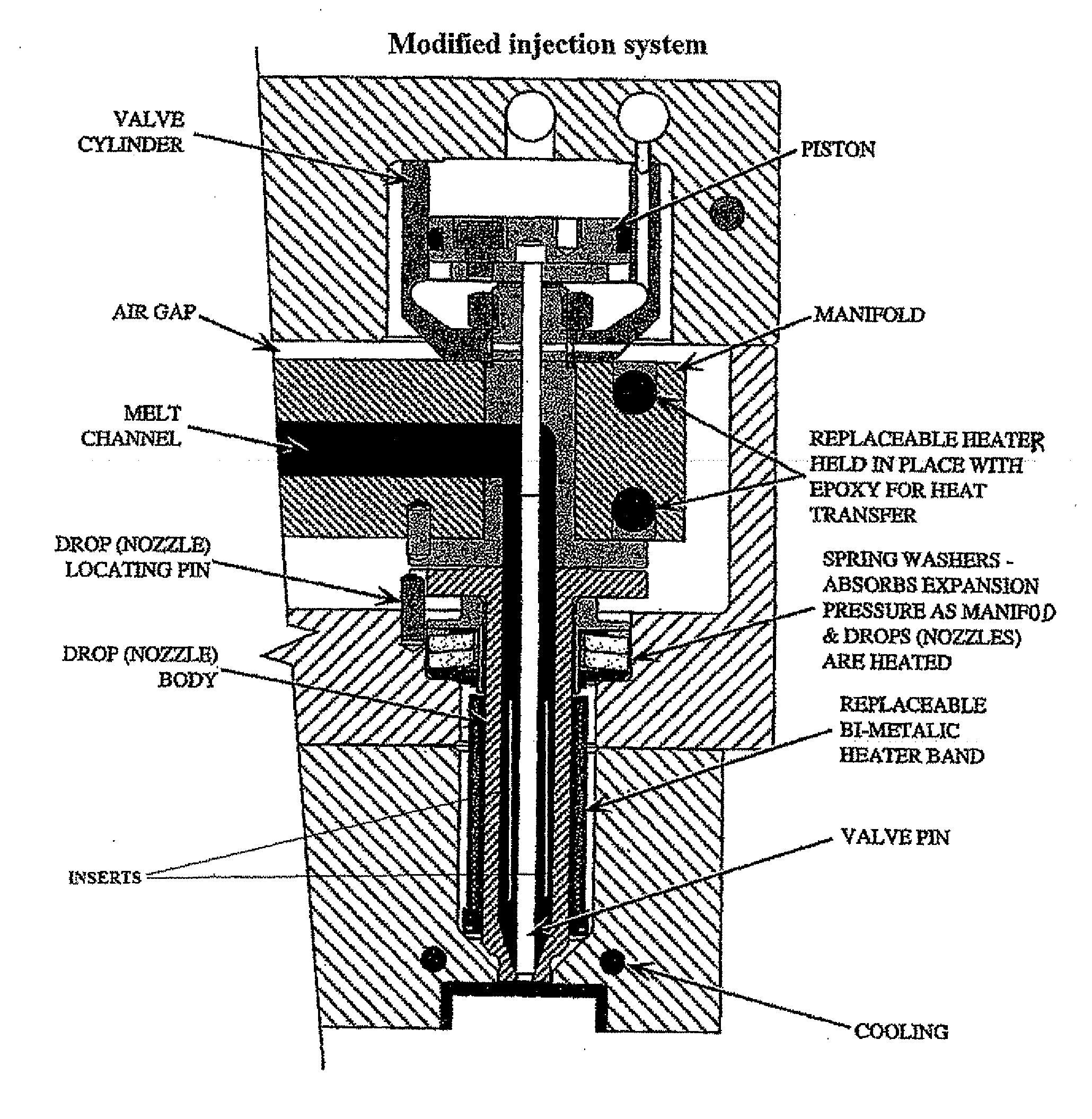

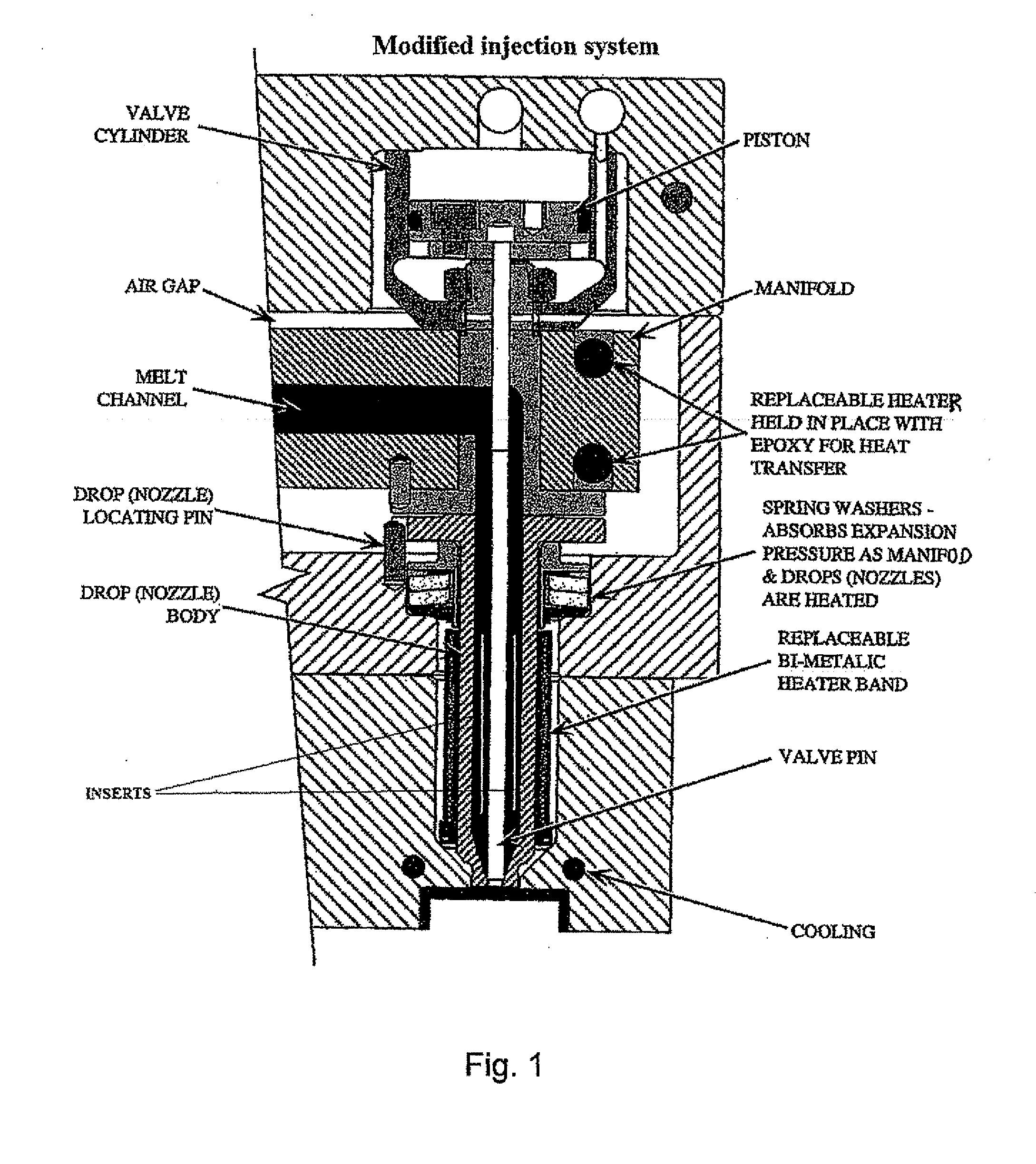

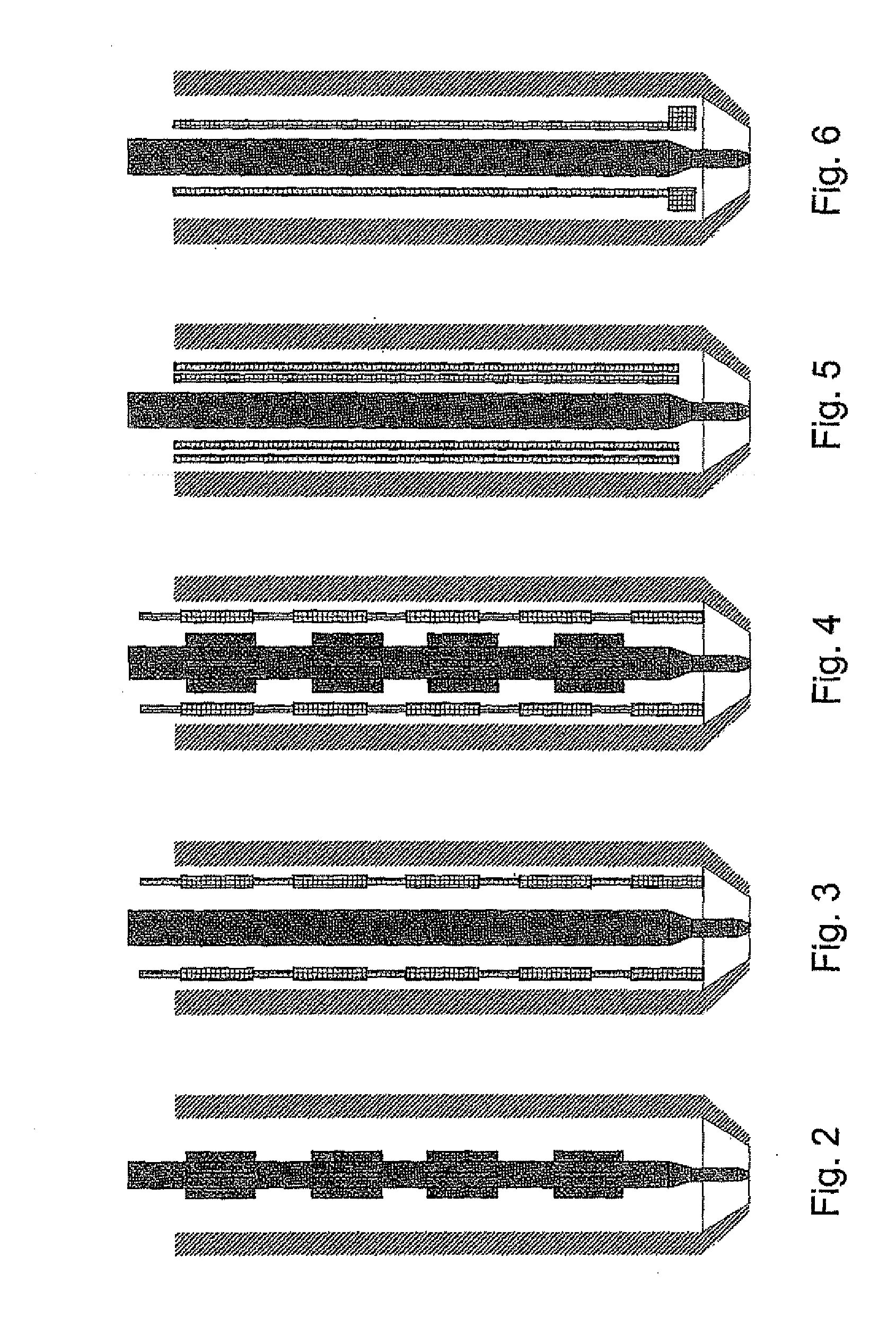

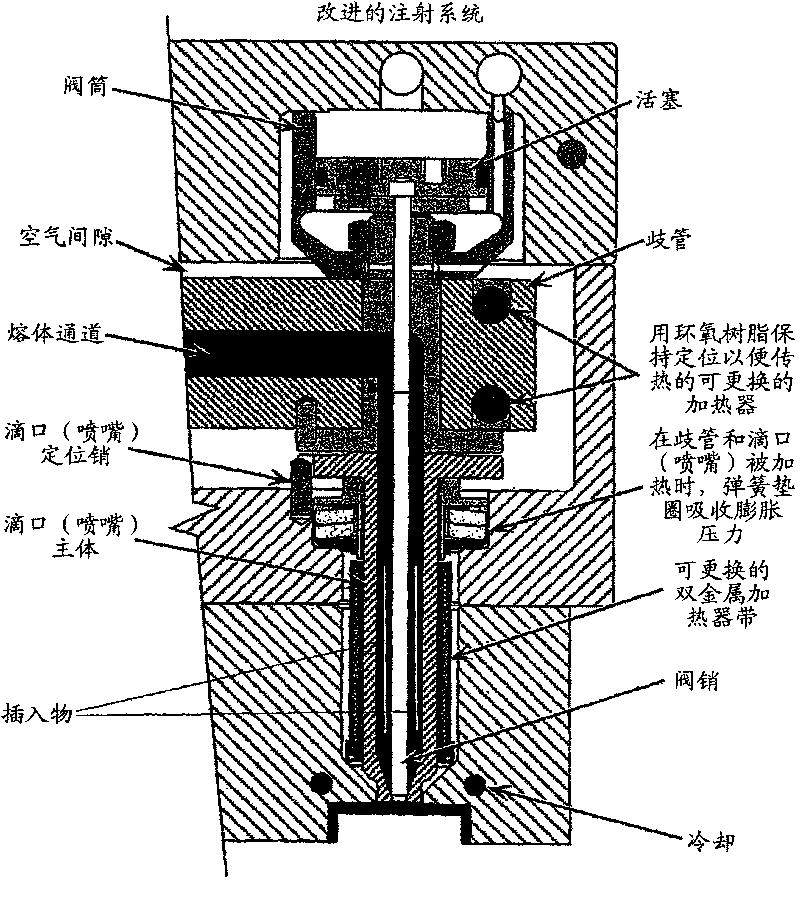

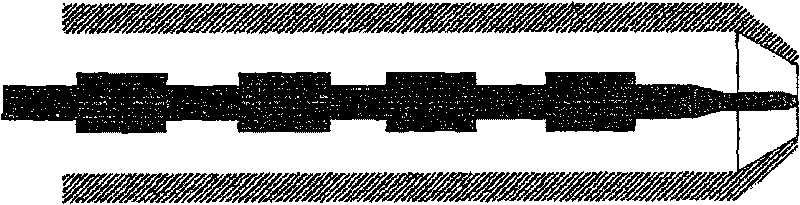

Modified hot runner systems for injection blow molding

ActiveUS20130029067A1Optimize wall thicknessImproved performance characteristicsSynthetic resin layered productsThin material handlingBlow moldingHot runner

An injection blow molding method for making a container having the steps of injecting a molten crystallizable polymer in a preform mold via a hot runner system and biaxially stretching the preform by blowing to form a container. The method further having the step to selectively modify the flow path of the molten crystallizable polymer within the hot runner system.

Owner:KEIRYO PACKAGING

Method for making raw ball arm blank with diversified inner wall thicknesses

The invention relates to the technical field of sports goods manufacturing, in particular to a method for making a raw ball arm blank with diversified inner wall thicknesses.The method comprises the steps of 1, cleaning a press bar die; 2, baking a steel core bar; 3, wrapping the steel core bar; 4, molding a silica gel press bar; 5, taking the silica gel press bar out; 6, making a raw ball arm blank pre-molded body; 7, molding the raw ball arm blank pre-molded body; 8, taking the silica gel press bar out.The raw ball arm blank produced with the method has more functions, the rejection ratio of raw ball arm blanks is reduced, and the obtained raw ball arm blank is stable in strength, high in ball control speed, good in hand feeling, uniform in ridge wall thickness and stable in quality.

Owner:TONGXIANG BONNY SCI & TECH COMPOSITE

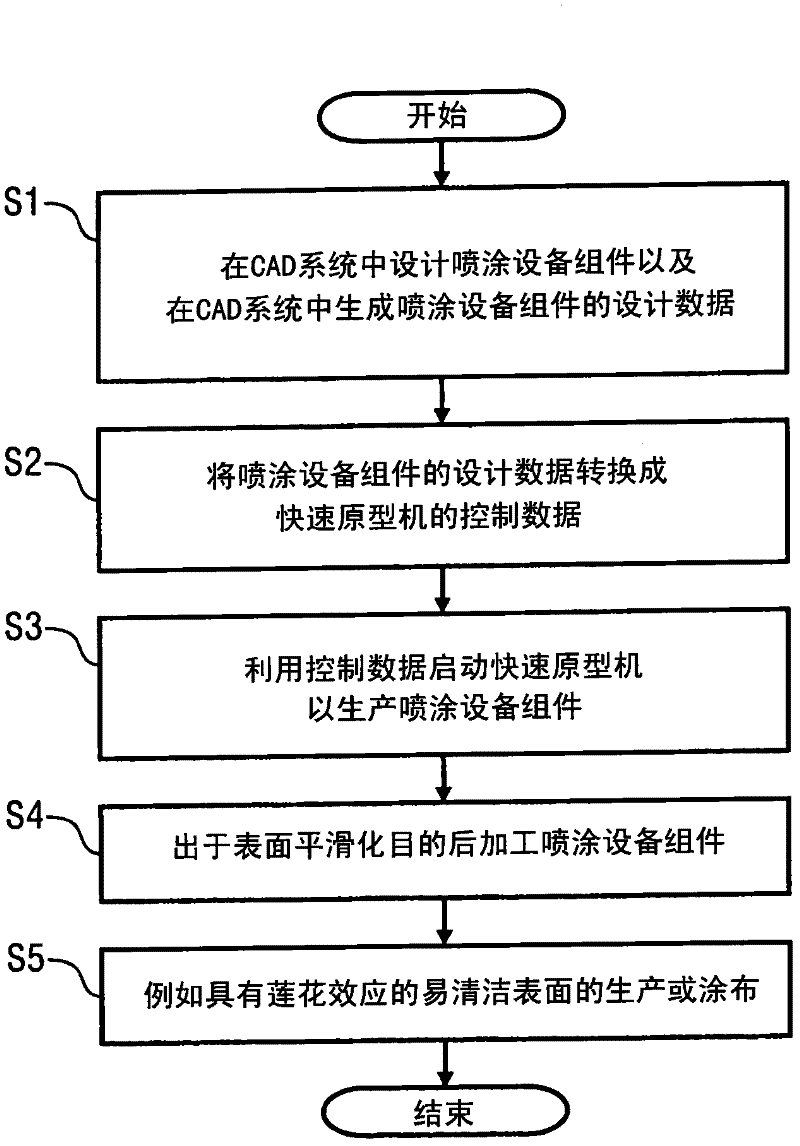

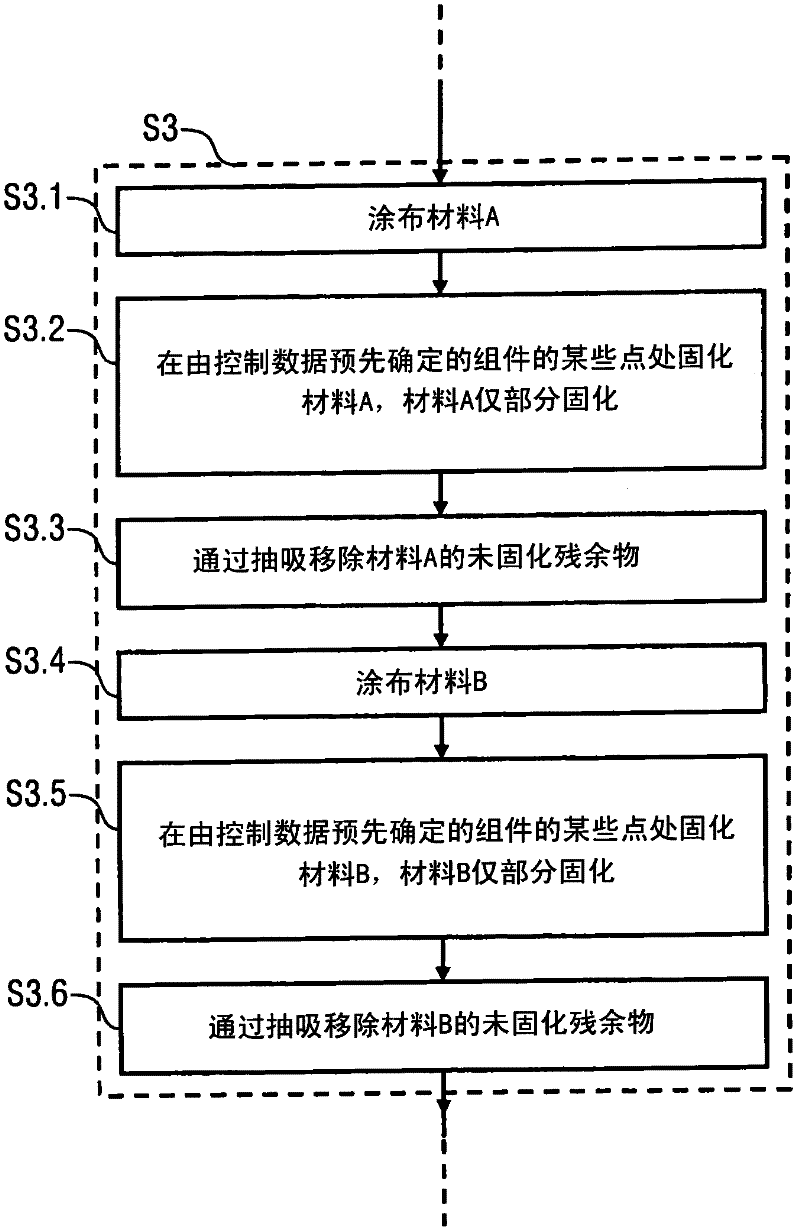

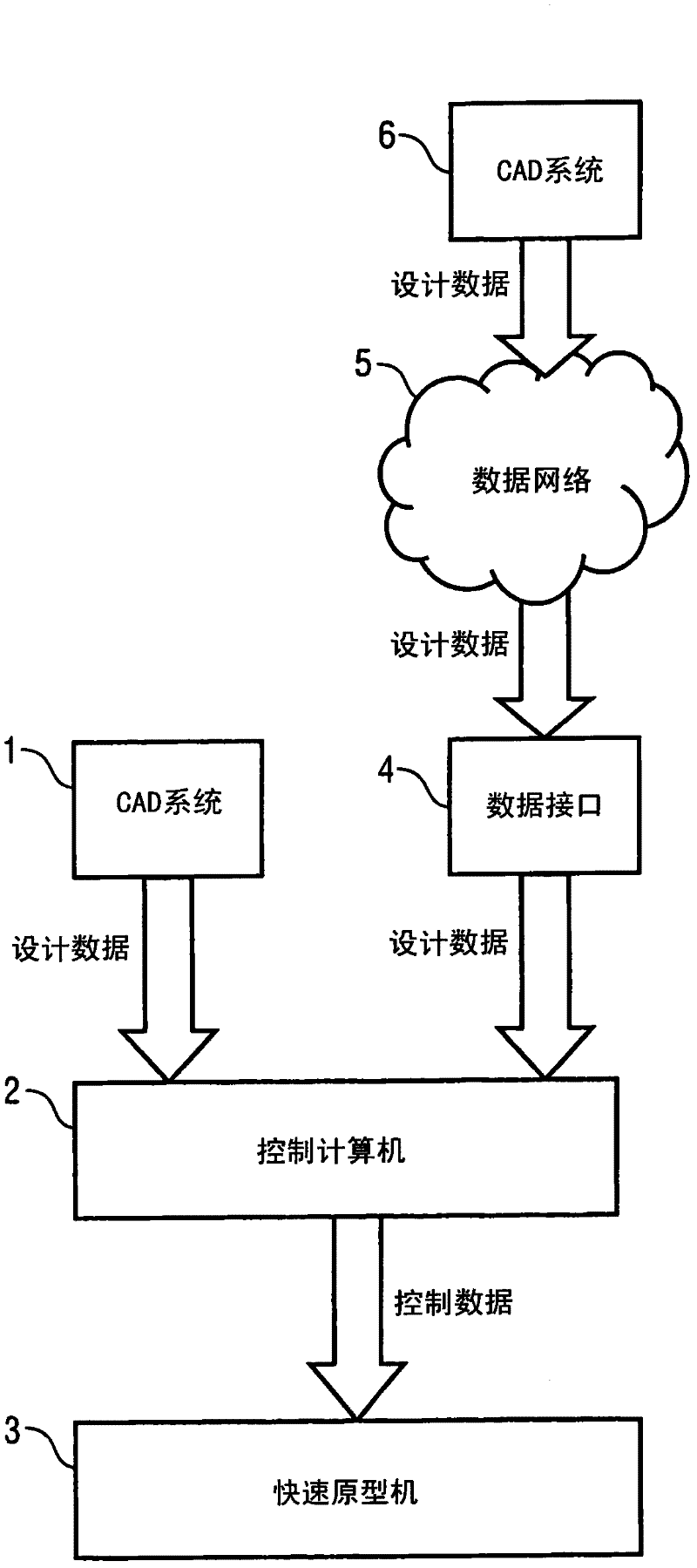

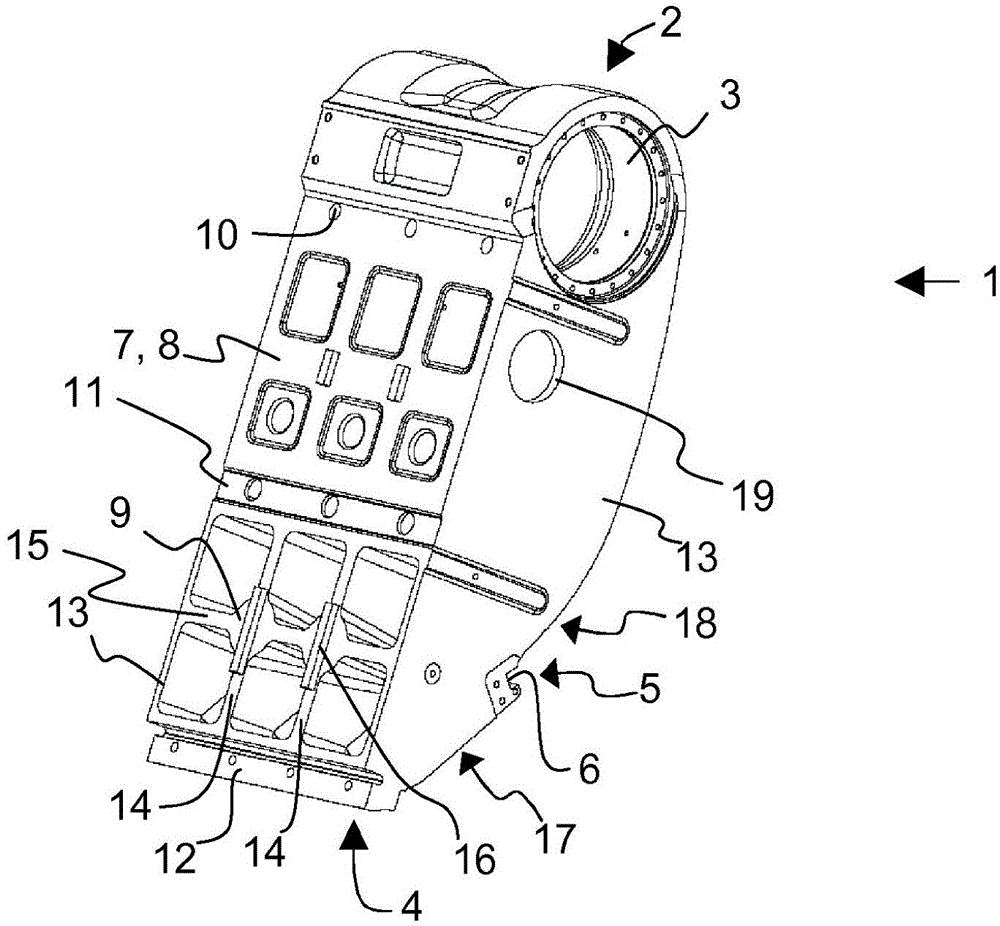

Production method for a paint plant component and corresponding paint plant component

InactiveCN102186652AReduce weightLow mass densityAdditive manufacturing apparatusMovable spraying apparatusRapid prototypingPlant Components

The invention relates to a production method for producing a paint plant component, in particular for producing a component of a colour changer, a colour valve, or a spray device. According to the invention, the paint plant component is produced in a rapid prototyping method. The invention also relates to a paint plant component that is produced accordingly.

Owner:DUERR SYST GMBH

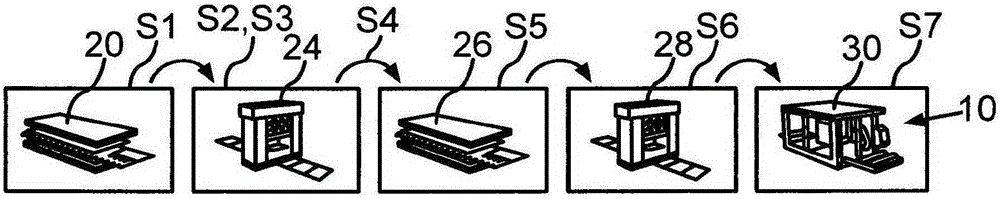

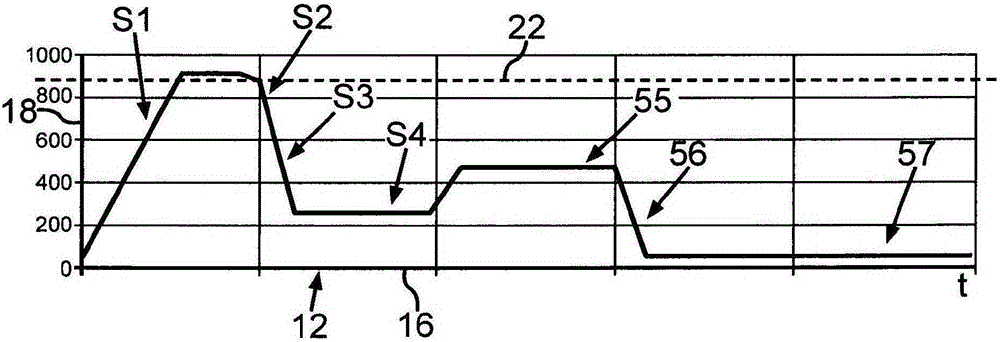

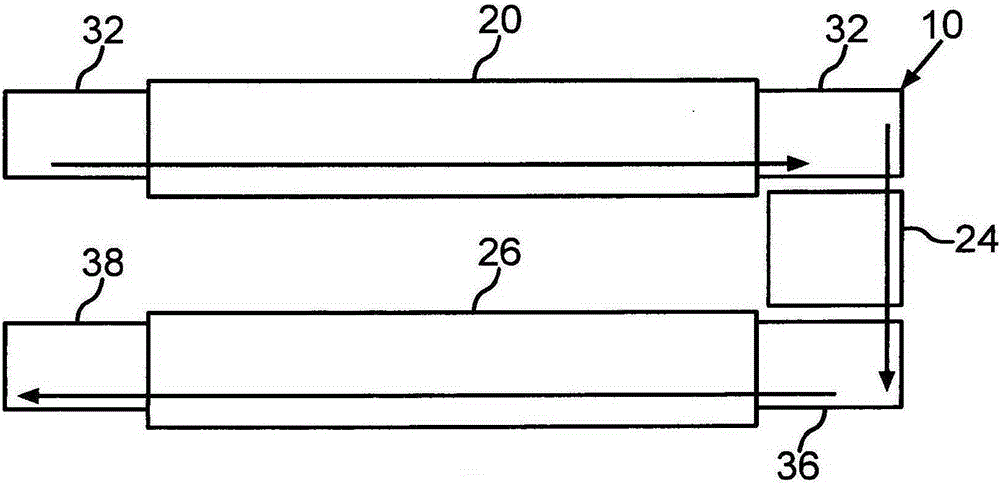

Process and installation for producing a press-hardened sheet steel component

InactiveCN105358718ATime-saving or cheap to manufactureImprove energy absorptionFurnace typesHeat treatment furnacesSheet steelTempering

The invention relates to a process and an installation for producing a press-hardened sheet steel component, comprising the steps of: a) heating (step S1) a component blank, formed from a hot-workable steel sheet, at least to the austenitizing temperature of the steel material by means of a heating device (20), b) hot working (step S2) the component blank by means of a forming tool (24), c) cooling (step S3) the component blank in the forming tool (24) to a temperature above the material-specific martensite finish temperature, preferably to a temperature of at least 200 DEG C, d) transferring (step S4) the component blank from the forming tool (24) to a heating device (26), e) tempering (step S5) the component blank while stabilizing the austenite by means of the heating device (26), wherein the component blank is transferred directly from the forming tool (24) to the heating device (26) (step S4) while avoiding cooling of the component blank to less than the material-specific martensite finish temperature, preferably less than 200 DEG C.

Owner:DAIMLER AG

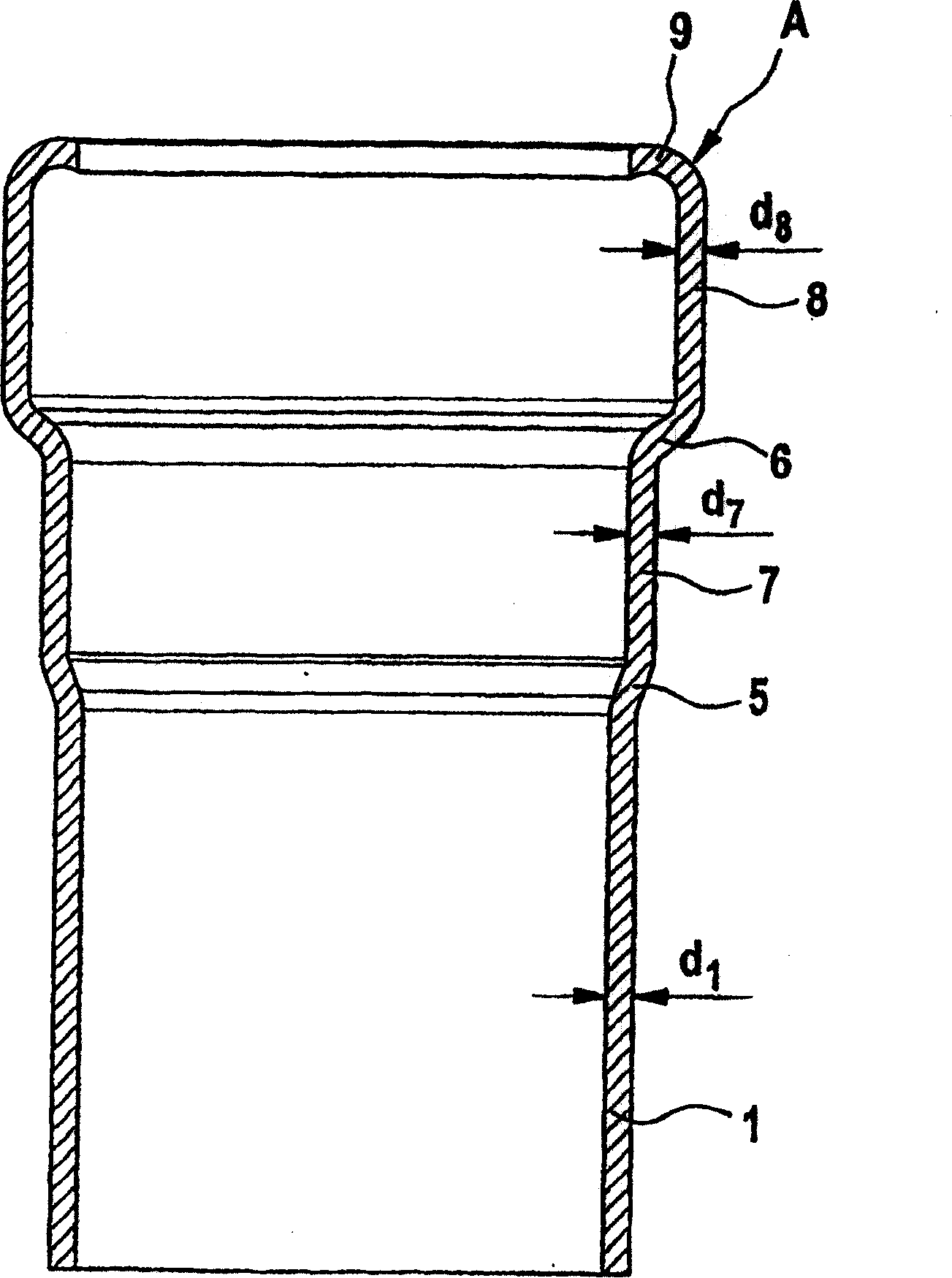

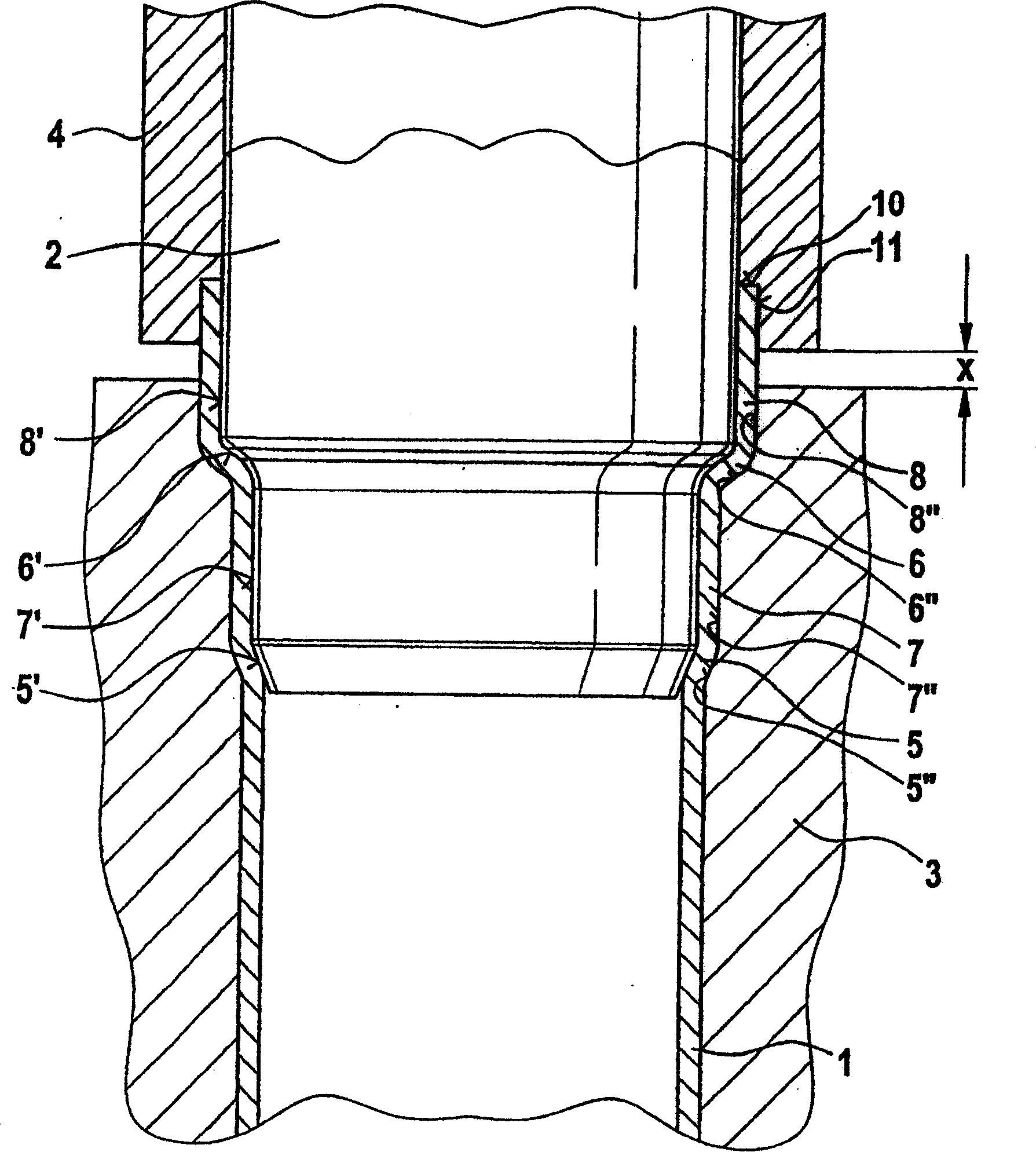

Method for producing a coupling on a pipe and device for producing said coupling

Owner:WITZIG & FRANK GMBH

Novel hot rolling and precision forging technique for waste oil pipes

ActiveCN106734330AReduce frictional resistanceUniform deformationMetal rolling arrangementsCurrent technologySizing

The invention provides a novel hot rolling and precision forging technique for waste oil pipes and belongs to the waste oil pipe restoration technology. The defects of other current technologies are overcome. The production technique comprises the following steps of primary selection, descaling, flaw detection, rough rolling, precision forging and sizing, straightening, penetrating, length fixing, top cropping, detection and storage, specifically, the oil pipes are put into storage after passing the detection. The novel hot rolling and precision forging technique has the significance that firstly, the production cost is low; secondly, the product models are complete; thirdly, the product quality is high; fourthly, pollution is avoided during production; and fifthly, the production efficiency is improved.

Owner:PUYANG SHUNKANG PETROLEUM ENG TECH

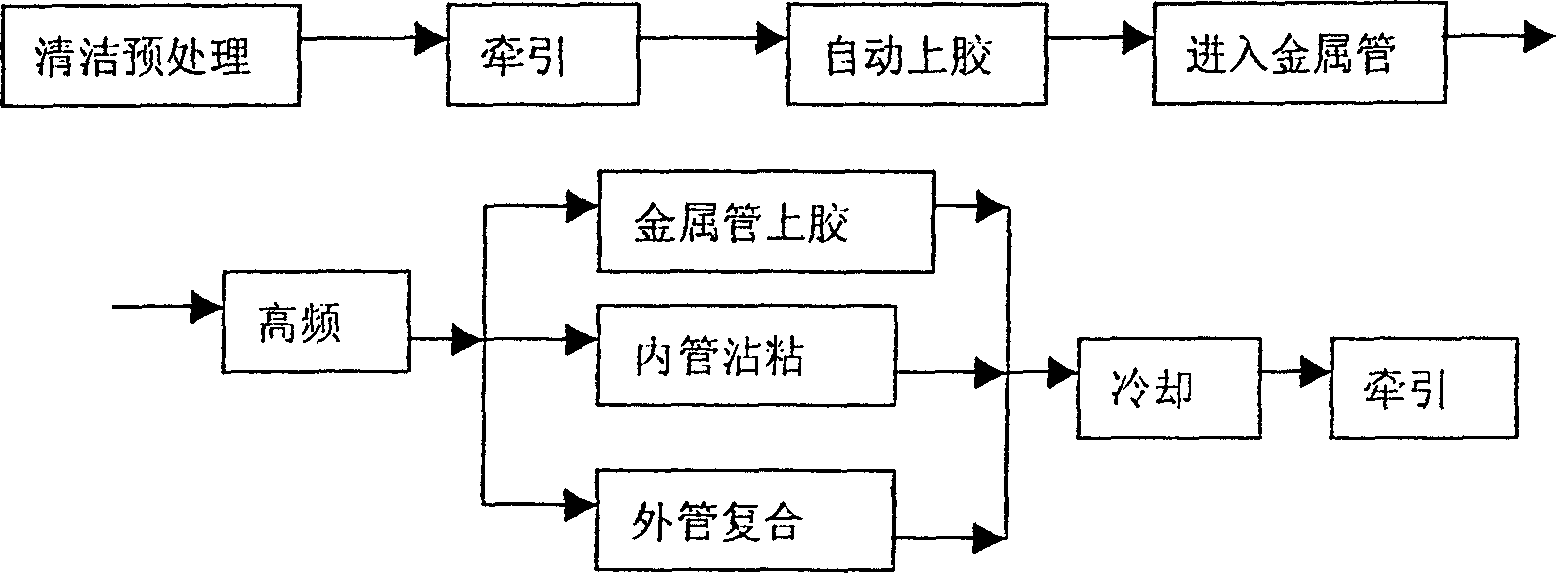

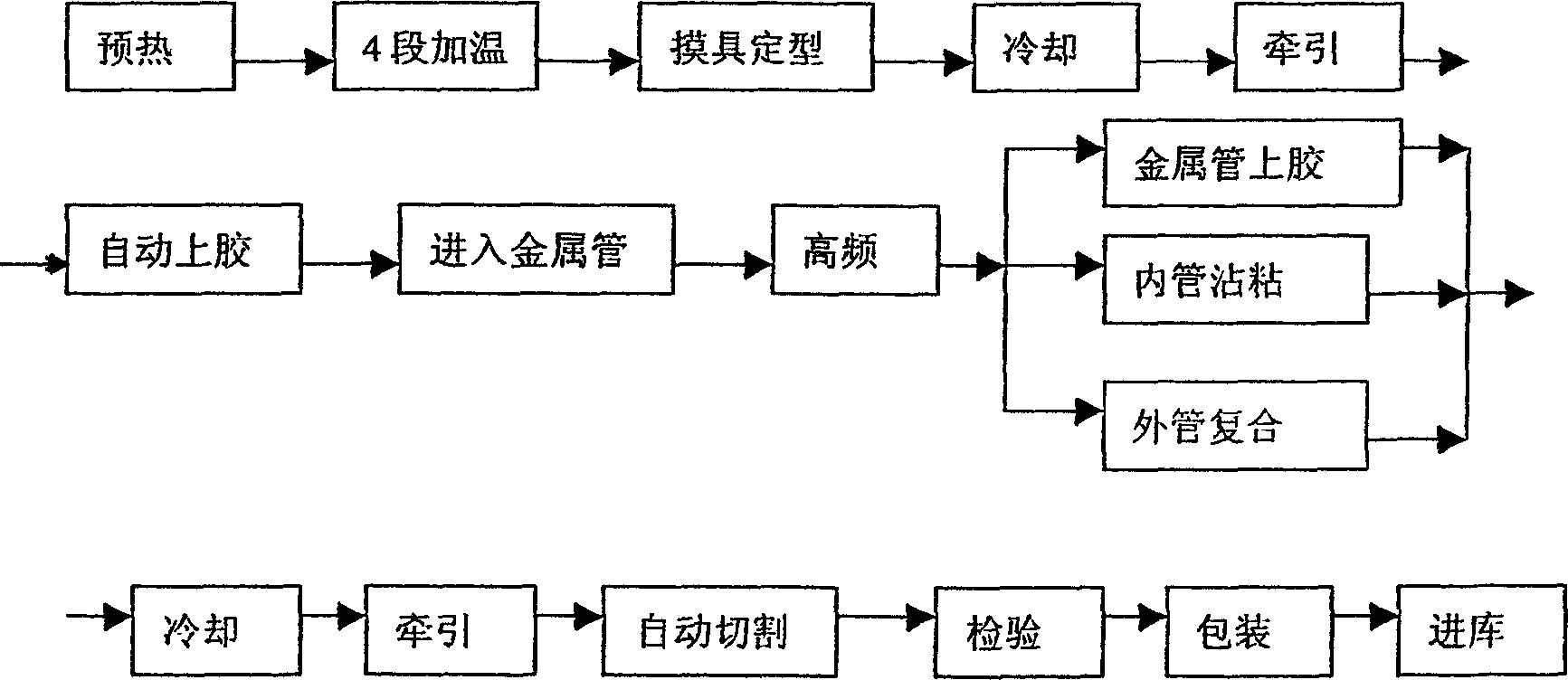

Producing teahnology for high-polymer composite pipe and its special die

The production process of the composite polymer pipe includes the following steps: coating one layer of thermosol to the inner surface of inner plastic pipe and inserting matched seamless metal pipe; reducing and drawing the combination of the inner plastic pipe and outer metal pipe; heating the reduced and drawn pipe; coating the outer surface of the outer metal pipe with adhesive; compounding one layer of outer plastic pipe; and cooling to form during drawing. The special production mold includes outer mold and inside core mold, the core mold consists of inner core mold and outer core mold, and there are inner molding nozzles and outer molding nozzles set between the inner core mold and the outer mold and between the outer core mold and the outer mold separately.

Owner:马林远

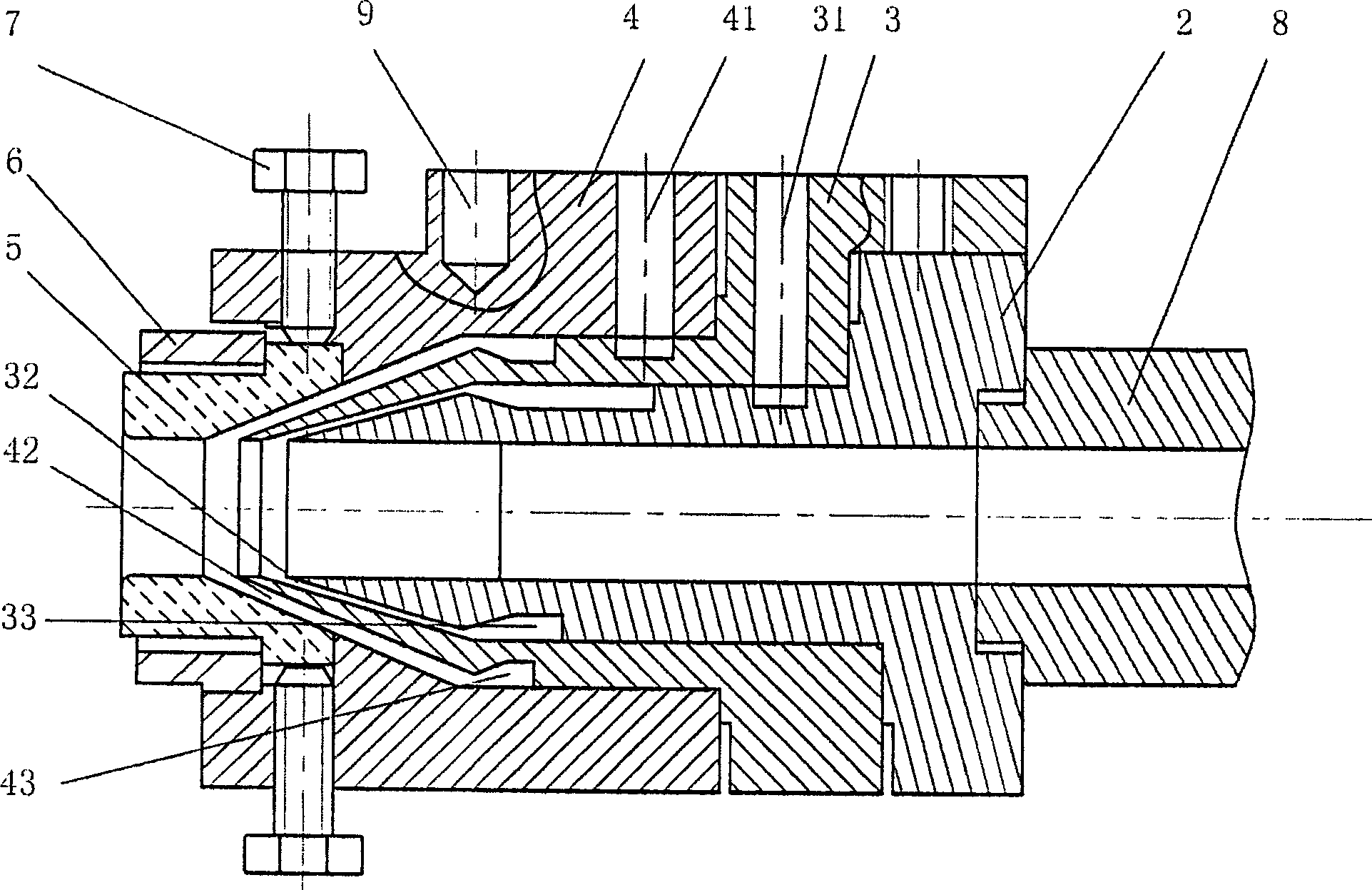

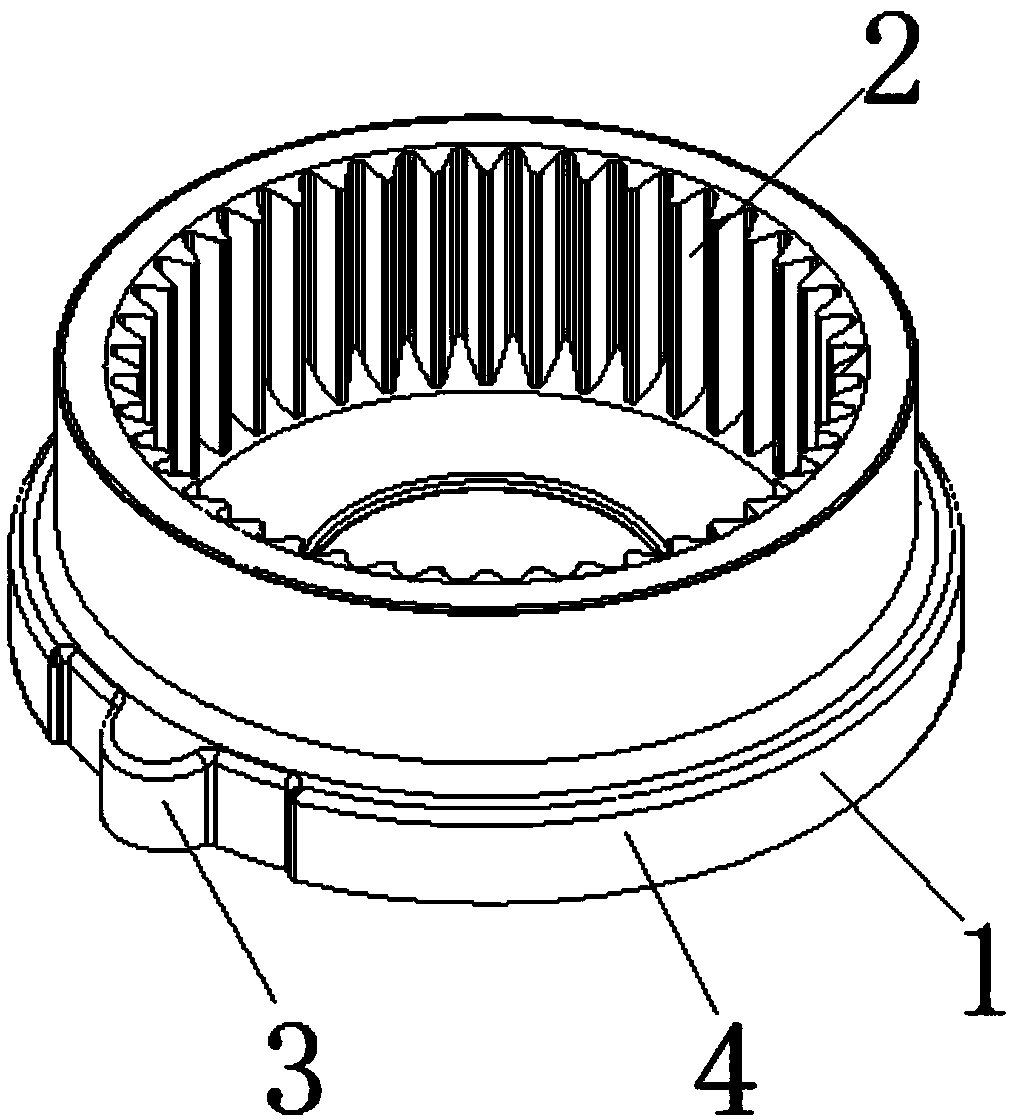

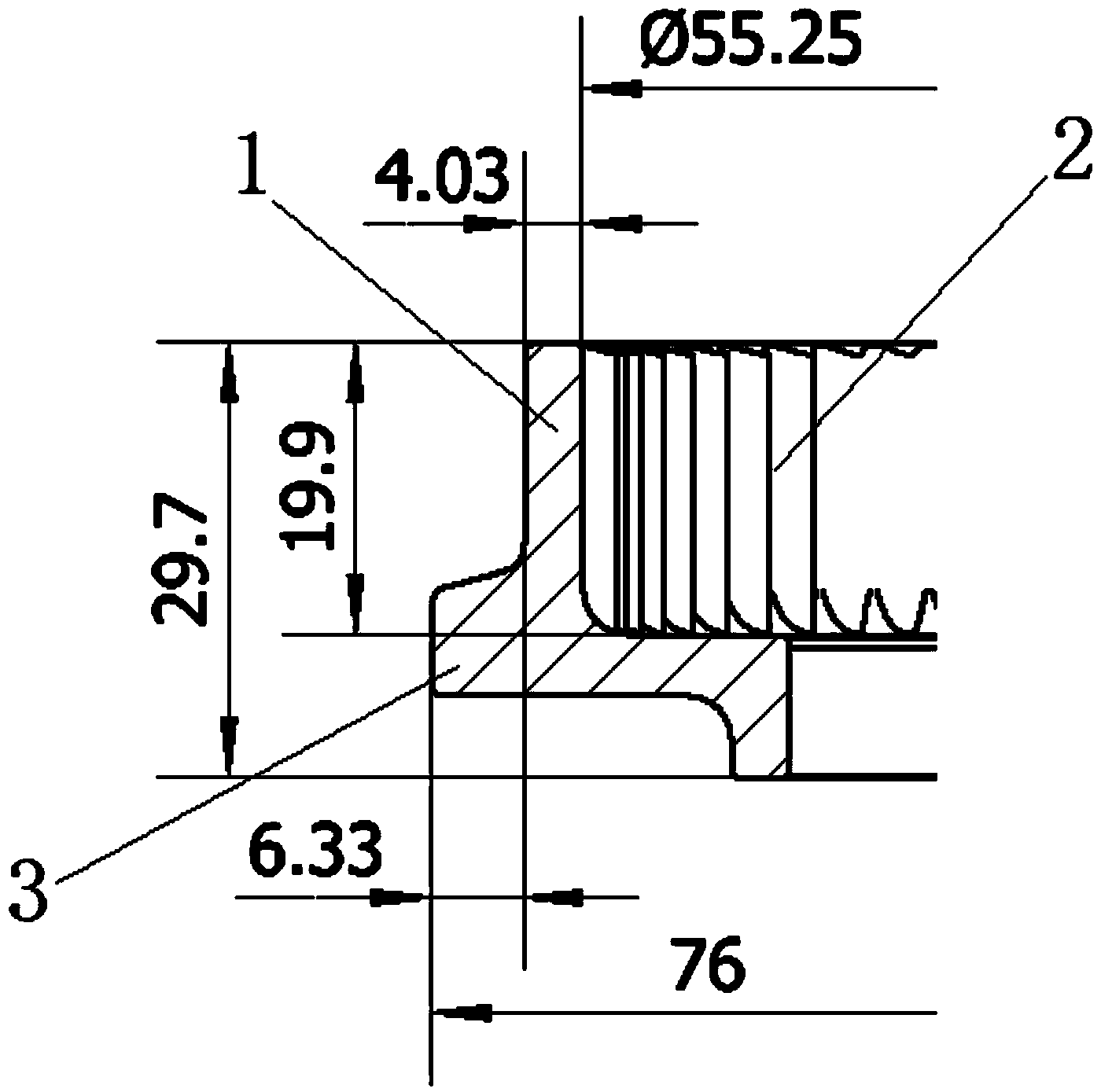

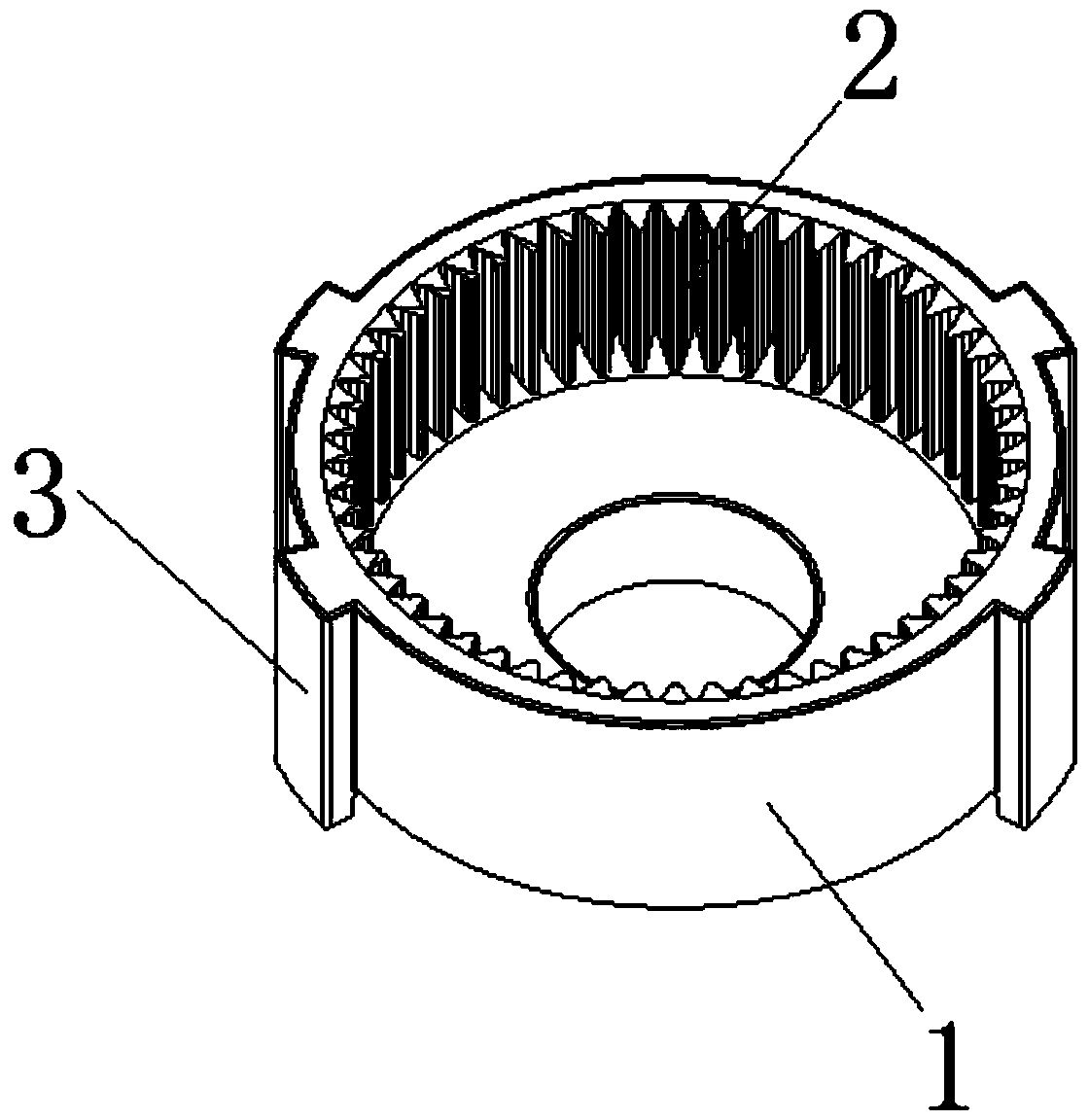

Compact high-power speed reduction gear ring for starting machine of diesel vehicle

InactiveCN104235312AOptimize wall thicknessOptimal heightPower operated startersPortable liftingEngineeringDiesel fuel

The invention discloses a compact high-power speed reduction gear ring for a starting machine of a diesel vehicle. The compact high-power speed reduction gear ring comprises a gear ring body; speed reduction teeth are arranged in the gear ring body; strip-shaped positioning ribs are evenly distributed on the outer surface of the gear ring body; the positioning ribs stick out from the bottom part of the gear ring body. According to the speed reduction gear ring disclosed by the invention, on the basis that the mechanical strength is ensured, the wall thickness and the height of a product are optimized, and the size is reduced, so that the speed reduction gear ring is lightweight, and meanwhile, the cost is reduced.

Owner:常熟市华德粉末冶金有限公司

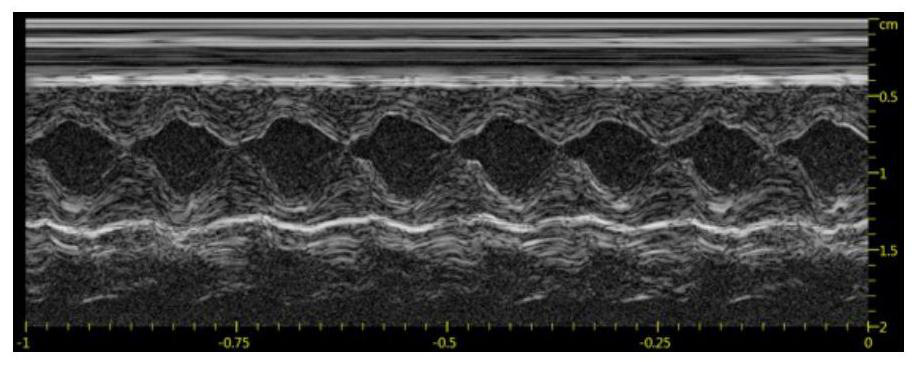

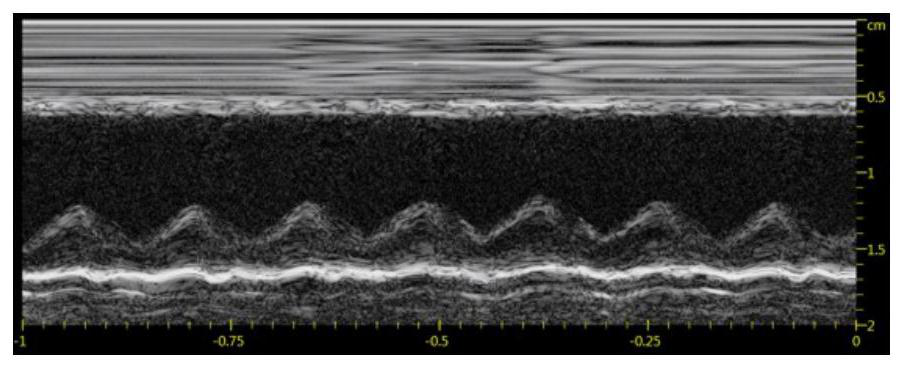

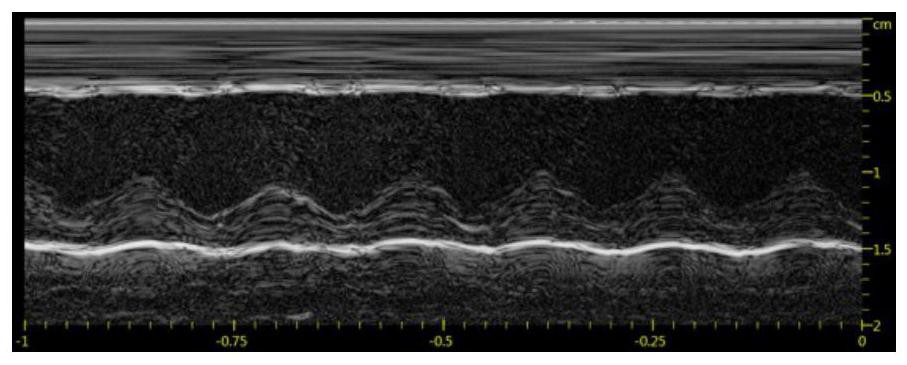

Application of a combined preparation of mesenchymal stem cell and exosome in preparation of myocardial infarction drug

PendingCN112402458AImprove the effect of treatmentPromote angiogenesisCell dissociation methodsSkeletal/connective tissue cellsBiophysicsRat heart

The invention provides application of a combined preparation of mesenchymal stem cell and exosome in preparation of myocardial infarction drug. The combined preparation of mesenchymal stem cell and exosome comprises mesenchymal stem cells and exosomes. The mesenchymal stem cells can secrete a large number of exosomes in the culture process, the exosomes secreted by the mesenchymal stem cells can adjust the local tissue microenvironment, promote angiogenesis, improve local blood supply, recover the thickness of the ventricular wall and improve the left ventricular ejection fraction of a myocardial infarction rat, and therefore the cardiac function of the rat is improved. The mesenchymal stem cells have a certain myocardial infarction treatment effect, the exosome suspension can provide a better living environment for the mesenchymal stem cells, and can maintain the activity and function of cells to the maximum extent.

Owner:陕西佰傲干细胞再生医学有限公司

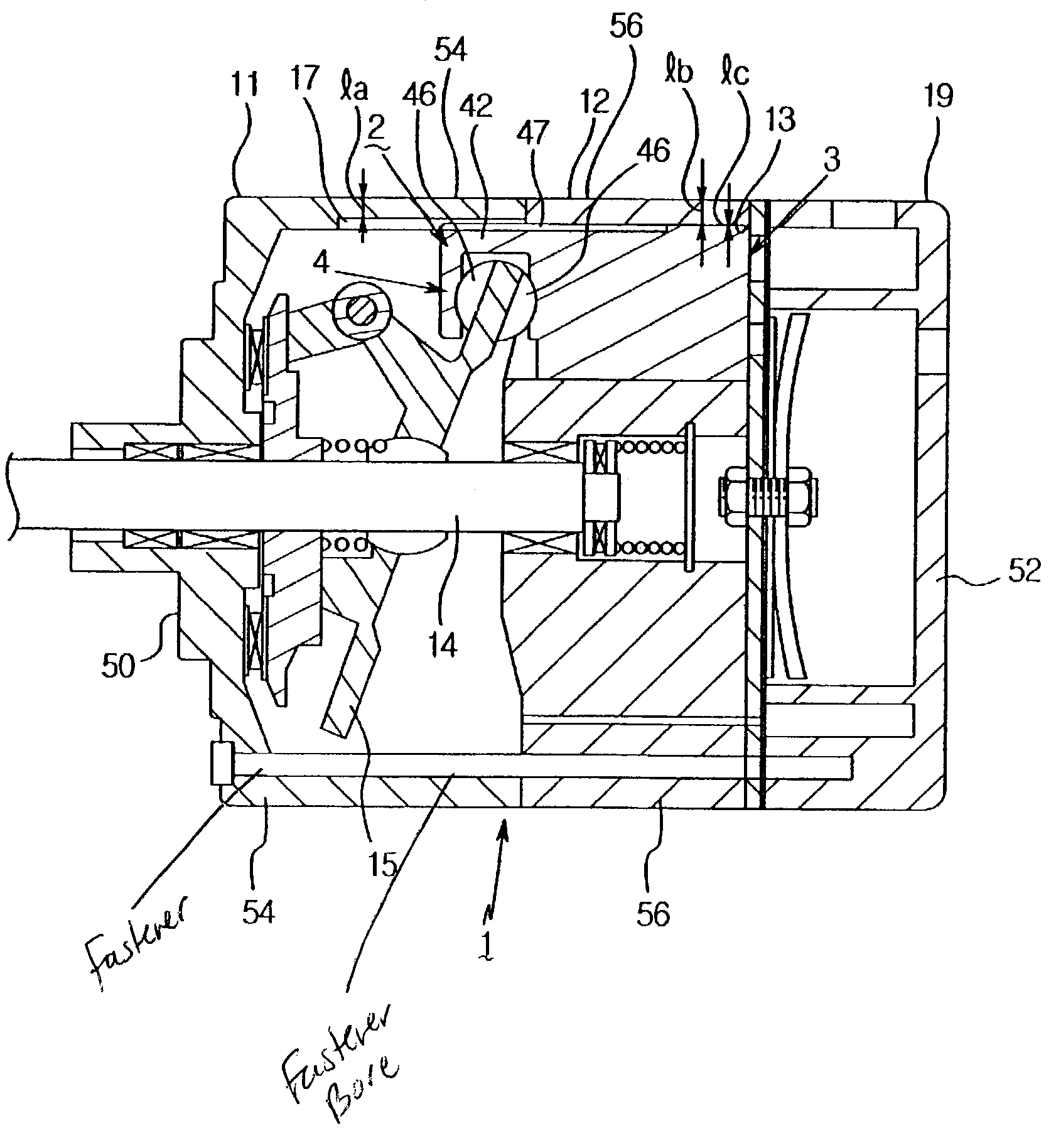

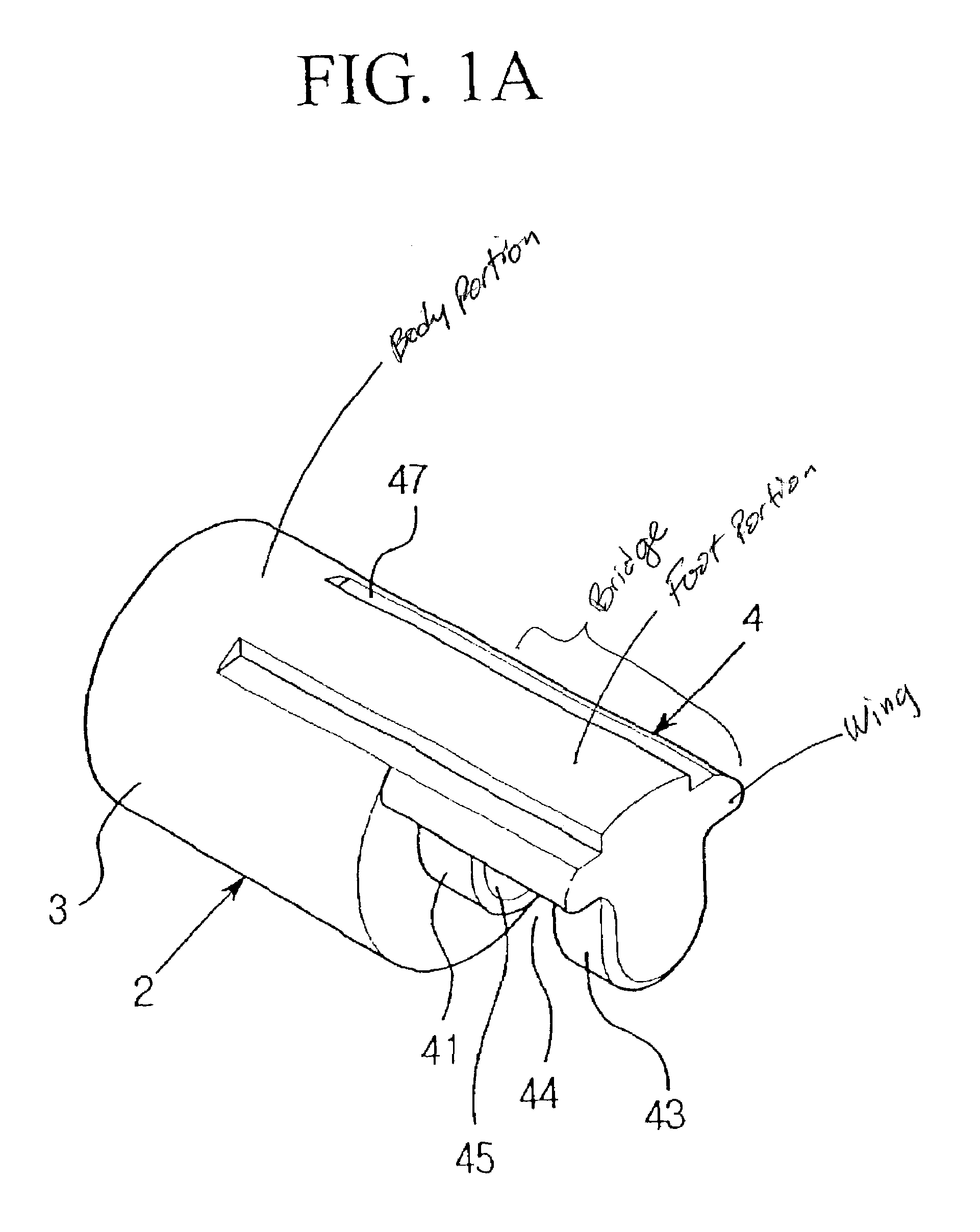

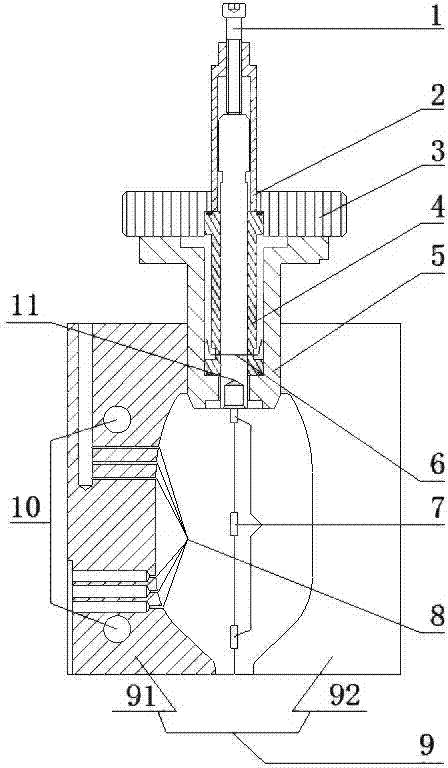

Piston assembly for a compressor

InactiveUS7056100B2Optimize wall thicknessReduce decreaseEngine sealsPlungersDrive shaftReciprocating motion

A compressor for a vehicle air conditioning system comprises a front casing in which is mounted a swash or wobble plate arrangement operatively connected to a drive shaft and a plurality of pistons each provided with a piston body at one end and a foot portion at its other. A cylinder block is also provided defining a plurality of cylinder bores equally distributed circumferentially around the drive shaft, in each of which bores one of the piston bodies can be reciprocated by the swash or wobble plate, as the drive shaft rotates. The inner wall surface of the front casing defines a plurality of longitudinally extending recesses in positions apposed to each piston. The piston body and the foot portion of each piston are connected by a bridge that is bending resistant and projects outwardly into these apposed recesses. Also, at least one side of the bridge is provided with a laterally projecting wing that supports the piston against the adjacent inner wall surface of the front casing to one side of the recess. The front casing and the pistons are thus designed for mutual interengagement and, in the piston, the requirement to provide a bending resistant portion has been divided away from the requirement to provide an anti-rotation locking arrangement.

Owner:VALEO SYST THERMIQUES

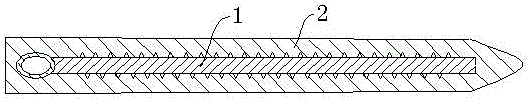

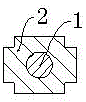

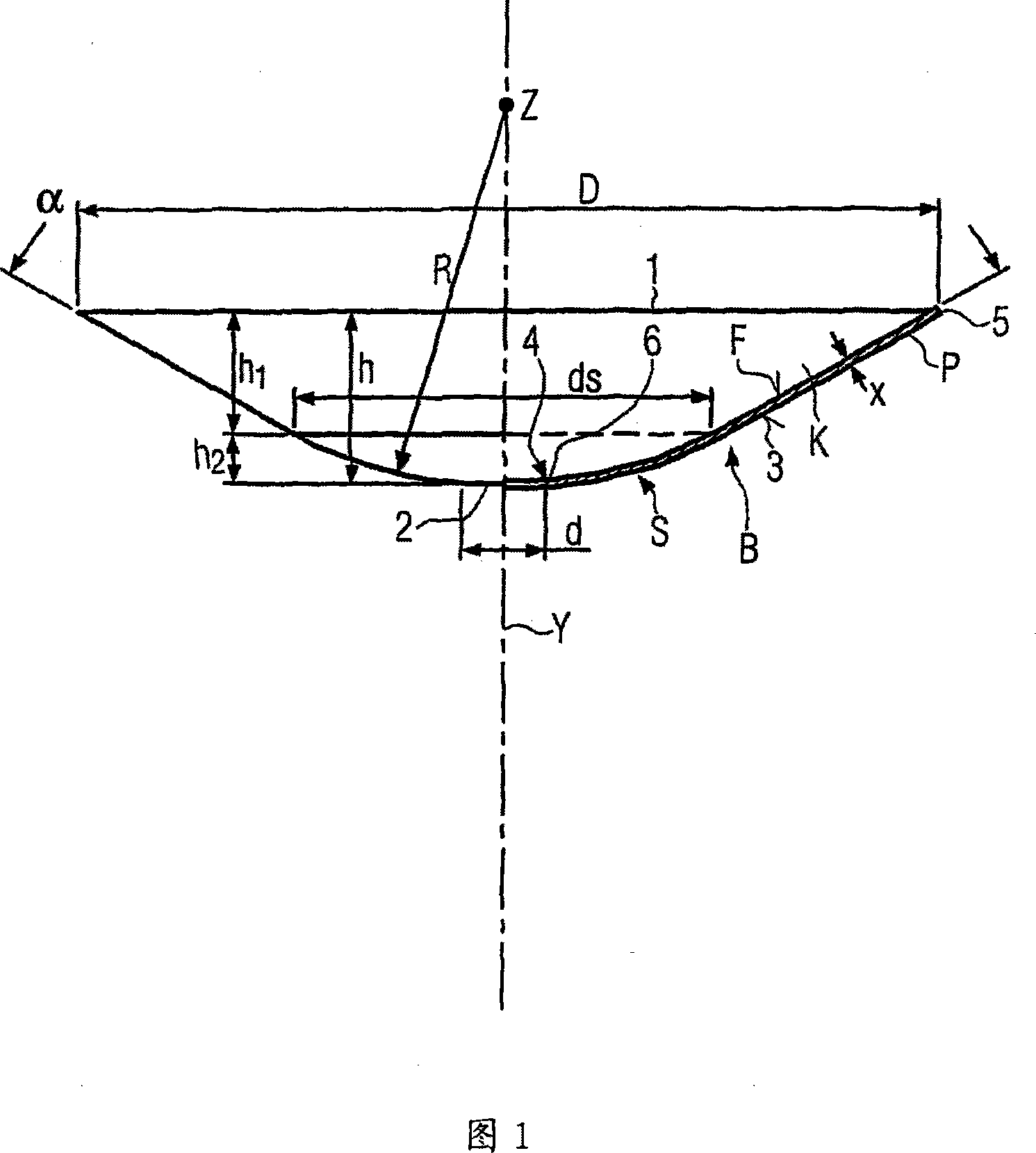

Yarn braking body

InactiveCN101023014ALow costDoes not seriously affect radial plasticityWeft knittingLoomsYarnPlastic materials

A yarn braking body B is a flexible frustocone coat K made from plastic material P and has a circumferentially continuous braking surface F which is defined by a part of the inner surface of the frustocone coat. The yarn braking body B has a circumferentially continuous support part S at the small diameter end 2. The support part S is spherical and one piece with the frustocone coat K and is made from the plastic material of the yarn braking body B such that the centre Z of the sphere lies in the axis Y of the frustocone coat K which axis Y is prolonged beyond the large diameter end 1.

Owner:IRO AB

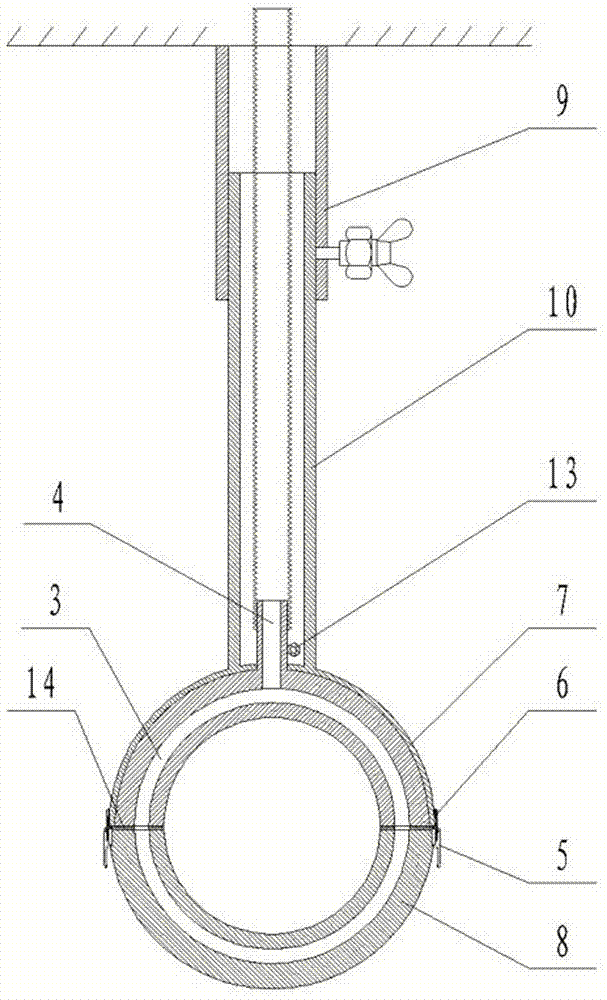

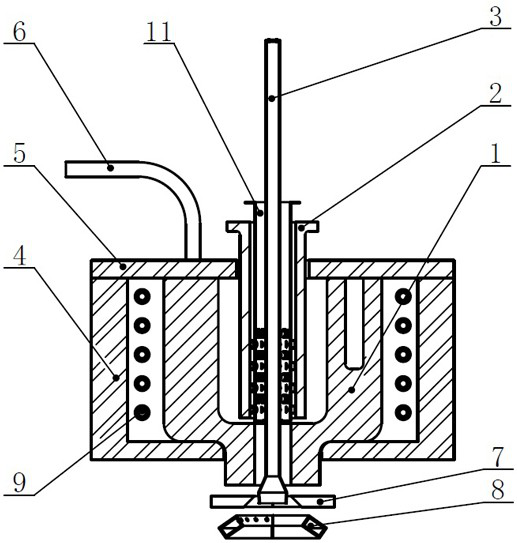

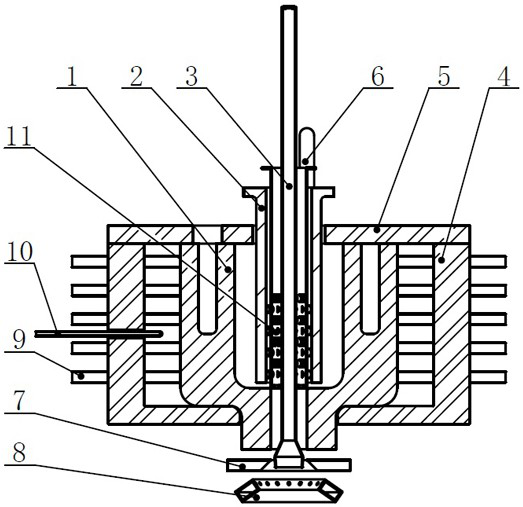

Adjustable air cooling device

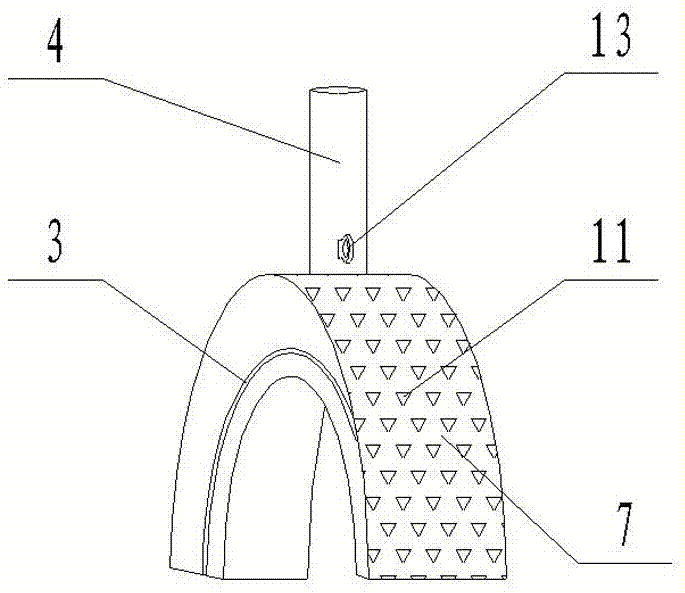

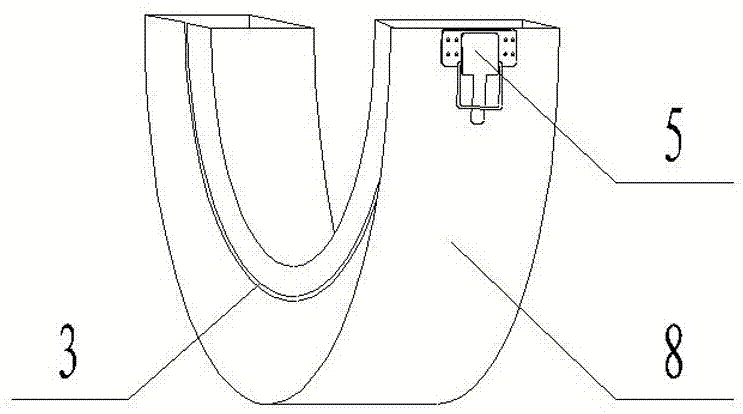

The invention provides an adjustable air cooling device. The adjustable air cooling device comprises air covers (1) and air cover fixing frames (2), wherein each of the air covers (1) is arranged at one end of the corresponding air cover fixing frame (2); at least one air duct (3) is formed in the side part of each of the air covers (1); an air intake connector (4) is arranged at the top of each of the air covers (1); one end of each of the air intake connectors (4) communicates with the corresponding air duct (3), and the other ends of the air intake connectors (4) are embedded in the air cover fixing frames (2) separately; locking buckles (5) are arranged on each of the air covers (1) in a symmetric manner; locking rings (6) are arranged on each of the air cover fixing frames (2) in a symmetric manner; each of the locking buckles (5) is connected with the corresponding locking ring (6) in a matched manner; and the two air cover fixing frames (2) are arranged on the two sides of a water cooling device separately. According to the adjustable air cooling device, the structure is simple, the assembly and disassembly are convenient, the annular cooling and drying of the surface of an extrusion molding part are realized, a good and uniform cooling effect is achieved, the wall thickness and mechanical property consistence of the extrusion molding part are better, and the performance and quality of products during the production process can be ensured easily.

Owner:SICHUAN NIGALE BIOTECH

Modified hot runner systems for injection blow molding

An injection blow molding method for making a container comprising the steps of injecting a molten crystallizable polymer in a preform mold via a hot runner system and biaxially stretching the preform by blowing, thereby forming a container, characterized in that said method further comprises means to selectively modify the flow path of the molten crystallizable polymer within the hot runner system.

Owner:KEIRYO PACKAGING

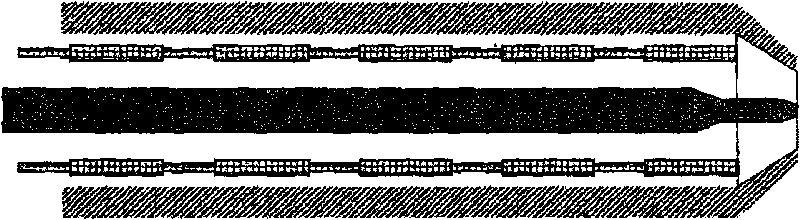

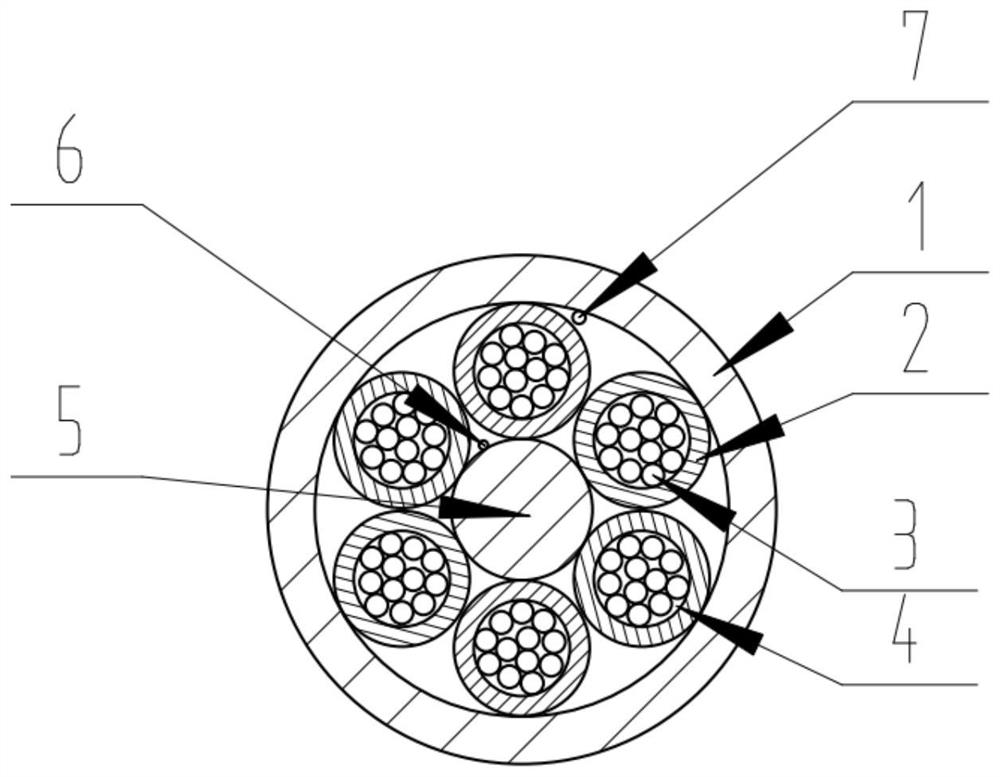

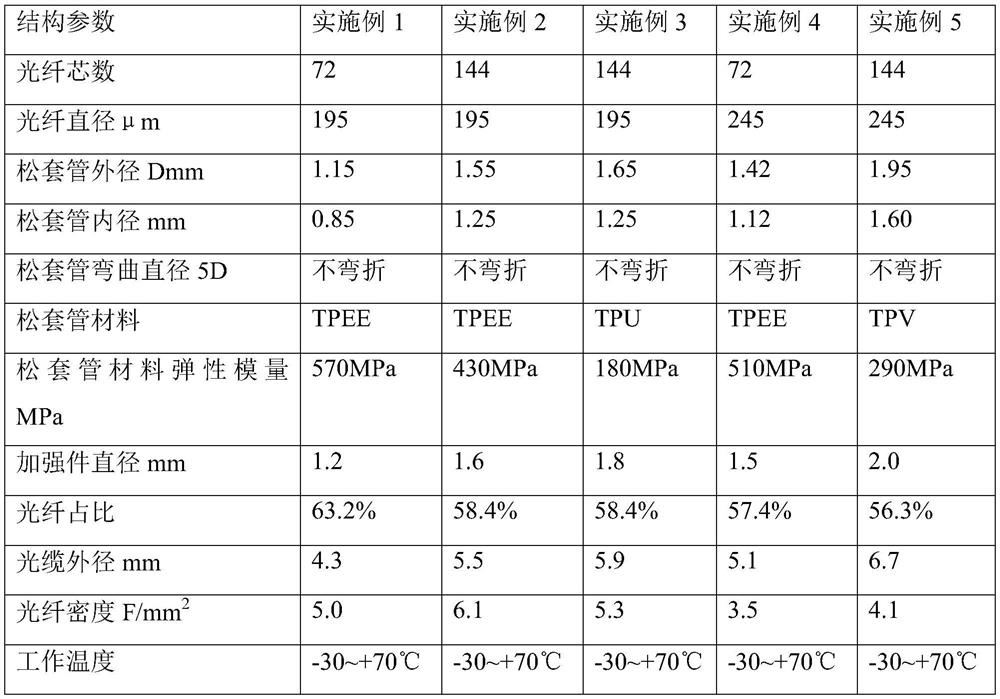

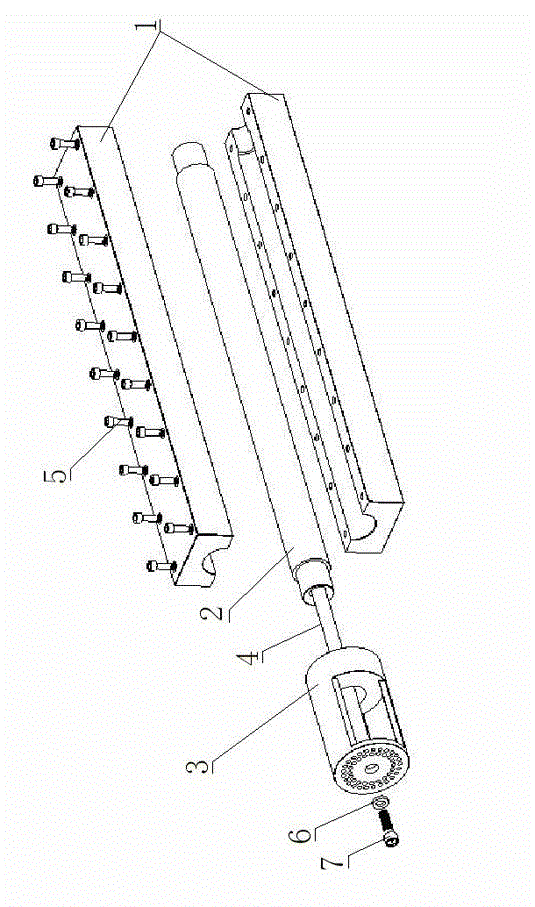

Soft sleeve air-blowing optical cable

PendingCN111830650ASimple structureSmall diameterGlass optical fibreFibre mechanical structuresPlastic materialsOptical communication

The invention relates to a soft sleeve air-blowing optical cable. The cable comprises a cable core and an outer sheath wrapping the cable core, wherein the cable core is a layer-stranded cable core and comprises a central reinforcer and a loose tube stranded at the periphery of the central reinforcer, an optical communication unit is sleeved in the loose tube, the optical cable is characterized inthat the loose tube is made of a flexible plastic material, the elastic modulus of the flexible plastic material is 100-700MPa, and the outermost layer is an outer sheath. The optical cable is simplein structure, small in diameter, light in weight, high in optical fiber density and good in air-blowing laying performance; the loose tube is made of the flexible sleeve plastic material, is good inflexibility, is easy to bend, cannot be bent, can achieve the small-bending-radius coiling in the connector box, enables the optical fiber coiled in a divergence mode to be better protected, does notneed to break the optical fiber, greatly facilitates branching and connection of an optical cable, and improves construction efficiency.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Carbon fiber pipe drawing and extruding die

A novel carbon fiber pipe drawing and extruding die comprises a die sleeve, a die core and a die carrier, wherein the die core is arranged in the die sleeve; the die core and the die carrier are connected through a mandrel; inner edges, which limit the die core to move in the axial direction, are arranged at two ends of the die sleeve; and the die sleeve is formed by combining two sets of aluminium housings symmetrically arranged up and down. Only the die core is die steel; the die sleeve and the die carrier are aluminium products; and the die is relatively light, low in manufacturing cost, convenient and fast to dismount, fast and uniform to heat, and high in curing speed. Under the same condition, the die is relatively small in occupied area; when carbon fiber pipes are produced, multiple pipes can be produced simultaneously on one production line, so that the production efficiency is improved greatly. The die is simple in structure, and convenient to operate, the wall thickness of the product produced is uniform, the product is attractive in appearance, and the curing degree is high. Meanwhile, all that is needed to replace with products with other specifications is to process the die core and the mandrel, so that the production cost is lowered remarkably.

Owner:LIANYUNGANG YINGYOU CARBON PLASTIC MATERIAL

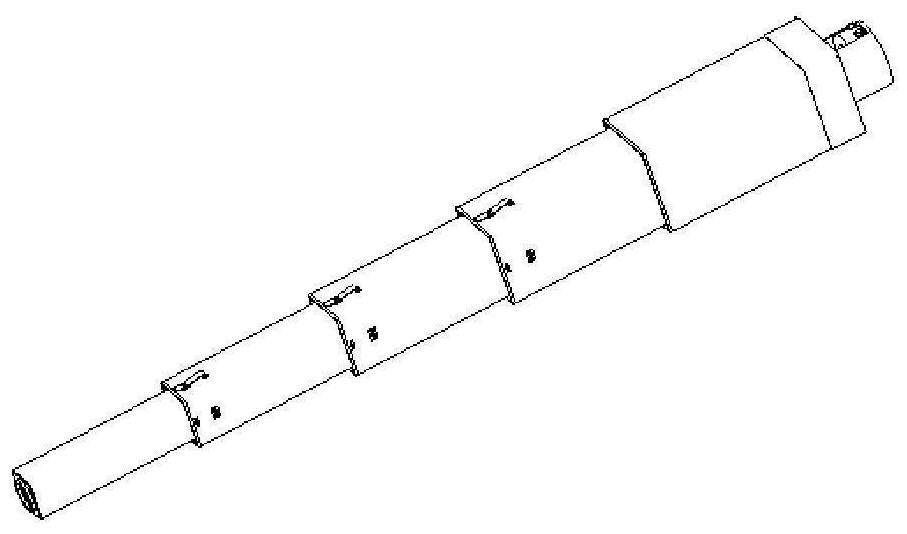

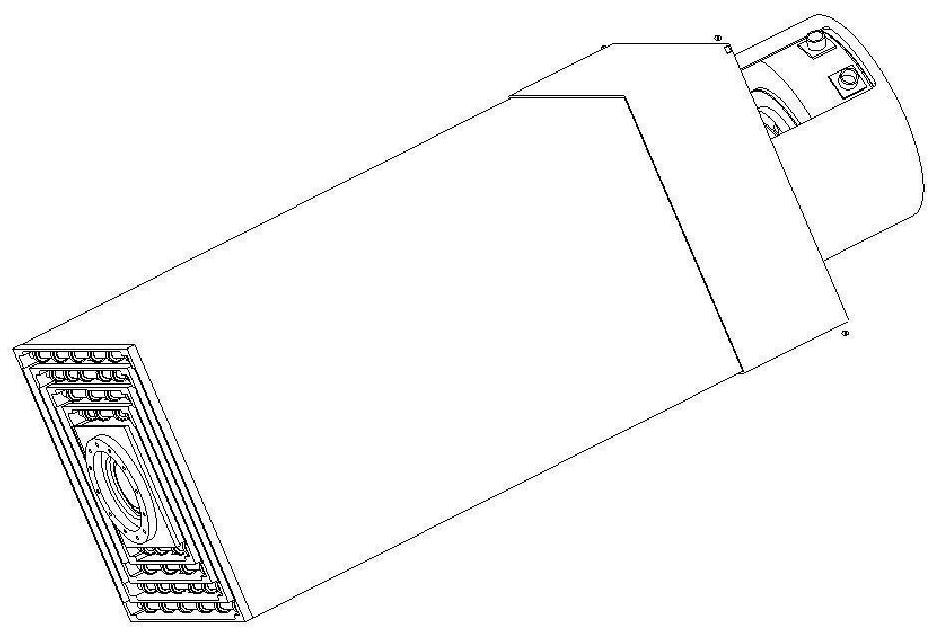

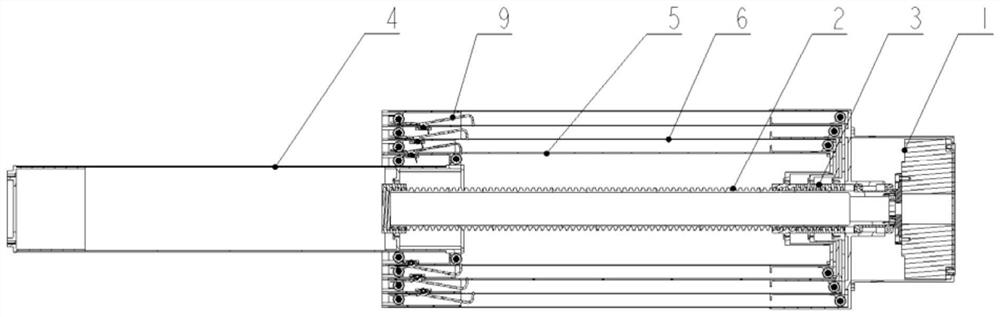

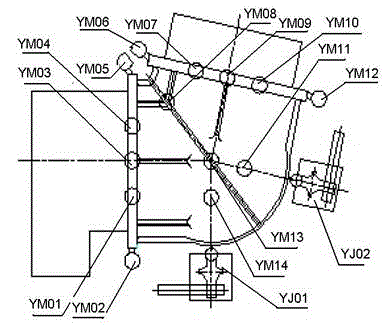

Reciprocating telescopic unfolding mechanism

PendingCN113685523AHigh reuse rateWide range of usage scenariosCosmonautic vehiclesGearingElectric machineryDrive motor

The invention discloses a reciprocating telescopic unfolding mechanism. The reciprocating telescopic unfolding mechanism comprises a driving motor, a transmission lead screw, N nuts, N stages of telescopic arms, a plurality of unfolding locking mechanisms, a plurality of folding locking mechanisms and a plurality of rolling bearings, wherein, the driving motor is connected with one end of the transmission lead screw through a rotating shaft, the nuts are installed at the ends, close to the motor, of the telescopic arms; the telescopic arms are connected with one another through the rolling bearings; and the unfolding locking mechanisms are arranged on the outer walls, away from the end part of the motor end, of the second-stage to (N-1)-stage telescopic arms, and the folding locking mechanisms are arranged on the inner walls, away from the end part of the motor end, of the second-stage to (N-1)-stage telescopic arms. The mechanism is unique and controllable in motion trail, reliable in locking, controllable in step-by-step stretching and unfolding, and automatic and repeatable in stretching and unfolding processes; through motor driving, the defect that passive driving unfolding impact is large is effectively avoided, the unfolding rigidity and strength can be subjected to adaptive optimization design according to requirements, and the storage ratio is high; and the mechanism can be widely applied to large-scale and even ultra-large-scale deployable structures in space, and has a wide application prospect.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

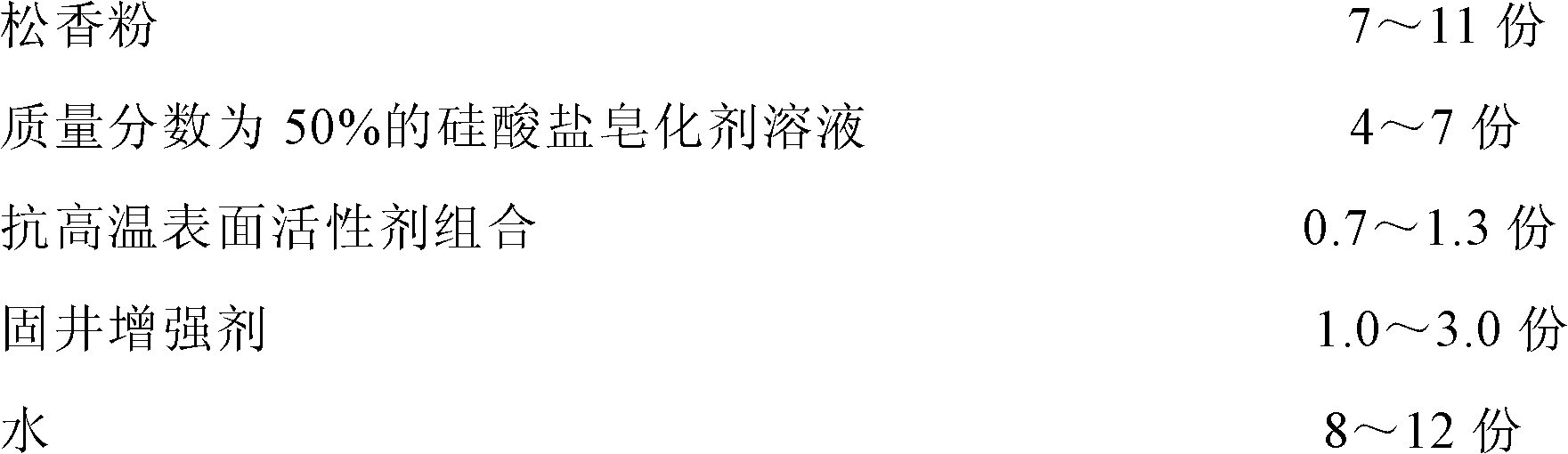

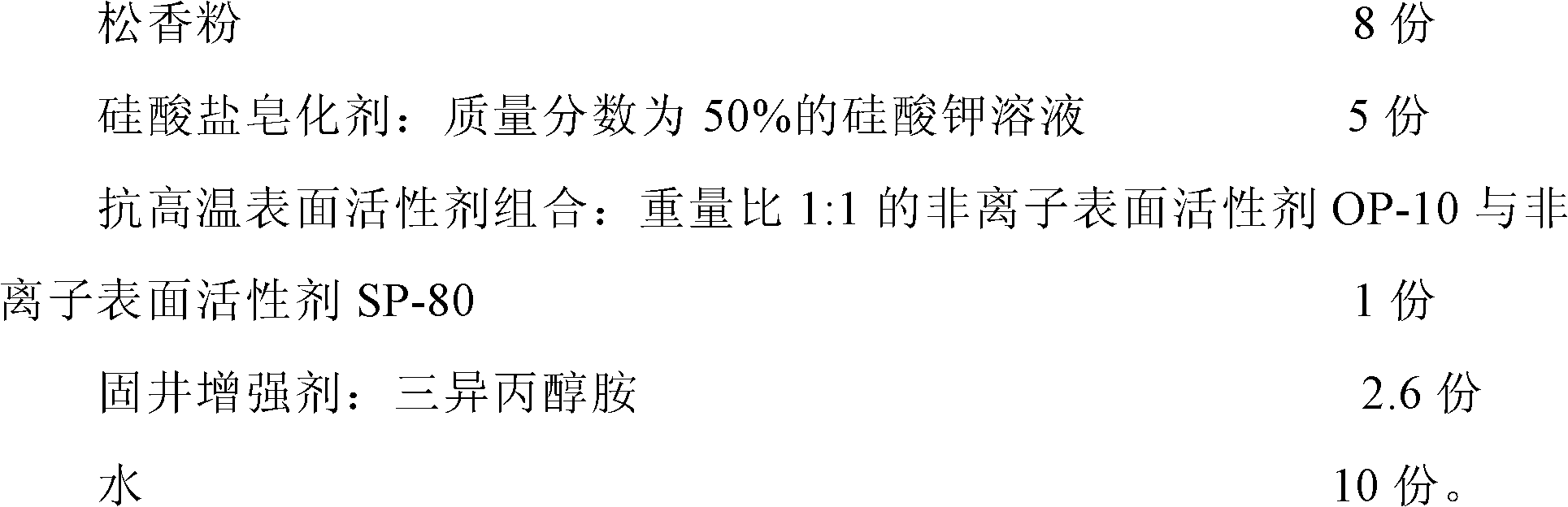

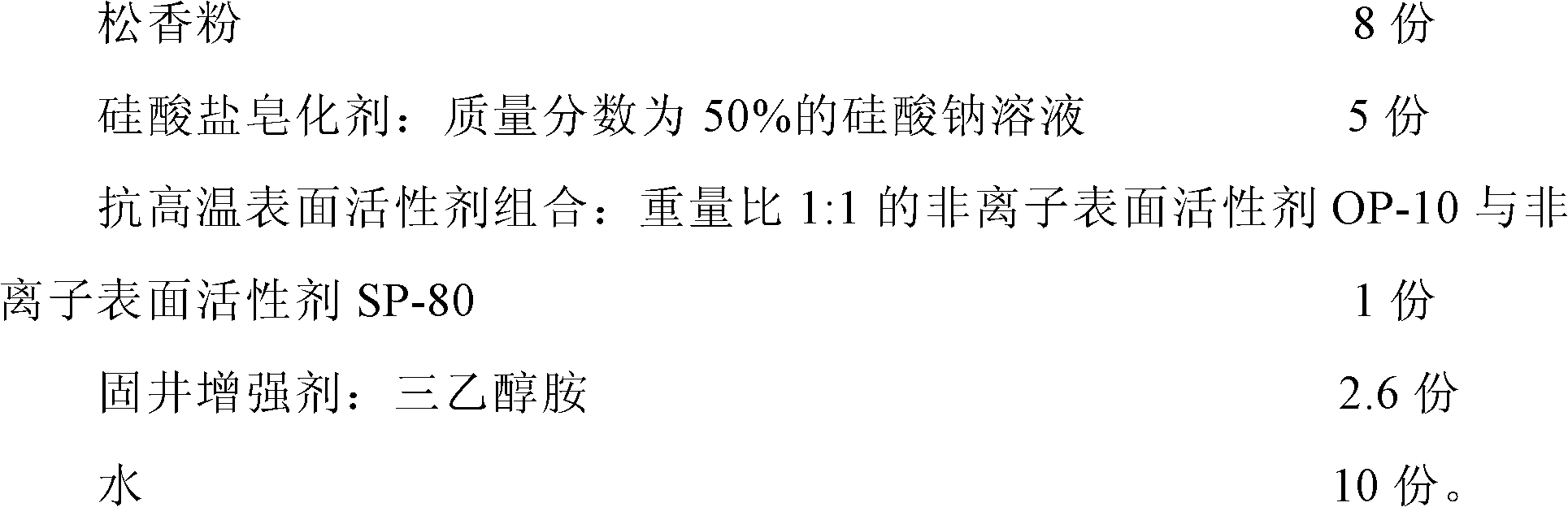

Micro-foam agent for oil field oil gas well cementation and preparation method thereof

InactiveCN102321460AImprove saponification effectHigh compressive strengthDrilling compositionROSIN POWDERLithium

The invention discloses a micro-foam agent for oil field oil gas well cementation. The micro-foam agent is prepared from a micro-foam agent half-finished product and silicate clay mineral in the weight ratio of 1:25-35; the micro-foam agent half-finished product is prepared from the following components in parts by weight: 7-11 parts of rosin powder, 4-7 parts of silicate saponifier, 0.7-1.3 parts of high-temperature-resistant surfactant combination, 1.0-3.0 parts of well cementation reinforcing agent and 8-12 parts of water, wherein the silicate clay mineral is sepiolite clay or lithium-based bentonite; the silicate saponifier is sodium silicate or potassium silicate; the well cementation reinforcing agent is triisopropanolamine or triethanolamine; and the high-temperature-resistant surfactant combination consists of OP-10 and SP-80 in the weight ratio of 1:1 or APG (Alkyl Polyglucoside) and SP-80 in the weight ratio of 1:1. The invention also provides a preparation method of the micro-foam agent. Thus, a novel ultra-low density micro-foam well cementation cement slurry system with fine foam, high stability, simple preparation process and superior overall performance is established.

Owner:XI'AN PETROLEUM UNIVERSITY

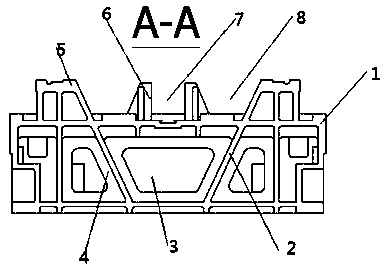

Lightweight high-rigidity gantry machining center machine base

PendingCN107914149AIncreased flexural section modulusHigh tensile strengthLarge fixed membersEngineeringMachine tool

The invention discloses a lightweight high-rigidity gantry machining center machine base. The lightweight high-rigidity gantry machining center machine base comprises a machine base body. A base is composed of two downwards parallel base plates. The two base plates are connected and fixed through a strengthening rib. The strengthening rib is in an inverted-W shape. The sharp ends of the triangularshapes of the two sides of the upper end of the strengthening rib penetrate the top base plate, top sliding rails are arranged on the tops of the sharp ends of the triangular shapes of the strengthening rib, and the three end portions of the lower end of the strengthening rib are connected and fixed to the base plate on the lower side. The lower parts of double guide rails of the base are supported by the inverted-W-shaped strengthening rib, and the weight of a movable component workbench on the guide rails and machined workpieces is scattered through the strengthening rib, the supporting area and range are set from small to large, the interior of the base is supported by the multiple triangles likely, the casting stress of castings is reduced to be minimum, the residual stress of the castings is eliminated through annealing and the rest of precipitation heat treatment, and the stability during machine tool movement is greatly improved; and meanwhile, the material cost is saved, and meanwhile rigidity is improved.

Owner:湖南巨人机床集团有限公司

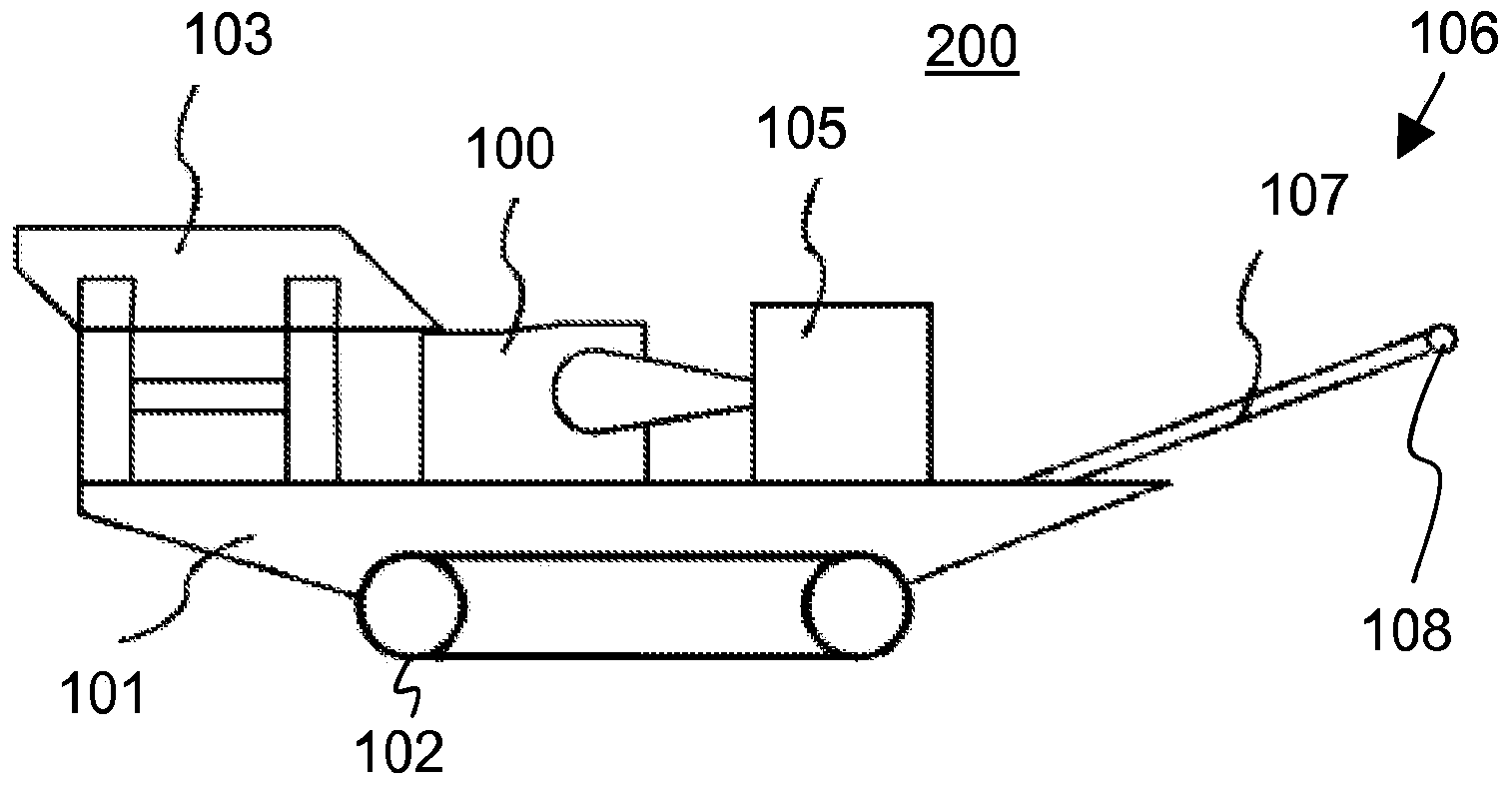

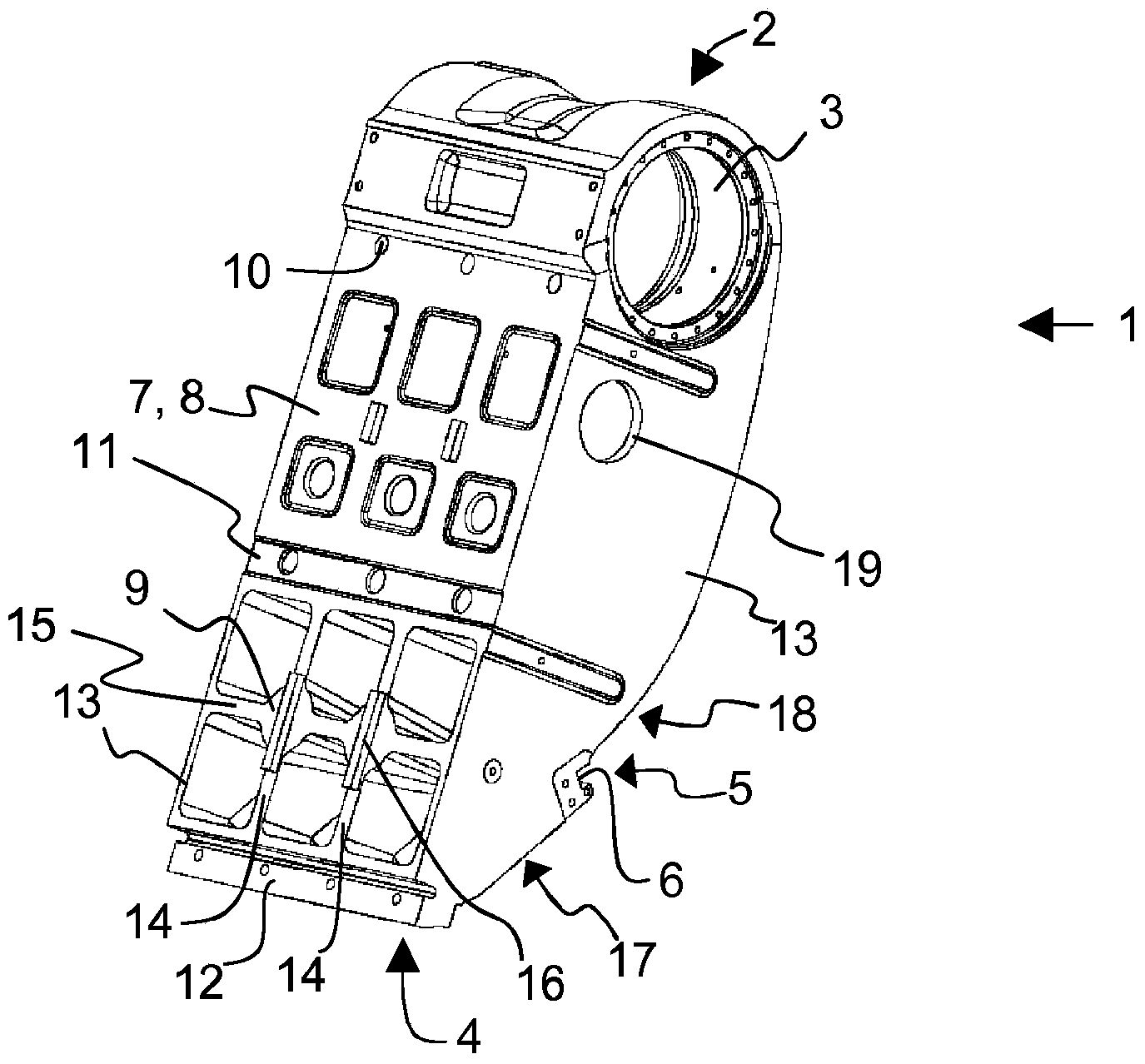

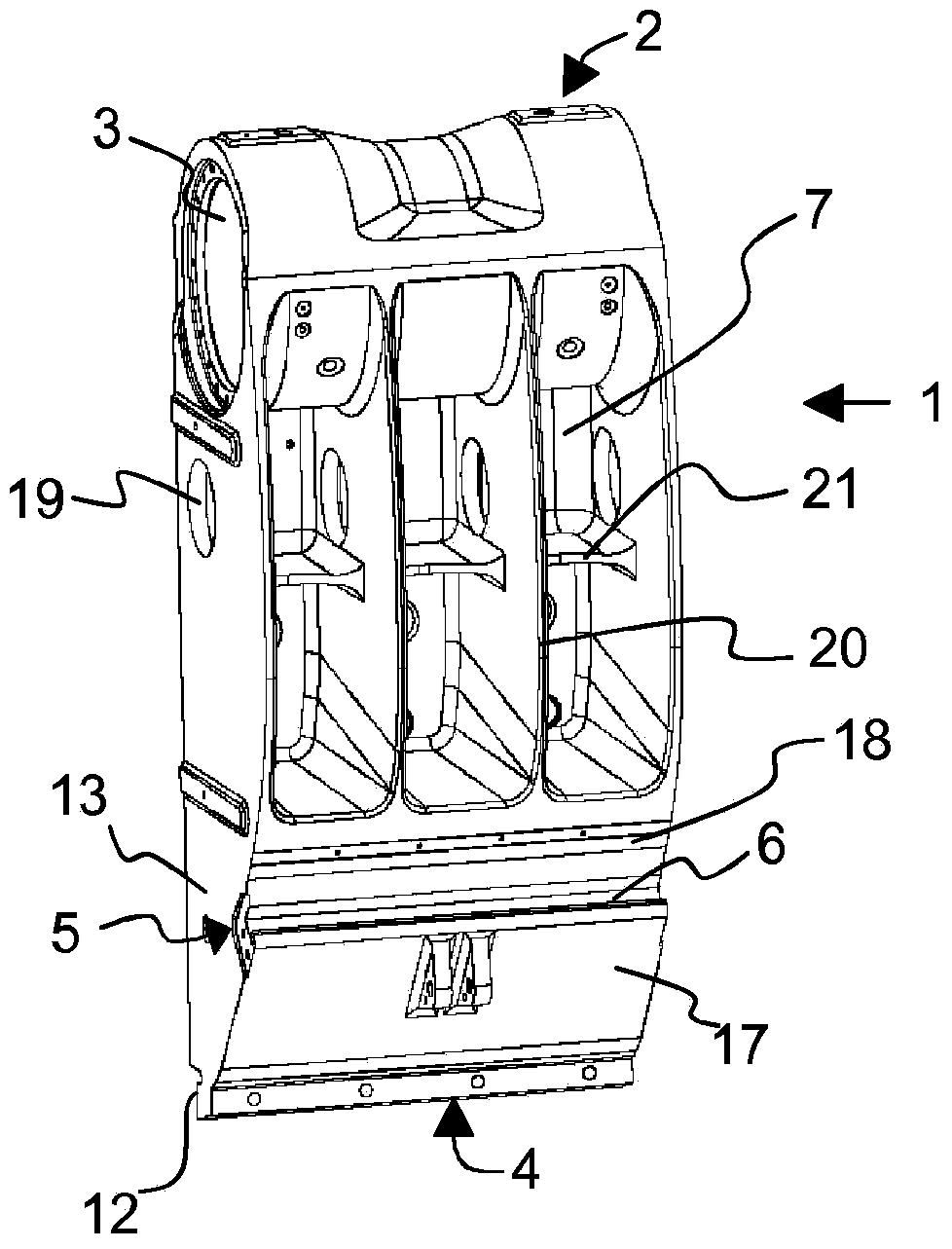

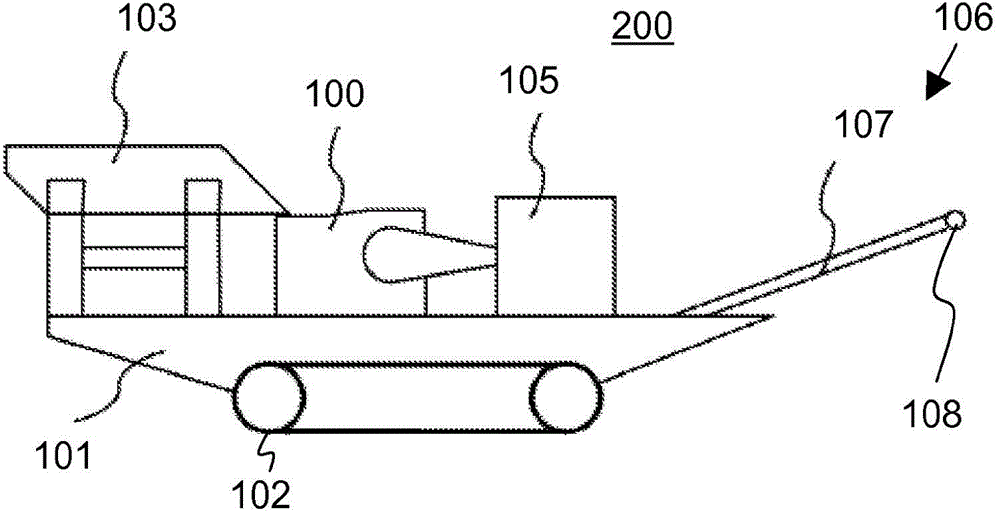

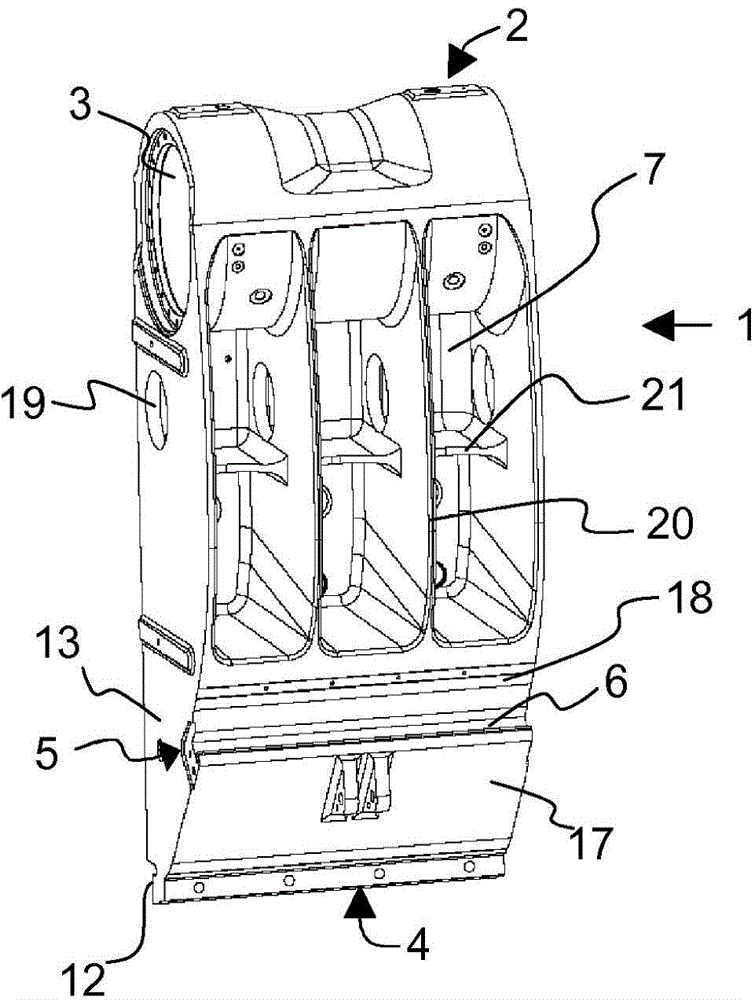

A pitman of a jaw crusher, a jaw crusher, a crushing plant and a crushing method

ActiveCN103906572AImprove abilitiesSave energy and materialGrain treatmentsHoneycomb structureEngineering

A pitman of a jaw crusher (1; 1') comprises an upper part (2), which comprises an upper supporting point (3) for supporting the pitman in the body of the jaw crusher, and a lower part (4) comprising a lower supporting point (5) for supporting the pitman in the body of the jaw crusher through a toggle plate. The lower part (4) of the pitman (1; 1') comprises sidewalls (13) and honeycomb structure open to the crushing direction, the structure comprises one or more cross-sectional supports (15) reaching from the first sidewall of the pitman to the second sidewalk. A jaw crusher (100), a crushing plant (200) and a method for increasing crushing capacity of mineral material are also provided.

Owner:METSO MINERALS INC

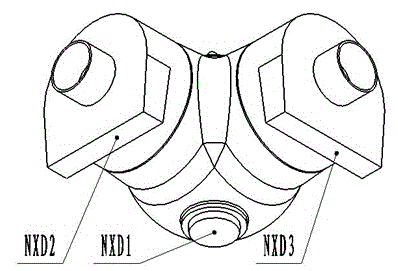

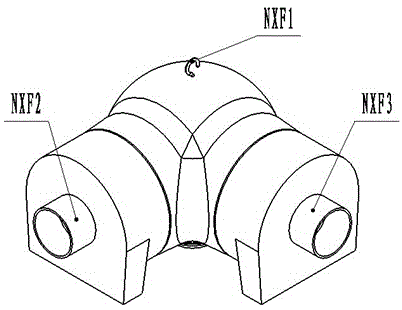

Casting device and process for large 90-degree pressure-resistant aluminum alloy bend shell of extra-high pressure GIS switching equipment

The invention relates to a casting device and process for a large 90-degree pressure-resistant aluminum alloy bend shell of extra-high pressure GIS switching equipment. The bend shell is of a 90-degree bend structure, flanges are arranged at the two ends of the bend shell, and the bend shell comprises a sand core lifting structure and a core box. The sand core lifting structure comprises a lifting hook, an embedded support connected with the lifting hook and a thick nut connected with the lifting hook and the embedded support. The core box is provided with a containing groove for containing a sand core, a notch for containing the lifting hook and a through hole allowing the containing groove and the notch to be communicated. The lower end of the embedded support of the sand core lifting structure is of a cross-shaped structure for locating two flange parts of the sand core respectively. The exact center of the upper portion between the two flanges of the sand core is located through the lifting hooks. An inner casting channel of the sand core comprises multiple vertical barrels connected with transverse casting channels and casting gates. By the adoption of the device and process, part casting quality can be improved, and it is guaranteed that parts receive the pressure of the hydraulic pressure destructive test requirement.

Owner:江苏华江科技有限公司

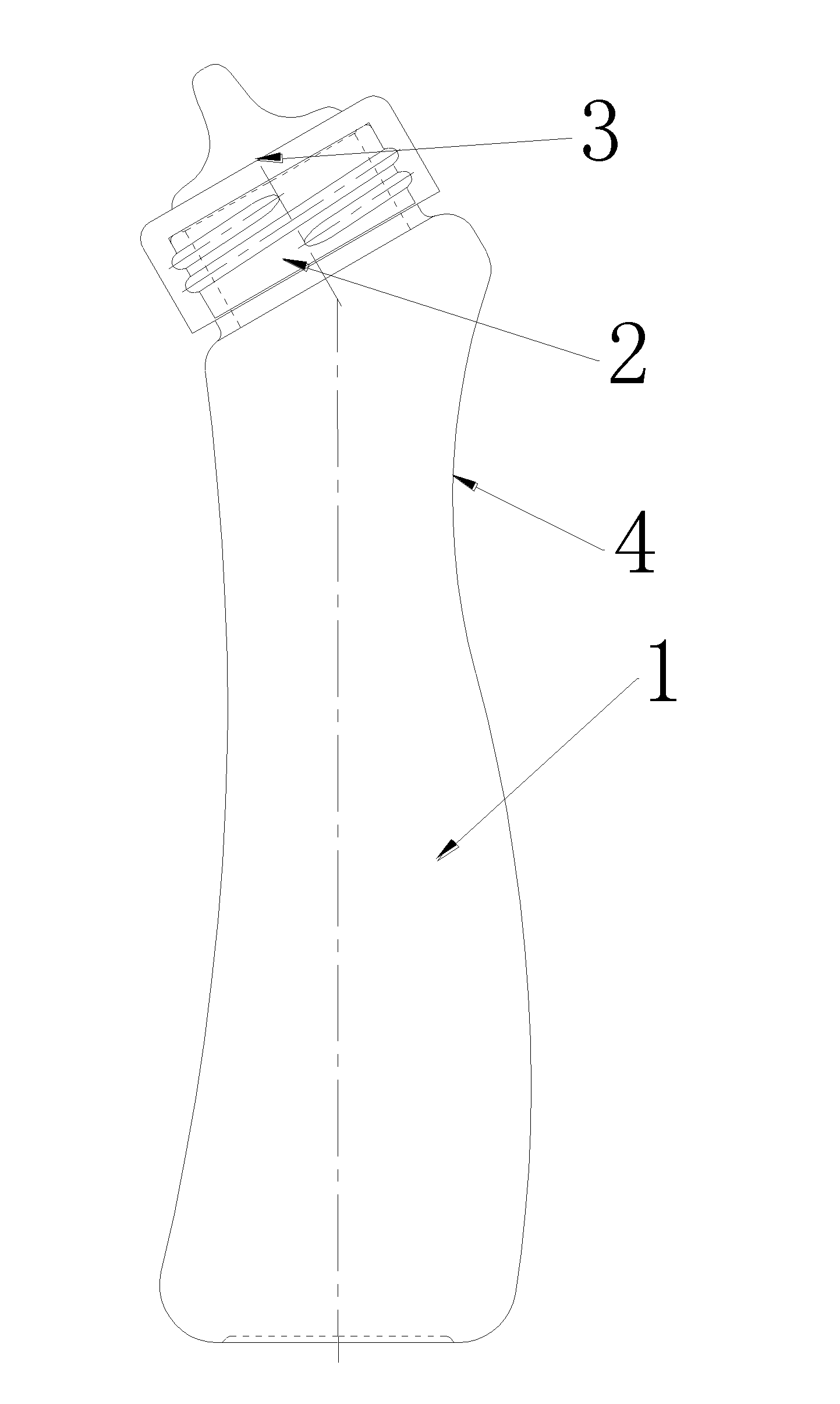

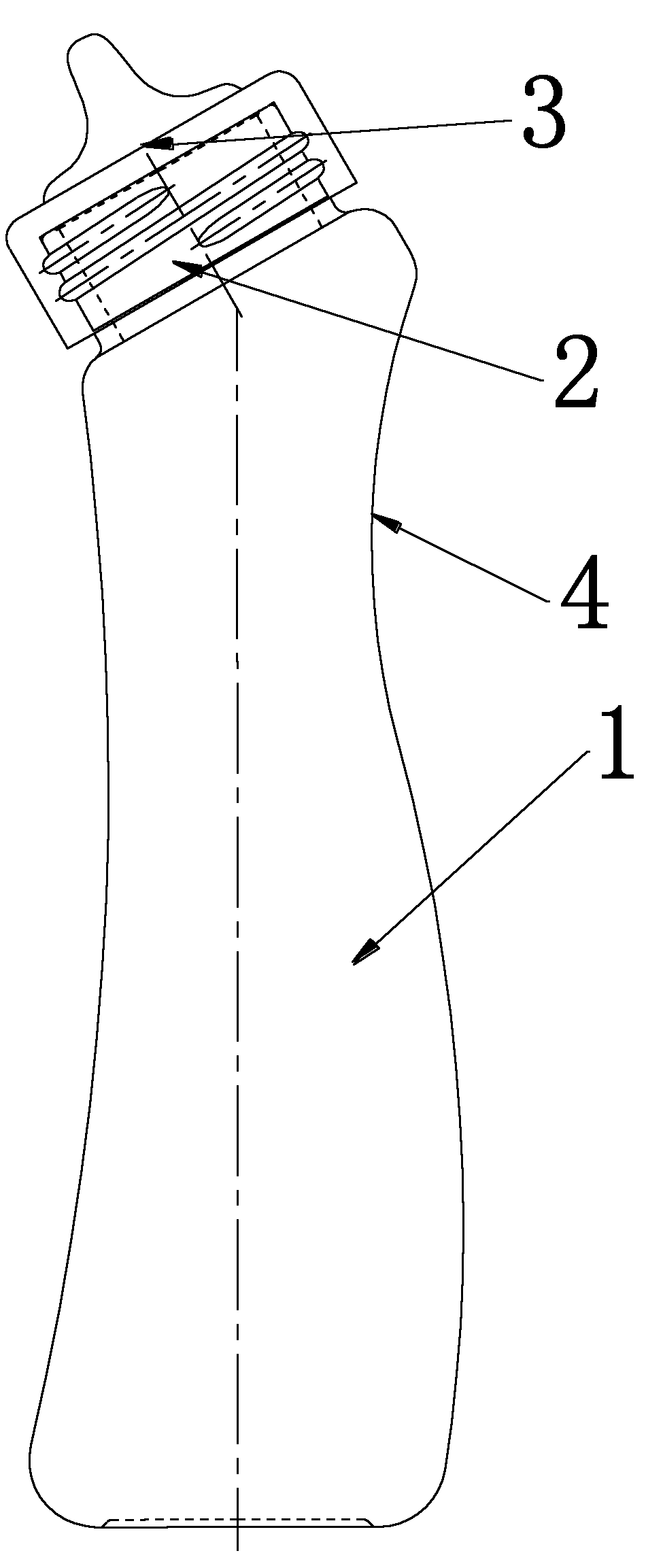

Bevel mouth special nursing bottle and production method thereof

InactiveCN102210631AInverted smoothEasy to holdFeeding-bottlesGlass blowing apparatusBottle neckEngineering

The invention designs a bevel mouth special nursing bottle, which mainly comprises a bottle body, a bottle neck and a nursing bottle cap, wherein the central line of the bottle neck and the central line of the bottle body form an angle of 145 to 160 DEG C. In production method of the bevel mouth special nursing bottle, a bottle neck mold is vertically arranged, a coarse mold is matched with the bottle neck mold and reversely placed, a bottle body mold in the coarse mold is obliquely arranged, liquid glass is filled into the coarse mold from bottom, then a small amount of air is blow into the coarse mold from the bottom of the coarse mold in a strong air flow immediately, and later an air blowing pipe is inserted from the middle of the bottle neck mold for blowing air till the nursing bottle is basically formed; the coarse mold is opened, the bottle neck mold and the nursing bottle are taken out at the same time, the nursing bottle is turned up and down twice, the liquidity of the glass in the coarse mold of the nursing bottle is kept, the nursing bottle is moved to the orifice of the air outlet pipe after turning, and a small amount of air is blown into the bottle body from the bottle neck; the nursing bottle is placed in a fine mold with the bottle neck obliquely placed, the bottle body is vertically downward, air is blown into the bottle body from the bottle neck, and the nursing bottle is formed into a specific size; and the nursing bottle is taken out, the bottle neck mold is opened, and thus, the bevel mouth special nursing bottle is obtained.

Owner:TONGXIANG HESHAN CRAFT GLASSWARE FACTORY

Blowing mould used for blowing plastic hollow container

Owner:SICHUAN KELUN PHARMA CO LTD

A pitman of a jaw crusher, a jaw crusher, a crushing plant and a crushing method

A pitman of a jaw crusher (1; 1') comprising an upper part (2), which comprises an upper supporting point (3) for supporting the pitman in the body of the jaw crusher, and a lower part (4) comprising a lower supporting point (5) for supporting the pitman in the body of the jaw crusher through a toggle plate. The lower part (4) of the pitman (1; 1') comprises sidewalls (13) and honeycomb structure open to the crushing direction, which structure comprises one or more cross-sectional supports (15) reaching from the first sidewall of the pitman to the second sidewalk A jaw crusher (100), a crushing plant (200) and a method for increasing crushing capacity of mineral material.

Owner:METSO OUTOTEC (FINLAND) OY

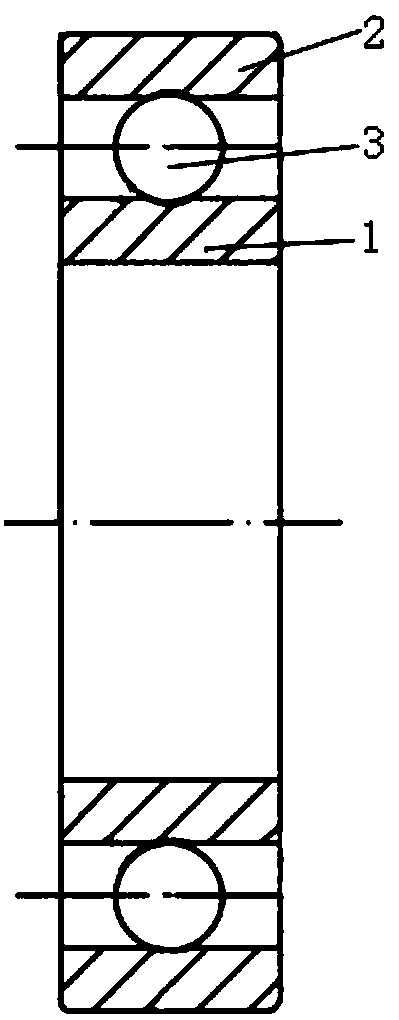

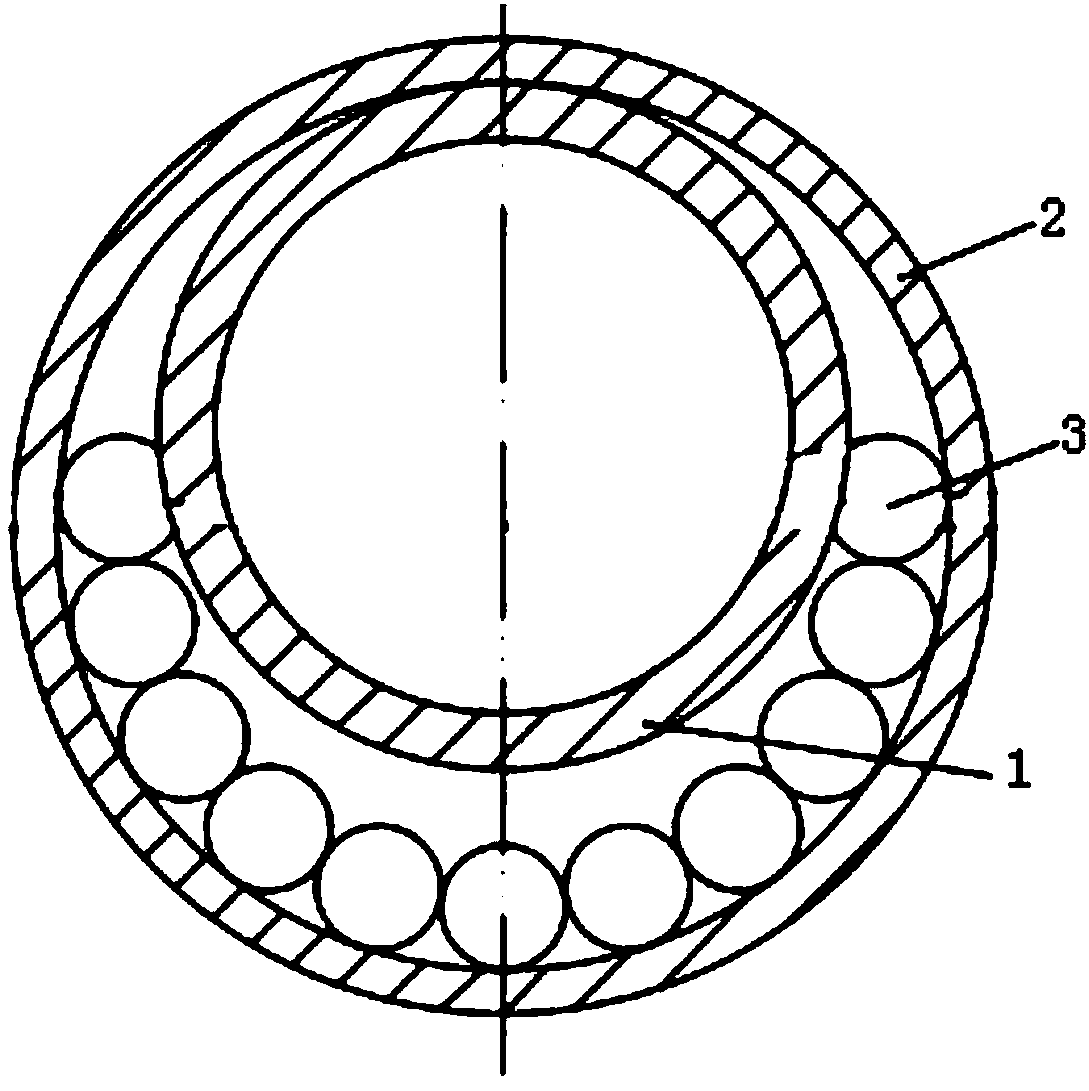

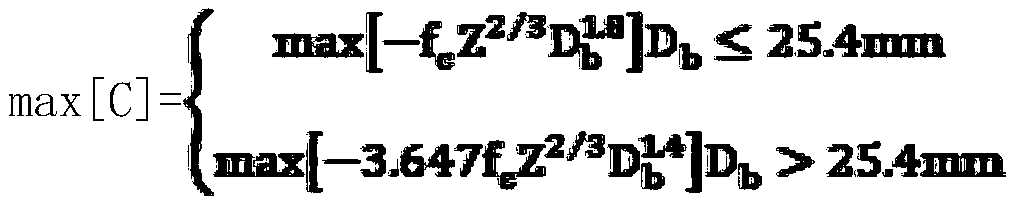

Structural design method of rolling ball bearing

ActiveCN108229044AOptimize wall thicknessGeometric CADSpecial data processing applicationsBall bearingRolling-element bearing

The invention provides a structural design method of a rolling ball bearing. The method comprises the steps that an objective function of a rolling bearing design is determined, a rated dynamic load of the bearing is taken as the an objective function, the maximum rated dynamic load under the optimal bearing structure is determined, and according to a bearing structure size boundary condition, a bearing manufacturing and assembly structure size boundary condition, a bearing ring contacting load boundary condition, and a bearing structure optimization design based on the genetic algorithm, geometric structure data based on the comprehensive design of the bearing structure, assembly and service load is obtained. The structural design method of the rolling ball bearing has the advantages thattime consumption is short, the method can be combined with test methods and guide tests, thereby saving the test cost, and has the advantages of high efficiency, low cost, strong practicability and the like based on the numerical analysis method.

Owner:WUHAN UNIV OF TECH

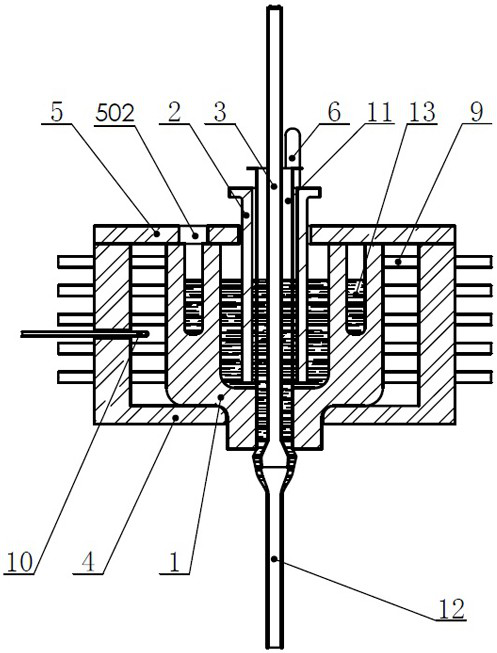

Drawing device and method for small-batch multi-variety high-uniformity glass tubes

PendingCN113277710AExtended stayIncrease the heat exchange areaGlass drawing apparatusPipeMechanical engineering

The invention discloses a drawing device and method for small-batch multi-variety high-uniformity glass tubes and belongs to the technical field of special glass manufacturing. The invention mainly aims to solve the problems of unstable drawing quality, low yield and the like of special application glass tubes with small market demand and multiple varieties (formulas). The drawing device is mainly characterized by comprising a forming furnace body, a material basin, a material homogenizing barrel, a leading-in pipe, a stirrer and a forming part, the material basin is arranged in the forming furnace body, the leading-in pipe is located on the upper portion of the forming furnace body and is coaxial with a leading-in hole in a cover plate, and an outlet of the leading-in pipe extends into the leading-in hole, the material uniformizing barrel is coaxial with a leakage opening in the material basin, and a certain gap is kept between the lower edge of the material uniformizing barrel and the inner bottom surface of the material basin, the stirrer is arranged inside or outside the material uniformizing barrel and is coaxial with the material uniformizing barrel, and the forming part is arranged at the lower part of the forming furnace body. The drawing quality of small-discharge-amount glass tube forming can be solved with a specific process method. The drawing device is mainly used for drawing small-batch multi-variety high-uniformity glass tubes.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com