Producing teahnology for high-polymer composite pipe and its special die

A production process and composite pipe technology, applied in the field of multi-layer composite pipe production process, can solve the problems of unreasonable production process, high cost of production equipment, affecting product quality, etc., and achieve convenient operation, low investment cost and low internal stress small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

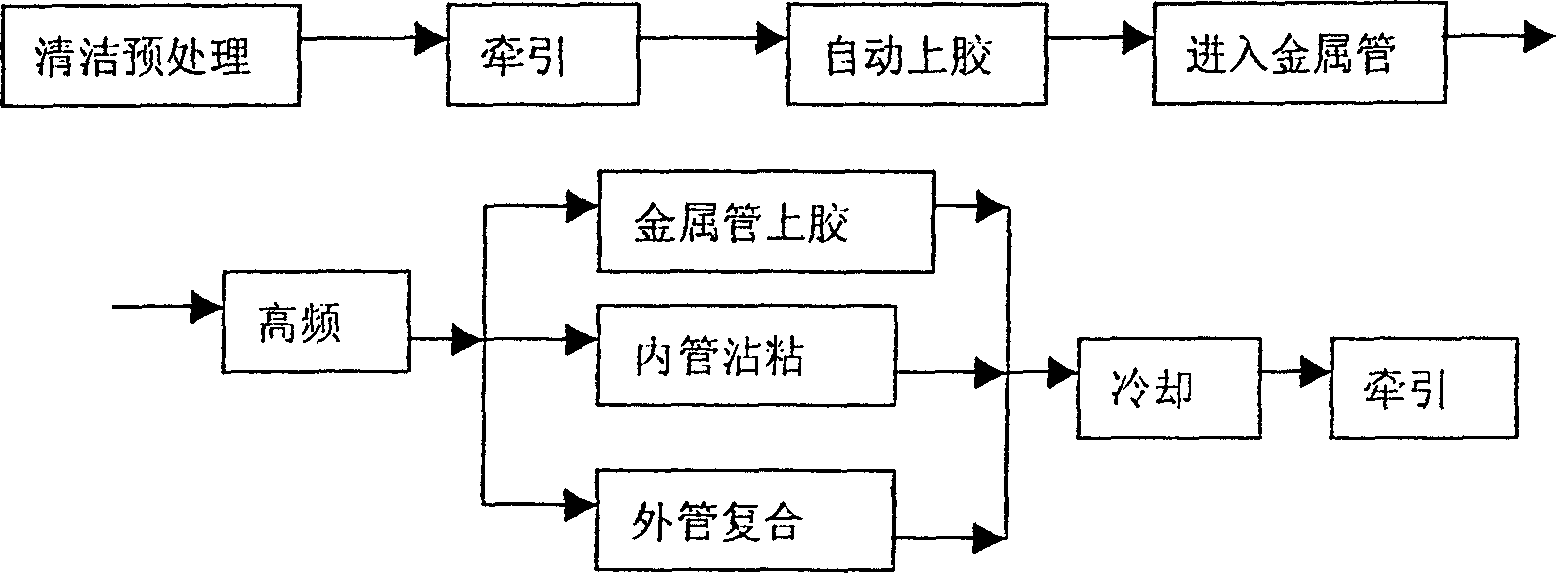

Method used

Image

Examples

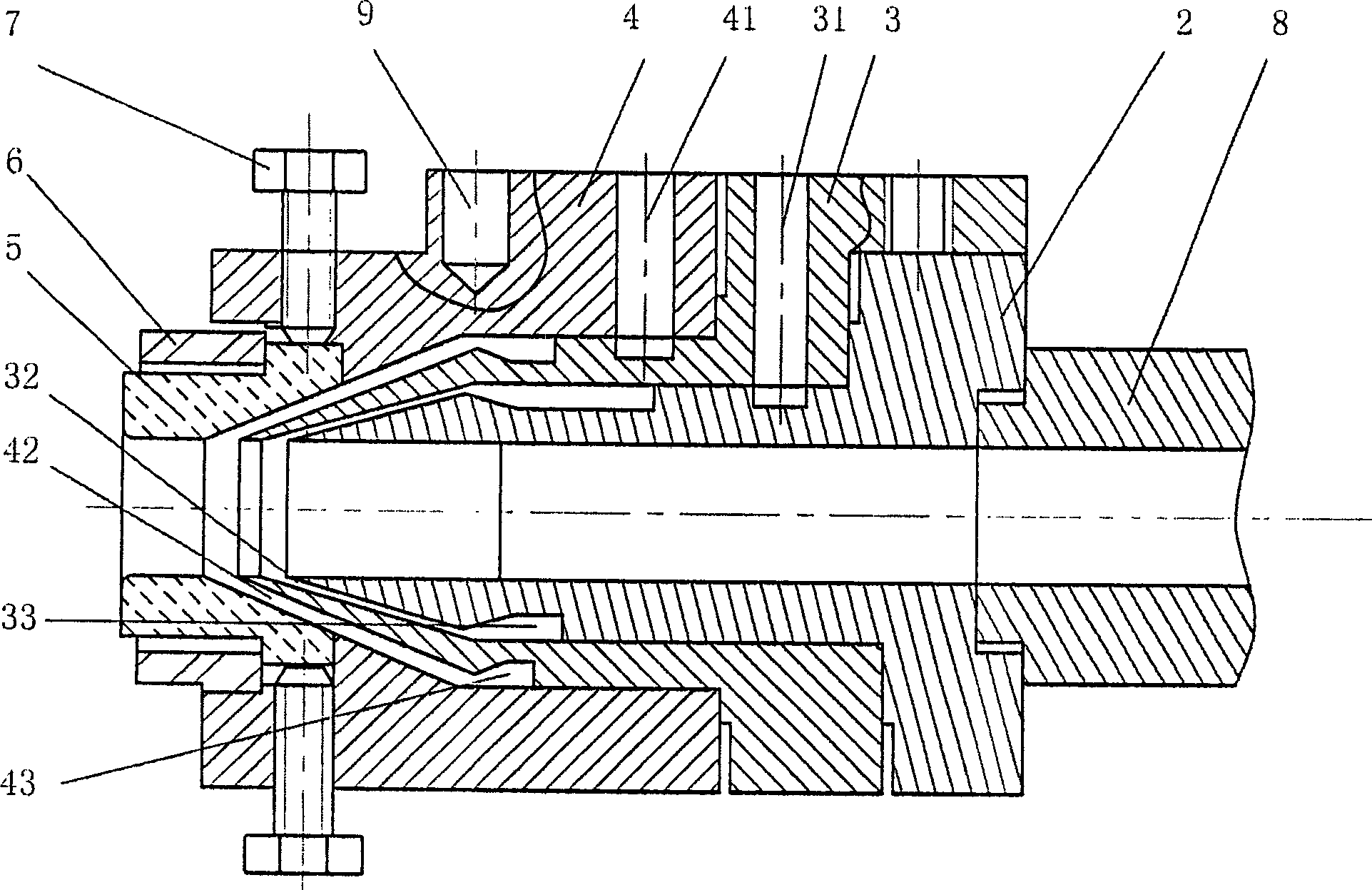

Embodiment 1

[0031] Embodiment 1: the mechanical equipment used in the present invention has extruder, hot-melt machine, automatic cutting machine etc. and all can adopt known machinery, wherein the pipe drawing machine and the special-purpose mold of the polymer composite pipe of one of main mechanical equipment are then It is specially developed and improved by the applicant. Among them, the structure of the special mold for multi-layer composite pipe is as attached image 3 As shown, its length, width, and height are 160×120×100mm. The mold is composed of an outer mold 4 and a core mold inside it, wherein the core mold is composed of an inner core mold 2 and a center core outside it. mold 3, and one end between the two and the outer mold 4 is respectively provided with an inner injection nozzle 32 and an outer injection nozzle 42 arranged in a ring. The shapes of the cavities of the inner mandrel 2 and the middle mandrel 3 are similar to the cross-sectional shape of the pipe to be proc...

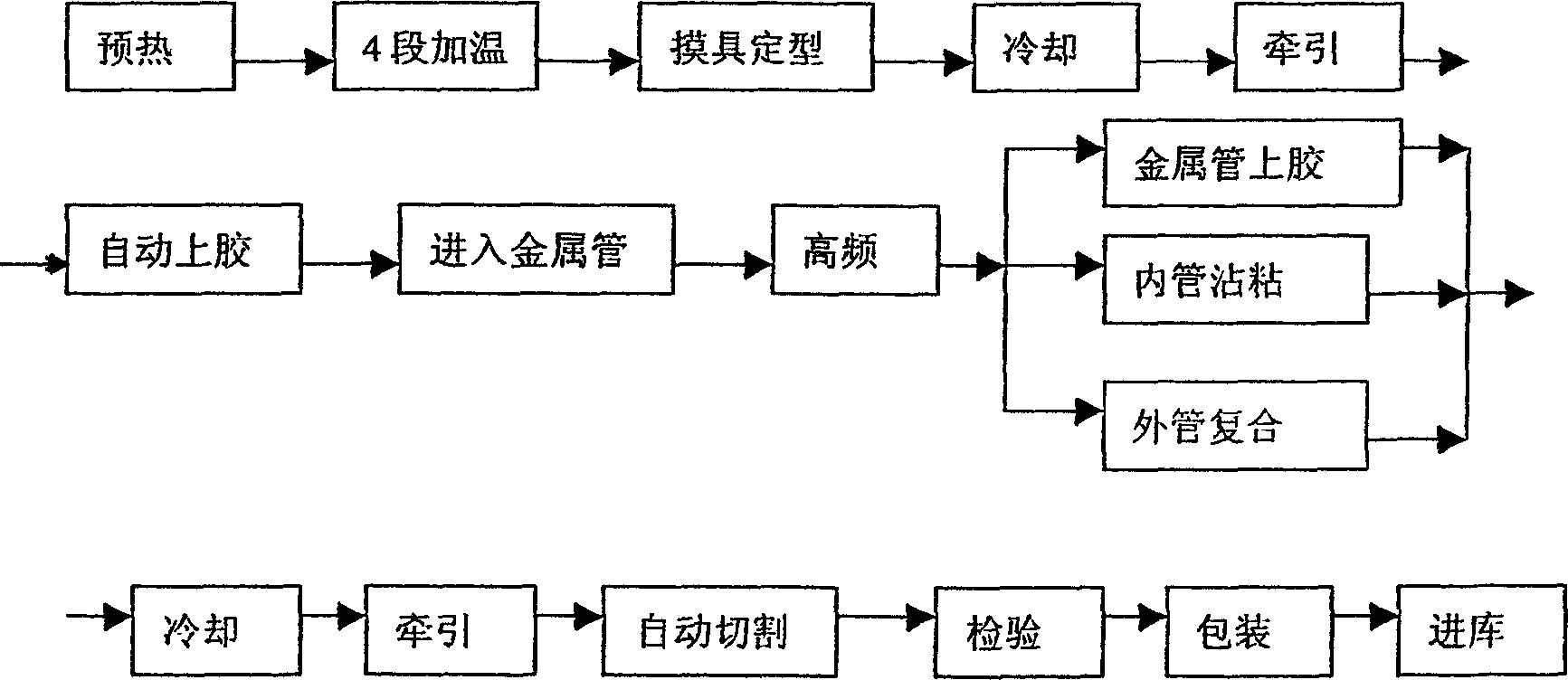

Embodiment 2

[0033] Embodiment 2: required mechanical equipment is with embodiment 1, and its technological process is as attached figure 2 shown. The inner tube is made of polypropylene or cross-linked polypropylene, and it is preheated. After 4 stages of heating, it enters the mold and is shaped to form the required inner tube. After cooling, it passes through the polymer composite tube, one of the mechanical equipment. Drawing machine traction, the following production steps, process conditions, etc. are referring to embodiment 1. After completing the steps in Example 1, the polymer composite tube made is sprayed, and then enters an automatic cutting machine for automatic cutting. The staff inspects and packs the polymer composite tube, and finally the polymer composite tube is Composite pipes are put into storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com