Yarn braking body

A braking body and yarn technology, applied in thin material processing, textiles, papermaking, knitting, etc., can solve the problem of time-consuming replacement of the holding structure, and achieve the effect of easy replacement and reasonable cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

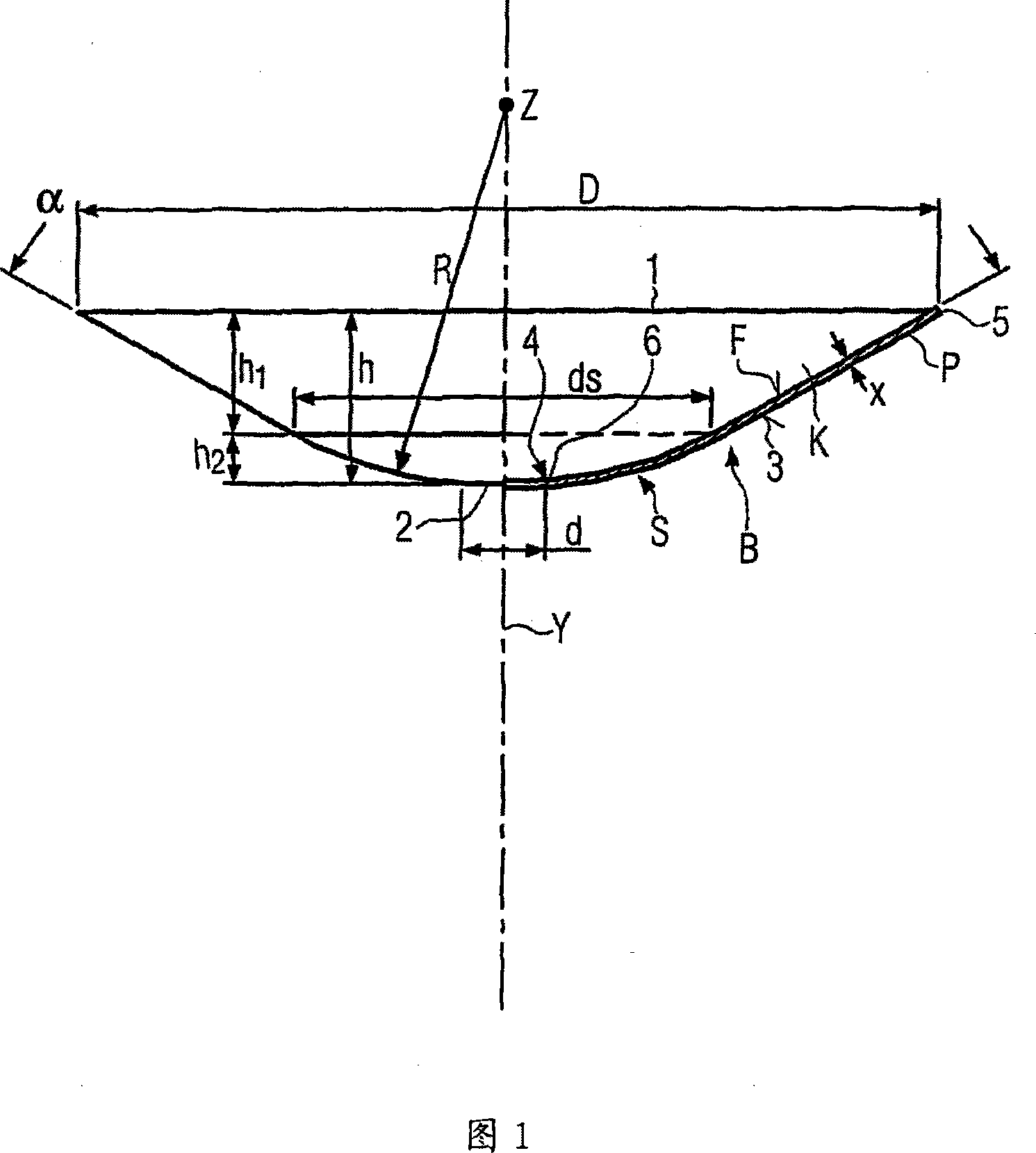

[0019] Conveniently, Fig. 1 provides a yarn braking body B of a knitting yarn feeding device (not shown) which cooperates with a circular extraction edge of a drum-shaped yarn storage body of the knitting yarn feeding device so that when the The yarn is driven or loaded with a small braking force when the yarn is extracted inwardly by the extraction edge and simultaneously rotates like the hands of a clock. Thus, the yarn braking body is arranged coaxially with the storage body from the front side opposite the extraction side and remains suspended so that it is centered on the extraction side but still remains capable of a certain movement. The yarn braking body B is a piece of plastic material, for example made of a thermoplastic P like polyester, PET or PVC. For example, the yarn braking body B is produced by vacuum setting on a forming die, sometimes even by thermal vacuum setting.

[0020] The yarn braking body B consists of a right frustoconical shell K and a spherical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com