Soft sleeve air-blowing optical cable

A soft sleeve and optical cable technology, applied in the field of photoelectric transmission, can solve the problems of increased optical fiber attenuation and easy bending of the sleeve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

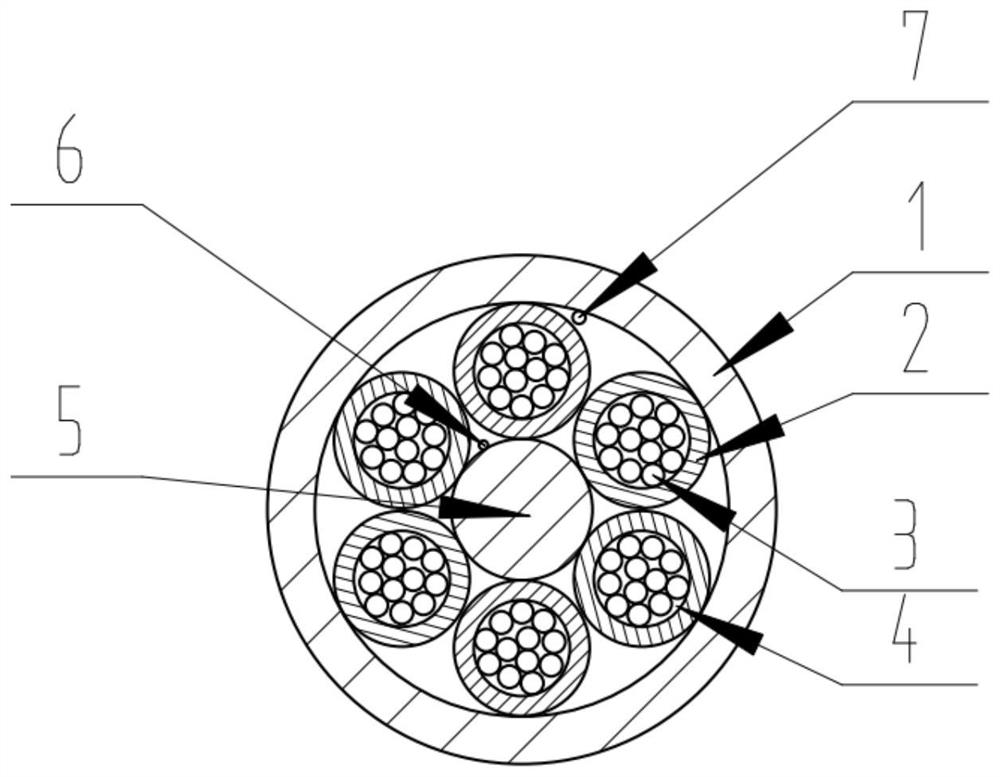

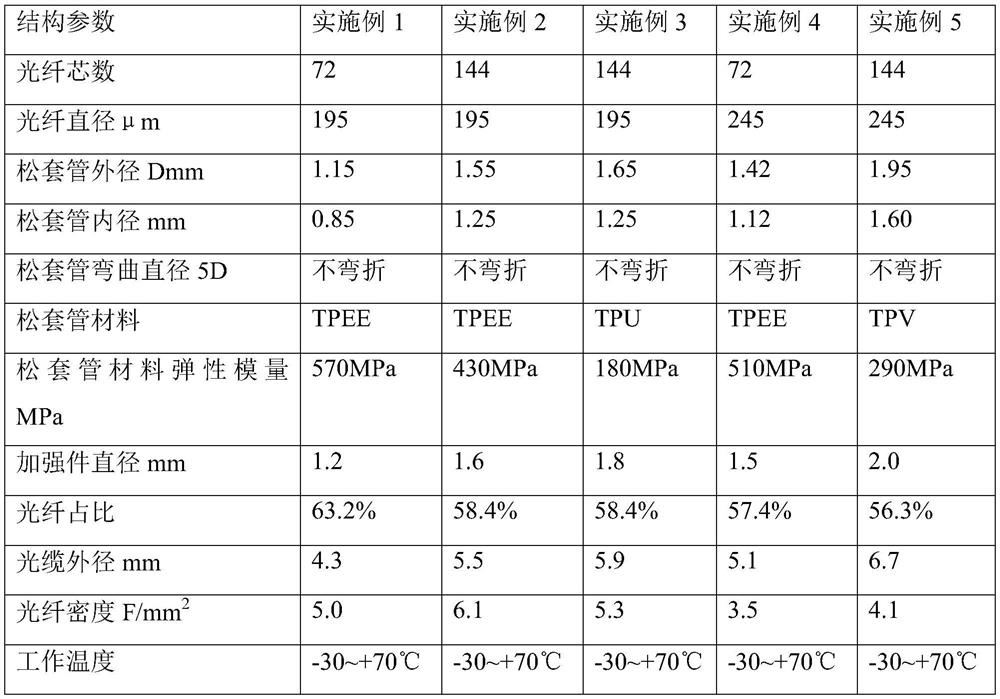

[0021] Examples of the present invention are figure 1 As shown, it includes an outer sheath 1 and a cable core wrapped in the outer sheath. The cable core includes a non-metallic central reinforcement 5 and a loose tube 2 twisted on the outer periphery of the central reinforcement. The loose tube is passed through After the SZ is twisted, it is bound by binding yarn. The loose tube is equipped with an optical communication unit 3 and filled with a water-blocking material 4. The water-blocking material is water-blocking powder or water-blocking ointment. The loose tube is made of TPEE, TPU Or TPV material is extruded at 200-240°C, and its elastic modulus is about 450MPa; the optical communication unit 3 is a bending-resistant single-mode optical fiber, the outer surface of the optical fiber is coated with inner and outer coatings, and the inner The elas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com