Reciprocating telescopic unfolding mechanism

A technology of unfolding mechanism and telescopic arm, which is applied in the field of reciprocating telescopic unfolding mechanism, can solve problems such as the contradiction between unfolding span and rigidity, and achieve the effects of improving structural adaptability, easy folding, and ensuring that unfolding is in place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments disclosed in the present invention will be further described in detail below in conjunction with the accompanying drawings.

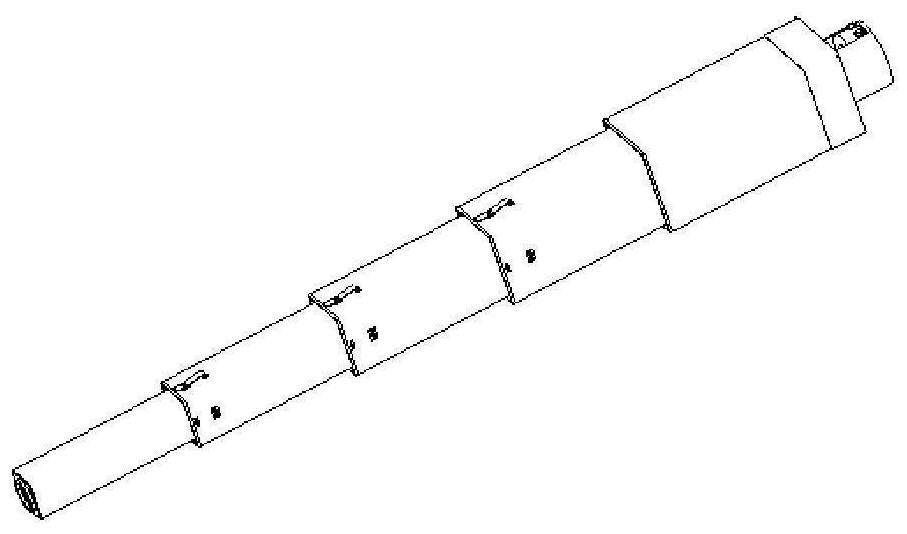

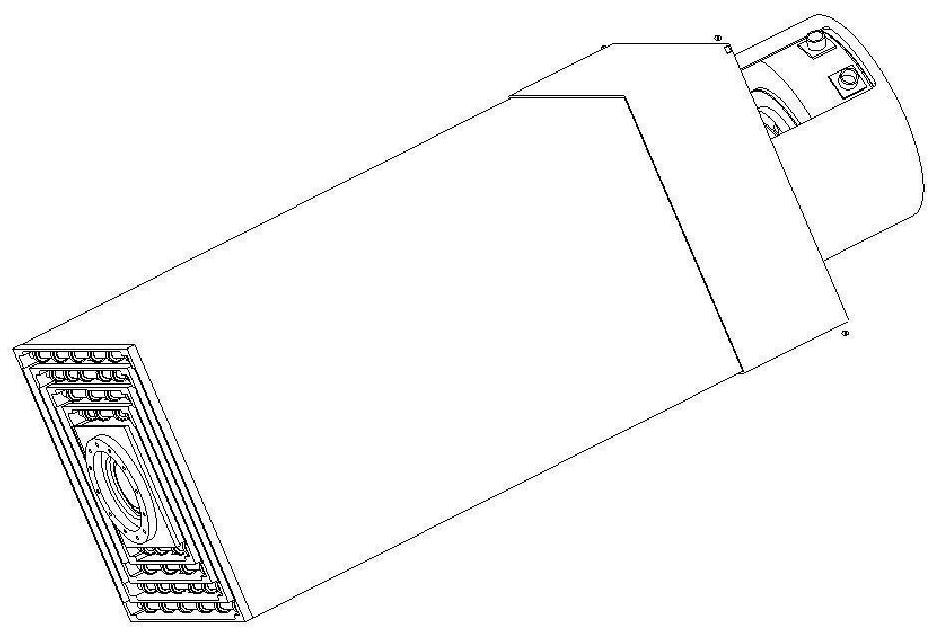

[0035] Such as figure 1 , 2 As shown, the present invention discloses a reciprocating telescopic expansion mechanism. The multi-stage telescopic arm in the main structure adopts carbon fiber rod, which is light in weight, high in strength and good in fatigue resistance; it adopts the driving mode of motor + lead screw, which has the advantages of small drive and large capacity. Output, simple structure, light weight, high reliability, good maintainability, low cost and other advantages.

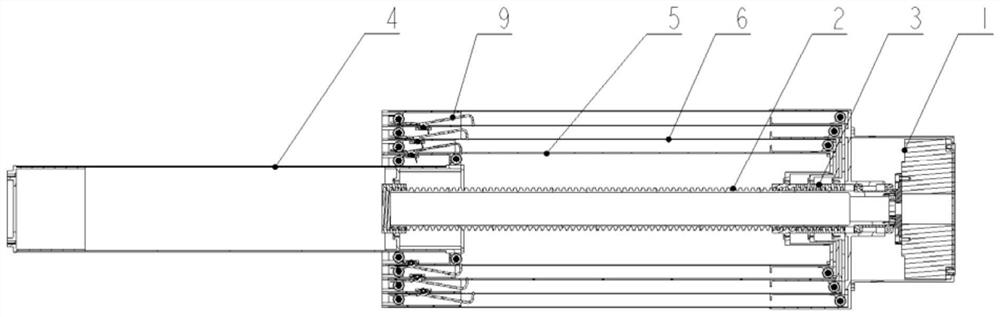

[0036] Such as image 3 , 4 As shown, the present invention proposes a reciprocating telescopic expansion mechanism, whose main function and purpose is to automatically unfold and lock reliably after being launched into orbit, and at the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com