A pitman of a jaw crusher, a jaw crusher, a crushing plant and a crushing method

A jaw crusher and crushing device technology, which is applied in the field of crushing mineral materials, can solve problems such as easy cracks, and achieve the effects of increasing capacity, improving quality, and saving materials and energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the following description, the same reference numerals denote the same components. It should be appreciated that the figures shown are not to scale as a whole and that they serve only to illustrate embodiments of the invention.

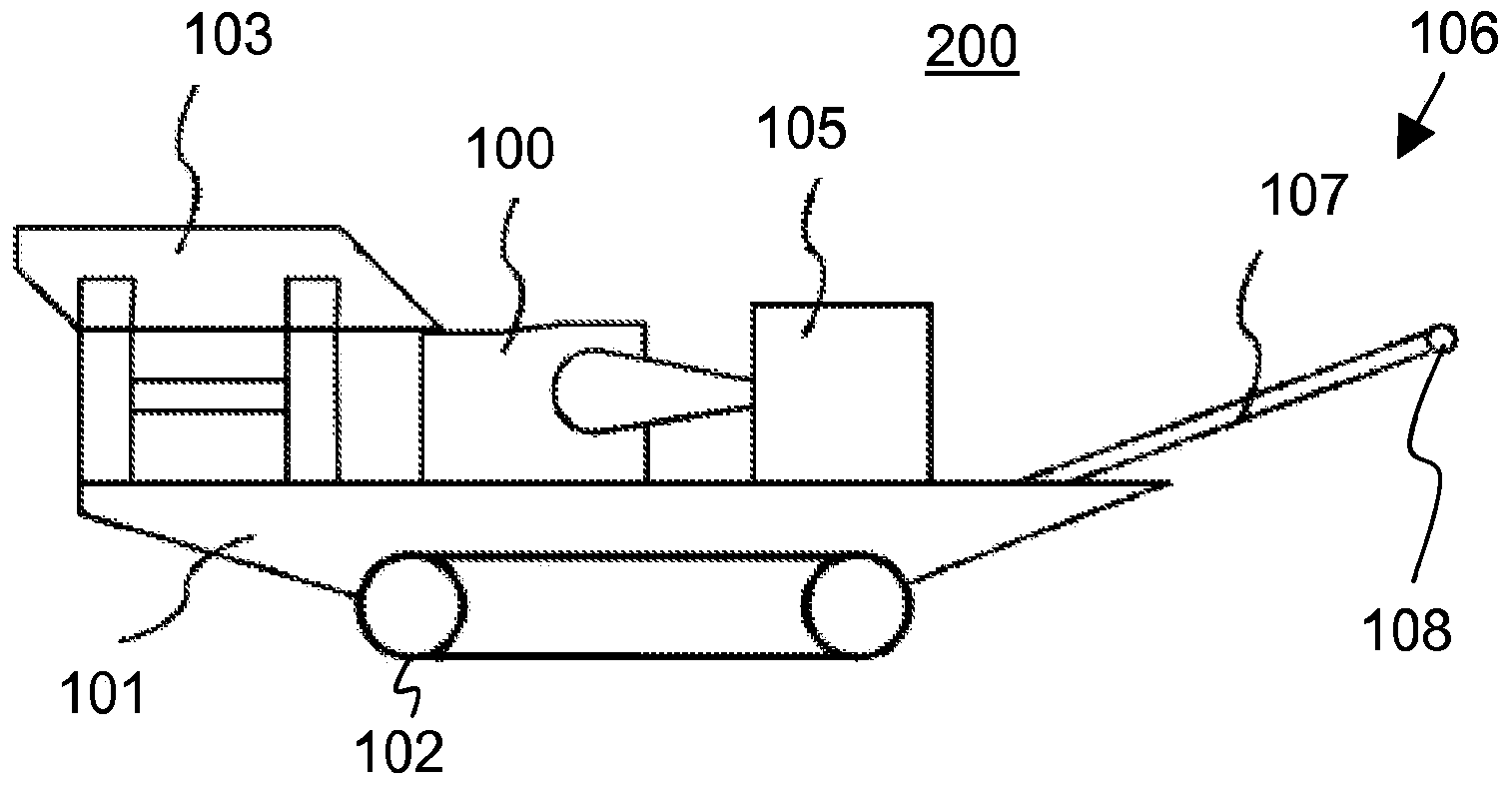

[0033] exist figure 1 In the figure, a mineral material processing equipment including a crushing device 200 of a jaw crusher 100 is shown. In the crushing device 200 there is a feeder 103 for feeding material to the jaw crusher 100 and a belt conveyor 106 for further conveying the crushed material from the crushing device.

[0034] figure 1 The belt conveyor 106 shown in includes a belt 107 arranged to travel around at least one drum 108 . The crushing device 200 also includes a power source and a control center 105 . The power source may for example be a diesel or an electric motor, which provides the energy used by the processing unit and hydraulic lines.

[0035] The feeder 103 , crusher 100 , power source 105 and conveyor 106 are att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com