Carbon fiber pipe drawing and extruding die

A pultrusion die and carbon fiber technology, applied in the field of new carbon fiber pipe pultrusion die, can solve the problem of bulkiness, ranging from 40 to 50 kilograms to hundreds of kilograms, easy to damage the inner wall and corner of the cavity, and difficult to process and disassemble. Too convenient and other problems, to achieve the effect of low cost, convenient and quick disassembly, and beautiful products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

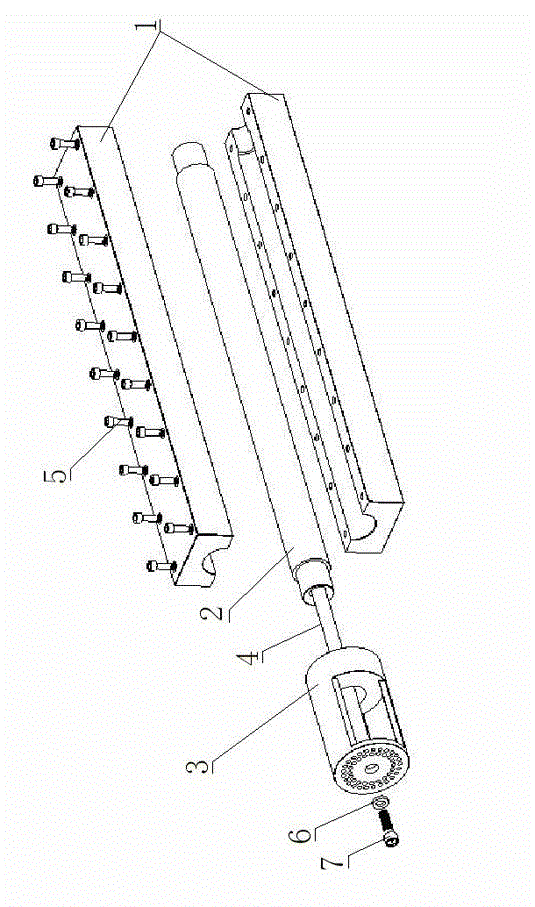

[0009] figure 1 Medium 1. Die sleeve, 2. Mandrel, 3. Die base, 4. Mandrel, 5. Hexagon socket bolt, 6. Pad iron, 7. Fixing bolt.

[0010] A pultrusion die for carbon fiber pipes, comprising a die sleeve, a die core and a die base. The die core is arranged in the die sleeve. The die core and the die base are connected by a mandrel. Both ends of the die sleeve are provided with restricting die cores. The inner edge of the axial movement prevents the core mold from being pulled during production. The die sleeve is composed of two sets of aluminum shells arranged symmetrically up and down. Two sets of aluminum shells are connected by hexagon socket bolts.

[0011] The mold base is a cylinder, the front end of the mold base is provided with a core rod through hole, the back end of the mold base is a fixed plate with a yarn hole, the mandrel is fixedly connected to the fixed plate, and a window is opened on both sides of the middle of the cylinder. . During production, you can easily ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com