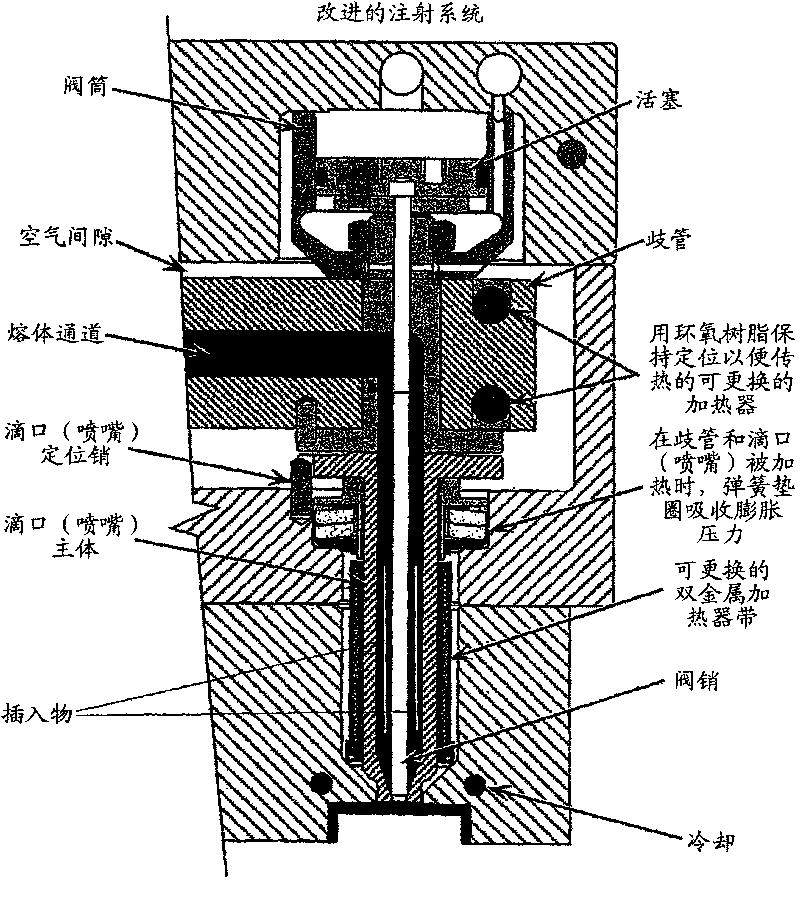

Modified hot runner systems for injection blow molding

A technology of injection blow molding and hot runner, which is applied in the fields of thermoplastic preforms, manufacturing of said containers, and manufacturing of said preforms, which can solve the problems of loss of mechanical strength of heat-set containers and achieve high heat resistance and gas resistance The effect of permeability mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

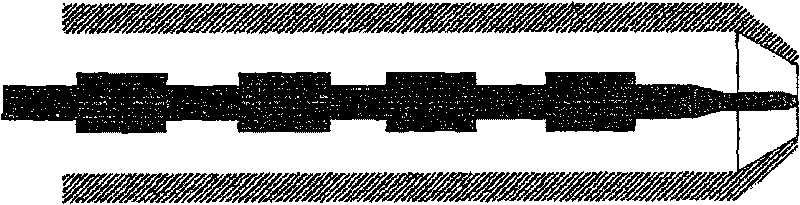

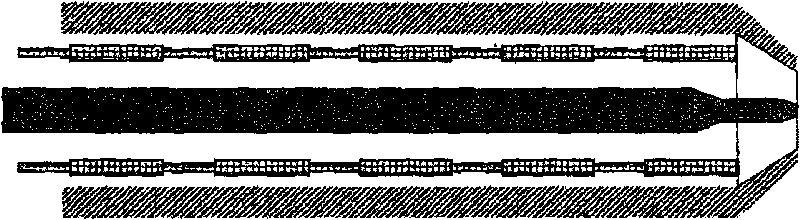

[0029]According to a first embodiment of the invention, the present invention relates to a method for manufacturing articles in general, or more specifically, preforms, and the resulting stretched polymers that provide equal or higher end performance characteristics from crystallizable polymers. Method of blow molding containers. The method includes modifying the hot runner system to induce new structures at the preform and / or container level.

[0030] Another embodiment of the present invention provides a method and apparatus for the cost-effective manufacture of these items in general, injection molded preforms and stretch blow molded containers in particular.

Summary of the invention

[0031] The present invention describes a method for the manufacture of preforms and containers made of crystallizable polymers, in particular preforms and containers of the stretch blow molded container type, and more particularly, the present invention describes A method for manufacturing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com