Bevel mouth special nursing bottle and production method thereof

A milk bottle and oblique mouth technology, which is applied to the oblique mouth special-shaped milk bottle and its production field, can solve the problems such as the thickness of the bottle body glass cannot be uniform, the product strength is reduced, and the physical health is affected, and it is convenient to suck, increase the fluidity, and form a good shape. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

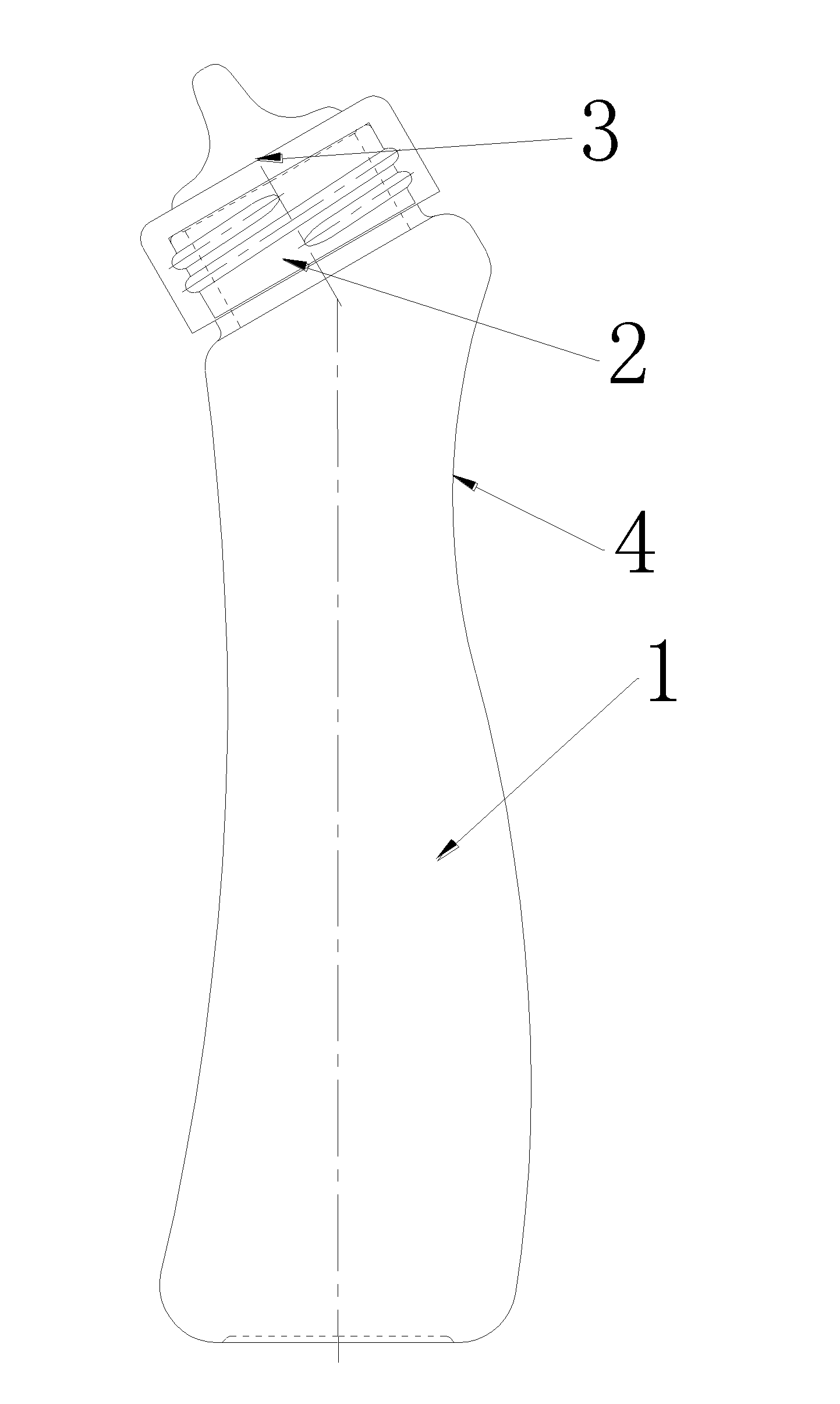

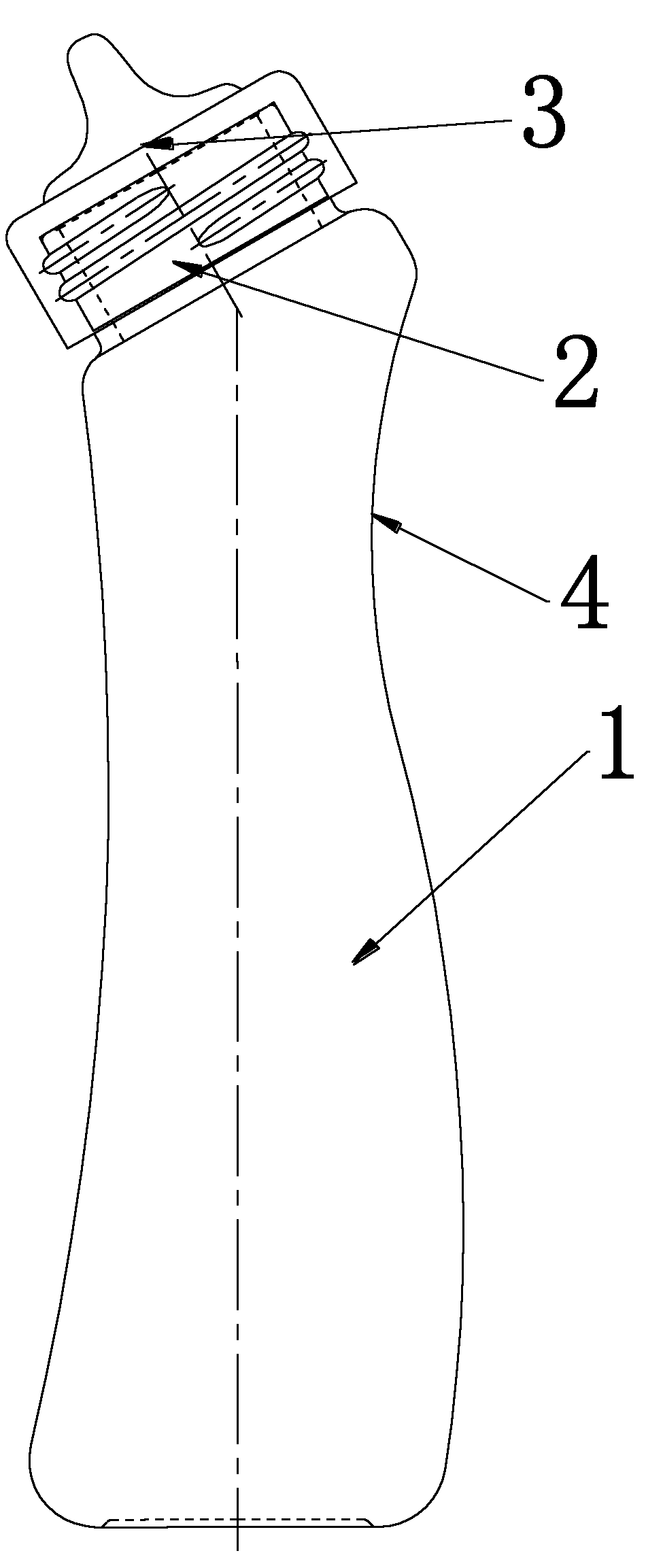

[0013] Such as figure 1 As shown, the special-shaped oblique mouth bottle described in this embodiment mainly includes a bottle body 1, a bottle neck 2 and a nipple cap 3, and the angle formed by the centerline of the bottle neck 2 and the centerline of the bottle body 1 is between 145 degrees and 160 degrees. A concave arc surface 4 is arranged on the bottle body 1, and the position of the arc surface 4 is the upper part of the bottle surface of the bottle body 1 corresponding to the extension line of the center line of the bottleneck 2, and the bottle body 1 forms an arc shape in the direction of the bottleneck 2 as a whole. .

[0014] The production method of the special-shaped milk bottle with oblique mouth: the bottleneck mold is vertically set, the rough mold is matched with the bottleneck mold, and inverted, the mold of the bottle body inside the rough mold is inclined, liquid glass is injected from the bottom of the rough mold, and the liquid glass is immediately poure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com