Uptake flue roof for copper smelting of flash furnace

A flash furnace and copper smelting technology, which is applied in the direction of furnace, furnace cooling, furnace charge, etc., can solve the problems of large thermal load impact, falling off, insufficient cooling strength of hanging bricks, etc., to achieve enhanced thermal deformation resistance and prolong service life , Excellent cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

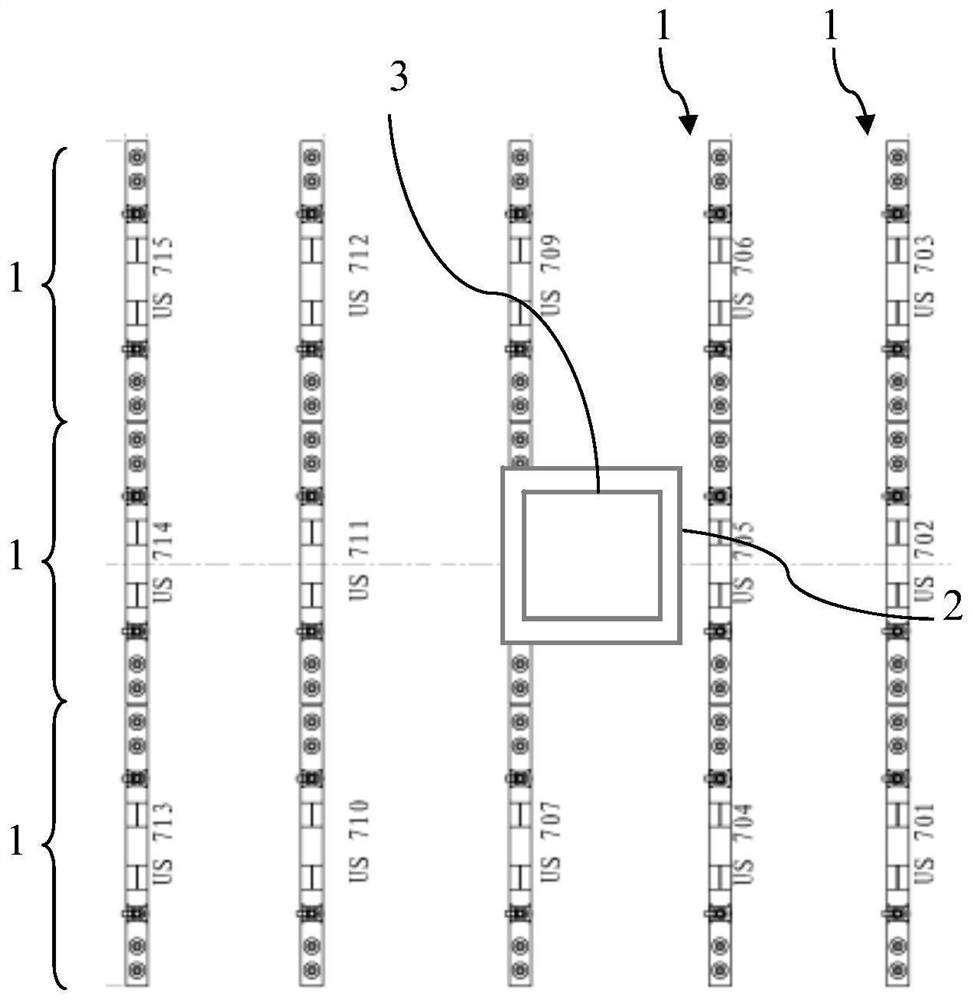

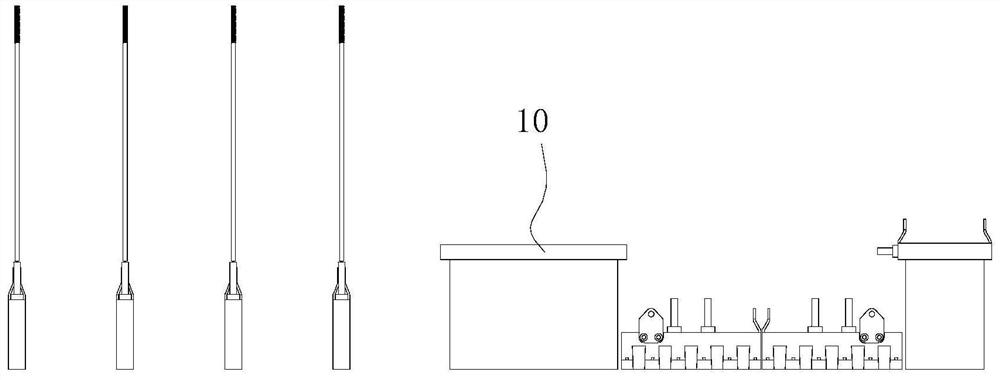

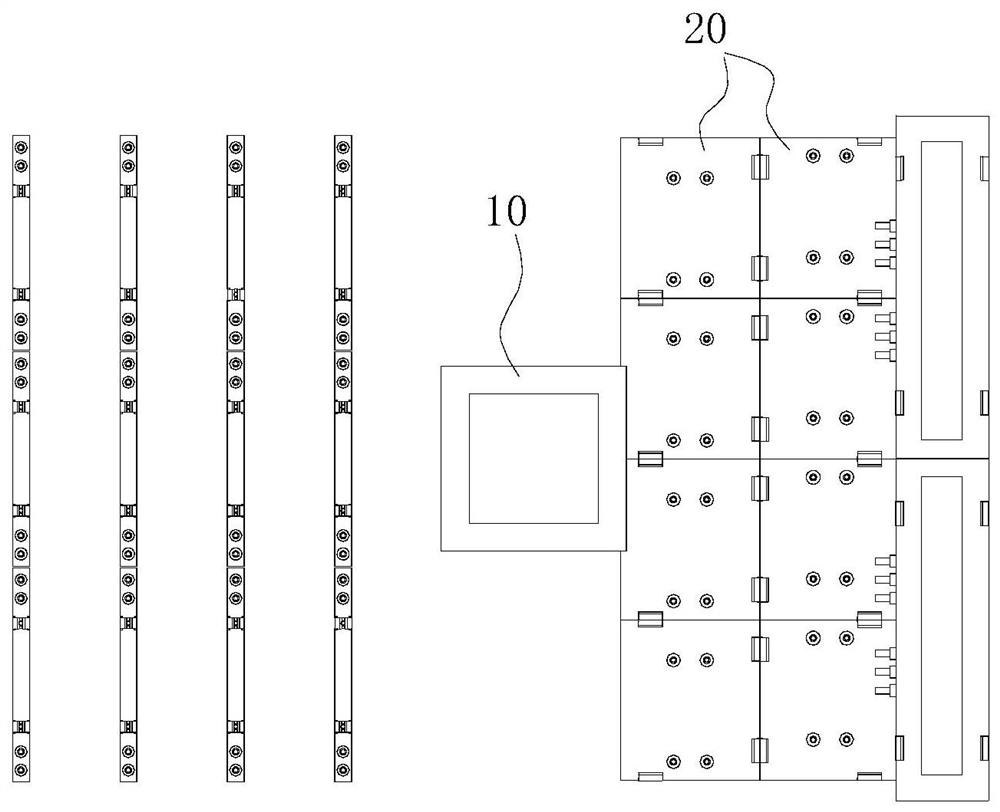

[0014] to combine figure 2 , 3 4. The basic task of the present invention is to ensure the cooling of the top area with severe heat load. The specific solution is a flash furnace copper smelting ascending flue top, and the square water jacket 10 in the middle is arranged with plate-shaped copper in the area near the boiler side Water jacket, the board surface of the plate-type copper water jacket is placed flat, and the plate-type copper water jacket is composed of copper water jacket units 20 arranged adjacent to the board edges. The inside of the copper water jacket unit 20 is provided with a cooling water channel 21, and the copper water jacket unit 20 The refractory layer 22 is arranged on the lower plate of the cooling water channel 21, and the water inlet and outlet pipes of the cooling water channel 21 extend to the upper plate of the copper water jacket unit 20, and the upper plate of the copper water jacket unit 20 is also provided with lifting lugs 23.

[0015] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com