Heat-resistant medium-chromium vermicular graphite cast iron glass mold material and preparation method thereof

A glass mold material, vermicular graphite cast iron technology, applied in the direction of improving process efficiency, etc., can solve the problems of short service life, insufficient thermal deformation resistance and oxidation resistance, low wear resistance and heat resistance, and achieve improvement Effect of service life, improvement of thermal deformation resistance and oxidation resistance, high wear resistance and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

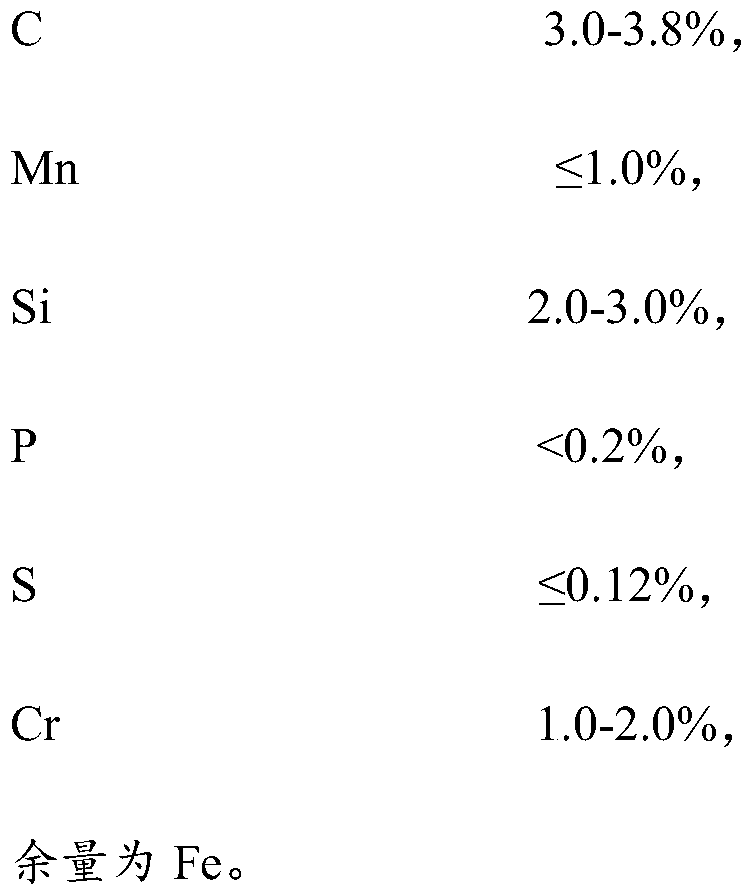

Method used

Image

Examples

Embodiment 1

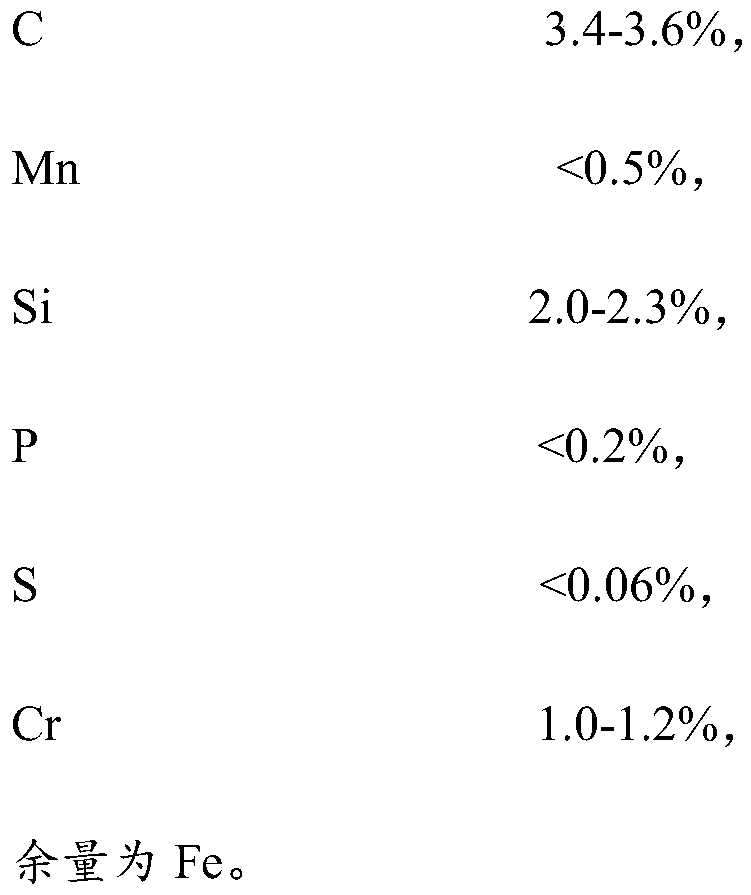

[0036] (1) Raw material preparation: Analyze the chemical composition of pig iron, steel scrap, recycled materials, ferromanganese, ferrosilicon, and ferrochromium, and then weigh the above furnace materials according to the following mass percentages and arrange them in the electric furnace: C 3.4%, Mn 0.4%, Si2. 3%, P 0.18%, S0.05%, Cr 1.0%, and the balance is Fe.

[0037] (2) Smelting: Put the pig iron, scrap steel, and returned materials weighed according to the proportion into the electric furnace for smelting, and then add ferromanganese, ferrosilicon, and ferrochrome to continue smelting. When the temperature reaches 1450°C, carry out sampling analysis of chemical elements and Adjust the percentage content of chemical elements, confirm that the composition of the front of the furnace is qualified, continue to heat up, and smelt at 1520 ° C to obtain the original molten iron;

[0038] (3) Cremation and inoculation: add 0.8% of the total mass of the original molten iron t...

Embodiment 2

[0043] (1) Raw material preparation: Analyze the chemical composition of pig iron, steel scrap, recycled materials, ferromanganese, ferrosilicon, and ferrochrome, and then weigh the above furnace materials according to the following mass percentages and arrange them in the electric furnace: C 3.6%, Mn 0.3%, Si2. 0%, P 0.18%, S0.03%, Cr 1.2%, and the balance is Fe.

[0044] (2) Smelting: Put the pig iron, scrap steel, and returned materials weighed according to the proportion into the electric furnace for smelting, and then add ferromanganese, ferrosilicon, and ferrochrome to continue smelting. When the temperature reaches 1450°C, carry out sampling analysis of chemical elements and Adjust the percentage content of chemical elements, confirm that the composition of the front of the furnace is qualified, continue to heat up, and smelt at 1520 ° C to obtain the original molten iron;

[0045] (3) Cremation and inoculation: add 0.6% of the total mass of the original molten iron to ...

Embodiment 3

[0050] (1) Raw material preparation: Analyze the chemical composition of pig iron, steel scrap, recycled materials, ferromanganese, ferrosilicon, and ferrochromium, and then weigh the above furnace materials according to the following mass percentages and arrange them in the electric furnace: C 3.5%, Mn 0.4%, Si2. 1%, P 0.1%, S0.05%, Cr 1.1%, and the balance is Fe.

[0051] (2) Smelting: Put the pig iron, scrap steel, and returned materials weighed according to the proportion into the electric furnace for smelting, and then add ferromanganese, ferrosilicon, and ferrochrome to continue smelting. When the temperature reaches 1450°C, carry out sampling analysis of chemical elements and Adjust the percentage content of chemical elements, confirm that the composition of the front of the furnace is qualified, continue to heat up, and smelt at 1520 ° C to obtain the original molten iron;

[0052] (3) Cremation and inoculation: add 0.8% of the total mass of the original molten iron to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com