Connecting flange for exhaust system of passenger car and method for preventing welding deformation

A technology for connecting flanges and exhaust systems. It is used in flange connection, welding equipment, applications, etc., and can solve the difficulty of ensuring the flatness of the flange connection end face, the sealing problem of the exhaust system, and the exhaust gas leakage of the whole vehicle. problems, to achieve the effect of improving thermal deformation resistance, ensuring sealing performance, and increasing filling density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

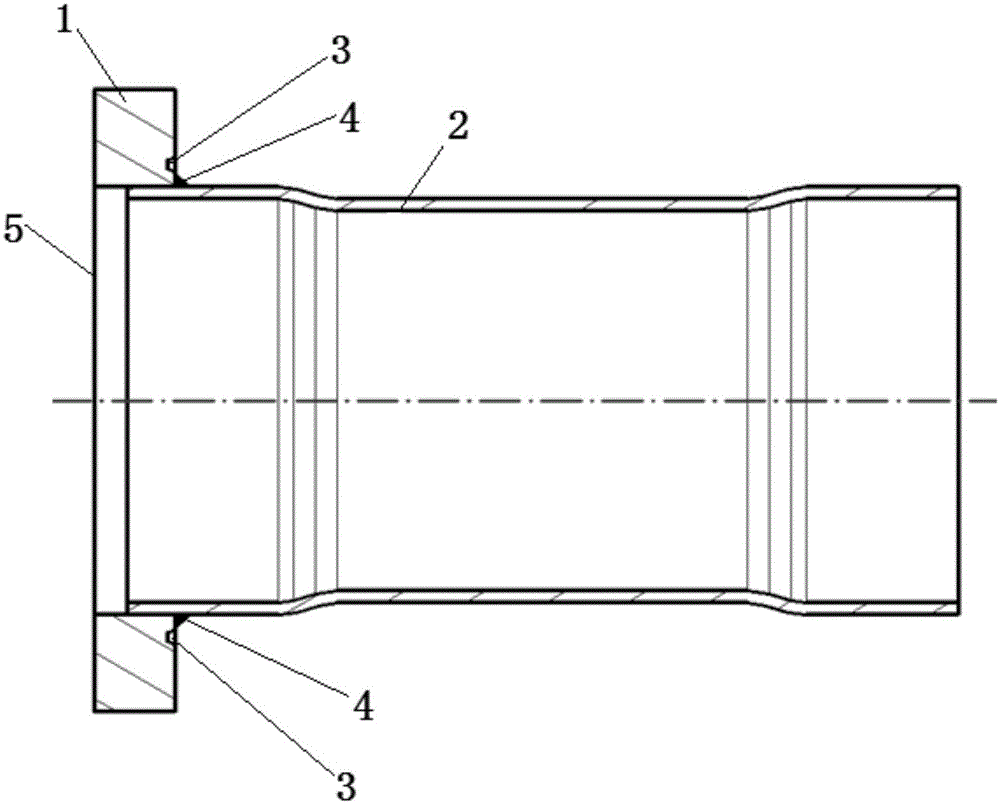

[0017] like figure 1 As shown, the connecting flange of the passenger car exhaust system, one end of the connecting flange 1 is welded to the connecting pipe 2 of the exhaust system, the other end face of the connecting flange 1 is the flange connecting end face 5, and the flange connecting end face 5 is a plane; An anti-deformation groove 3 is provided on the periphery of the welding seam 4 on the end face where the connecting flange 1 and the connecting pipe 2 are welded. The present invention punches a groove 3 at the welding edge of the connecting flange 1 and the connecting pipe 2 to increase the filling density at the welding edge of the flange, improve the thermal deformation resistance of the material, and reduce the deformation of the connecting flange 1 after welding , to ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com