Organic silica gel packaging material of large-power LED and preparation method thereof

A silicone gel sealing, high-power technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low use efficiency, cracks, light transmittance reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Example 1 : the preparation of the single-component silica gel product of the present invention

[0076] Synthesis and purification of component A:

[0077] 1. Raw materials ①Octamethylcyclotetrasiloxane, referred to as D4, is distilled to take the middle part (head and tail removed), with a purity of about 99.9%.

[0078] ② The mixed ring body (liquid) of diphenylhexamethylcyclotetrasiloxane and tetraphenyltetramethylcyclotetrasiloxane, take the distillate in the range of 236-256℃ / kpa. The refraction is between 1.49-1.53, colorless and transparent, and can be used immediately after distillation.

[0079] ③Hexamethyldisiloxane, referred to as MM, is distilled to take the middle part (head and tail removed), with a purity of over 99.2%.

[0080] ④1. Vinyl 1.1.3.3.3 Pentamethyldisiloxane, used for rectification, instant distillation. The purity is about 99% (subject to gas chromatography test)

[0081] *All raw materials must be used after rectification, must be dist...

Embodiment 2

[0100] Synthesis and purification of component A: changing the structure of the end-capping agent to increase the organopolysiloxane with T-type structure

[0101] 1. Selection of raw materials

[0102] ①Hexamethyldisiloxane and methyl D4, rectified, take the middle part, the purity is above 99.8%

[0103] ②1. Vinyl 1.1.3.3.3 Pentamethyldisiloxane, the middle part is taken after rectification, and the purity is >99%

[0104] ③CH3Si(OEt3)3 after rectification to get about 99.5% product

[0105] All the above-mentioned raw materials are ready to be used by distillation, and the purity is more than 99.2% by chromatographic tracking.

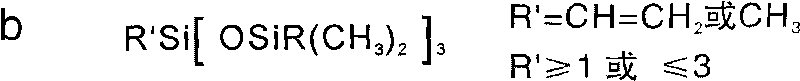

[0106] 2. A reaction synthesis, ① first synthesize the product of CH3Si[OSi(CH3)2R]3, R1=CH3 or CH2=CH. In the flask, add methyltriethoxysilane, then add vinyl and methyl respectively A total of 3 moles of the head-sealing agent is added, and toluene is added to be 1 / 2 of the total amount of siloxane, and stirred. Then add CF3SO3H catalyst 1.2‰,...

Embodiment 3

[0144] Example 3: The preparation of the two-component silicone gel product of the present invention (add the silicone gel made of MQ resin filler) Synthesis and refining of component A:

[0145] A material raw material preparation

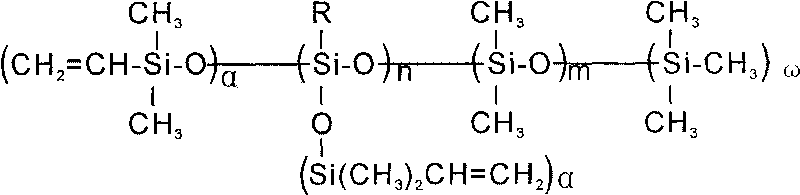

[0146] (1) a.w-divinyl polydimethylsiloxane with viscosity ((25°C) 950mpa.s, structural formula:

[0147] (1) (Viscosity) (25°C) 950mpa.s α-ω-=vinyl poly=methyl siloxane structural formula

[0148] m=260

[0149] The reaction crude product was refined to remove odor and low molecular weight, and after filtration, a transparent and colorless product with high purity was obtained for future use, with a refractive index of 1.406.

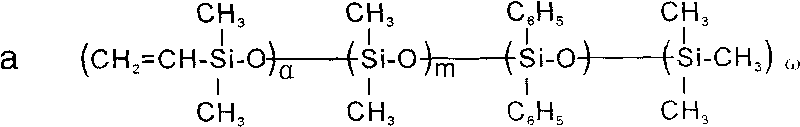

[0150] (2) Viscosity (25°C) 930mPa.s, the molecular end part is (CH3)2(CH=CH2)SiO 1 / 2, the chain link is blocked, and the other part and the second end are (CH3)3SiO 1 / 2 end-blocked polyorganosiloxane.

[0151] The crude product is refined to deodorize and remove low-molecular substances. After filtration, a trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com