Chromium plating rack for cylinder liner bore

A cylinder liner and inner hole technology, which is applied in cylinders, cylinder heads, melt spraying, etc., can solve the problems of high ventilation effect requirements, poor penetration resistance, and reduced insulation performance of the equipment, and achieve good ventilation effects and heat resistance of the equipment. The effect of improving the deformation ability and increasing the flowability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

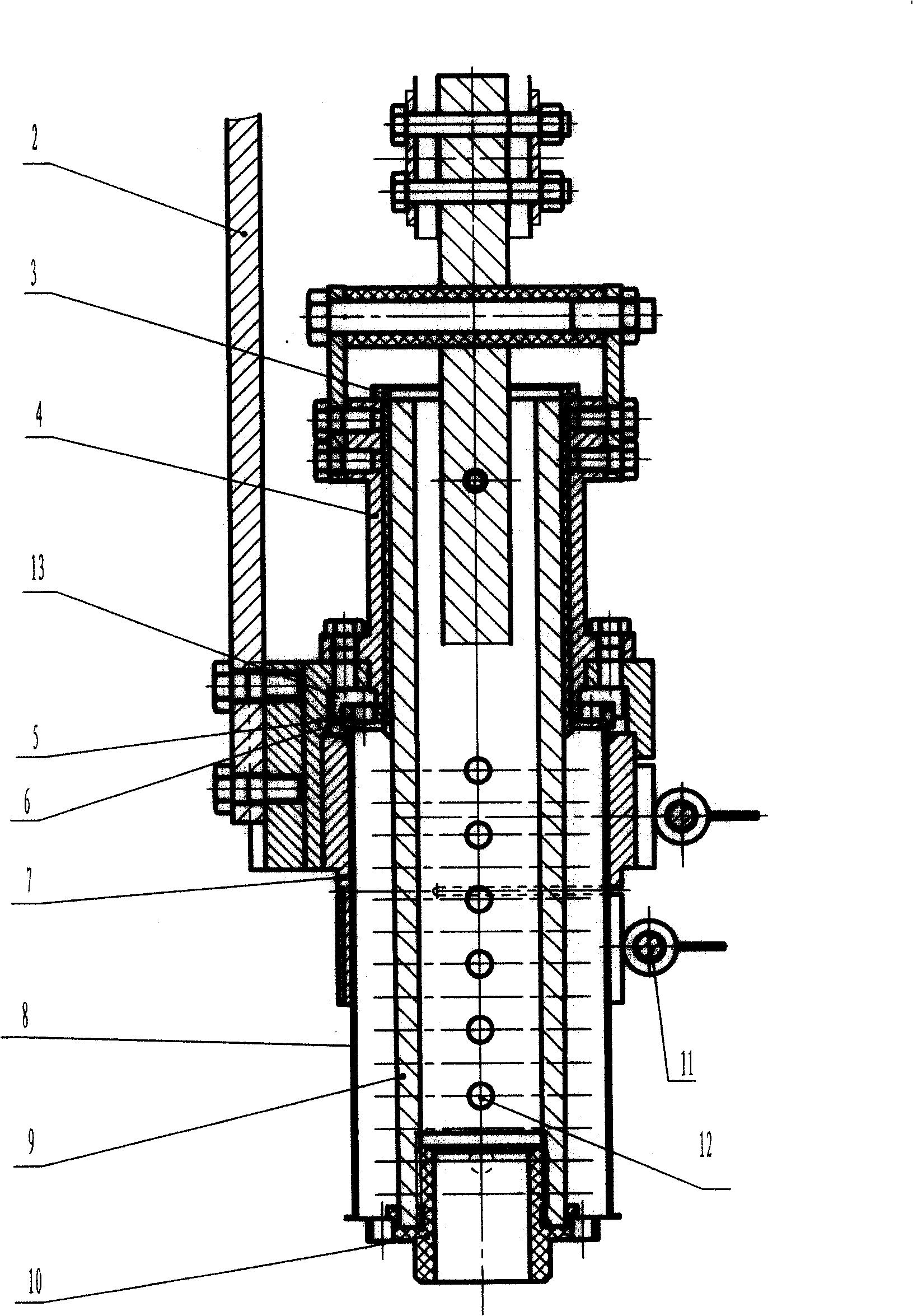

[0014] Example 1, a chrome-plated hanger for the inner hole of a cylinder liner, refer to figure 1 , an anode insulating sleeve 3 is provided on the outside of the anode 9, an anode positive sleeve 4 is arranged outside the anode insulating sleeve 3, a leading ring 5 is fixed on the lower end of the anode positive sleeve 4, and the cathode guide rod 2 is fixedly connected with the leading ring 5 , the anode insulating sleeve 3 of the inner anode 9 of the leading ring 5 is provided with an upper power line cover 6, and a gas detour cavity 13 is formed between the upper power line blocking cover 6 and the leading ring 5, and a cylinder liner clamp is arranged on the inner side of the lower end of the leading ring 5 Clamping ring 7, clamping screw 11 is provided on the outside of cylinder liner clamping ring 7, lower power line retainer 10 is provided at the lower end of anode 9, hole 12 is provided on anode 9, and the outer diameter of the bottom end of anode 9 is larger than tha...

Embodiment 2

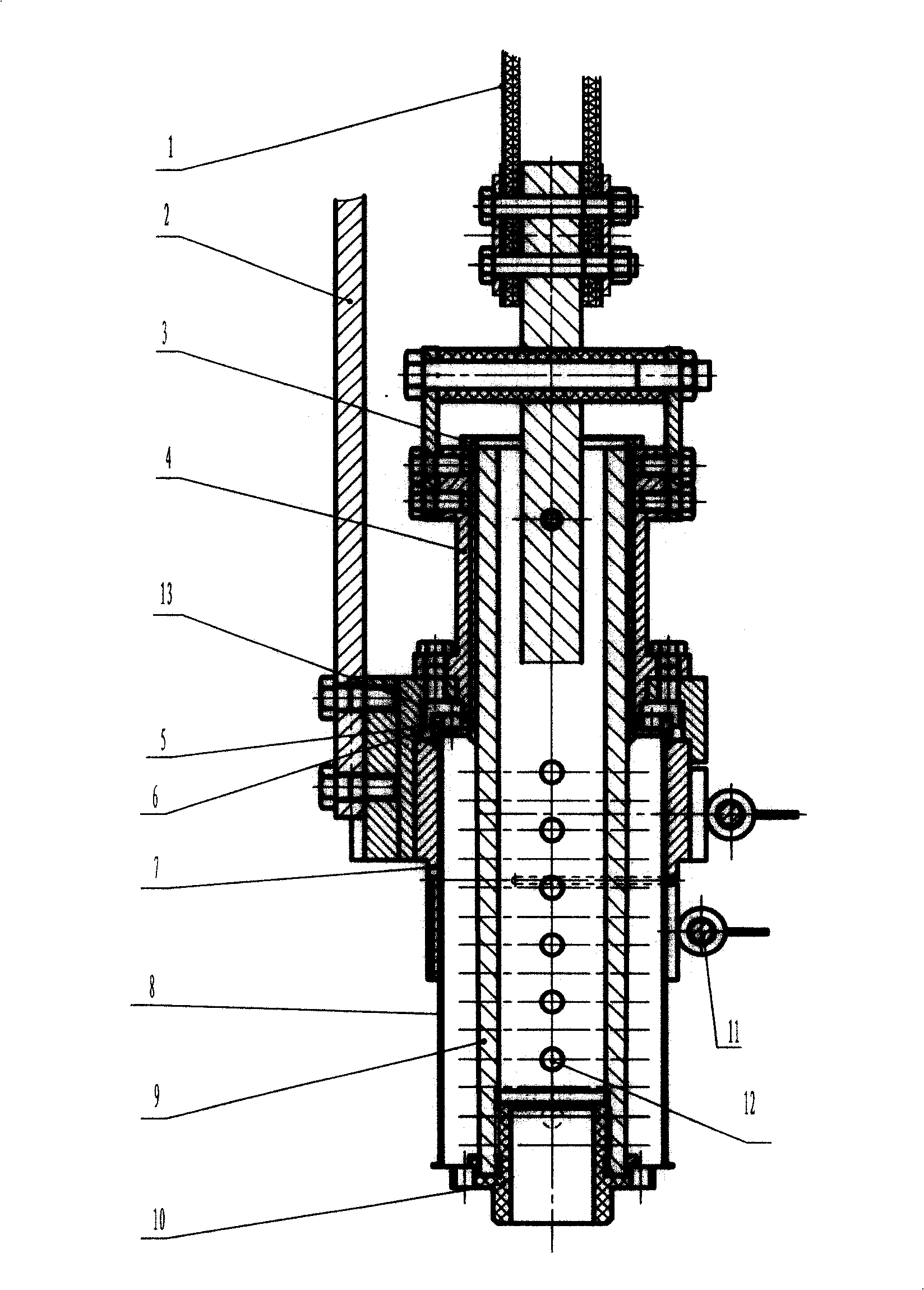

[0015] Embodiment 2, a kind of cylinder liner inner hole chrome-plated hanger, refer to figure 2 , on the basis of Example 1, the anode 9 is connected to the positive pole of the power supply through a flexible conductive braid 1, the anode insulating sleeve 3 is a PP-R or F4 plastic structure, and the anode 9 adopts a lead-tin alloy containing 7-8% tin, Others are identical to Example 1.

[0016] When using the invention, refer to figure 1 , 2 , the cylinder liner 8 is placed between the anode 9 and the cylinder liner clamping ring 7 to clamp, the anode 9 is located in the inner hole of the cylinder liner 8, just turn on the power supply, and the anode positive position sleeve 4, the leading ring 5 and the upper power line Under the constraints of the cover 6 and the clamping ring 7 of the cylinder liner, the axis of the inner hole of the plated cylinder liner 8 coincides with the axis of the outer circle of the anode 9, so as to ensure that the coating thickness of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com