Water seam-split body internal water cooling type flexible contact electromagnetic continuous casting crystallizer

A continuous casting crystallizer and soft contact technology, which is applied in the field of metallurgical continuous casting crystallizers, can solve the problems of affecting the quality of casting slabs, not applying industrial production, and unstable industrial production, etc., to achieve improved surface quality and productivity, high heat resistance Effect of deformability, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

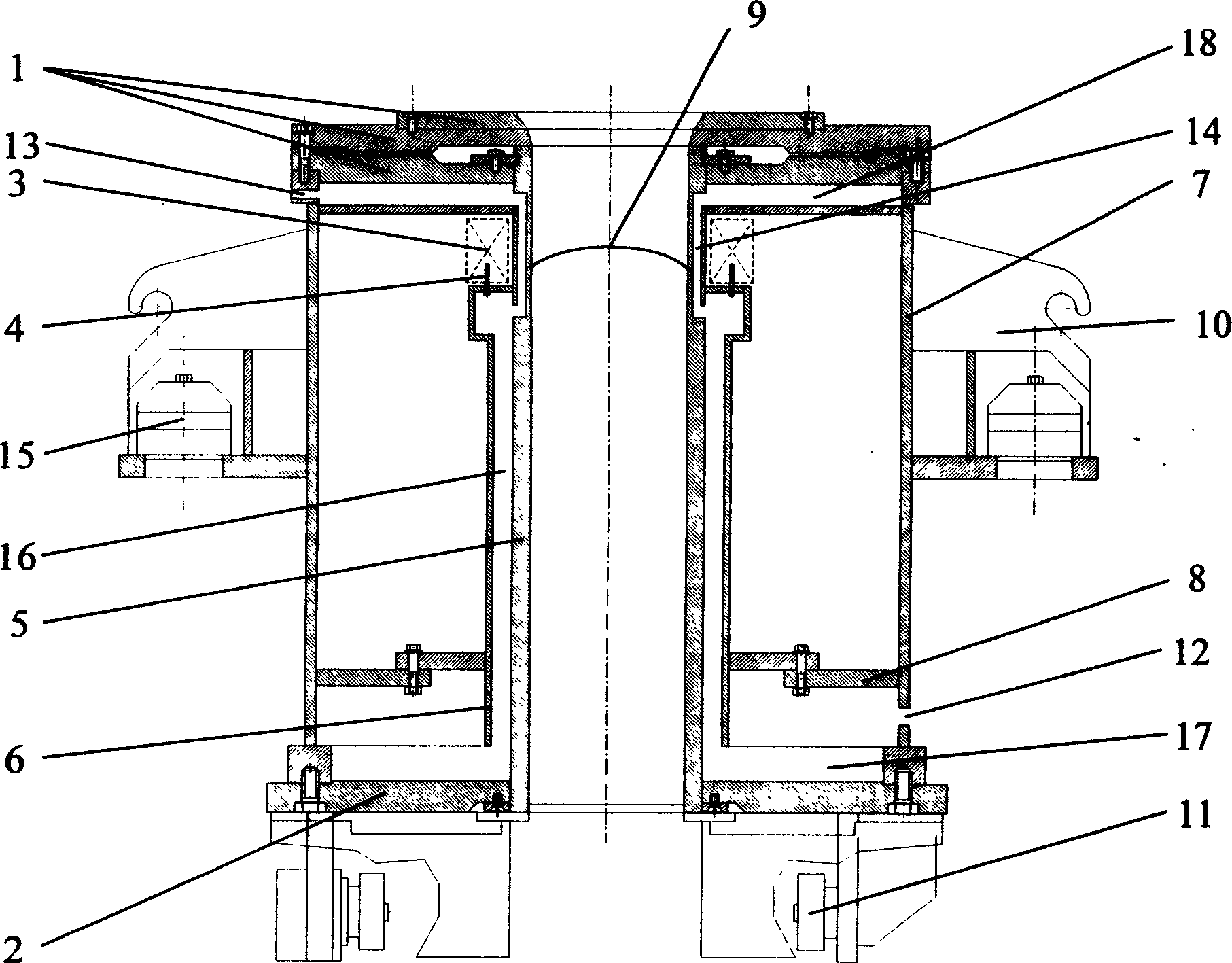

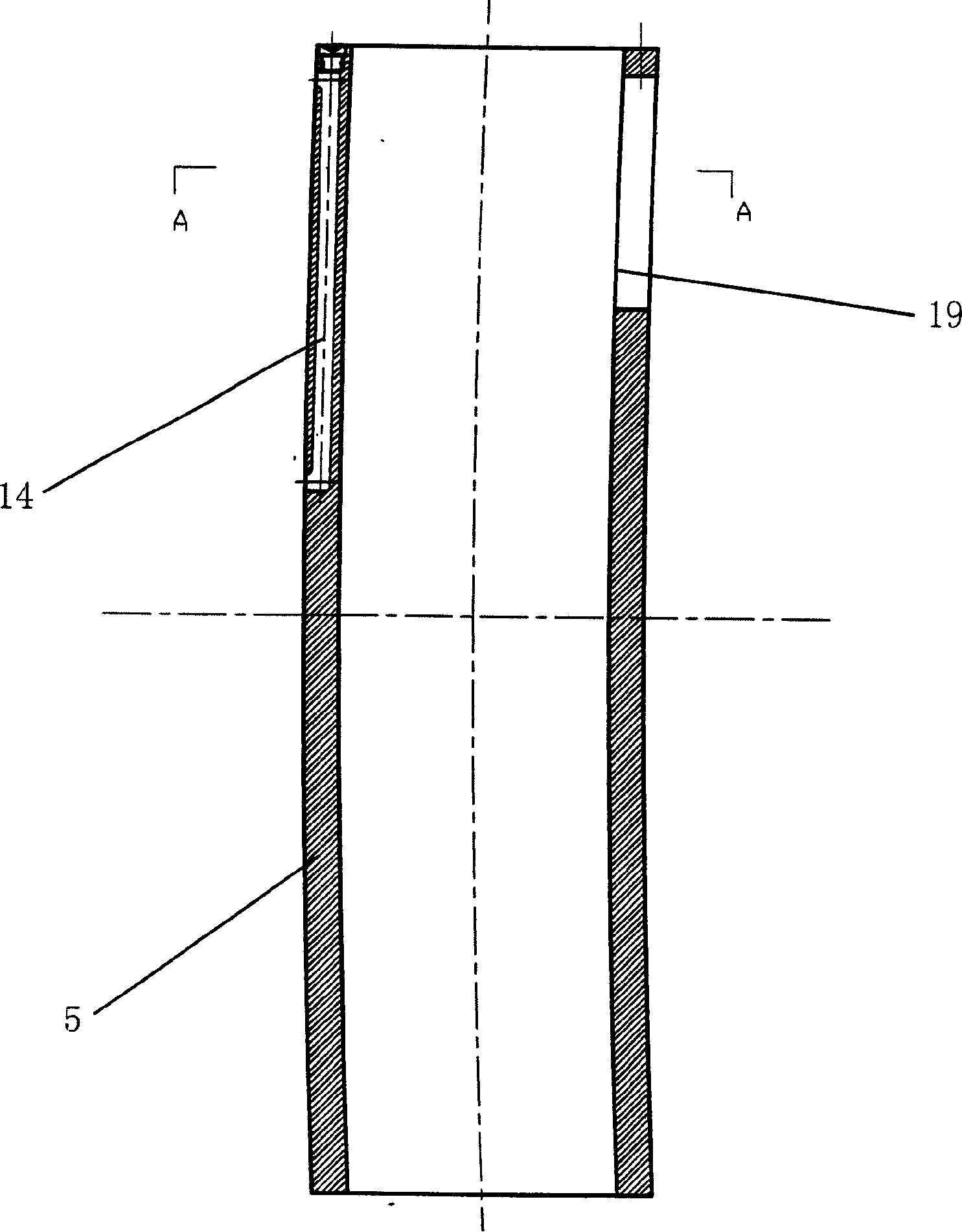

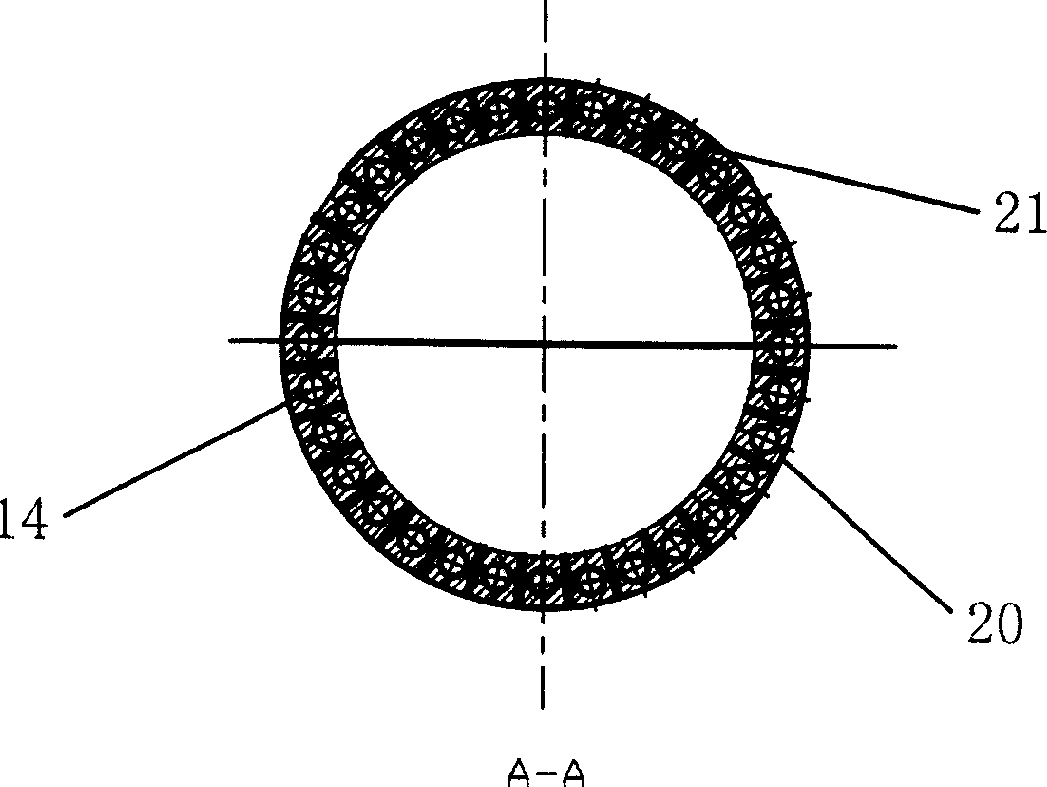

[0015] Example 1, see figure 1 , 2 , 3, the crystallizer of the present invention has a crystallizer casing (5), and diameter is the round billet crystallization casing casing of 178mm, adopts phosphorus deoxidized copper material to make, the crystallization casing top is apart from the top 10mm place below, has The middle slit structure with a length of 150mm and a width of 0.2mm, the slit (19) is filled with insulating material mica sheets, and the formed split body (20) has a total of 32 pieces, and a cooling water pipe (14) of Φ8mm is arranged in it ; The upper and lower ends of the crystallizer sleeve (5) and the shell (7) are respectively fixed by the upper flange (1) and the lower flange (2), and in the shell (7), around the crystallizer sleeve The center position of pipe (5) top slit (19) place is equipped with high-frequency coil (3), and coil (3) is installed on the horizontal plane of cooling water jacket (6) top by bracing frame (4). The cooling water jacket (6)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com