Multi-groove pot of continuous carding machine

A technology of multi-slot pot and strip machine, applied in the direction of tea processing before extraction, can solve the problems of not completely eliminating the longitudinal deformation of the pot body, weakening the thermal deformation resistance of the split pot, restraining the longitudinal expansion of the pot body, etc. The pot frame is deformed, the longitudinal restraint is eliminated, and the thermal deformation resistance is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

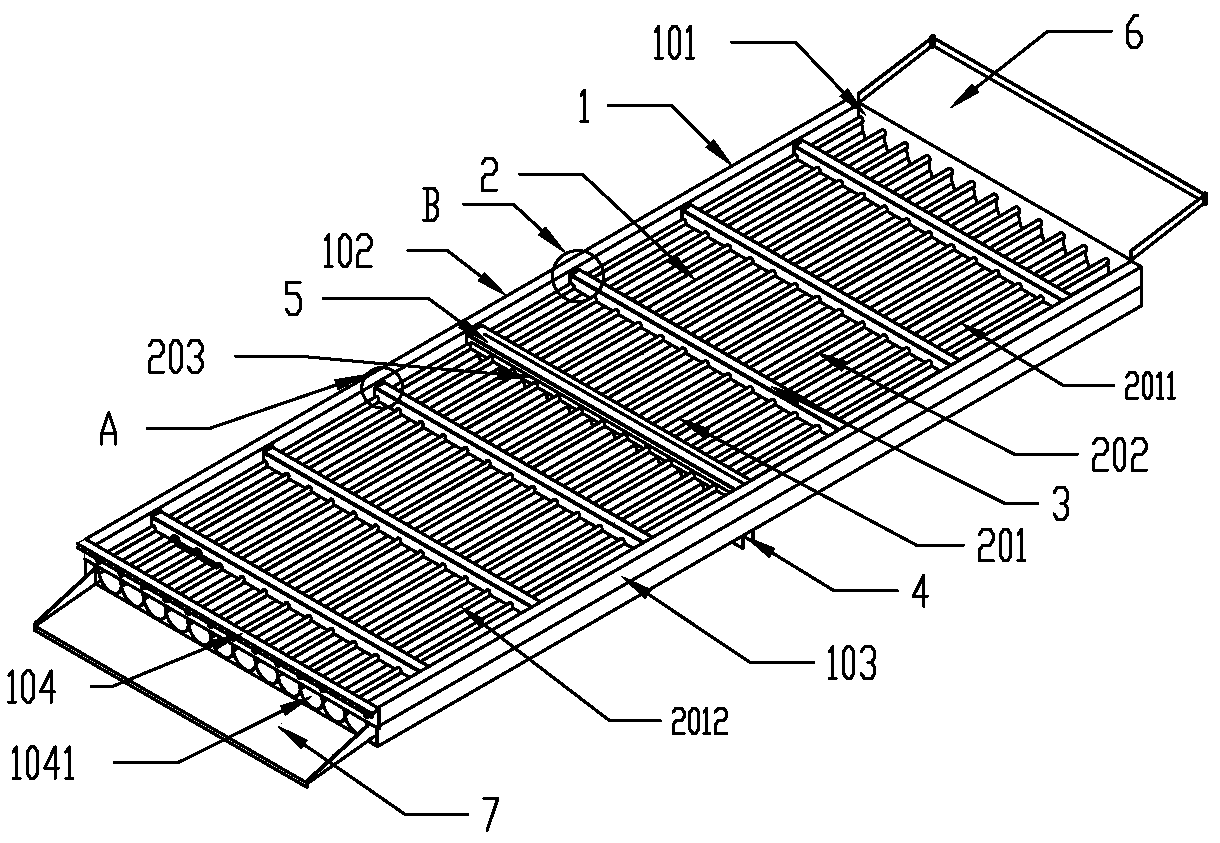

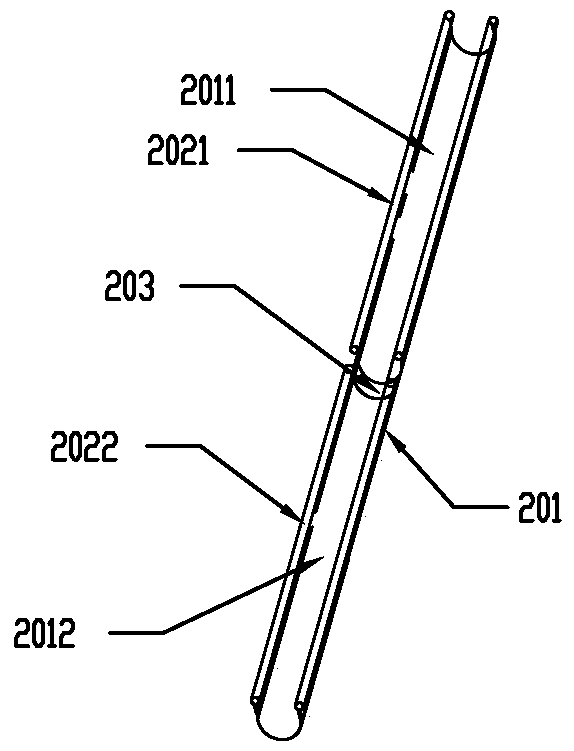

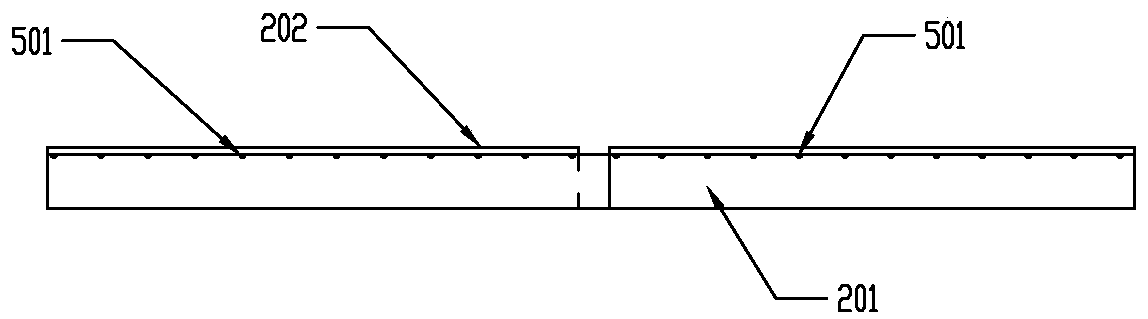

[0046] see figure 1 It is a multi-groove pot of a continuous slitting machine under the technical solution of the present invention. The multi-slot pot includes a pot frame 1 , a pot body 2 , a buffer plate 3 , a spacer plate 4 , a reinforcing bow plate 5 , and a feed guide groove 6 and a discharge guide groove 7 .

[0047] Described pot frame 1 comprises the rectangle structure that is welded into by pot frame front wallboard 101, pot frame left wallboard 102, pot frame right wallboard 103, pot frame rear wallboard 104. The front wall panel 101 of the pot frame is connected and fixed with the feed guide groove 6, the rear wall panel 104 of the pot frame is connected and fixed with the discharge guide groove 7, and the rear wall panel 104 of the pot frame is a sheet metal bending structure, and an outlet is arranged at the bottom. The feed port 1041 and the discharge port 1041 section are consistent with the section of the U-shaped groove plate 201, and the front wall panel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com