Cable tooling mould

A cable worker and mold technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of prolonging the flow time of cable cell cladding materials, shortening the time of cable plastic flow, and large cable mold volume. To achieve the effect of shortening the volume, easy disassembly and assembly of the taper, and large amount of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

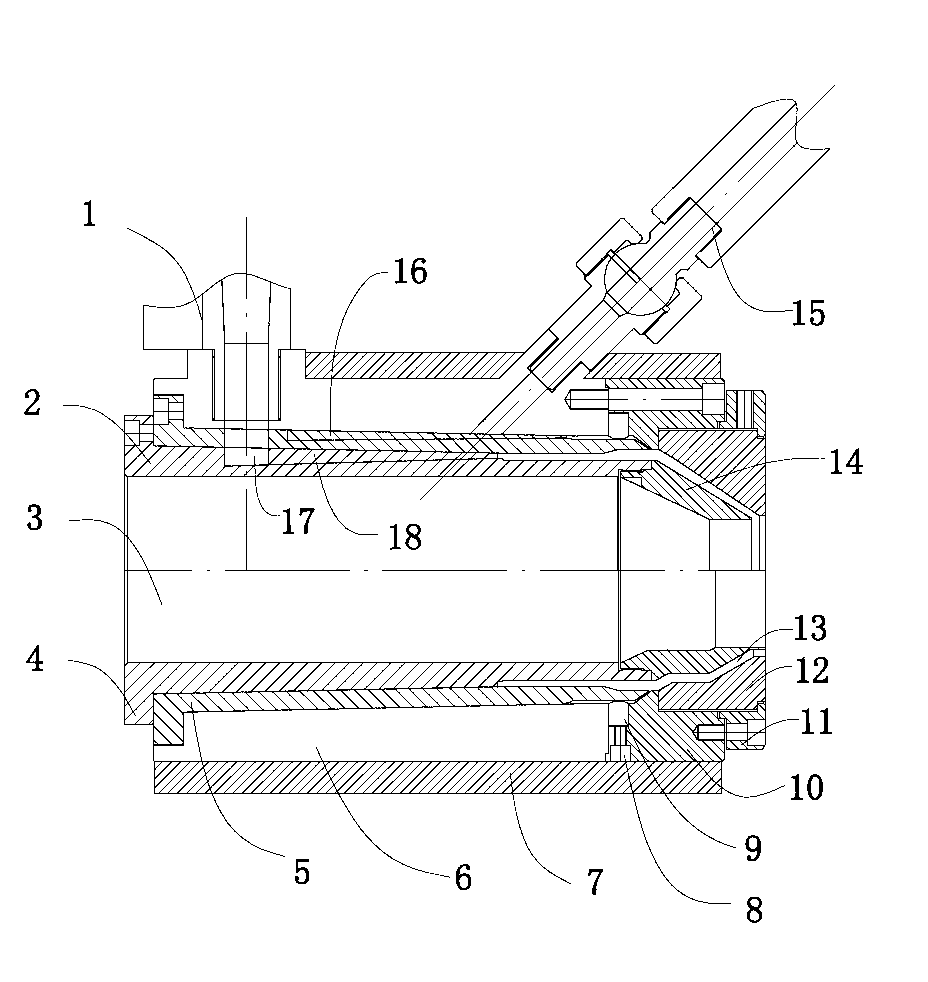

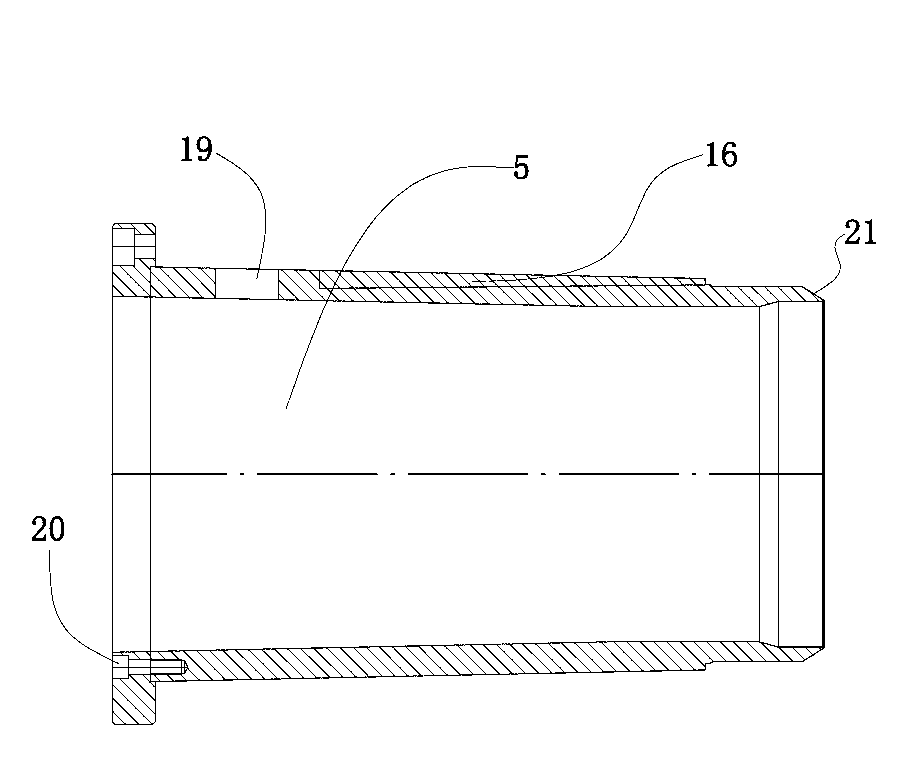

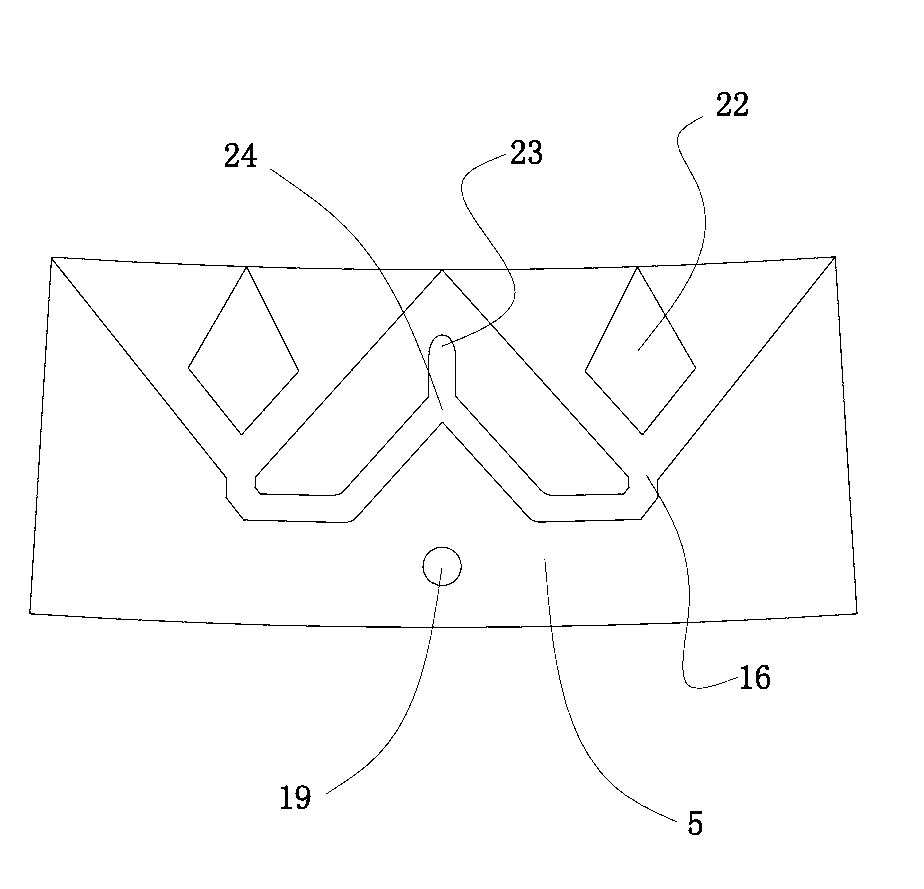

[0024] Embodiment: a kind of cable tooling mold (see attached figure 1 ), including the core base 2, the rubber sleeve 5, the machine head 6, the resistance heater 7, the outer surface of the core base 2, the inner and outer surfaces of the rubber sleeve 5, and the machine head The inner surface of 6 is conical, the taper of the cone is 2.2°, the roughness of the conical surface is 8um, the middle of the core seat 2 is a cylindrical cable core channel 3, and the end of the core seat 2 is a Lan 4, the flange is provided with a plurality of evenly distributed threaded connection holes, and the flange is also provided with disassembly screw holes 20, the mold core seat 2 is fixed to the rubber road sleeve 5 through the threaded connection holes, and the outer surface of the mold core seat 2 The surface is provided with a sheath glue path 18, the left end of the sheath glue path 18 is the cable sheath extrusion inlet 17, the cable sheath extrusion inlet 17 is close to the entry en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com