A kind of dispensing device and solid crystal machine

A glue dispensing device and glue dispensing technology, applied in the mechanical field, can solve problems such as decreased adhesion, easy oxidation of glue, and decreased product quality, so as to reduce the degree of oxidation, reduce the probability of oxidation, and increase the amount of glue produced. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

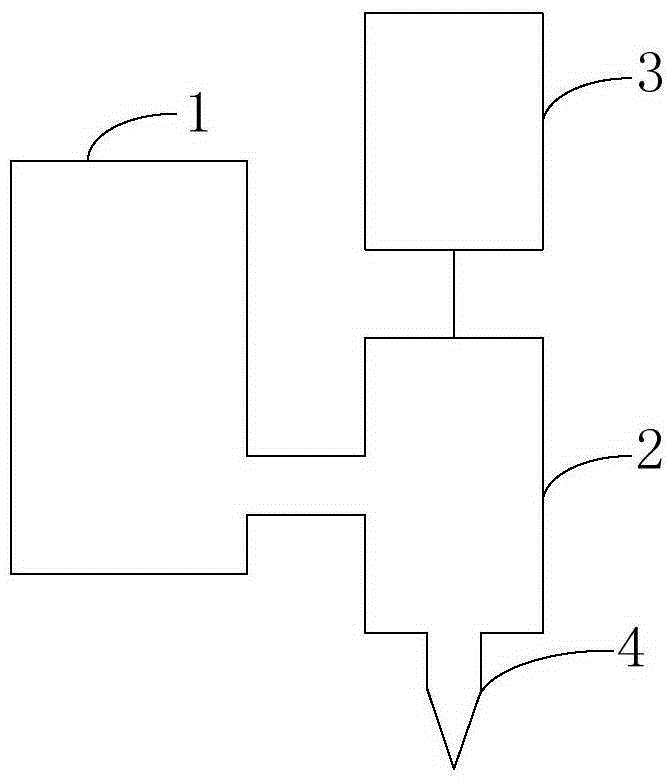

[0021] refer to figure 1 , an embodiment of the dispensing device of the present invention, the dispensing device includes a glue container 1 , a glue channel 2 , a driving assembly 3 and a dispensing nozzle 4 . Wherein, the glue container 1, the glue channel 2 and the glue dispensing nozzle 4 are sequentially connected to form a closed system. The driving assembly 3 drives the glue in the glue container 1 to enter the glue dispensing nozzle 4 from the glue channel 2, and output from the glue dispensing nozzle 4 to the glue dispensing position, so as to realize glue dispensing.

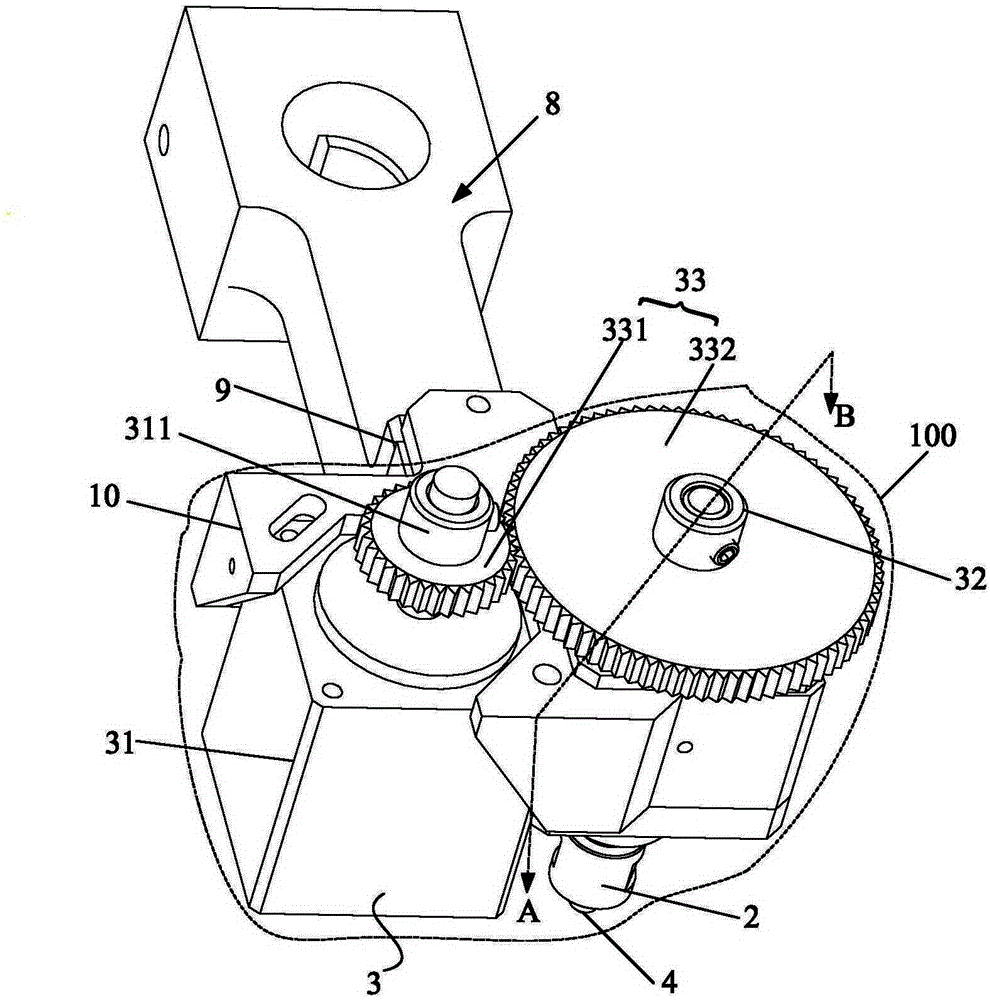

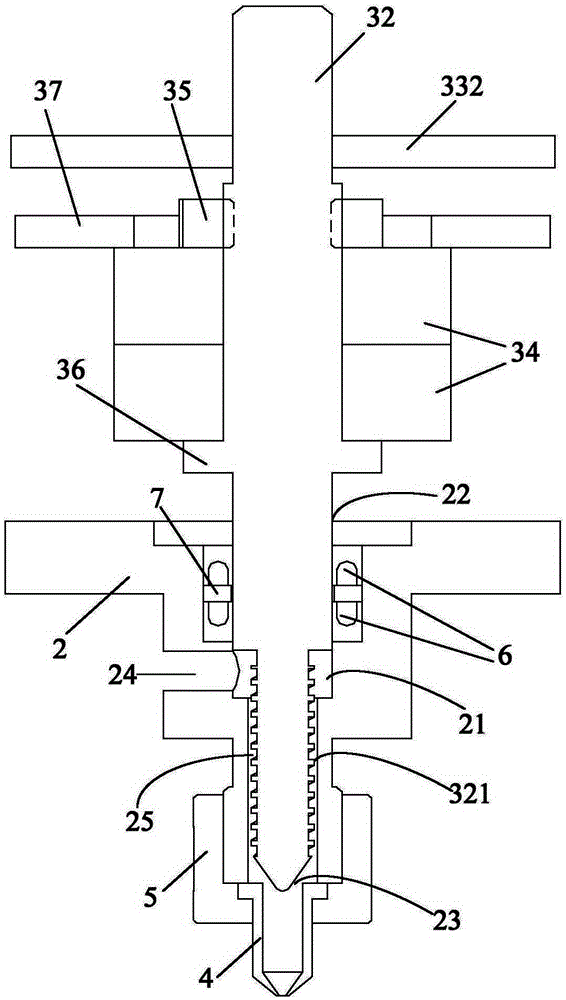

[0022] Specifically, see figure 2 and image 3 , the driving assembly 3 of this embodiment includes a motor 31 and a threaded shaft 32 driven by the motor 31 . The motor 31 is a stepping motor. The threaded shaft 32 is connected with the output shaft 311 of the motor 31 through the transmission mechanism 33 . More specifically, the transmission mechanism 33 includes a first gear 331 and a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com