A feeder for concrete processing

A concrete and feeder technology, applied in the direction of conveyor objects, transportation and packaging, packaging, etc., can solve the waste of manpower and other problems, achieve the effect of improving the cleaning effect, improving the scraping effect, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

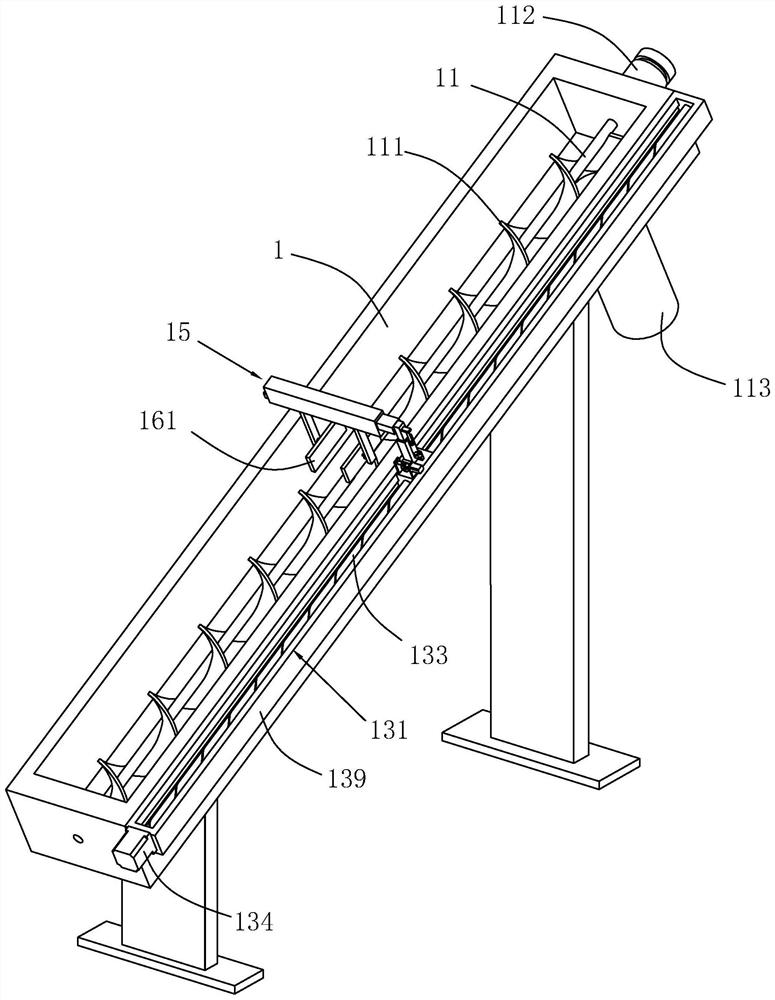

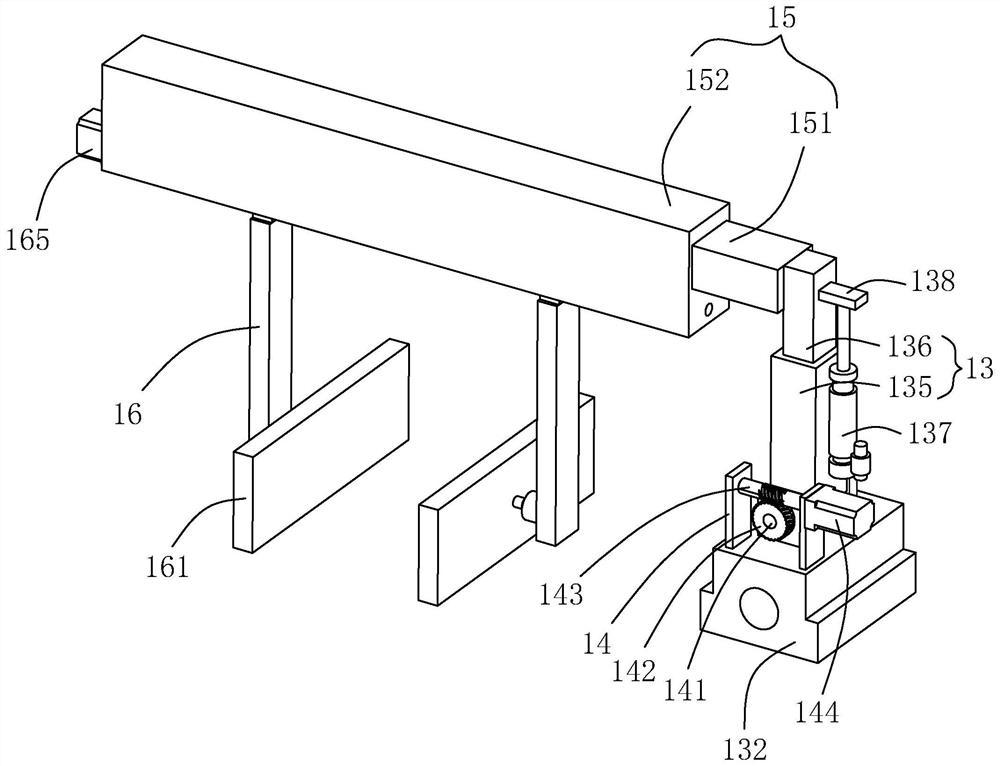

[0033] Attached to the following Figure 1-4 This application will be described in further detail.

[0034] The embodiment of the present application discloses a feeder for concrete processing. refer to figure 1 , a feeder for concrete processing, comprising a casing 1, a rotating shaft 11 is arranged in the casing 1 along the length direction of the casing 1, and a screw blade 111 is fixed on the rotating shaft 11 along the length direction of the rotating shaft 11 One end of the casing 1 is fixedly provided with a drive motor 112 for driving the rotating shaft 11 to drive the helical blade 111 to rotate, and one end of the casing 1 is connected with the casing 1 and is provided with a discharge pipe 113 .

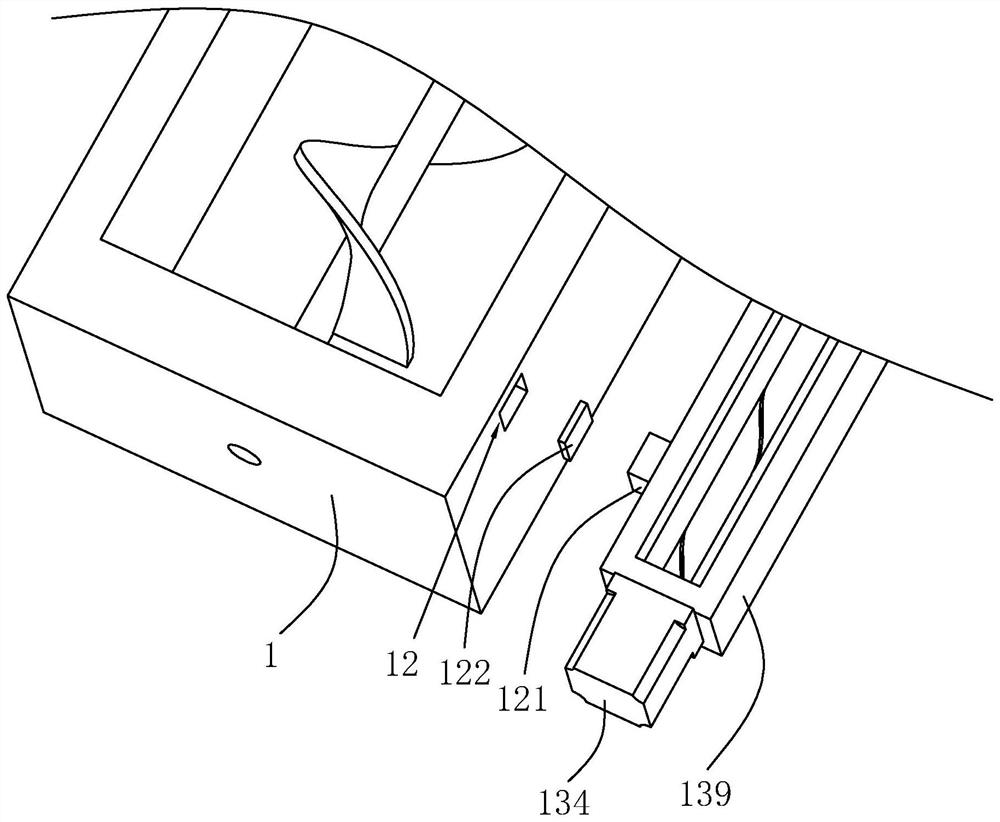

[0035] combine figure 1 and figure 2 , a rod body 139 is detachably connected to one side of the casing 1 along the length direction of the casing 1, and a plurality of slots 12 are opened on the surface of the casing 1 facing the rod body 139. The insert blocks 121...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com