Protector of underground oil extraction machine

A technology of protection device and oil extraction machine, which is applied in the fields of fluid extraction, earthwork drilling, wellbore/well components, etc., can solve the problems of waste of manpower, material and financial resources, accelerated wear, rough surface, etc., to ensure work quality and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

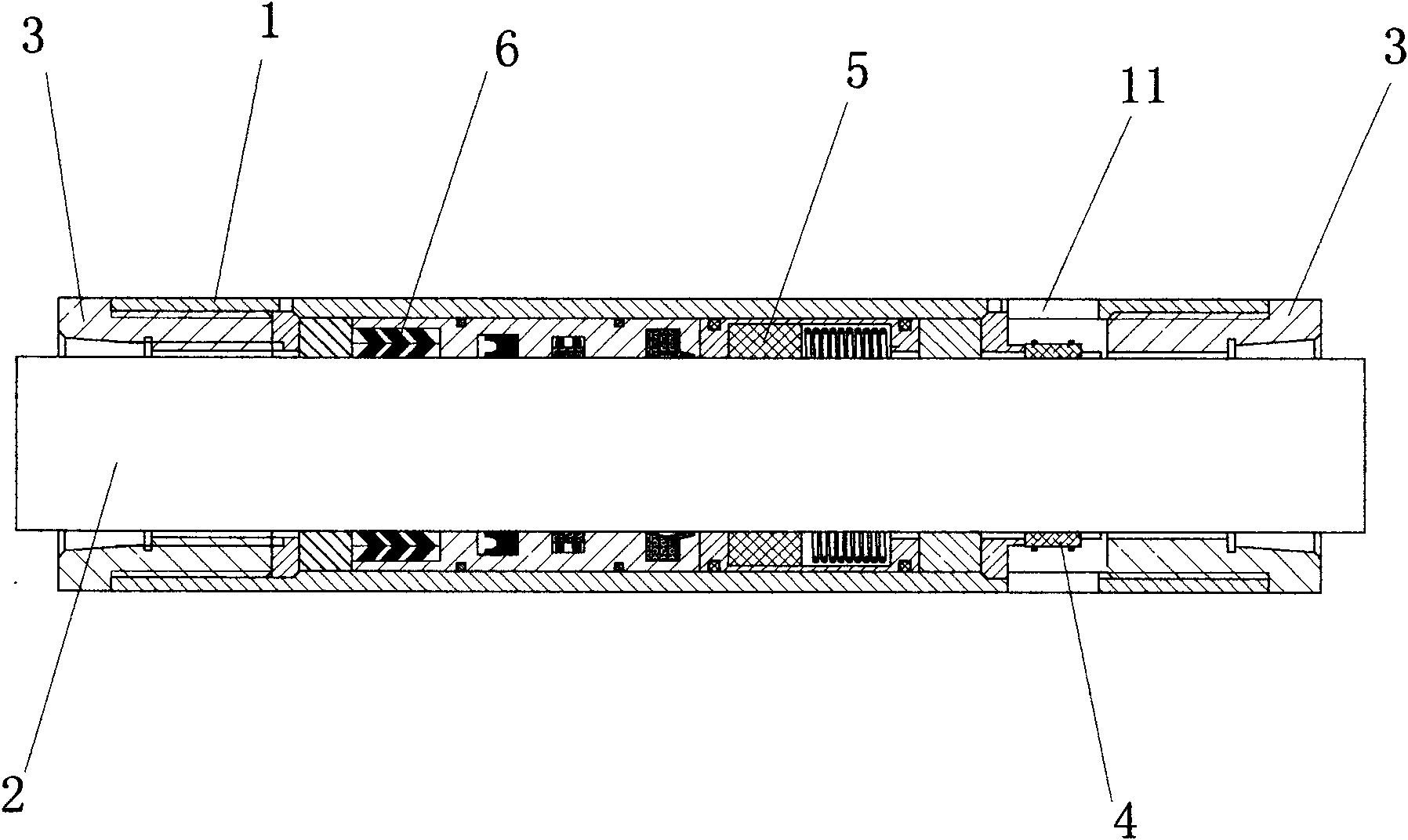

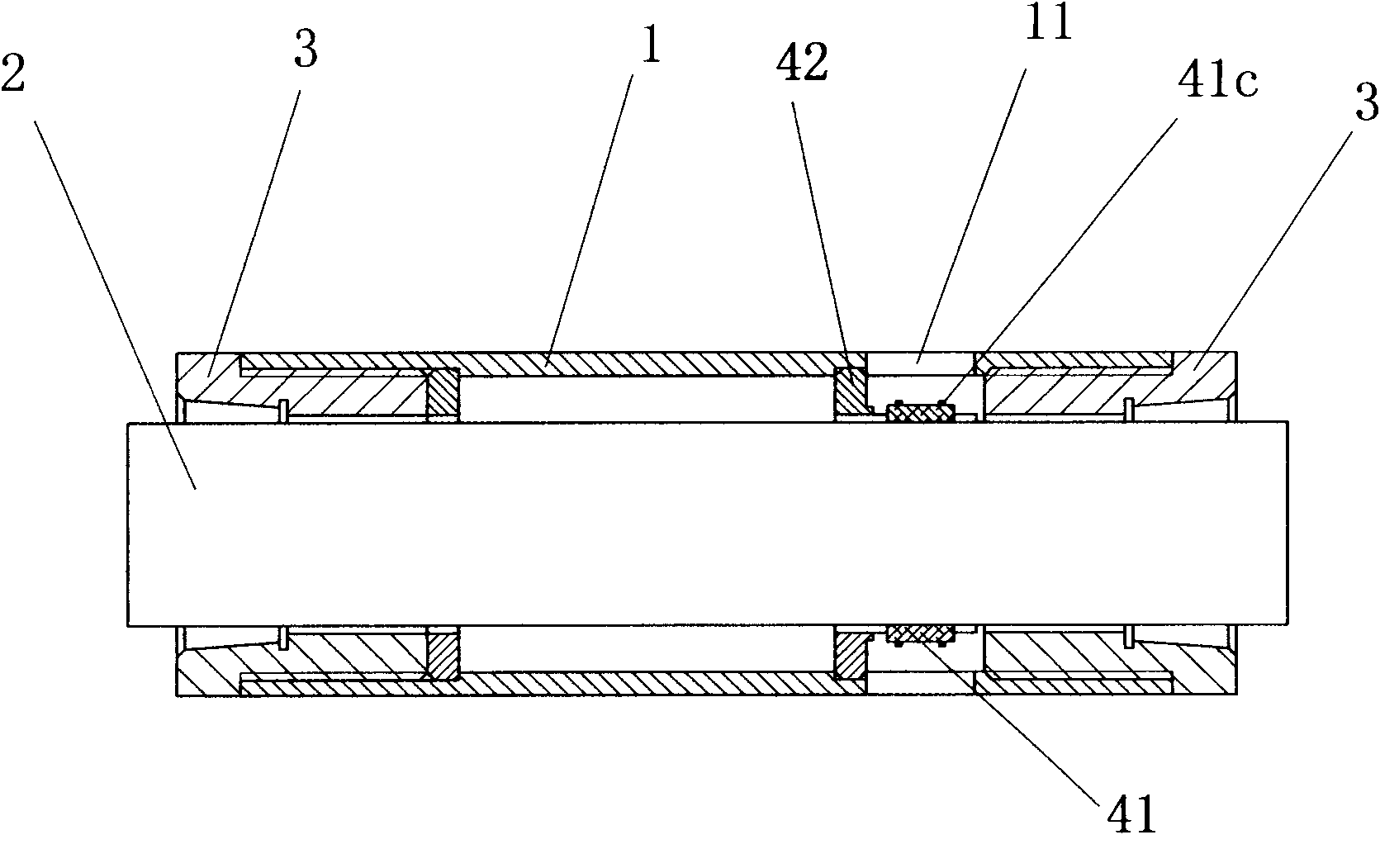

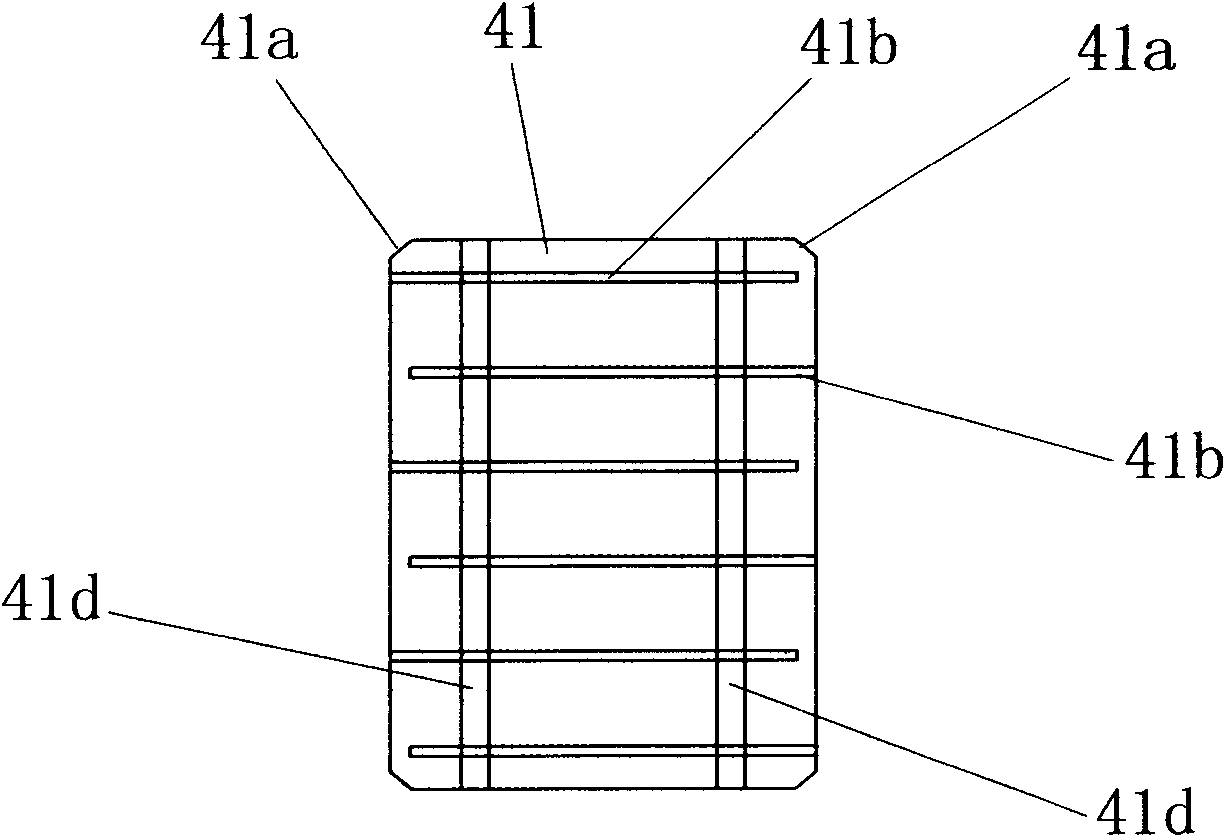

[0021] The invention as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a protective device for an underground oil extraction machine includes an outer pipe 1, a connecting rod 2 and adapters 3 arranged at both ends of the outer pipe 1, and a decontamination device 4 and a filtering device 5 are arranged between the outer pipe 1 and the connecting rod 2 And sealing device 6, wherein: above-mentioned filtering device 5 comprises skeleton 51, is provided with the filtering layer 52 that is flexible structure in skeleton 51, and the inner diameter of described filtering layer 52 is slightly smaller than skeleton 51 two ends apertures and between connecting shaft 2 For interference fit, an elastic compensating mechanism 53 is also provided at one end of the filter layer 52 .

[0022] The filter layer 52 is a cylindrical screen made of wear-resistant plastics or metal wires or wear-resistant plastics and metal wires. The above-mentioned elastic compensating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com