Soil sampling device for preventing disturbance damage to soil sample layer during sampling separation

A technology for sampling devices and soil samples, applied in sampling devices, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of soil falling, affecting sample storage and sample retention, and sample mixing, etc., to achieve easy removal and improved convenience. The effect of sex and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

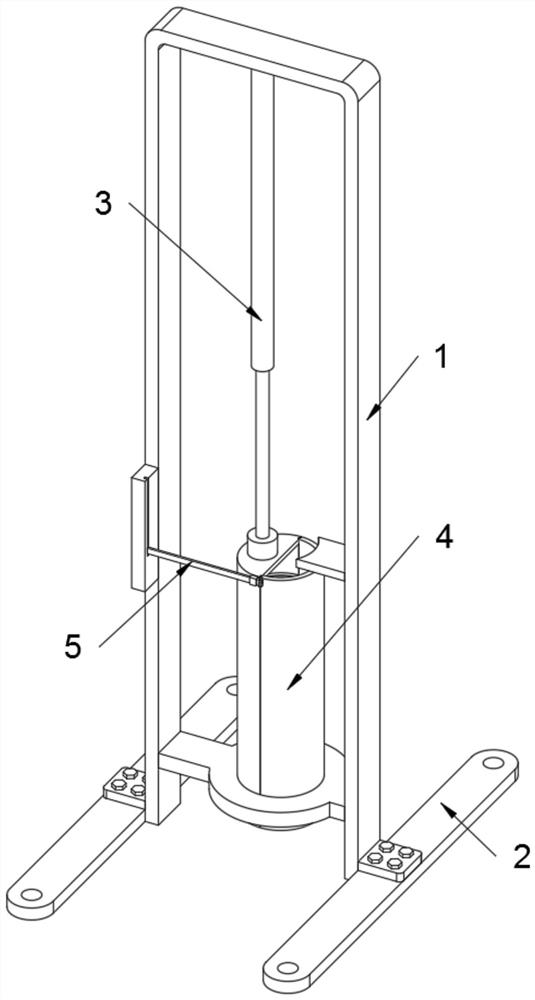

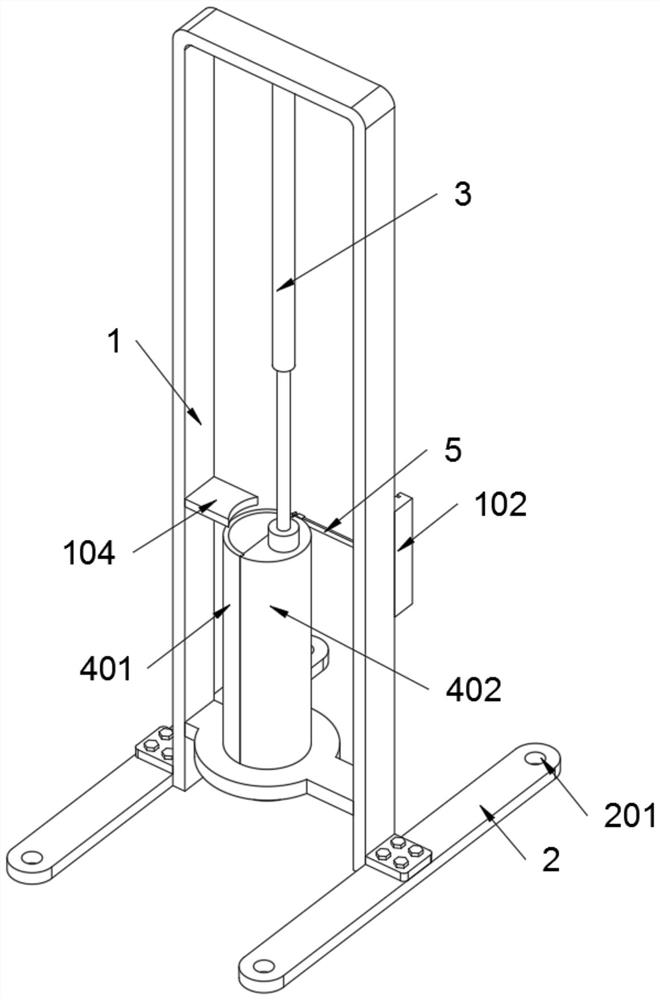

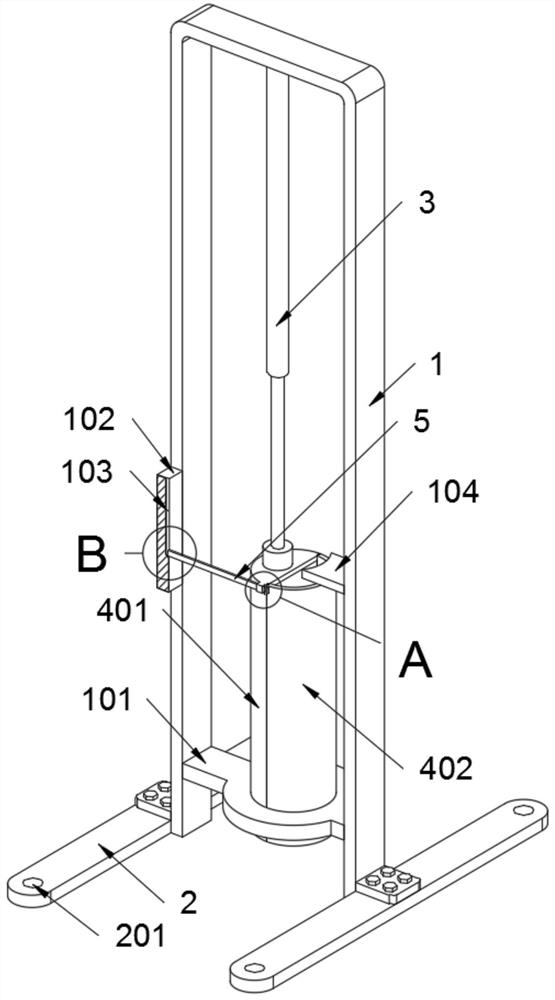

[0035] as attached figure 1 to attach Figure 9 Shown:

[0036] The present invention provides a soil sampling device that prevents disturbance and damage to the soil sample layer when sampling is separated, comprising a frame body 1 adjusting groove 103 and a sampling cylinder B402; the frame body 1 is a concave structure, and the frame body 1 is fixedly connected with two bolts. A fixed seat 2, and an electric telescopic rod 3 is also fixedly connected with a bolt on the frame body 1; refer to as Figure 8 with Figure 9 , the adjustment groove 103 is opened on the right end face of the adjustment block 102, and the adjustment groove 103 is axially aligned with the elastic bolt 5; when the elastic bolt 5 follows the sampling cylinder structure 4 and moves up 5cm Contact, and at this time, the elastic bolt 5 and the clamping seat 40202 are in an unlocked state; the head end of the electric telescopic rod 3 is fixedly connected with a sampling cylinder structure 4 through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com