Exhaust pipe for diesel mining machinery

A technology for exhaust pipes and mines, applied in exhaust devices, mechanical equipment, engine components, etc., can solve the problems of damage, the inability of the flue gas to be directly discharged and accumulated, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

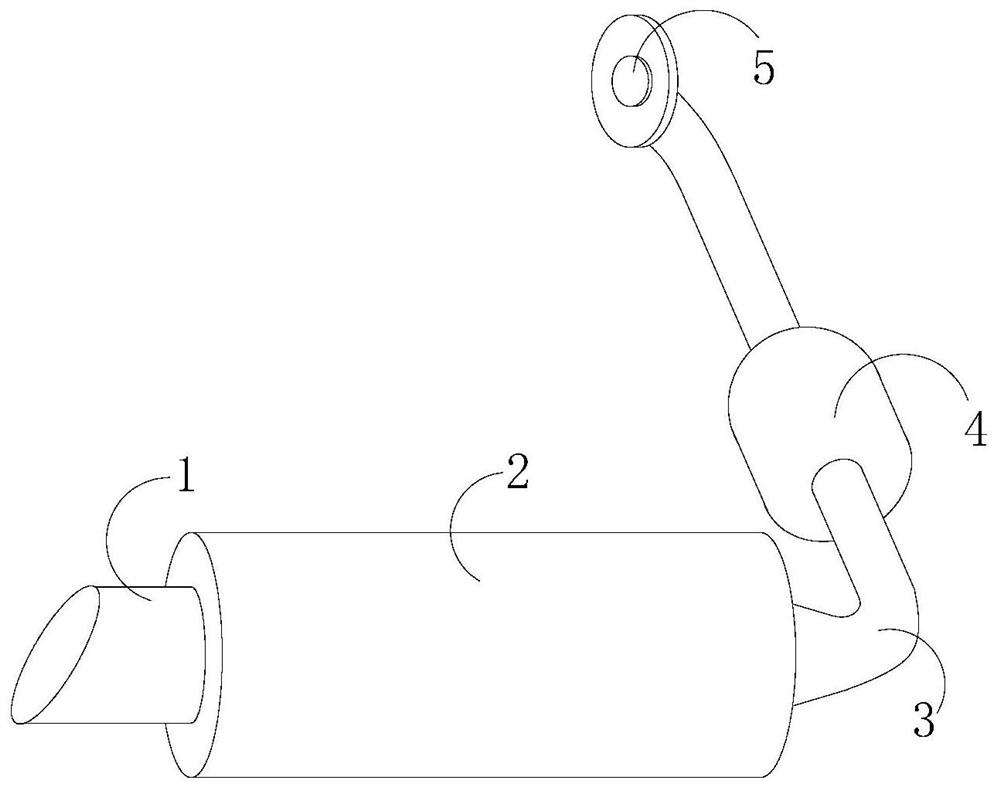

[0024] see Figure 1-Figure 5 , the present invention provides an exhaust pipe for diesel mining machinery. Its structure includes an output end 1, a pipeline 2, a connecting pipe 3, a transition pipe 4, and a connecting end 5. The output end 1 communicates with the pipeline 2, and the pipeline 2 The connecting pipe 3 is connected to the transition pipe 4, the transition pipe 4 communicates with the connecting end 5, and the connecting pipe 3 is set up in an "L" shape;

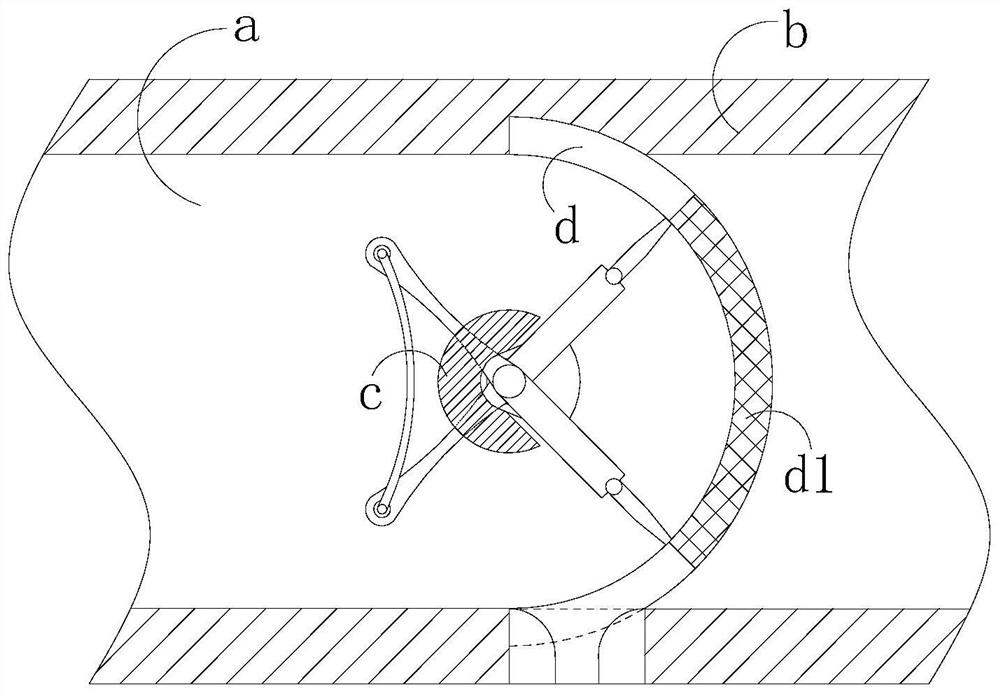

[0025] The pipeline 2 is composed of a channel a, a wall layer b, an anti-blocking mechanism c, and a filter layer d. The cavity surrounded by the wall layer b is a channel a, and the channel a is provided with an anti-blocking mechanism c. The anti-blocking mechanism c cooperates with the filter layer d, and the wall layer b is connected with the filter layer d.

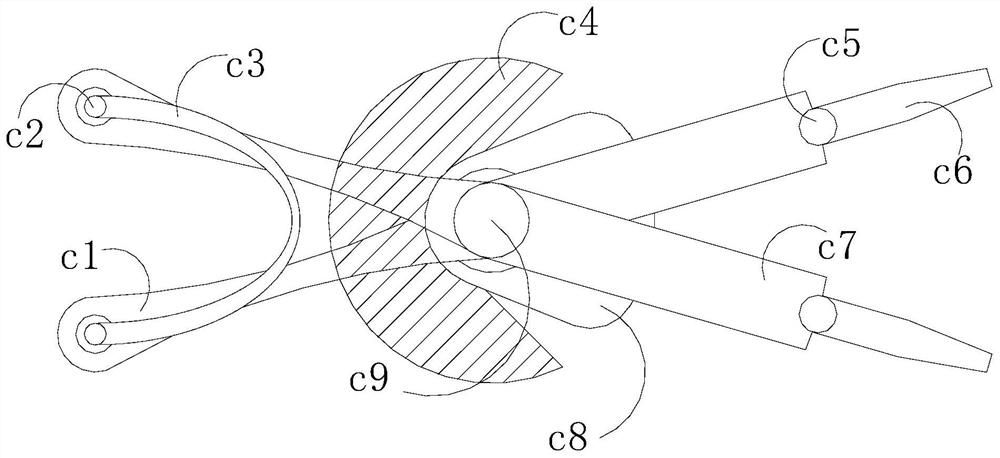

[0026] The anti-blocking mechanism c is composed of a movable plate c1, a fixed rod c2, a soft layer c3, a limit block c4, a fixed shaft c5, a scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com